Your grinding wheel selection for complex contour grinding is a critical balancing act. You must evaluate five key factors to achieve a perfect surface and an efficient grinding process.

- Workpiece Material

- Required Precision (Finish and Form)

- Process Parameters

- Wheel Construction

- Total Cost

A methodical approach to this selection is essential. The right grinding wheel boosts productivity and ensures a quality part surface, while the wrong wheel increases rework, downtime, and long-term costs. Your final choice directly impacts your operational success.

Key Takeaways

- Choosing the right grinding wheel is important for good results and saving money.

- Consider the material you are grinding and pick the best abrasive type for it.

- The wheel’s bond and core material affect how well it works and how long it lasts.

- Always follow safety rules, especially when grinding at high speeds.

- Look at the total cost over time, not just the wheel’s price, to find the best value.

Key Factors for Grinding Wheel Selection

The first step in your grinding wheel selection is understanding the core components. The abrasive grain type, its compatibility with your material, and the bond system holding it all together are foundational to your success.

Conventional vs. Superabrasive Grains

You have two main grain families to choose from: conventional and superabrasive. Each type offers different performance characteristics. Conventional abrasives like aluminum oxide are common, but superabrasives like Diamond or Cubic Boron Nitride (cBN) provide significant advantages for demanding grinding jobs.

| Metric | Conventional Abrasives | Superabrasives (Diamond, cBN) |

|---|---|---|

| Cutting Efficiency | Require more power and force | Require less power for efficient cutting |

| Wear Resistance | Lower wear resistance | Significantly higher wear resistance |

| Hardness | Inferior hardness | Superior hardness for tough materials |

| Thermal Conductivity | Lower thermal conductivity | Enhanced heat transfer, less workpiece damage |

Superabrasives are more cost-effective in high-volume production. They require fewer wheel changes and less dressing, boosting uptime. This makes them the best wheel type for grinding hard materials like ceramic coatings.

Abrasive Choices for Different Materials

Your workpiece material dictates the correct abrasive type. Workpiece compatibility is non-negotiable for effective grinding. For example, grinding high-nickel alloys like Inconel works well with ceramic or cBN wheels due to their durability. For advanced ceramics or tungsten carbide, diamond is the superior abrasive type. Its extreme hardness ensures efficient cutting and a better surface finish compared to other options.

Expert Tip: For hard-to-grind materials, a customized solution is often best. Aimgrind specializes in superabrasive grinding wheels for these exact challenges. Our diamond grinding wheels deliver the durability and precision needed for grinding hard alloys, ceramics, and composites.

How Bond Systems Affect Form Holding

The bond is the glue holding the abrasive grains. It controls the wheel’s form-holding ability and the self-sharpening of grinding wheel action. The bond type you choose impacts the hardness of grinding wheel and its performance.

- Vitrified Bond: This type offers excellent heat resistance and superior shape retention. Its porous structure promotes cooler cutting.

- Resin Bond: This wheel type offers more flexibility, making it suitable for high-speed grinding and fine finishing.

- Metal Bond: This type provides the best form-holding for complex profiles. It is ideal for grinding extremely hard materials like tungsten carbide or hardened tool steels where maintaining dimensional accuracy is critical. The hardness of grinding wheel with a metal bond ensures profile integrity.

The right bond ensures the wheel wears correctly, exposing new cutting edges. This self-sharpening of grinding wheel process is vital for consistent grinding. The overall grinding wheel hardness depends on the combination of grain type, bond type, and structure. The hardness of grinding wheel is a key part of your selection.

Optimizing for Complex Contour Grinding

After selecting your wheel’s core components, you must optimize your process parameters. For complex contour grinding, this means fine-tuning grit size, balancing removal rates with wheel wear, and managing speed and coolant. These adjustments directly impact your final part quality and operational efficiency in surface grinding.

