Aluminum oxide stands out as the most common abrasive for general-purpose grinding. Its versatility and low cost make it ideal for grinding ferrous metals like steel. Many grinding wheels use this material for everyday tasks. While it is one of the most popular abrasives, other options exist for specific materials. Different jobs require a different abrasive, from conventional types to superhard materials.

Key Takeaways

- Aluminum oxide is the most common abrasive for grinding wheels. It works well for steel and other iron metals.

- Silicon carbide is a good choice for non-ferrous metals like aluminum. It is harder than aluminum oxide.

- Diamond abrasives are best for very hard materials. These include ceramics and tough alloys.

- Always match the abrasive to the material you are grinding. This helps prevent damage and ensures good results.

The Most Popular Abrasives for General Use

Choosing the right abrasive is key to efficient grinding. While many options exist, a few conventional abrasives stand out for their widespread use in various industries. These popular abrasives form the backbone of many workshops and manufacturing facilities.

Aluminum Oxide: The Industry Standard

Aluminum oxide is the most common abrasive for grinding wheels. Its popularity comes from its durability and low cost, making it perfect for many metalworking applications. This abrasive works best on ferrous metals with high tensile strength. Common materials include:

- Steel and stainless steel

- Cast iron and other iron alloys

- Welds

This material comes in several types. Each type has unique properties suited for different tasks. A high-quality aluminum oxide can make a significant difference in performance.

| Type of Aluminum Oxide | Key Properties | Typical Applications |

|---|---|---|

| Brown | Toughest and most common type. | Rough grinding and cutting and grinding wheels. |

| White | More friable (breaks easily), cuts freely. | Grinding heat-sensitive tool steels. |

| Pink/Ruby | Tougher than white, very sharp. | Precision grinding on hardened steels. |

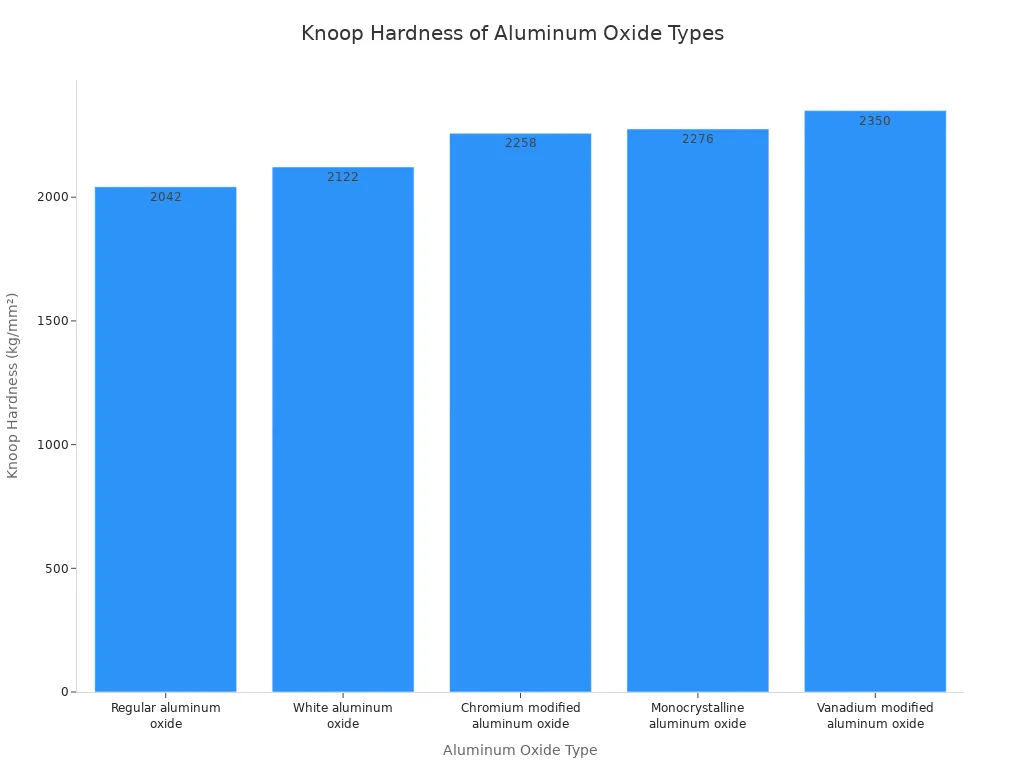

The hardness of an abrasive affects its performance. Aluminum oxide has a Mohs hardness of about 9.0. Different formulations show slight variations in hardness, which impacts their grinding ability.

