Your grinding wheels wear out too fast. This is a common issue with many grinding wheels, but you can solve it. Most grinding problems stem from three primary causes.

- An incorrect grinding wheel choice.

- Machine setup grinding issues.

- Improper grinding technique.

This guide helps you diagnose the root cause for your grinding wheels. You can improve your grinding efficiency and lower costs for your grinding wheel. This improves your entire grinding process.

Key Takeaways

- Choose the right grinding wheel for your job. A wrong wheel wears out fast or does not cut well.

- Check your machine setup. Vibrations or loose parts make grinding wheels wear down quickly.

- Use correct grinding settings. Pushing the wheel too hard with fast feeds or deep cuts shortens its life.

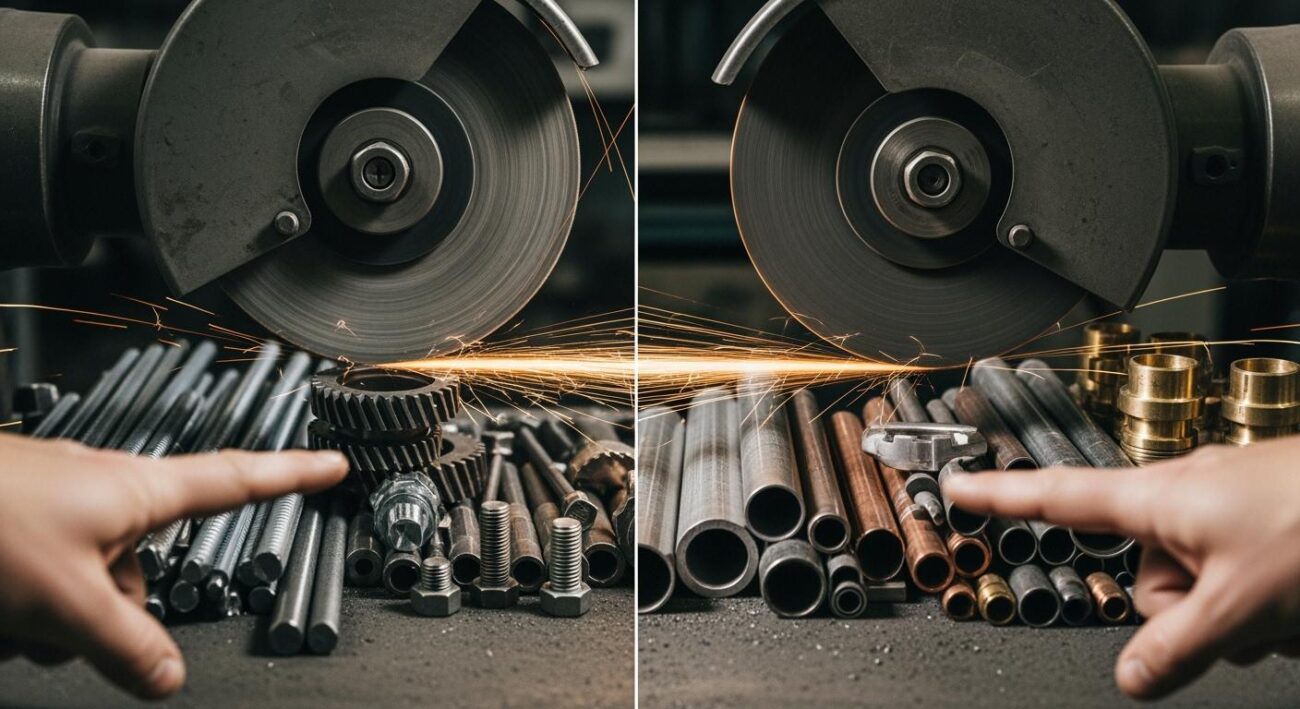

Why Grinding Wheels Wear Out: Incorrect Selection

You must match your grinding wheel to your specific job. Selecting a wheel with the wrong bond, grit size, or abrasive material is a primary reason grinding wheels wear out too fast. An incorrect choice leads to inefficient grinding performance. It can also cause problems like glazing, where the wheel surface becomes smooth, or loading, where the wheel clogs with material.

Symptom: Wheel Life Too Short

You notice your wheel life too short. This is a clear sign of a mismatch between the grinding wheel and the application. Excessive wheel wear often happens when the workpiece material has a strong affinity with the abrasive. This causes the grinding wheel to break down much faster than it should, reducing its operational life.

Soft Bond or Grit Causes Rapid Wear

A bond that is too soft causes rapid wheel wear. The bond releases the abrasive grains before they are fully used. You might also use a grit size that is too fine for the job. This also makes your grinding wheels wear out. Choosing the right hardness makes a huge difference in your grinding process.

Pro Tip: Your wheel life may double if you increase the hardness by just one grade. A small change can significantly improve your wheel’s life and performance.

Symptom: Wheel Not Cutting Effectively

Sometimes the wheel not cutting is the main problem. Your wheel cutting slowly is a symptom of glazing or loading.

- Glazing: The grinding wheel surface looks shiny and smooth. This happens when the abrasive grains become dull instead of breaking away to expose new, sharp grains.

- Loading: The wheel’s pores get clogged with chips from the material you are grinding. This often occurs with soft or ductile materials.

When your wheel not cutting, you lose efficiency. You must stop and dress the wheel, which removes usable abrasive and shortens its life.

For these complex issues, expert help is invaluable. Aimgrind specializes in customized cutting and grinding wheels. With nearly two decades of experience, we design personalized formulas for your specific materials. Our diamond grinding wheels are a premium solution for hard materials. They offer superior durability with various bond types, like resin and metal, that we match perfectly to your application to extend wheel life.

