A grinding wheel is a composite tool. It uses two essential grinding wheel materials: an abrasive grain for cutting and a bonding agent to hold the grains together. The choice of material defines the grinding wheel’s purpose. The most common types of grinding wheel abrasive include Aluminum Oxide, Silicon Carbide, Ceramic Alumina, and Diamond. Understanding these different types of abrasives is crucial in a rapidly expanding industry. The global grinding wheel market shows significant growth:

- It is projected to increase by USD 6.29 billion.

- The market is expected to grow at a rate of 5.2% between 2024 and 2029.

- The estimated market size for 2025-2029 is USD 6292.3 million.

Key Takeaways

- Grinding wheels have two main parts: abrasive grains for cutting and a bonding agent to hold them.

- Different abrasive materials like aluminum oxide, silicon carbide, and diamond work best for specific materials.

- The grit size of a grinding wheel affects how fast it removes material and the smoothness of the finish.

- The bond’s hardness, called grade, helps you choose the right wheel for hard or soft materials.

- Choosing the correct grinding wheel materials improves work quality and keeps operators safe.

The Core Grinding Wheel Materials

The grinding wheel composition is a careful balance of two key components. These grinding wheel materials work together to create an effective cutting tool. One part cuts the workpiece, and the other part holds everything together.

Abrasive Grains: The Cutting Component

Abrasive grains are the tiny, sharp particles that perform the actual cutting. The effectiveness of a grinding wheel depends heavily on the properties of these grains.

- Hardness: This property shows how well a grain resists scratching.

- Friability: This is the grain’s ability to fracture under pressure. This process exposes new, sharp cutting edges, which is called self-sharpening.

- Grain Size: The size of each grain affects the final surface finish.

Different grains have unique cutting characteristics. Some grains, like ceramic alumina, generate less heat and last a long time. Other grains are better suited for specific workpiece materials. The right grain choice ensures efficient and precise work for any grinding wheel.

Bonding Agents: The Holding Component

Bonding agents act like the glue in a grinding wheel. The bond secures the abrasive grains, giving the grinding wheel its shape and strength. This system provides toughness, heat resistance, and wear resistance. The bond must hold the grains firmly during grinding but also release dull grains to expose fresh ones.

Note: The bond system is critical for operational efficiency. Different bonds create bonded abrasives with unique performance traits.

Common bond types for bonded abrasives include:

- Vitrified (V): A hard, rigid bond that looks like glass. It is porous, which helps with cooling and removing debris. It is excellent for precision work.

- Resinoid (B): A synthetic resin bond that is strong and tough. It works well for high-speed and rough grinding operations.

- Metal Bond: The hardest bond type, often used with diamond abrasives for grinding very hard materials like ceramics and glass. This bond offers the longest grinding wheel life.

Exploring Different Types of Abrasives

The performance of a grinding wheel depends heavily on its abrasive material. Different types of abrasives have unique properties. These properties make them suitable for specific jobs and materials. Understanding these grinding wheel types helps users select the right tool for maximum efficiency.

Aluminum Oxide: For Ferrous Metals

Aluminum oxide is a tough and versatile abrasive. It is the most common choice for grinding ferrous metals like carbon steel and alloy steel. Its hardness allows it to withstand high pressure and heat. This resilience means the grinding wheel does not dull quickly.

Key advantages of aluminum oxide include:

- Cost-Effectiveness: It is generally less expensive than other abrasive grains.

- Versatility: It works on many surfaces and for different grinding processes.

- Longevity: The material resists wear, leading to a longer-lasting grinding wheel.

- Performance: It maintains a sharp cutting edge for extended periods.

Technicians use it for many tasks, from aggressive material removal and shaping metal parts to achieving fine surface finishes.

Silicon Carbide: For Non-Ferrous & Non-Metallic Materials

Silicon carbide is harder and sharper than aluminum oxide. Its grains are sharp and needle-like. They break away easily during use, revealing new cutting edges. This characteristic makes it perfect for materials sensitive to pressure and heat.

