For most workshops, a table grinding wheel made from aluminum oxide is the most useful. This type works with many metals and does not wear out fast. Many people pick it because it lasts long and works well. The table below shows popular table grinding wheel choices for easy comparison:

|

Wheel Type |

Best For |

Durability |

Material Compatibility |

|---|---|---|---|

|

Aluminum Oxide |

General Use |

High |

Ferrous Metals |

|

Silicon Carbide |

Non-Ferrous/Stone |

Medium |

Non-Ferrous/Stone |

|

Diamond/CBN |

Precision/Hard |

Very High |

Hard Materials |

The best table grinding wheel depends on what material you use, what job you do, and the finish you want.

Key Takeaways

-

Pick a grinding wheel that matches your material. This helps you get better results and makes your tool last longer.

-

Choose the right grit size for your job. Use coarse grit to remove material fast. Use fine grit for a smooth finish. Use very fine grit to polish.

-

Pick the correct bond type for your work. Use vitrified for tough jobs. Use resin for smooth finishes. Use metal for hard materials.

-

Always check the wheel size before you use it. Make sure the RPM rating is right. Make sure the wheel fits your machine. This keeps you safe and helps the wheel work well.

-

Wear personal protective equipment every time. Follow safety steps like mounting the wheel the right way. Balance the wheel and dress it often. This helps you avoid accidents.

Introduction

Importance of Choosing the Right Grinding Wheel

Picking the right grinding wheel is important for good results. The wheel you use changes how well your grinding job goes. It also affects how fast and smooth the work is. If you match the wheel to the job, you get better cuts. You also spend less time fixing problems. The right wheel helps stop damage to your tools and workpieces. It also makes your grinding tools last longer.

A good grinding wheel can help a lot in your workshop. Here are some main reasons why:

Cutting is faster and you do not need to fix the wheel as much.

There is less shaking, so your tools and workpieces stay safe.

You do not have to change wheels as often, so you save time.

The wheel keeps its shape and does not get too hot or clogged.

Your tools last longer and your work looks the same every time.

There are many kinds of grinding wheels. Each one has its own grain and bond. If the wheel grain is harder than what you are grinding, it works better and lasts longer. Good wheels may cost more at first, but they help you work better and last longer.

Key Factors Affecting Performance

Many things change how a grinding wheel works. The three most important are:

1. Material Being Ground: The kind of material tells you which abrasive, grain, grit size, and bond to use. 2. Grinding Pressure: How hard you press changes how the wheel works and how long it lasts. 3. Required Form and Finish Accuracy: The look and shape you want help you pick the right grit, grade, and bond.

Each thing changes how your work turns out. If you know these things, you can pick the best wheel and get good results every time.

Types of Grinding Wheels for Workshop Use

To pick the right grinding wheel, you need to know the types. Each type has its own shape, size, material, grit, and bond. These things change how the wheel works and what jobs it does best.

Wheel Shapes

Grinding wheels come in many shapes. Each one is made for a certain job or tool.

Straight Wheels

Straight wheels are used the most. They have a flat surface. They are good for many grinding jobs. People use them to sharpen tools and smooth metal edges. The grinding part is on the outside edge.

Cylinder Wheels

Cylinder wheels have a big, flat side. They are used to grind flat surfaces. These wheels are often found in factories. They do not have a hole in the middle, so they fit special machines.

Tapered Wheels

Tapered wheels have a thin edge. This shape helps grind small spaces or grooves. They are good for careful work where straight wheels cannot reach.

Dish/Cup Wheels

Dish and cup wheels look like a bowl. The grinding part is on the side. These wheels are good for grinding flat surfaces and sharpening cutting tools.

Saucer Wheels

Saucer wheels look like a shallow bowl. They are great for sharpening saw blades and other cutting tools. The shape makes it easy to reach curved surfaces.

Tip: Straight wheels work for most jobs, but other shapes help with special tasks.

Wheel Sizes

The right size wheel keeps you safe and helps you work well. Size means diameter, thickness, and arbor hole.

Common Diameters for Bench Grinders

|

Wheel Diameter (inches) |

|---|

|

6 |

|

7 |

|

8 |

|

10 |

Most shops use wheels that are 6, 7, 8, or 10 inches wide. An 8-inch wheel that is 1 inch thick is common for most jobs.

