You can solve frustrating grinding wheel loading. The solution involves a straightforward, three-part strategy. Mastering these areas will significantly improve your wheel performance and eliminate loading issues for good.

Your Action Plan to Stop Loading:

- Select the correct grinding wheels.

- Optimize your grinding parameters.

- Perform regular maintenance. Our maintenance and angle grinder tips will guide your grinding process.

Key Takeaways

- Grinding wheel loading happens when the wheel gets clogged with material. This stops the wheel from cutting well and can cause problems like bad finishes or overheating.

- Choose the right grinding wheel for your job. Use a softer wheel with bigger grit and an open structure for soft materials. This helps prevent clogging.

- Adjust your machine settings. Make sure the wheel speed and how fast it moves across the material are correct. This helps the wheel cut cleanly.

- Use coolant correctly. Coolant helps wash away chips and keeps the wheel from getting too hot. Make sure it hits where the wheel touches the material.

- Dress your wheel to fix loading. Dressing removes clogged material and makes the wheel sharp again. Always follow safety rules when you do this.

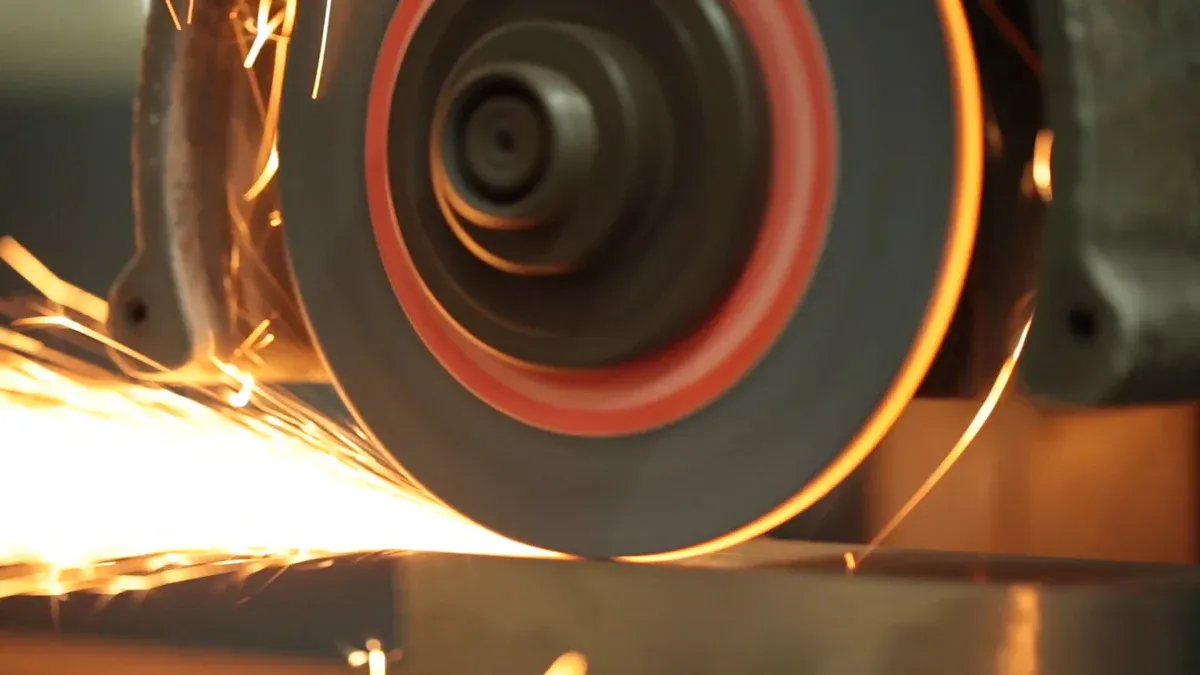

Understanding Grinding Wheel Loading

Before you can solve loading issues, you need to understand what they are. Recognizing the problem early is the first step in our troubleshooting and prevention tips. This knowledge helps you keep your grinding operations running smoothly.

What is Wheel Loading?

Grinding wheel loading is the technical term for when the wheel’s pores get clogged with chips from your workpiece. This often happens when grinding soft materials. It can also result from using the wrong grinding wheels or incorrect machine settings. The clogged wheel can no longer cut effectively. This leads to serious issues like poor surface finishes, reduced cutting action, and dangerous overheating.

