When you pick a vitrified grinding wheel, you get good heat resistance. It is also very strong and gives accurate results. On the other hand, resinoid bond grinding wheels and resin bond wheels are more bendy and cost less. The table below shows how vitrified and resin wheels are different in important ways:

|

Property/Aspect |

Vitrified Bond Wheels |

Resin Bond Wheels |

|---|---|---|

|

Heat Resistance |

High |

Poor |

|

Durability |

Robust |

Lower |

|

Precision |

High |

Lower |

|

Surface Finish |

Better |

Lower |

|

Cost |

Higher |

Lower |

You can see that each wheel has good and bad points. What you pick depends on what you need to grind, the kind of wheel, and the finish you want.

Key Takeaways

-

Vitrified grinding wheels can handle heat very well. They are very precise. This makes them great for hard jobs on steel and carbide. These wheels keep their shape even when pressed hard. They cut fast and do not need sharpening often. Their self-sharpening design helps with this. You must handle and store vitrified wheels with care. This stops cracks or chips from happening. Always check for damage before you use them. This keeps you safe and helps the wheel last longer. Dressing vitrified wheels needs special tools and time. Using CNC or laser dressing can help. These methods make the job more accurate and easier. Pick the right wheel type and grit size for your job. This depends on your material and finish needs. Doing this gives you the best results and helps the wheel last longer.

Vitrified Grinding Wheels: Definition and Composition

Basic Definition

Grinding wheels with abrasive grains bonded by ceramic materials

A vitrified grinding wheel is a tool made with abrasive grains. These grains are stuck together by ceramic materials. The special bond used is called a vitrified bond. This bond uses things like clay, glass, or porcelain to hold the grains. OSHA says vitrified bond grinding wheels use inorganic bonds. These bonds are made from clay, glass, porcelain, or other ceramic stuff. This helps you see how these wheels are not like other wheels.

Created through high-temperature firing process (vitrification)

To make a vitrified grinding wheel, you heat the mix to a very high temperature. This step is called vitrification. The heat melts the bond materials and makes a strong, glass-like structure. The wheel becomes hard and stable after this. This process gives the wheel its special strength and long life.

Key Components

Abrasive grains (alumina, silicon carbide, diamond, or CBN)

Vitrified bond grinding wheels have different abrasive grains. The most common grains are fused alumina and silicon carbide. Some wheels use diamond or CBN for harder jobs. These grains do the grinding and cut away material from your work.

Bonding materials (clay, feldspar, quartz)