Important Note: Operators should avoid using aluminum oxide grinding wheels on soft, non-ferrous metals like aluminum or brass. These materials can clog the wheel’s pores, causing it to overheat and potentially crack.

Silicon Carbide: For Non-Ferrous Materials

Silicon carbide is another one of the popular abrasives. It is harder and sharper than aluminum oxide. This makes it the ideal choice for grinding materials with lower tensile strength. It excels at grinding non-ferrous metals like aluminum and titanium. It also works well on cast iron and non-metallic materials like stone and glass.

There are two main types of silicon carbide: black and green. Each has distinct characteristics.

| Property | Black Silicon Carbide | Green Silicon Carbide |

|---|---|---|

| Hardness (Mohs) | ≈9.2 | ≈9.4 |

| Toughness | Higher (less friable) | Lower (more friable) |

| Typical Use | Grinding wheels, blasting. | Precision polishing, fine finishing. |

Black silicon carbide is tougher. It resists impact well, making it suitable for tough grinding jobs like cleaning castings or removing flashing. Green silicon carbide is purer and harder. Its sharp, friable nature is perfect for achieving fine finishes on hard but brittle materials.

Zirconia Alumina: For Rough Grinding

Zirconia alumina is a high-performance abrasive. It is a blend of zirconium oxide and aluminum oxide, typically with 10-25% zirconia. This combination creates an exceptionally tough and durable grain. It is a top choice for aggressive grinding and heavy stock removal.

The main advantage of this abrasive is its self-sharpening action. During grinding, the grains fracture under pressure. This process exposes new, sharp cutting edges. This continuous renewal allows for a very high rate of material removal. The constant sharpness ensures a fast and efficient stock removal process.

Zirconia alumina lasts longer and cuts faster than standard aluminum oxide, especially under high pressure. This makes it ideal for demanding jobs like weld removal and foundry snagging, where rapid stock removal is essential.

These abrasives provide excellent performance for a wide range of common grinding tasks.

Superhard Abrasives for Advanced Grinding Wheels

Conventional abrasives meet their limits when facing extremely hard materials. For grinding tasks involving ceramics, hard alloys, and composites, operators need superhard abrasives. The market for these advanced tools is growing quickly. Projections show the super abrasives market will increase by USD 3.41 billion between 2024 and 2029. This growth highlights their rising importance in modern manufacturing.

Diamond: For Hard and Brittle Materials

Diamond is the ultimate abrasive material due to its unmatched hardness. It is the top choice for grinding the toughest materials. While natural diamonds exist, the industry now relies on synthetic diamonds. Synthetic diamonds offer greater consistency and are more economical for industrial use.

| Characteristic | Natural Diamonds | Synthetic Diamonds |

|---|---|---|

| Origin | Mined from the earth | Man-made in a laboratory |

| Cost | Very expensive | More cost-effective and readily available |

| Properties | Fixed natural properties | Can be engineered for specific applications |

| Industry Use | Largely replaced | The popular choice for modern grinding wheels |

Specialized brands like Aimgrind excel at creating custom solutions for these demanding jobs. Their diamond grinding wheels are premium products for precision industries. Key sectors rely on this technology for superior results.

- Aerospace Manufacturing: Requires tight-tolerance grinding of titanium, nickel alloys, and ceramic composites.

- Medical Device Manufacturing: Needs high-quality surface finishes for surgical tools and orthopedic implants.

- Electronics and Tooling: Demands precision for cutting tools and semiconductor components.

Studies show the impact of high-quality diamond grinding. Using advanced conditioning methods on a resin-bonded diamond wheel reduced the mean roughness depth on alumina ceramic by 11%. This leads to a better surface finish and less workpiece degradation.

Diamond grinding wheels use different bond types for various tasks.

- Metal Bonds: Offer extreme durability for grinding ceramics, glass, and tungsten carbide.

- Resin Bonds: Provide shock resistance for grinding composites and some ceramics.

- Vitrified Bonds: Deliver high precision for finishing advanced ceramics and pre-sintered tungsten carbide.

- Electroplated Bonds: Feature a single abrasive layer for aggressive cutting and shaping complex parts.

These advanced cutting and grinding wheels provide long tool life and achieve superior finishes.