It is important not to confuse loading with glazing. Glazing happens when the abrasive grains on the wheel become dull. This creates a smooth, glassy surface. While both are types of wheel wear, loading involves clogging, whereas glazing involves dulling. Understanding this difference is key to fixing these common grinding issues. Proper wear management is crucial for performance.

Signs of a Loaded Wheel

You can spot a loaded wheel by looking for specific signs. These symptoms are clear warnings that you need to address the loading problem. Here are some troubleshooting and prevention tips for loading to watch for:

- Shiny or Smeared Wheel Face: The wheel surface looks metallic and smeared instead of grainy. This is a primary sign of wear.

- Burn Marks on the Workpiece: Blue or brown marks appear on your material. This indicates excessive heat and overheating from inefficient grinding.

- Increased Grinding Noise: You may hear a loud squealing or rubbing sound instead of the normal cutting noise. This change signals abnormal wear.

- Drop in Cutting Speed: The wheel removes material much slower than usual. This forces you to apply more pressure, worsening the wear and the problem.

Recognizing these signs early helps you take corrective action before major problems arise. These are the first troubleshooting and prevention tips for your grinding process.

Core Strategies to Prevent Loading

Preventing grinding wheel loading is more efficient than fixing it. You can achieve a smooth, productive workflow by focusing on three key areas. These proactive strategies form the foundation of good grinding practice and are essential troubleshooting and prevention tips for your workshop.

Select the Right Grinding Wheels

Your first line of defense is proper wheel selection. The right wheel specification directly counters the causes of loading. You should consider three main factors: wheel grade, grit size, and structure.

- Choose a Softer Grade: A softer grade grinding wheel has a bond that breaks down more easily. This feature is actually a major advantage. As abrasive grains become dull during grinding, the weaker bond releases them. This process exposes new, sharp abrasive particles underneath. This continuous self-sharpening action maintains a consistent cut and prevents material from clogging the wheel.

- Select a Coarser Grit: Coarser grit particles are larger and spaced farther apart. This creates more room between the grains, known as chip clearance. This ample space allows the grinding chips to be evacuated efficiently instead of getting stuck. This is especially important in roughing operations where you remove a lot of material quickly.

- Use an Open Structure: For soft, ductile, or gummy materials like aluminum and copper, you need a wheel with an open structure. These wheels (often rated 8-14) have the most space between abrasive grains, which is ideal for preventing clogging. Using silicon carbide abrasives is also recommended for these low-tensile strength metals.

Making the right choice can feel complex. This is where expert guidance becomes invaluable. At Aimgrind, we specialize in customized grinding solutions. Our team analyzes your material and process to recommend the perfect grinding wheels for your application. Our conventional bonded abrasives offer a cost-effective and versatile solution, available in various structures designed specifically to prevent loading on all types of grinders, including common grinding wheels for angle grinders.

Adjust Grinding Parameters

Even the best grinding wheels can fail if your machine settings are incorrect. Optimizing your grinding parameters ensures the wheel performs as designed. Pay close attention to your speeds and feeds.

Pro Tip: Think of your grinding parameters as a recipe. Changing one ingredient affects the final result. Small adjustments can make a big difference in preventing loading.

Increasing the traverse speed (the rate at which the wheel or workpiece moves side-to-side) can lead to a poor surface finish and higher wheel wear. This change affects how chips are formed and removed, potentially causing them to clog the wheel. A slower traverse speed often allows the wheel to cut more cleanly. Similarly, an excessively deep cut forces the wheel to remove too much material at once, quickly leading to loading. Start with the manufacturer’s recommended settings for your grinders and make small, incremental adjustments to find the sweet spot for your specific job. This is one of the most effective troubleshooting and prevention tips.

Use Coolant Correctly

Coolant does more than just reduce heat. It plays a critical role in flushing chips away from the grinding zone. Neglecting coolant or applying it improperly is a direct path to a loaded wheel. You must ensure the coolant jet is aimed precisely where the wheel meets the workpiece.

The right flow rate and pressure are also essential for effective chip removal. Different grinding operations and materials have different needs. For example, High-Pressure Coolant (HPC) and Minimum Quantity Lubrication (MQL) are two advanced methods that offer excellent results.