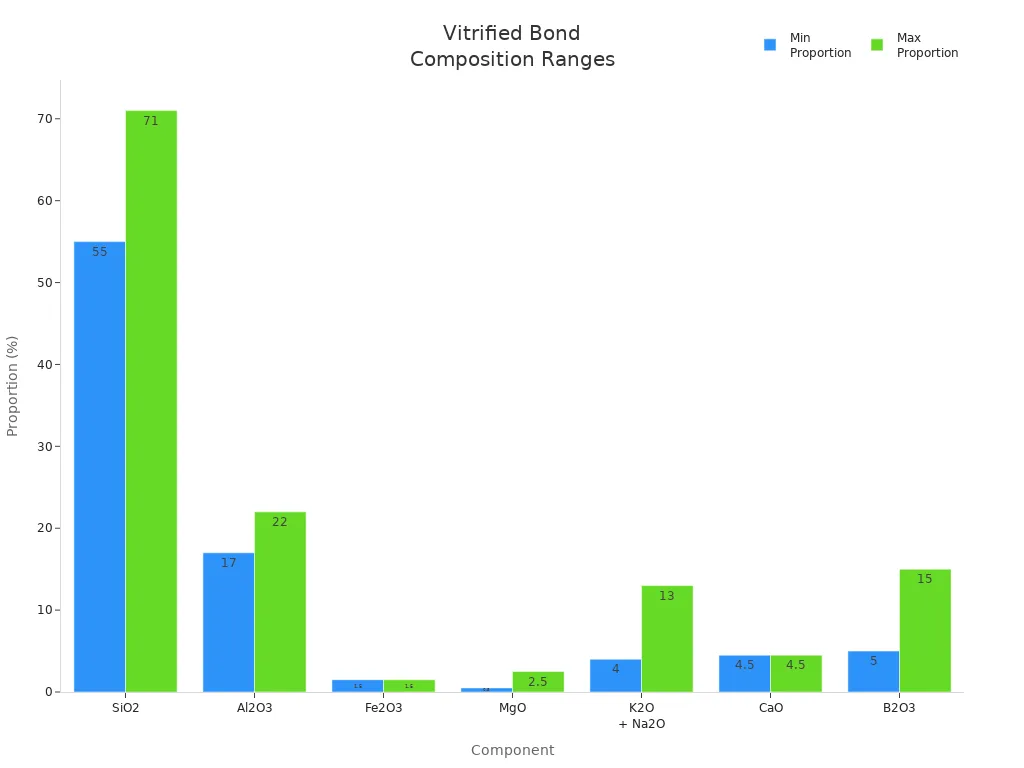

The bond keeps everything together in the wheel. In a vitrified bond, you find clay, feldspar, and quartz. These melt during firing and make a glassy layer around the grains. The table below shows what is in the bond of a vitrified grinding wheel:

|

Component |

Proportion Range (%) |

|---|---|

|

SiO2 |

|

|

Al2O3 |

17 – 22 |

|

Fe2O3 |

~1.5 |

|

MgO |

0.5 – 2.5 |

|

K2O + Na2O |

4 – 13 |

|

CaO |

~4.5 |

|

B2O3 |

5 – 15 |

Pore-forming agents for controlled porosity

Pore-forming agents are also added to the mix. These agents make tiny holes, called pores, inside the wheel. The pores help cool the wheel and remove chips when grinding. When you use vitrified bond diamond grinding wheels or CBN wheels, the pores help the grinding go smoother and faster.

Tip: Pick the right mix of abrasive grains, bond materials, and pore-forming agents to match your grinding job.

Advantages of Vitrified Grinding Wheels

High Structural Stability

Maintains shape under heavy grinding forces

A vitrified grinding wheel keeps its shape during hard jobs. Studies show these wheels do not change shape under strong force. For example, when grinding engine valves, the wheel does not shake or vibrate much. This means you get steady results and the wheel lasts longer, even with tough work.

Minimal deformation during operation

The vitrified bond makes the wheel very tough. Tests show the wheel keeps its shape with only a little wear. The surface finish stays smooth, and the wheel does not bend much. Computer models also show the wheel can handle stress and keep its shape while working.

Excellent Heat Resistance

Withstands high temperatures without bond degradation

Vitrified grinding wheels can take a lot of heat. The bond stays strong up to about 800°C. This is hotter than most other wheels can handle. You can grind fast or use heavy loads without the bond breaking.

Reduces thermal damage to workpiece

These wheels also protect your workpiece from heat. Studies show vitrified CBN wheels stop burns and keep the surface strong. This lowers the chance of cracks and keeps the part hard. Models show the bond helps heat move away and keeps less heat in the workpiece. So, you get a better finish and less heat damage.

Tip: Vitrified wheels help stop burns and cracks on strong steel parts.

Superior Cutting Performance

Fast material removal rates

Vitrified grinding wheels cut fast and work well. Tests show they remove material at 4 to 18 μm/min, based on speed and pressure. You get good results quickly, even with hard jobs.

Good self-sharpening characteristics

The vitrified bond helps the wheel sharpen itself. As you grind, the bond breaks just enough to show new grains. This keeps the wheel sharp and means you do not need to dress it often. The pores help chips leave and keep the wheel cool, making it work better.

Versatile Applications

Suitable for both rough and precision grinding

You can use vitrified grinding wheels for many jobs. They work for rough grinding and for jobs that need high accuracy. The strong bond and pores help you get a fine finish.

Used across various industries (automotive, aerospace, tool manufacturing)

Many industries use these wheels for hard jobs. For example, car and plane makers use them to grind gear teeth. The wheels help make better parts, waste less, and save time.

Disadvantages of Vitrified Grinding Wheels

Brittleness Concerns

Prone to chipping or cracking under impact

You need to know that vitrified grinding wheels can chip or crack if you drop them or hit them hard. The ceramic bond makes these wheels strong but also brittle. If you do not handle them with care, you might damage the wheel before you even start grinding.

Requires careful handling and storage

To keep your wheels safe, you should follow some important storage and handling steps:

-

Store vitrified wheels in a dry place with steady temperatures between 18 and 26°C and about 45% humidity.

-

Lay cutting discs flat and do not stack them in a way that could cause damage.