Thickness Considerations

Thicker wheels last longer and are good for tough jobs. Thinner wheels cut faster and are better for careful work. Pick the thickness that fits your job.

Arbor Hole Compatibility

The arbor hole must fit the grinder’s spindle. Always check the size before you buy a wheel. If it does not fit, it can be unsafe.

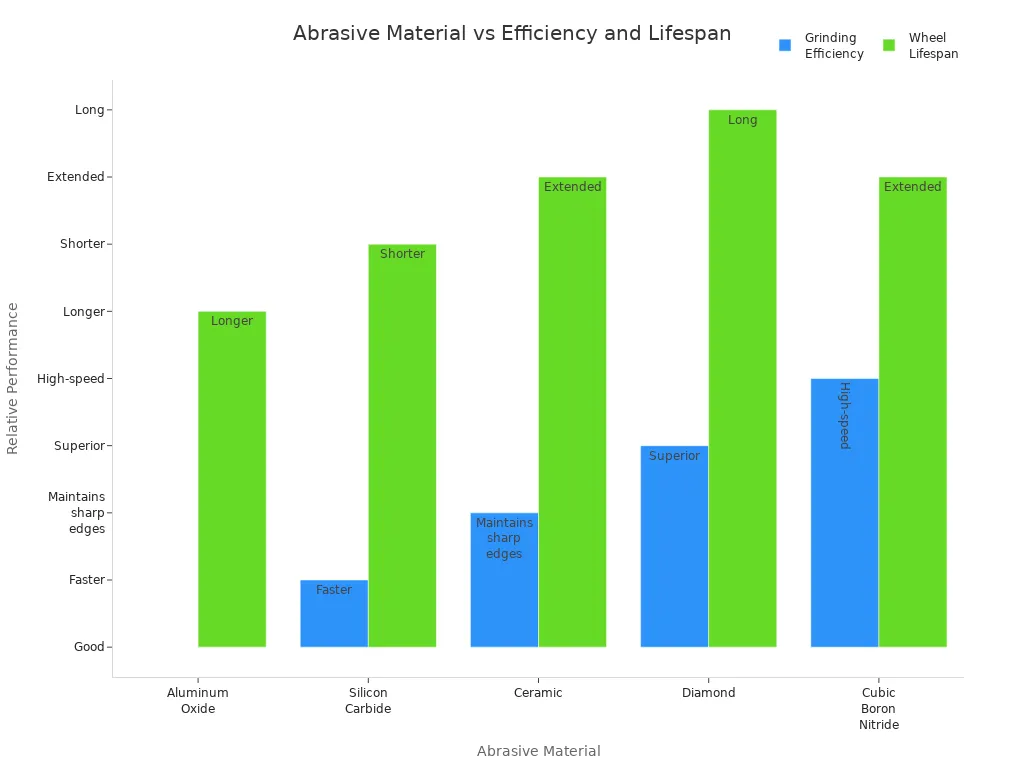

Abrasive Materials

The material of the wheel changes how well it cuts and how long it lasts. The most common materials are:

|

Abrasive Material |

Key Properties |

Suitable Workpiece Materials |

Impact on Grinding Efficiency |

Effect on Wheel Lifespan |

Typical Applications |

|---|---|---|---|---|---|

|

Aluminum Oxide |

High hardness, toughness, good wear resistance |

Ferrous and non-ferrous metals |

Good cutting ability and material removal rates |

Longer wheel life |

Metal fabrication, automotive, aerospace, general manufacturing |

|

Silicon Carbide |

Very hard, thermally conductive, brittle |

Non-ferrous metals, glass, ceramics |

Faster cutting rates |

Shorter lifespan |

Precision grinding of hardened steels, stone, glass, ceramics |

|

Ceramic |

Exceptional durability and heat resistance |

Hard materials |

Maintains sharp edges longer, minimizes heat |

Extended wheel life |

Precision tasks in aerospace and automotive |

|

Unmatched hardness and cutting efficiency |

Hard, abrasive materials |

Superior surface finish, high efficiency |

Long tool longevity |

Precision grinding, tool manufacturing, hard materials |

|

|

CBN |

Exceptional thermal stability and chemical resistance |

Hardened steels, superalloys |

High-speed grinding, consistent results |

Extended tool life |

Automotive, aerospace, high precision grinding |

Note: Aluminum oxide wheels are good for most jobs. Diamond and CBN wheels are best for hard or careful work.