It is the preferred choice for two main categories:

- Non-Ferrous Metals: It provides a uniform finish on materials like aluminum, brass, bronze, and titanium. Its high cutting power removes material efficiently.

- Non-Metallic Materials: Silicon carbide is one of the hardest conventional abrasives. This hardness allows it to grind brittle materials like stone, glass, and ceramics without causing damage.

Zirconia Alumina: Self-Sharpening for Steel

Zirconia alumina is a durable abrasive grain known for its self-sharpening ability. During grinding, the grains micro-fracture under pressure. This process constantly exposes fresh, sharp cutting edges. This action extends the life of the grinding wheel and ensures a consistent cut.

Did You Know? The self-sharpening nature of zirconia alumina allows it to provide a cooler cut, which is especially useful on hard-to-grind materials.

It excels in high-pressure applications on steel and stainless steel. Common uses include:

- Heavy stock removal

- Weld blending

- Edge chamfering

- Surface preparation

These bonded abrasives thrive under tough conditions and require heavy pressure to keep the grain sharp.

Ceramic Alumina: Precision on Hard Alloys

Ceramic alumina is a high-performance abrasive created through a special manufacturing process. It has a unique microcrystalline structure. This structure allows the abrasive to fracture in a controlled way, creating a continuous supply of new cutting surfaces. This self-sharpening action prevents the abrasive from dulling quickly.

The fine grain structure gives ceramic alumina exceptional durability and a low wear rate. It performs well under high temperatures and pressure. This makes it the ideal choice for precision grinding on hard materials like titanium and other superalloys. These advanced bonded abrasives deliver outstanding performance where other grains fail.

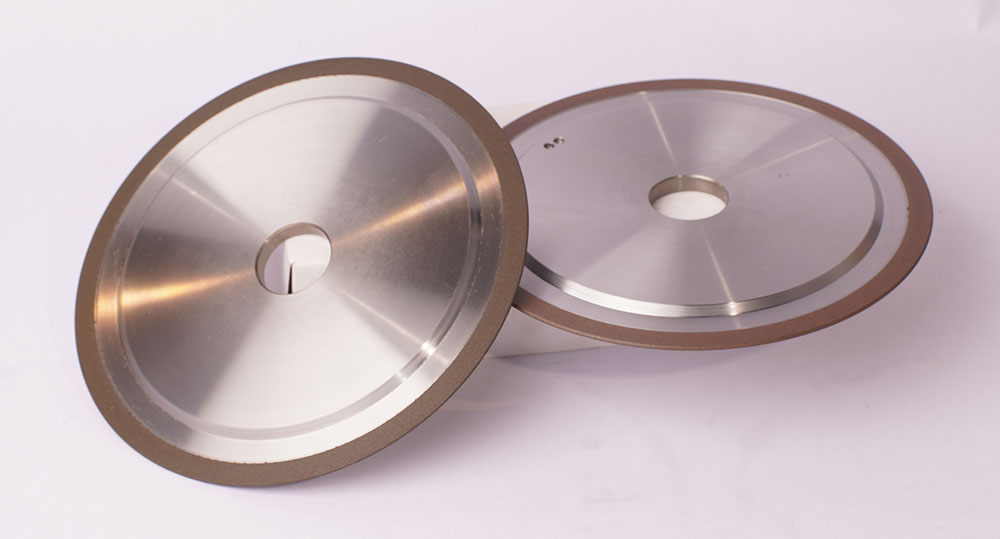

Superabrasives: Diamond and CBN

Superabrasives are materials at the top of the hardness scale. The two main superabrasives are diamond and Cubic Boron Nitride (CBN).