-

Use cushioned supports for large wheels to avoid stress and chipping.

-

Place soft grade, straight cup wheels base-to-base and rim-to-rim to prevent edge chipping.

-

Before mounting, perform a ring test by tapping the wheel with a non-metallic object. A clear ringing sound means the wheel is not cracked.

-

Do not use wheels that sound dull during the ring test.

-

Make sure wheels are dry and free from packaging before testing.

Tip: Careful storage and handling help you avoid accidents and keep your grinding wheels in good shape.

Dressing Challenges

Requires specialized dressing tools and techniques

When you use vitrified wheels, you need special dressing tools. Rotary dressers with diamond particles work best. These tools let you shape the wheel with high speed and accuracy. The rotary dresser has a cylinder covered with diamond particles. This method gives you a precise shape and keeps the wheel sharp. You will not find this level of precision with resinoid bond grinding wheels or resin bond wheels. Those wheels use simpler dressing methods and focus more on cooling during grinding.

Dressing process can be time-consuming

Dressing vitrified wheels takes more time than dressing resin wheels. You must use the right tools and take care to get the best results. If you rush, you might damage the wheel or lose its shape. This extra step can slow down your work, especially if you need to dress the wheel often.

Limited Flexibility

Not suitable for applications requiring vibration damping

Vitrified wheels have high stiffness and low flexibility. You will not get good results if your grinding job needs the wheel to absorb vibrations. In these cases, resinoid bond or resin wheels work better because they can handle more movement and shocks.

Poor performance in interrupted cutting scenarios

-

Vitrified wheels do not work well for interrupted cuts or jobs that need high toughness.

-

You should use resinoid bond grinding wheels for rough or interrupted grinding.

-

Vitrified wheels need careful design and are limited in speed, usually up to 80 m/s.

-

These limits mean you must match the wheel to the job to avoid problems.

Note: If your job needs a flexible wheel or you expect lots of stops and starts, choose a resinoid bond or resin bond wheel instead.

Mitigation Strategies for Disadvantages

Material Modifications

Adding toughening agents to reduce brittleness

You can make vitrified grinding wheels stronger by adding special materials. For example, nano-AlN helps stop cracks from growing. This makes the wheel tougher and less likely to break. Changing the number and size of pores also helps stop cracks. These changes help the wheel last longer and work better. The wheel grinds smoother and gives a nicer finish. You will notice less heat and less rubbing when you use it. This means you do not have to change wheels as often. You can spend more time working and less time fixing problems.

Optimizing pore structure for better performance

You can make the wheel work better by changing the pores inside it. Using things like dextrin and changing the pressure helps control the pores. If you set the porosity to about 40%, you get a good mix of strength and grinding power. Wheels with the right pores cut faster and keep things cooler. You also get a smoother finish and the wheel does not wear out as fast. Small, well-shaped pores help the wheel last longer and work more smoothly.

Advanced Dressing Techniques

Implementing CNC-controlled dressing processes

New dressing methods help keep your wheel in great shape. CNC-controlled dressing lets you shape the wheel very accurately. You can get the same shape every time you dress the wheel. This method is much faster than old ways and saves you time.

Using laser-assisted dressing methods

Laser-assisted dressing is another new way to shape wheels. It uses a laser to shape the wheel without touching it. This means the tool does not wear out. You can control the surface very well and even add tiny textures. Here are some benefits:

|

Benefit |

Description |

|---|---|

|

No tool wear |

The laser does not wear out the tool |

|

Excellent repeatability |

CNC and laser give the same results each time |

|

High accuracy |

You can control the wheel surface very well |

|

High speed |

This method is much faster than old ways |

|

Microtexturing ability |

You can make tiny textures on the wheel surface |

Tip: Using CNC or laser dressing helps you get better results and saves time on fixing your wheel.

Operational Adjustments

Proper wheel selection for specific applications

Always pick the right wheel for your job. Match the wheel type, grit size, and amount to the material you want to grind. This helps you get the best results and makes the wheel last longer.

Implementing optimized grinding parameters

You can make grinding better by changing how you use the wheel. Use the right coolant to keep things cool and stop the wheel from getting clogged. Dress and true the wheel often to keep it sharp. Watch for shaking and keep your machine in good shape. These steps help you avoid damage and make the wheel last longer. Some people have saved money and changed wheels less by following these tips.