Grit Size Selection

Grit size tells you if the wheel is rough or smooth. It measures how big the grains are. The job you do decides which grit size you need.

Coarse Grit (10-24)

Coarse grit wheels take off material fast. They are good for rough work and shaping. Use coarse grit when you do not need a smooth finish.

Medium Grit (30-60)

Medium grit wheels are a mix of fast cutting and smooth finish. Most shops use medium grit for regular grinding. It is good for sharpening and smoothing.

Fine Grit (70-180)

Fine grit wheels make a smoother finish. They are good for finishing and sharpening fine tools. Fine grit takes off less material but leaves a cleaner surface.

Very Fine Grit (220+)

Very fine grit wheels are for polishing and careful work. They make the smoothest surfaces. Use them for final touches or delicate jobs.

-

Coarse grits like 30, 50, and 80 are used for fast cutting.

-

A 46 grit wheel is used for rough grinding and gives a 1.0 Ra finish.

-

Medium grits, from 46 to 100, are best for most shop jobs.

-

Fine grits wear out faster but make smoother finishes.

-

Always pick the right grit for your job to get the best results.

Bond Types

The bond holds the grains together. Different bonds change how the wheel works and how long it lasts.

|

Bond Type |

Durability & Strength |

Performance Characteristics |

Suitable Applications |

|---|---|---|---|

|

Resin Bond |

Flexible, less robust than vitrified |

Smoother grinding, exposes fresh edges |

Finer finishes, not for heavy-duty grinding |

|

Metal Bond |

Maximum strength, holds grains tightly |

Slow wear, less aggressive |

Grinding hard materials, long wheel life |

|

Electroplated |

Thin, precise bonding |

Thin wheels, delicate finishing |

Ultra-fine finishing tasks |

|

Rubber Bond |

Flexible, shock absorbing |

Good for light grinding, deburring |

Aluminum, plastics, light grinding |

|

High strength, rigid, heat resistant |

Consistent, good shape retention, superior finish |

Heavy-duty, surface/cylindrical/tool grinding |

Vitrified bonds make strong, glass-like wheels. These wheels can take high heat and pressure. They last a long time and keep their shape. Resin bond wheels are more bendy and give a smoother finish. Metal bonds are best for hard jobs and last a long time. Electroplated and rubber bonds are for special jobs that need careful or flexible work.

Market insight: Bonded abrasives, like resin and vitrified bond wheels, are the most used at 60%. Resin bond wheels are popular because they work well for many jobs.

Choosing the Right Wheel for Your Tasks

Grinding Ferrous vs. Non-Ferrous Metals

Picking the right grinding wheel helps you get better results. Ferrous metals, like steel and cast iron, need wheels with aluminum oxide or ceramic. These wheels cut hard metals well and keep the finish even. Non-ferrous metals, such as aluminum and brass, work best with silicon carbide wheels. Silicon carbide grains are sharper and stop the wheel from getting clogged. This keeps the surface smooth.

|

Abrasive Type |

Suitable Materials |

Notes on Use and Characteristics |

|---|---|---|

|

Aluminum Oxide |

Ferrous metals (steel, cast iron) |

Good for general grinding, keeps its shape, resists heat |

|

Silicon Carbide |

Non-ferrous metals (aluminum, brass) |

Stops loading, sharper grains, good for softer metals |

|

Ceramic/Aluminum Oxide |

Hard steel alloys |

Cuts fast, lasts long, less tool burn |

|

Cubic Boron Nitride (CBN) |

Hard steel alloys, carbide tools |

Costs more, lasts long, not for carbon steel |

Tip: Always use the right abrasive for the metal. This gives you the best finish and removes material faster.

Sharpening Tools vs. Heavy Stock Removal

Grinding wheels are used for different jobs. Sharpening needs fine grit wheels with vitrified or resin bonds. These wheels give you control and a smooth finish. CBN wheels are great for sharpening. They do not get hot and keep their shape. This helps you get a nice finish on cutting tools.