Using Grit Size to Control Surface Finish

Grit size determines the texture of your finished surface. A coarser grit (lower number) removes material quickly but leaves a higher surface roughness. A finer grit (higher number) produces a smoother surface but at a slower cutting rate. You must choose a grit size that balances speed with the required surface roughness for your application.

| Grit Size | Material Removal | Surface Finish (Ra) | Best For |

|---|---|---|---|

| Coarse (24-60) | High | High Roughness | Rough Grinding |

| Medium (80-180) | Moderate | Medium Roughness | General Purpose |

| Fine (220+) | Low | Low Roughness | Finish Grinding |

Caution: Be aware that finer grits increase grinding pressure and heat. This raises the risk of thermal damage or burn on the workpiece surface. A wheel with a closed structure can also trap heat, making the problem worse. Proper coolant application is essential when using fine-grit wheels for surface grinding.

Balancing Removal Rate (Q-prime) and Wheel Wear (G-ratio)

Efficiency in grinding is a balance between two key metrics:

- Q-prime (Q’): The material removal rate. A higher Q-prime means you are cutting material faster.

- G-ratio: The grinding ratio, which measures the volume of material removed versus the volume of wheel wear. A high G-ratio means your wheel lasts longer.

Your goal is to maximize both, but they often work against each other. Pushing for a higher removal rate can increase wheel wear and cutting force. For high-efficiency deep grinding, Q-prime values can reach 20 mm³/mm/sec, far exceeding the typical 3-5 mm³/mm/sec of standard surface grinding. Superabrasive wheels offer a significant advantage here. A CBN wheel produces 100-300 times less debris from wheel wear than a conventional wheel, indicating a much higher G-ratio and longer life. This reduces dressing frequency and boosts productivity.

The Role of Wheel Speed and Coolant

Wheel speed and coolant are critical for success in complex contour grinding. The correct wheel speed optimizes the cutting action of the abrasive grains. A higher speed generally improves surface finish but also generates more heat and force. You must operate the wheel within its specified speed limit for safety and performance.

Coolant is your best defense against heat. A high-pressure coolant system is especially effective. It breaks through the air barrier created by a high-speed wheel, ensuring fluid reaches the cutting zone. This has several benefits:

- Lowers grinding force and reduces wheel wear.

- Keeps the wheel structure clean for a better cutting action.

- Allows for more aggressive feed rates without damaging the part surface.

- Improves chip removal, preventing surface imperfections and leading to a lower final surface roughness.

Properly managed speed and coolant help you maintain a stable grinding process, protect the workpiece, and achieve the desired contour and roughness.

Wheel Construction, Weight, and Safety

Beyond abrasives and bonds, the physical construction of your grinding wheel plays a vital role in performance and safety. You must consider the wheel’s weight, its core material, and the strict safety protocols required for any grinding operation.

Why Wheel Weight Impacts Machine Integrity

The weight of your grinding wheel directly affects your machine’s health. An improperly balanced wheel, where the center of gravity does not align with the axis of rotation, creates significant problems. This imbalance generates eccentric vibration during the grinding operation.

These vibrations are destructive. They cause premature wear on critical machine components and compromise your part quality.

- Machine Damage: Vibration leads to accelerated wear on spindle bearings and other sensitive parts, reducing your machine’s lifespan.

- Tolerance Issues: The vibration also impacts shape and position accuracy, making it difficult to hold tight tolerances for roundness, cylindricity, and flatness. It can even cause chatter marks on the workpiece surface.

A well-balanced wheel minimizes stress on your equipment, ensuring a stable cutting process and protecting your investment.