Diamond is the hardest known material. It is the ultimate abrasive for grinding extremely hard materials like tungsten carbide, advanced ceramics, and composites. Synthetic diamonds are now common and offer consistent quality and tailored properties for specific applications.

| Feature | Natural Diamond | Synthetic Diamond |

|---|---|---|

| Consistency | Variable | Highly Consistent |

| Purity | May contain impurities | Higher purity |

| Cost | Higher | More cost-effective |

| Control | Limited | Precise control over properties |

Cubic Boron Nitride (CBN) is the second-hardest material after diamond. Its crystal structure, similar to diamond’s, gives it extreme hardness and thermal stability. However, CBN has a key advantage over diamond. Diamond’s carbon reacts with iron at high temperatures, causing it to break down. CBN does not react with iron, making it the superior choice for grinding hardened ferrous metals like high-speed steel and tool steels.

For the most demanding applications on hard materials, specialized tools are essential. With nearly two decades of experience, Aimgrind has deep expertise in this area. Specialized tools like Aimgrind’s diamond grinding wheels offer superior durability and precision for grinding ceramics and composites. Investing in these wheels improves productivity through longer tool life and shorter cycle times, reducing the overall cost per piece.

For a superabrasive grinding wheel, the core that holds the abrasive rim is also important. It is typically made of metal or ceramic.

| Core Material | Key Strengths |

|---|---|

| Steel | Strong, durable, and resists expansion. Ideal for high-force jobs needing tight tolerances. |

| Aluminum | Lightweight and excellent at dissipating heat, which prevents damage to the workpiece. |