Here are some typical pressure and flow rate recommendations:

| Coolant Method | Flow Rate / Pressure Range |

|---|---|

| High-Pressure Coolant (HPC) | 70 to 1000 bar |

| Minimum Quantity Lubrication (MQL) | 10–100 mL/h (lubricant), 4–8 bar (air pressure) |

Studies show significant benefits:

- A 70-bar HPC system can completely prevent chip welding when grinding certain types of stainless steel.

- An MQL system using vegetable oil can reduce chip welding by 45% in other stainless steel applications.

For your grinders, ensure your coolant system is clean and the nozzles are unobstructed. Proper coolant application is a non-negotiable step for high-performance grinding and is key to avoiding issues with your grinding wheels for angle grinders. Whether you are using standard flood coolant or a high-pressure system, consistent and targeted application is what matters most for your grinding wheels for angle grinders.

How to Fix a Loaded Wheel

When prevention is no longer an option, you need a reliable fix. A loaded wheel is not a lost cause. You can restore its cutting ability quickly and safely with the right techniques. This process involves two key actions: dressing and truing.

Dressing to Restore Sharpness

Dressing is your primary method for fixing a loaded wheel. This process removes the clogged layer of material from the wheel’s surface. It also fractures dull abrasive grains, exposing fresh, sharp cutting edges underneath. Ignoring wheel dressing leads to poor performance and potential damage to your workpiece.

Before you begin any dressing or grinding work, you must prioritize safety. Proper precautions protect you from injury and ensure a successful outcome.

Safety First! Your Non-Negotiable Checklist 📝

- Always wear your personal protective equipment (PPE), especially ANSI Z87+ safety glasses.

- Ensure all machine guards are in place and correctly positioned to protect you.

- Inspect the grinding wheel for any cracks or damage before you start.

- Confirm the machine’s speed does not exceed the maximum RPM marked on the wheel.

- Hold the dressing tool firmly and support it against the tool rest.

Once you are ready, you can select a dressing tool. Different tools create different surface finishes. Star dressers and diamond dressers are two common choices.

| Feature | Star Dresser | Diamond Dresser |

|---|---|---|

| Action | Crushes and breaks away the bond and dull grains. | Cuts and shears away the bond and dull grains. |

| Resulting Surface | Leaves a rougher, more open surface. | Leaves a finer, more precise surface. |

| Best For | Quickly fixing a heavily loaded wheel and rough grinding. | Precision grinding and achieving a fine finish. |

| User Skill | Easy to use for basic dressing. | Requires more technique for optimal results. |

To dress the wheel, you will turn on the grinder and let it reach full speed. Gently bring the dressing tool into contact with the face of the spinning wheel. Move the tool steadily across the entire wheel face. You will see the metallic shine of the loading disappear, revealing the wheel’s original grainy texture. This simple action removes the surface wear and restores the wheel’s cutting ability. A coarser dressing pass is often best to resolve loading, as it opens the wheel structure and reduces future clogging. This process does create some wear on the wheel itself.

Truing for Geometric Accuracy

You should not confuse dressing with truing. While they are often performed together, they have different goals. Truing restores the geometric shape of the grinding wheel. Its main purpose is accuracy, not just cleaning.

Over time, a wheel can develop problems that affect its shape.

- It can become “out-of-round,” causing vibration.

- Its face can become uneven, leading to inconsistent grinding.

- Its profile or corner can break down from wear.

Truing corrects these issues. You use tools like a brake truing device or a dedicated conditioning wheel to reshape the grinding wheel. This ensures the wheel is perfectly concentric with the spindle and has a flat, true face. A properly trued wheel reduces vibration, improves surface finish, and minimizes wheel wear.

Truing vs. Dressing: What’s the Difference?

- Truing makes the wheel round and straight. Think of it as restoring the wheel’s perfect shape.

- Dressing makes the wheel sharp. Think of it as sharpening the cutting edges.

After truing, a wheel’s surface might be too smooth to cut effectively. You must follow up with a dressing pass. Dressing will remove the outermost bond material and expose the sharp abrasive grains needed for efficient grinding. This two-step process of truing then dressing is essential for high-precision grinding operations where both geometric accuracy and cutting performance are critical. Regular maintenance prevents excessive wear and keeps your operations running smoothly.