Understanding Core Materials and Their Impact

The core is the structural hub of the grinding wheel. The material you choose for the core influences the wheel’s performance, especially at high speed. Different materials offer a trade-off between stiffness, weight, and cost. The hardness of grinding wheel is also a factor in this choice.

| Feature | Carbon Fiber | Steel | Aluminum |

|---|---|---|---|

| Weight | Low (reduces machine stress) | Heavy (can strain machinery) | Lighter than steel |

| Stiffness | High (ideal for high-speed cutting) | High | Moderate |

| Vibration Damping | Excellent | Poor | Fair |

For large-diameter wheels used in high-speed grinding, a carbon fiber core is often superior. Its low weight improves operator safety and reduces stress on spindle bearings. Furthermore, its ability to dampen vibration leads to a better cutting action, less chatter, and an improved surface finish. The overall grinding wheel hardness and performance are enhanced by the right core. Choosing a core that complements the hardness of grinding wheel ensures a stable operation.

Safety in High-Speed Grinding Operations

Safety is the top priority in every grinding process. A wheel failure at high speed is extremely dangerous. You can prevent accidents by understanding the primary causes of wheel breakage, which include:

- Operating the wheel beyond its maximum speed.

- Using a wheel with cracks or chips from poor handling.

- Improper mounting procedures.

- Excessive machine vibration.

You must always respect the maximum safe wheel speed marked on the wheel. Never operate a wheel at a speed higher than its rating. The importance of maximum safe operating speed cannot be overstated, as it is the primary defense against catastrophic failure. Always check your machine’s maximum speed settings before mounting a new wheel to ensure a safe grinding experience.

Evaluating the Total Cost of Operation

You must look beyond the initial purchase price to find the most cost-effective grinding wheel. A cheaper wheel can increase long-term expenses through lower efficiency and higher scrap rates. The true value lies in the total cost per part, which accounts for the wheel’s entire lifecycle in your grinding operation.