Machine Setup Grinding Problems

Your grinding wheel choice might be perfect, but your machine setup can still cause major grinding problems. A poorly configured machine undermines the performance of even the best grinding wheels. Issues like vibration, loose parts, or an insecure workpiece create instability. This instability leads to rapid wear, a poor surface finish, and inefficient grinding.

Spindle Vibration and Wobble

You should check your machine’s spindle for vibration or wobble. Excessive spindle vibration causes uneven and accelerated wheel wear. Even a tiny vibration creates damaging effects on your grinding wheel. This vibration generates irregularities during the grinding process, leading to a poor surface finish.

Did You Know? For precision grinding, spindle runout (wobble) should be extremely low. Many modern machines have a runout tolerance of around 0.0004 inches when measured 12 inches from the spindle face. Anything more can harm your wheel’s performance.

Vibrations cause other issues too:

- They create repeated impacts on the bearing races, causing damage.

- They generate extra heat, which degrades lubricants and harms machine components.

- They cause variations in the cutting depth, which regenerates more vibration.

Loose Machine Components

You need to inspect your machine for any loose components. Parts like belts, screws, and nuts can loosen over time. An imbalanced grinding wheel or unevenly tightened chuck screws also contribute to grinding problems. These loose parts cause misalignment and instability during grinding. This leads to uneven pressure on the wheel’s surface, causing it to wear down quickly and unevenly.

Regular maintenance is your best defense. You should create a simple checklist to inspect your equipment.

- Tighten all loose bolts and fasteners.

- Secure any loose wiring and cables.

- Ensure all sensors and gauges have tight connections.

Insecure Workpiece Clamping

You must ensure your workpiece is clamped securely. An insecure workpiece can move, bend, or roll during the grinding operation. This movement is a major cause of rapid wear on grinding wheels. When the workpiece shifts, it can pinch or twist the wheel. This not only wears down the abrasive surface but can also lead to wheel breakage, which is a serious safety hazard. Firmly clamping the workpiece prevents these movements and ensures consistent contact between the wheel and the material surface.

Aggressive Grinding Parameters

Your grinding process settings, or parameters, directly impact the life of your cutting and grinding wheels. Using parameters that are too aggressive is a common reason your grinding wheels wear out quickly. You must balance speed with control to achieve optimal performance. Pushing the machine too hard creates excessive heat and stress, which breaks down the abrasive surface.

Excessive Feed Rate

You might be pushing the material into the wheel too quickly. This is called an excessive feed rate. Aggressive feeds increase the machine’s load and generate too much heat. This can cause thermal damage to both the workpiece and the grinding wheel.

Quick Tip: Controlled feeds distribute energy evenly. This prevents heat spikes while still removing material effectively. Proper use of coolant is also essential to manage heat during the grinding process.

Too Large Depth of Cut

You could be taking too deep of a cut with each pass. The depth of cut has a big impact on your grinding results. You should use different depths for different stages of the job.

- Roughing: You can use the heaviest possible depth of cut to remove a lot of material quickly. This is limited by your machine’s power and rigidity.

- Finishing: You must use a shallower cut for finishing passes. This creates a good surface finish and achieves tight tolerances.

Using a depth of cut that is too large for the task puts immense pressure on your cutting and grinding wheels, causing rapid wear.

Incorrect Grinding Wheel Speed (RPM)

You need to operate your cutting and grinding wheels at the correct speed. Both running too fast and too slow can cause problems. Running a wheel above its maximum rated RPM is extremely dangerous. The stress can cause the wheel to crack or even burst.

Running a wheel too slowly is also bad for performance.

- The abrasive grains become dull instead of breaking away.

- This causes the workpiece surface to burn from friction.

- It reduces the efficiency of your grinding operation.

Adjusting speed requires you to balance other factors. When you change the grinding speed, you should also adjust the feed rate to maintain stable performance. A good flow of coolant helps manage temperature changes. Finding the right balance for your grinding wheels is key to extending their life.

You now know why your grinding wheels wear out. The cause is often found in one of three areas:

- The grinding wheel itself

- Your machine setup

- Your grinding process

Start with a systematic check of your parameters to solve grinding problems. Inspecting your grinding wheels and adjusting your feed rate can improve wheel life. For complex grinding issues or to find the perfect grinding wheel for your application, consult an expert. A comprehensive evaluation of your grinding application can lead to huge gains in performance and cost savings.

Contact Aimgrind to achieve optimal performance in your grinding operations.

Grind with Passion, Achieve with Aim.

FAQ

How do I know if my grinding wheel is too soft?

You can tell your wheel is too soft if it wears down very quickly. A soft bond releases the abrasive grains before they are fully used. This rapid breakdown is a clear sign you need a harder wheel for your job.

Can coolant affect wheel wear?

Yes, coolant is very important. Not enough coolant causes heat to build up. This heat can damage both the wheel and your workpiece. Proper coolant flow helps manage temperature, reduces wear, and extends the life of your grinding wheel.

What is wheel dressing and does it shorten wheel life?

Wheel dressing cleans a loaded or glazed wheel. It removes dull grains to expose a fresh cutting layer. While dressing does remove abrasive material, it is necessary for good performance. Proper technique minimizes the amount of wheel you remove.

Why is my workpiece surface burning?

A burned surface often means your wheel is glazed or running too slow. The dull abrasives create friction instead of cutting cleanly. This friction generates excess heat, which scorches the material you are grinding.

Contact Us

For More Grinding Solution or Customized Abrasive Tools