Dressing and Maintenance Methods

Mechanical Dressing Techniques

Diamond dresser tools for precision shaping

Diamond dresser tools help you shape vitrified grinding wheels very accurately. These tools keep the wheel sharp and keep its shape. They work well for most normal grinding jobs. Diamond dressers take away old grains and show new abrasive surfaces. This helps you get a clean and even cut each time.

Rotary dressers for complex profiles

Rotary dressers let you make special shapes on your grinding wheels. They use a spinning cylinder with diamond particles on it. You can make the same shape over and over again, which is important for advanced work. Rotary dressers are fast and very precise, but they cost more and are harder to use in some shops.

Here is a table that compares common mechanical dressing methods:

|

Mechanical Dressing Method |

Effectiveness and Suitability |

Limitations and Challenges |

|---|---|---|

|

Oilstone Dressing |

Often used but only shows a small part of the abrasive grain; not good for porous cBN wheels in high-efficiency deep grinding. |

Shows little abrasive grain; not good for HEDG. |

|

Roller Dressing |

Good and accurate for shaping wheels. |

Hard design and higher price. |

|

Air-borne Abrasive Blasting |

Best for porous cBN wheels in HEDG; uses silicon carbide abrasives for steady wear resistance. |

Hard to control because blasting settings can change. |

Non-Traditional Dressing Methods

Electro-discharge dressing for conductive wheels

Electro-discharge dressing, or Wire Electrical Discharge Conditioning (WEDC), works for wheels with conductive materials. This method does not use force and does not wear out tools. It helps you get accurate and repeatable wheel shapes. WEDC shows new abrasive grains without hurting them, so you get better grinding and longer wheel life.

Ultrasonic-assisted dressing for delicate applications

Ultrasonic-assisted dressing uses fast vibrations to shape the wheel. This method is good for small or delicate grinding wheels. You get a smooth surface and avoid cracks or chips. Ultrasonic dressing is gentle and keeps your wheel in good shape, especially with sensitive materials.

Maintenance Best Practices

Regular wheel balancing procedures

You should balance your grinding wheels often. A balanced wheel shakes less and gives a smoother finish. It also helps the wheel wear evenly and last longer. Always check the balance before you start a new job.

Proper storage conditions to prevent damage

Keep your vitrified grinding wheels in a dry place. Make sure the temperature stays the same and do not stack wheels in ways that could break them. Handle wheels gently to stop chips or cracks. Always look at your wheels before using them and follow the maker’s rules for storage and handling.

Tip: Teach all workers how to handle and care for wheels safely. Check wheels for cracks or chips before every use. Use the right wheel for your material and job. Dress the wheel often to keep it sharp and working well.

Application Considerations

Ideal Use Cases

High-precision surface grinding

Vitrified grinding wheels are best for jobs needing high accuracy. They help you get smooth surfaces and tight measurements. Many fields like cars, planes, and medicine use these wheels. They are good for tasks that need careful grinding. You can trust them for jobs where the wheel must keep its shape for a long time.

Mass production of hardened components

Vitrified wheels work well in big factories making many parts. They are used to grind hard steel, engine parts, and tools. These wheels last much longer than regular ones. Some reports say they can last 100 to 300 times longer. You also save time because grinding is much faster. The pores in the wheel help coolant flow and remove waste, which makes grinding better.

Tip: Pick vitrified CBN wheels for steel and ferrous alloys. Use vitrified diamond wheels for ceramics and carbides.

Limitations

Not recommended for flexible or interrupted cuts

Do not use vitrified wheels if your job needs a soft or bendy wheel. They do not handle shaking or sudden stops well. Resin wheels are better for jobs with lots of shocks or changes.

Challenging for very hard or tough materials

Vitrified wheels may not work well on very hard or tough stuff. They can wear out faster or even break. For these jobs, you might need a different wheel or change how you grind.

Selection Criteria

Matching wheel specifications to workpiece material

You must pick the right wheel for your part. Here is a simple chart:

|

Workpiece Material |

Recommended Abrasive |

|---|---|

|

Steel |

Aluminum oxide, ceramic alumina |

|

Cast iron, non-ferrous |

Silicon carbide |

|

Carbides, hardened steel |

Diamond, CBN |

Pick the abrasive that matches your material. Choose the right grit size for your job. Use coarse grit for fast work and fine grit for smooth finishes.