Upfront Price vs. Long-Term Cost-Per-Part

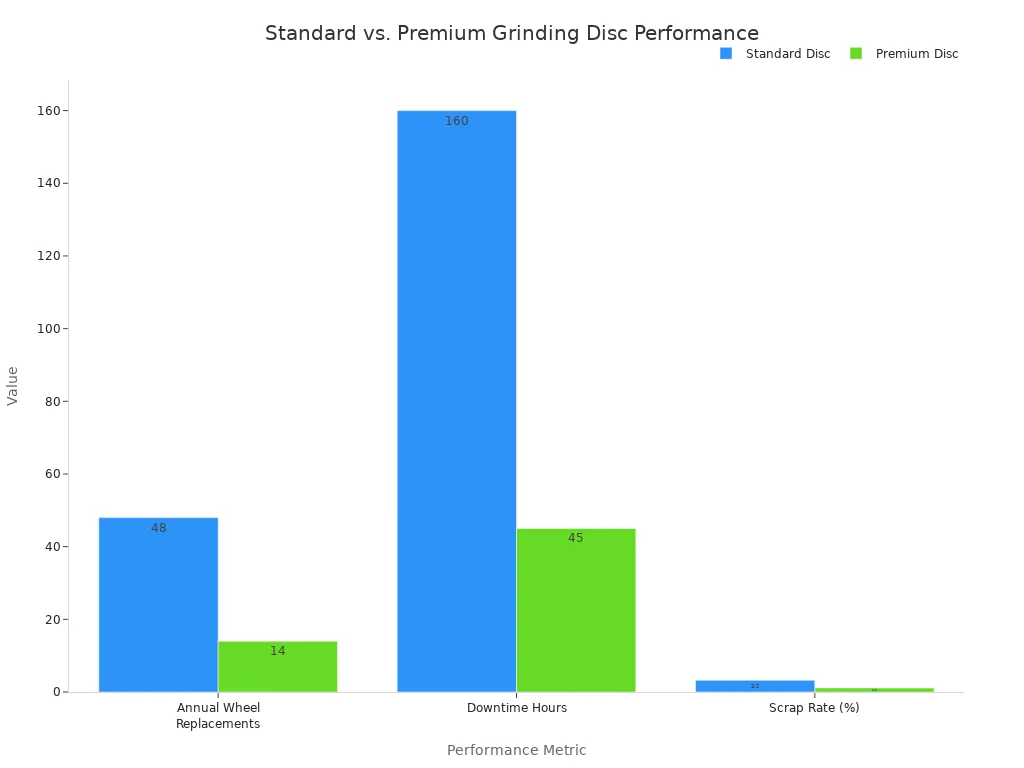

A higher-priced superabrasive wheel often delivers significant savings. For example, one analysis showed that a wheel costing 50% more than a competitor’s actually projected an annual savings of $25,000. This was due to a 10% increase in parts per wheel and a one-second reduction in cycle time. The initial investment pays off through higher productivity. A premium wheel also improves quality, which reduces waste. This comparison shows how a premium disc can drastically lower costs over time.

| Cost Factor | Standard Disc | Premium Disc |

|---|---|---|

| Annual Wheel Replacements | 48 | 14 |

| Downtime Hours | 160 | 45 |

| Scrap Rate | 3.2% | 1.1% |

Factoring in Dressing Frequency and Cycle Time

Dressing frequency directly impacts your productivity. A wheel that holds its form longer requires fewer interruptions for dressing. Vitrified CBN wheels, for instance, need much less frequent dressing than conventional aluminum oxide wheels. This benefit reduces machine downtime and operator labor.

Reducing dressing time is a powerful way to shorten your overall grinding cycle. In some cases, dressing can take up to eight minutes of a grinding cycle. A high-performance wheel that requires less dressing allows for more cutting time, which increases your part throughput and grinding speed. This optimization of your grinding operation boosts your overall output and lowers costs.

Making the Final Cost-Effective Selection

Your final grinding wheel selection should be a data-driven decision. You can calculate the Total Cost of Ownership (TCO) to make an objective comparison. This process involves collecting key data points for your entire operation.

- Tool & Operating Data: Include the wheel purchase price, tool life, and consumable costs.

- Time & Labor Data: Factor in tool changeover time, operator labor rate, and machine hourly rate.

- Quality Data: Track scrap and rework rates caused by tooling issues.

This comprehensive analysis helps you see the full financial impact of your grinding wheel choice. It ensures your selection delivers the best balance of performance, speed, and cost for every grinding job. The right wheel improves your grinding speed and process speed, while the wrong wheel slows your speed.

Your final grinding wheel selection for complex contour grinding requires a balanced approach. Successful grinding depends on your evaluation of these key areas:

- Workpiece Material & Abrasive Choice

- Precision, Process, and Finish

- Wheel Construction and Safety

- Total Cost of the Grinding Operation

The right wheel delivers the best performance across these factors. For challenging complex contour grinding jobs, partnering with an expert validates your selection. Collaborations can cut grinding time in half and extend wheel life, optimizing your entire grinding process. To ensure your grinding wheel choice is perfect, consult with an Aimgrind application expert.

FAQ

What determines the hardness of a grinding wheel?

The bond type and grain spacing define the wheel’s hardness. A harder wheel type has a stronger bond. This hardness helps it resist grain shedding under high grinding force. The right hardness type is key for your grinding job. This type of hardness affects the grinding.

Which bond type is best for my grinding?

Your grinding application dictates the bond type. A vitrified bond type offers great hardness and form holding. A resin bond type is good for high-speed cutting. A metal bond type provides the highest hardness for precision surface grinding. Each type affects grinding performance.

When should I use a superabrasive wheel type?

You should choose a superabrasive wheel type for grinding hard materials. This wheel type excels at high-speed grinding. It reduces grinding force and maintains its hardness. This type of wheel improves the cutting process and the final surface quality.

How do I balance grinding speed and force?

You must manage grinding speed and force for a good surface finish. High speed can improve the surface but increases force and heat. The correct wheel hardness and bond type help manage this force. This balance is vital for any grinding operation. This type of cutting requires precision.

Contact Us

For More Grinding Solution or Customized Abrasive Tools