Heavy stock removal is different. You need coarse grit wheels, like Type 27 or Type 28 with aluminum oxide. These wheels take off material fast and can handle tough jobs. Resin bonds help absorb shock and deal with vibration. Bigger wheels help you remove more material during hard jobs.

|

Criterion |

Description |

Application to Task |

|---|---|---|

|

Resin is flexible and cool, metal is strong, vitrified is stable |

Resin for heat, metal for heavy jobs, vitrified for sharpening |

|

|

Grit Size |

Coarse for tough grinding, fine for polishing and sharpening |

Coarse for removing, fine for sharpening |

|

Wheel Diameter |

Big wheels for heavy grinding, small wheels for careful work |

Big for removing, small for sharpening |

|

Material Compatibility |

Match bond and grit to the material |

This helps your tools last longer |

Surface Finishing vs. Cutting Applications

Surface finishing means making the workpiece look smooth and even. Fine or very fine grit wheels with vitrified bonds help make a shiny finish. These wheels take off just a little bit of material and leave the workpiece looking polished. For cutting, you need coarse grit wheels with strong resin or metal bonds. These wheels cut through tough materials fast.

-

For a smooth finish:

-

Use fine grit wheels, 120 or higher.

-

Pick vitrified bonds for steady work.

-

Choose wheels made for your material.

-

-

For cutting and tough grinding:

-

Use coarse grit wheels.

-

Pick resin or metal bonds for strength.

-

Use bigger wheels to cover more space.

-

Grinding wheels work best when you match them to the job. This helps you get a smooth finish and remove material quickly.

Safety and Usage Tips

Proper Wheel Mounting & Balancing

You must mount and balance grinding wheels with care. Always clean the mounting area to get rid of oil, dust, or metal bits. Flanges need to fit the wheel’s size and type. If flanges are dirty or broken, the wheel may shake. Tighten bolts evenly so the wheel does not get stressed. A balancing arbor helps you find the heavy side of the wheel. You can add small weights to fix the balance. After dressing the wheel, check the balance again. Checking balance often stops shaking, gives better finishes, and keeps machines working well.

Treat grinding wheels gently, like you would with glass. Even tiny cracks can make the wheel break and cause danger.

RPM Rating Compliance

It is very important to match the wheel’s RPM rating to the grinder’s speed. If a wheel is made for 6,650 rpm but the grinder runs at 8,500 rpm, the wheel can break and hurt someone. Always check the grinder’s speed and the wheel’s top RPM before you start. The wheel’s RPM must be the same or higher than the grinder’s speed. Use guards and hand protection for extra safety. Only use wheels for the jobs and materials they are made for.

-

Never use a wheel faster than its RPM rating.

-

Always follow the maker’s rules for both the grinder and the wheel.

PPE and Guard Requirements

Personal protective equipment (PPE) keeps workers safe from flying pieces, dust, and loud sounds. The table below lists the main PPE you need for grinding:

|

PPE Category |

Description and Purpose |

Safety Standard |

|---|---|---|

|

Eye/Face Protection |

Safety glasses, face shields, goggles for debris and sparks |

OSHA 29 CFR 1926.102, ANSI Z87.1 |

|

Hearing Protection |

Earplugs or earmuffs for loud noise |

OSHA 29 CFR 1910.95 |

|

Respiratory Protection |

Dust masks or respirators for dust and silica |

OSHA 29 CFR 1926.1153, 1910.134 |

|

Hand Protection |

Cut-resistant gloves for cuts and heat |

OSHA 29 CFR 1910.132 |

|

Body Protection |

Long sleeves, aprons, or coveralls made of non-flammable material |

OSHA guidelines |

|

Foot Protection |

Steel-toe boots with slip-resistant soles |

OSHA 29 CFR 1926.96 |

|

Head Protection |

Hard hats for impact protection |

OSHA 29 CFR 1910.135, ANSI Z89.1 |

|

Machine Safety |

Safety guards on machines to prevent wheel breakage |

OSHA 29 CFR 1926.303, ANSI B7.1 |

Workers should tie back long hair and not wear loose clothes or jewelry. This helps stop things from getting caught in the machine.