Troubleshooting Common Abrasive Tool Issues

Even with the best practices, you might still face problems. Knowing how to diagnose and solve these issues quickly keeps your projects on track. This guide for troubleshooting common abrasive tool issues will help you identify the problem and find the right solution. These troubleshooting and prevention tips are essential for any operator.

Symptom-to-Solution Guide

Use this simple chart to address common grinding wheels issues. It provides quick fixes and long-term strategies for troubleshooting common abrasive tool issues on your grinders.

Quick Tip: A shiny wheel face is a sign of glazing. This condition creates excessive heat, leading to workpiece burn marks and potential overheating. Addressing glazing is a key part of troubleshooting common abrasive tool issues.

| Symptom | Immediate Solution | Root Cause & Long-Term Fix |

|---|---|---|

| Shiny Wheel & Burn Marks | Dress the wheel immediately. Use a quick pass to remove the loaded or glazed layer. Ensure your coolant is aimed directly at the grinding zone to prevent overheating. | Your wheel grade may be too hard or the grit too fine. This is one of the most common mistakes. Consider an Aimgrind wheel with a softer grade or more open structure. These troubleshooting and prevention tips for glazing will reduce future issues. |

| Excessive Noise or Squealing | Stop the grinder and inspect for debris trapped between the wheel and guard. Check for signs of glazing or uneven wear. A light dressing pass can sometimes resolve the noise. | The noise often points to glazing, an out-of-balance wheel, or excessive vibration. Review your dressing technique. These troubleshooting and prevention tips for excessive noise or vibration will help you maintain your grinders. |

| Uneven or Rough Finish | True the wheel to restore its geometric shape, then dress it to expose sharp abrasives. Check that the workpiece is securely mounted. This is a critical step in troubleshooting common abrasive tool issues. | An uneven finish often results from a poorly dressed wheel or incorrect traverse speeds. These troubleshooting and prevention tips for uneven or rough finishes will improve your grinding quality. This is one of the common mistakes to avoid. |

| Sudden Wheel Breakage | Stop the machine immediately. Wheel breakage is a severe problem. Do not use the machine until you inspect the spindle, flanges, and guards for damage. Discard all fragments of the broken wheel safely. | Breakage can result from a damaged wheel, excessive speed, or improper mounting. Always inspect new grinding wheels for cracks before mounting. These troubleshooting and prevention tips for wheel breakage are vital for safety. |

By following this guide for troubleshooting common abrasive tool issues, you can handle most problems you encounter with your grinding wheels for angle grinders. Regular maintenance and correct operating procedures are your best defense against wear, overheating, and breakage. These troubleshooting and prevention tips for inefficient grinding and troubleshooting and prevention tips for overheating will help you avoid downtime and improve the performance of your grinding wheels for angle grinders. These troubleshooting common abrasive tool issues will help you with your grinding wheels for angle grinders.

You can master your grinding process and prevent grinding wheel loading. Proactive strategies are always more effective than reactive fixes. Just as choosing better wheels improves a truck’s efficiency and load capacity, selecting the right grinding wheels with expert help from a brand like Aimgrind prevents loading. These troubleshooting and prevention tips show that consistent maintenance avoids the pitfalls of poor maintenance.

Your Final Checklist:

- Choose the right wheel first.

- Tune your grinding parameters.

- Follow our maintenance and angle grinder tips.

These troubleshooting and prevention tips are your path to peak performance.

FAQ

What causes loading on grinding wheels for angle grinders?

Using the wrong wheel on soft metal is the top cause. A hard wheel clogs quickly. This is one of the most common issues you will face. Proper wheel selection for your grinding wheels for angle grinders prevents this problem.

How often should I dress my wheel?

You should dress your wheel when you see loading or glazing. For many grinders, this means dressing before each precision job. Regular dressing prevents performance issues and ensures a clean, safe cut every time you work.

Can I use one wheel for both steel and aluminum?

You should avoid this practice. Grinding aluminum on a wheel meant for steel causes severe loading issues. Always use a dedicated wheel for soft metals. This simple step helps your grinders and grinding wheels for angle grinders perform correctly.

Why does my grinder vibrate so much?

Vibration often points to an out-of-round wheel. You need to true the wheel to restore its shape. This problem is common with many grinders and can lead to poor finishes and other issues if you do not correct it.

Contact Us

For More Grinding Solution or Customized Abrasive Tools