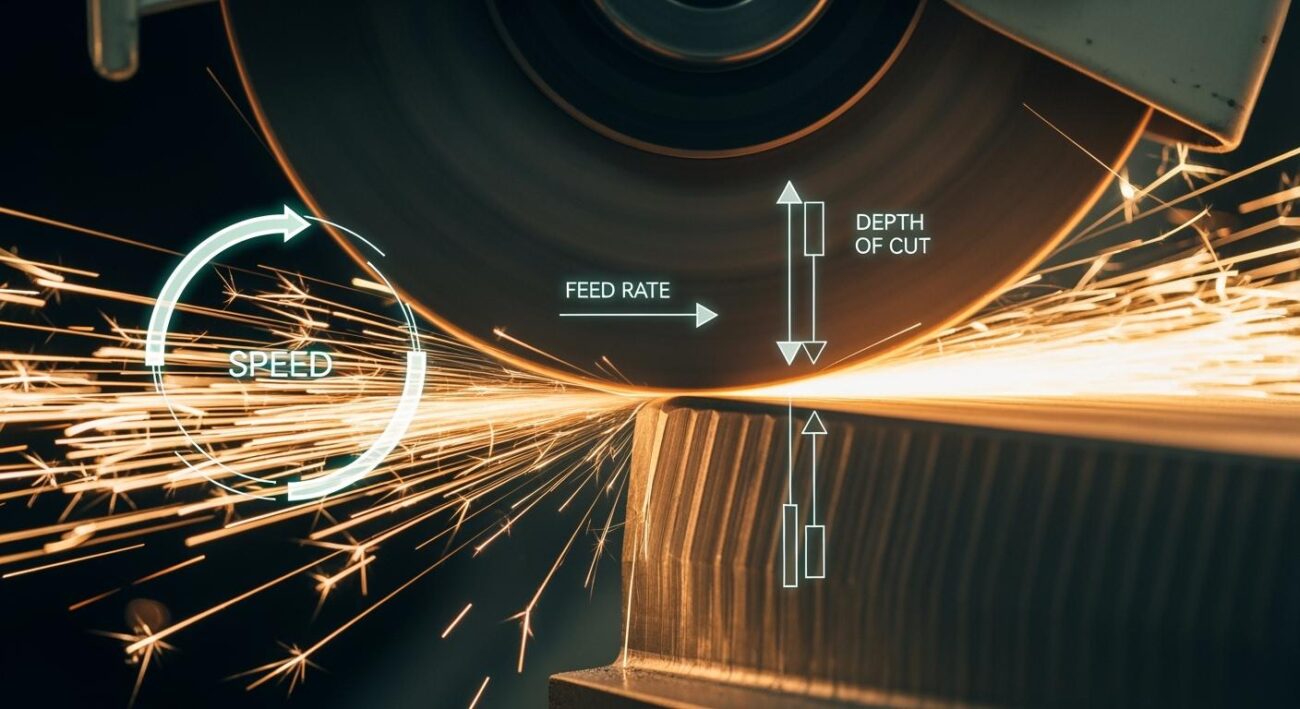

How Materials Impact Grinding Wheel Performance

The abrasive and bond are the core grinding wheel materials. However, two other factors, grit size and grade, also define how a grinding wheel performs. These properties determine the balance between speed and finish. They also ensure the tool wears correctly for the job.

Grit Size: Balancing Removal Rate and Finish

Grit size refers to the size of the individual abrasive grains on a grinding wheel. It is measured with a number. A lower number means larger, coarser grains, while a higher number indicates smaller, finer grains.

- Coarse Grits (24-60): These remove a lot of material quickly. They are ideal for initial shaping or removing deep scratches. However, they leave a rough surface.

- Medium Grits (80-150): These offer a balance. They remove material at a moderate rate and leave a better finish.

- Fine Grits (180+): These remove very little material. Their purpose is to create a smooth, polished surface.

Pro Tip: There is always a trade-off between removal rate and surface quality. Using a coarse grit grinding wheel gets the job done fast but requires more steps to achieve a smooth finish. Operators often start with a coarse grit and then use a grinding wheel with a finer grit to refine the surface.

Grade: The Hardness of the Bond

The grade of a grinding wheel measures the hardness of its bonding agent. It does not refer to the hardness of the abrasive grains. A letter from A (soft) to Z (hard) represents the grade. The grade determines how strongly the bond holds onto the abrasive grains.

A key rule in grinding is to use a soft-grade wheel for hard materials and a hard-grade wheel for soft materials.

| Workpiece Material | Recommended Bond Grade | Why It Works |

|---|---|---|

| Hard Materials (e.g., tool steel) | Soft (A-J) | The bond breaks down easily, exposing fresh, sharp abrasive grains to continue cutting efficiently. |

| Soft Materials (e.g., aluminum) | Hard (P-Z) | The bond holds grains longer, preventing the wheel from wearing down too quickly on soft, gummy materials. |

The bond also affects the maximum safe speed of bonded abrasives. For example, resinoid bonds allow for higher speeds than silicate bonds. Choosing the right grade for your bonded abrasives ensures both safety and optimal performance.

A grinding wheel is an engineered tool made from a specific combination of abrasive grains and a bonding agent. The correct grinding wheel selection is crucial. It involves matching the abrasive to the workpiece, such as aluminum oxide for steel or diamond for hard ceramics. The right grinding wheel materials prevent issues like micro-cracks and ensure operator safety.

Understanding these factors empowers users to achieve better results. Partnering with experts like Aimgrind for a custom grinding wheel ensures superior efficiency and productivity for any application. This makes every grinding wheel a solution.

FAQ

What are the main materials in a grinding wheel?

A grinding wheel has two main parts. Abrasive grains perform the cutting action. A bonding agent holds these grains together. This simple combination creates an effective grinding wheel for many jobs.

How do you choose the right grinding wheel?

Match the grinding wheel to your workpiece material. Different types of abrasives work best on specific surfaces. For example, use aluminum oxide for steel and diamond for hard ceramics. The correct grinding wheel ensures a good result.

What is the difference between a hard and soft grinding wheel?

The grade determines the hardness of a grinding wheel.

- A soft wheel releases grains easily, making it ideal for cutting hard materials.

- A hard wheel holds grains longer, which is better for soft materials.

Understanding these grinding wheel types is important for performance.

When should you use a superabrasive grinding wheel?

Use a superabrasive grinding wheel for extremely hard materials. Diamond wheels cut ceramics and composites. CBN wheels are the best choice for hardened steels. These advanced wheels offer superior precision and a long life.

Contact Us

For More Grinding Solution or Customized Abrasive Tools