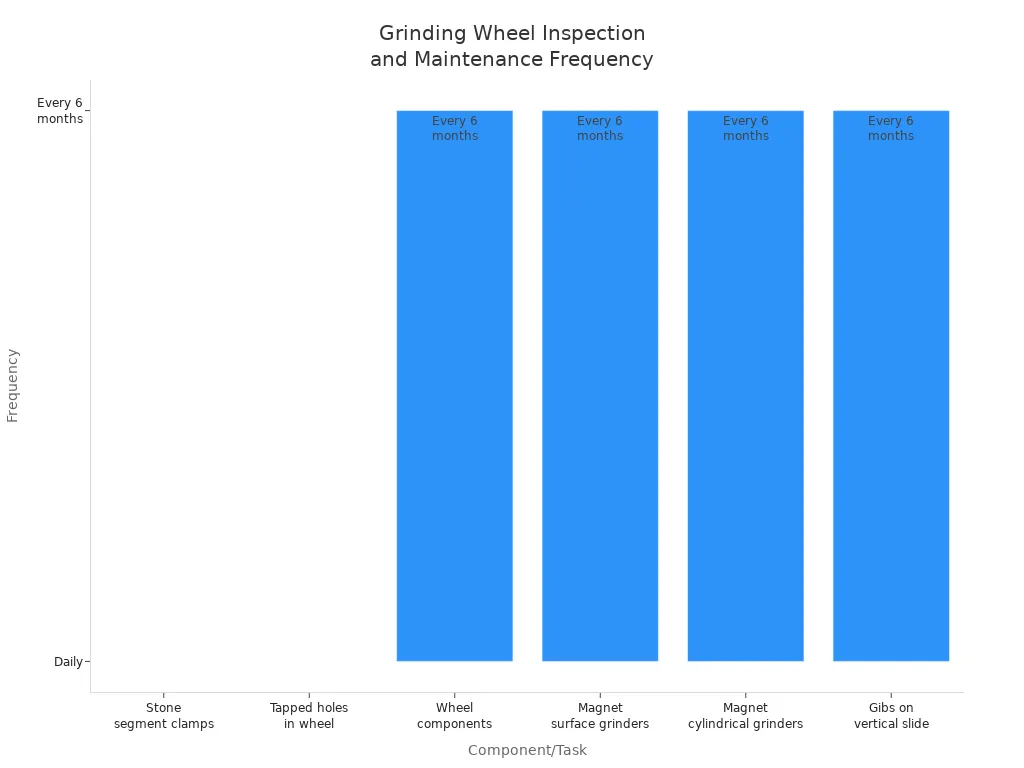

Inspection & Maintenance

Checking and caring for grinding wheels often keeps them safe and working well. Workers should look at clamps and screws every day for damage or wear. Broken parts can make the wheel fall or break. Tapped holes in the wheel need daily checks for stripped threads. Every six months, take off the wheel and clean the adapter, spindle, and guard. Clean and oil the magnet and gibs too. This plan helps stop big problems and keeps machines working right.

Keeping your workspace clean, using dust collectors, and following a care plan help stop accidents and make your tools last longer.

Common Mistakes to Avoid

Incorrect Grit/Abrasive Selection

Many people in workshops pick the wrong abrasive or grit size. This happens a lot when they do not know what each job needs. Sometimes, they use aluminum oxide on ceramics. But silicon carbide is better for ceramics. Using the wrong abrasive makes grinding bad and wears out the wheel faster. Picking the wrong grit size is also a problem. Coarse grit takes off material fast but leaves rough marks. Fine grit makes things smoother but works slower. Some people only care about how fast they can grind. Others only want a smooth finish. The best choice depends on what the job needs. You must match the abrasive and grit size to your work. If you do not, the wheel can glaze, wear out too soon, or not cut right.

Picking the right abrasive and grit size helps the wheel last longer and gives a better finish.

Ignoring Wheel Specifications

Some workers do not check the grinding wheel’s details. They forget to look at the speed rating or how to mount it. They may not use blotters when needed. This can make the wheel break and send pieces flying. People can get hurt. Too much shaking can break machine parts. If the wheel is not clamped right, it can slip or crack. Using the wrong wheel or speed can cause accidents, even with guards. Not checking for cracks or chips is risky. One worker got badly hurt by using a broken wheel. He did not check it first. Checking wheels and learning the right way helps stop these problems.

Overheating Workpiece

Grinding can make the workpiece too hot. High heat can put a white layer on the metal. This makes the metal weaker and ruins the finish. Heat can also change the metal and cause cracks. The part may not last as long. The surface can get damaged and look bad. Sometimes, the metal melts in spots and cannot be used. Using coolant is very important. Coolant takes away heat and chips. It keeps the wheel clean. This helps the finish look good and keeps the workpiece safe.