Considering required surface finish and tolerances

Think about how smooth and exact you want your part. For rough jobs, use a softer wheel with more space between grains. For careful jobs, use a harder wheel with grains packed close together. Make sure the wheel fits your machine’s speed and how it mounts. Always follow safety rules and check your wheel before using it.

Note: When you match the material, finish, and machine, you get the best grinding results.

Future Development Trends

Material Innovations

Nanostructured bond materials

New nanostructured bond materials are changing how vitrified grinding wheels work. These bonds use tiny particles to make the wheel stronger and more stable. This gives better heat resistance and helps the wheel last longer. Now, you can pick a wheel that matches your grinding job. Cold Isostatic Pressing (CIP) makes the wheel dense and even. This means there are fewer weak spots in the wheel. High porosity lets coolant move through the wheel better. This keeps your work cool and stops burns.

-

Nanostructured bonds help the wheel handle heat and grind better.

-

Evenly spread abrasive grains give a smoother finish.

-

Special mixing and pressing methods make wheels last longer.

Hybrid bond systems

Hybrid bond systems mix the best parts of different materials. You get the strength of vitrified bonds and the bendiness of resin or metal bonds. This mix helps you grind faster and more accurately. Hybrid systems also make it easier to shape the wheel and keep its form. You will see less wear and better results, even with hard jobs.

Manufacturing Advancements

3D printing of vitrified wheels

3D printing lets you make grinding wheels with special shapes. You can design wheels with cooling channels or slots that are hard to make with old ways. This process uses less energy and less work. The wheels have better grain spread and resist wearing down. 3D laser printing can stick diamond particles to steel. This makes wheels for tough grinding jobs. These new wheels are good for work that needs high accuracy and strength.

AI-optimized wheel designs

AI now helps design and make grinding wheels. You can use AI to find the best shape and structure for your job. AI makes the process faster and more exact. Using AI means you get the same results every time and waste less material.

Sustainability Improvements

Eco-friendly raw materials

You can help the planet by picking wheels made with eco-friendly materials. Makers now use superabrasive grains like diamond and CBN. These last longer and work faster. Some companies use bonding agents from plants and recycled abrasives. These choices cut down on waste and help reuse materials. Some wheels are made for dry grinding or use coolants that break down in nature.

-

Recycling old wheels helps get back useful materials.

-

Checking the whole life of a wheel helps companies make greener choices.

-

Digital sensors and machine learning help save energy during grinding.

Energy-efficient production processes

Energy-saving ways now help make vitrified grinding wheels. Companies set the right speeds and feed rates to use less power. New bonding methods stop grain loss and keep things clean. Many factories follow rules to use fewer harmful materials and recycle more. These steps help you get good wheels and protect the earth.

Note: The future of vitrified grinding wheels is about smarter materials, better ways to make them, and greener choices. You can expect wheels that work better and are kinder to the environment.

Vitrified grinding wheels give you high strength, heat resistance, and long life. You get steady results with hard materials. Resin bond wheels offer more flexibility and work well for fast, smooth finishes. To choose the right wheel, follow these steps:

-

Use vitrified wheels for heavy-duty grinding of steel, cast iron, or carbide.

-

Pick resin bond wheels for high-speed, precision, or finishing jobs.

-

Match wheel hardness and structure to your material and grinding method.

Always think about your workpiece, finish, and grinding speed before you decide.

FAQ

What makes vitrified grinding wheels different from resin bond wheels?

Vitrified wheels use a ceramic bond. This bond gives you more strength and heat resistance. Resin bond wheels use a plastic-like bond. You get more flexibility and a lower price with resin wheels.

Can you use vitrified grinding wheels for all materials?

You can use vitrified wheels for steel, cast iron, and hard alloys. They do not work well on soft metals or materials that need a flexible wheel. Always check the wheel type before you start.

How do you know when to dress a vitrified grinding wheel?

You should dress the wheel when you see a drop in cutting performance or a rough surface finish. Dressing helps keep the wheel sharp and in the right shape.

Are vitrified grinding wheels safe to use?

Yes, they are safe if you handle and store them with care. Always check for cracks before use. Follow the manufacturer’s safety tips and wear protective gear.

How do you store vitrified grinding wheels properly?

Store your wheels in a dry place with steady temperatures. Lay them flat or use cushioned supports. Keep them away from moisture and sudden impacts.

Contact Us

For More Grinding Solution or Customized Abrasive Tools