Ceramic Alumina: For Precision Grinding

Ceramic alumina is another top-tier abrasive. It is a high-purity, man-made grain. The unique structure of this abrasive material allows it to micro-fracture during grinding. This process constantly exposes new, sharp cutting edges, creating a self-sharpening effect. This action allows for cool, fast cutting on difficult materials.

Ceramic alumina is especially effective for precision grinding on hard-to-grind alloys. It performs well on materials that generate significant heat. Its high thermal stability makes it ideal for:

- Hardened steels above 45 HRC, such as D2 or A2 tool steel.

- Nickel-based superalloys like Inconel, common in aerospace.

- Hard alloyed steels and hard cast iron.

The unique properties of ceramic abrasives make them essential for high-performance grinding applications where precision and efficiency are critical.

How to Choose the Right Abrasive

Selecting the correct abrasive is crucial for effective grinding. The material of the workpiece is the most important factor. A mismatch can lead to poor performance, damaged parts, and worn-out grinding wheels. Making the right choice ensures efficient material removal and a quality finish.

Matching Abrasive to Material

The hardness of a material directly relates to the required abrasive hardness. Hard materials like ceramics or hardened steel need a very hard abrasive, such as diamond or silicon carbide, for effective cutting. Softer materials like aluminum require a different approach. Using the wrong abrasive causes problems like wheel loading, where particles clog the wheel, or glazing, where the wheel becomes smooth and stops cutting.

Pro Tip: A general rule for grinding is to use a hard abrasive for hard materials and a softer abrasive for soft materials. This simple principle helps prevent wheel damage and ensures a good rate of stock removal.

Choosing the right abrasive involves several factors. Operators must consider the abrasive type, grit size for finish quality, and bond type. For example, an open structure wheel prevents clogging during the stock removal of soft metals. Each choice affects the overall grinding performance.

A Quick Selection Guide

This guide helps match popular abrasives to common materials. It simplifies the selection process for many grinding tasks. While many specialized abrasives exist, this table covers some of the most frequent applications.

| Workpiece Material | Grinding Application | Recommended Abrasive |

|---|---|---|

| Steel (Carbon/Stainless) | General grinding, stock removal | Zirconia Alumina or Aluminum Oxide |

| Aluminum | General purpose grinding | Aluminum Oxide |

| Cast Iron | Rough grinding and finishing | Zirconia Alumina or Aluminum Oxide |

| Glass & Ceramics | General grinding (wet) | Silicon Carbide |

| Titanium | Intermediate and finish grinding | Silicon Carbide |

This quick guide provides a starting point. For complex jobs or advanced materials, a detailed analysis of all grinding parameters is necessary for optimal material removal.

Aluminum oxide is one of the most popular abrasives for everyday grinding. However, selecting the correct abrasive is vital for top performance.

The material of the workpiece is the most important factor in choosing the right grinding wheels.

Using specialized grinding wheels for tough materials can increase productivity by over 40%. For challenging grinding tasks, expert solutions from a provider like Aimgrind ensure efficiency and quality.

FAQ

What is the most popular abrasive for grinding wheels?

Aluminum oxide is the most popular abrasive for general use. Its durability and cost-effectiveness make it the industry standard for grinding ferrous metals like steel. Many workshops rely on it for daily tasks.

Can I use one grinding wheel for all materials?

No, operators should not use a single wheel for all materials. Each abrasive performs best on specific materials. A mismatch can lead to poor results, wheel damage, and safety risks.

Quick Tip 💡: Always match the abrasive to the workpiece material. Use a hard abrasive for hard materials and a softer one for soft materials to ensure the best performance.

When should I use a diamond grinding wheel?

Diamond grinding wheels are necessary for extremely hard or brittle materials. Operators use them for grinding ceramics, tungsten carbide, and advanced composites. These wheels provide superior precision and longevity for tough jobs.

What happens if I use the wrong abrasive?

Using the wrong abrasive causes several problems. It can lead to wheel “loading,” where the wheel clogs with material. It can also cause “glazing,” where the wheel becomes smooth and stops cutting effectively.

See Also

Selecting Optimal Bench Grinding Wheel Materials for Specific Requirements

Identifying the Ideal Grinding Wheel for Your Carbide Tooling

Finding the Perfect Grinding Wheel Dresser for Your Workshop

Selecting the Appropriate Metal Grinding Wheel for Every Project

Understanding Grinding Wheel Varieties and Their Real-World Uses

Contact Us

For More Grinding Solution or Customized Abrasive Tools