Neglecting Wheel Dressing

If you do not dress the wheel, grinding gets worse. The wheel changes shape as it wears down. This makes the surface rough and uneven. Parts may not come out the right size. The wheel does not cut as well and wears out faster. Dressing the wheel often brings out new grains and fixes its shape. This keeps grinding steady and the finish smooth. Safety rules say to dress the wheel often. This helps it cut better, stay cool, and lowers the chance of accidents.

Conclusion

Summary of Selection Criteria

Picking the best table grinding wheel depends on many things. Durability is important because a strong wheel lasts longer. This means you do not have to stop work often. Grit size is also key. It changes how fast you can grind and how smooth the surface looks. The bond type should fit the job’s needs for strength and bendiness. Material compatibility makes sure the wheel works well and does not harm your project. Workshops should also think about how fast they remove material, how quick the wheel spins, and how coolant is used. These things affect how well the wheel works and how long it lasts. The weight of the wheel matters for safety and how hard the machine works, especially with big wheels. Cost is important too. You should think about how much you pay at first and how much you save over time. Getting the right finish and shape depends on picking the best grit and bond.

The table below shows the main things to think about for easy and hard materials:

|

Factor |

Easy-to-Grind Materials Recommendation |

Hard-to-Grind Materials Recommendation |

|---|---|---|

|

Material Being Ground |

Tough grains, coarser grit, harder bond |

Friable grains, finer grit, softer bond |

|

Grinding Pressure |

Optimize for stock removal |

Prevent overheating and damage |

|

Required Finish & Accuracy |

Coarser grit for rough removal |

Finer grit for precision and surface finish |

|

Area of Contact |

Larger area with tough grains |

Smaller area to reduce heat and wear |

|

Wheel Speed |

Higher speeds with durable grains |

Moderate speeds to avoid burning |

|

Coolant Use |

Use coolant for longer life and better finish |

Essential to prevent overheating |

|

Machine/Spindle Power |

Harder bonds and coarser grits with more power |

Softer bonds and finer grits with less power |

Final Recommendations

Start by knowing what materials you grind most in your shop. For most jobs, aluminum oxide wheels work well with ferrous metals. If you grind non-ferrous metals or very hard stuff, try silicon carbide or diamond wheels. Always pick the grit size that matches how smooth you want the finish and how much you need to remove. Use vitrified bonds for tough jobs and resin bonds for careful, fine work. Make sure the wheel’s weight and size are safe for your machine. Always use coolant to keep things cool and get a nice finish. Before you buy, look at both the price and how long the wheel will last. Try out a few wheels or ask the maker for advice to find what works best for your shop.

Tip: Make a checklist—know your material, pick the right abrasive, choose the grit for the finish you want, match the bond, and check if the wheel fits your machine. This helps you grind safely, quickly, and get great results.

Most experts say a 6-inch slow-speed grinder with an aluminum oxide table grinding wheel is best for most workshops. This setup is safe and works well for sharpening and general grinding. To pick the right table grinding wheel, use this checklist:

-

Figure out what material you will grind and what job you need to do.

-

Pick the right abrasive and grit for your task.

-

Make sure the wheel size fits your grinder.

-

Look at the manufacturer’s guide or try it out in your shop.

If you use the wrong wheel, your work may not turn out well. It can also be unsafe and cost more money. Always use the right wheel for your job and check trusted guides to get the best results.

FAQ

What is the safest way to check if a grinding wheel is damaged?

Tap the wheel gently with a non-metal tool. A clear ring means the wheel is safe. A dull sound means cracks may exist. Never use a wheel with cracks.

How often should someone dress a grinding wheel?

A worker should dress the wheel when it becomes dull or uneven. For best results, check the wheel before each use. Frequent dressing keeps the wheel sharp and safe.

Can one grinding wheel work for all materials?

No, one wheel cannot handle every material. Aluminum oxide works for most metals. Silicon carbide or diamond wheels suit non-ferrous or hard materials. Always match the wheel to the job.

Why does a grinding wheel overheat the workpiece?

A wheel overheats the workpiece when it grinds too fast or lacks coolant. High pressure or a dull wheel can also cause heat. Overheating weakens the metal and ruins the finish.

What PPE should workers wear when using a grinding wheel?

|

PPE Type |

Purpose |

|---|---|

|

Safety Glasses |

Protects eyes |

|

Gloves |

Shields hands |

|

Earplugs |

Reduces noise |

|

Dust Mask |

Blocks dust |

Workers should always use the right PPE for safety.

Contact Us

For More Grinding Solution or Customized Abrasive Tools