You want to find the best cost-performance ratio for your grinding wheels. This means looking beyond the initial price tag. The true value of a grinding wheel depends on three key factors: its purchase price, the wheel lifespan, and its grinding performance. A cheap abrasive wheel that wears out quickly or works slowly costs you more in the long run.

A low-cost grinding wheel isn’t a good deal if it doubles your grinding time or needs frequent replacement. Your final cost includes labor and wheel changeovers, making a better-performing wheel a smarter investment for efficient grinding.

With the precision grinding market growing, choosing the right wheel is crucial for effective performance.

Key Takeaways

- The best grinding wheel is not always the cheapest one. Consider its price, how long it lasts, and how well it grinds.

- Match the grinding wheel to the material you are working on. Different materials need different types of wheels for the best results.

- Abrasive type, grit size, and bond hardness affect how a grinding wheel performs. Choose these wisely for your specific job.

- High-performance wheels can save you money in the long run. They reduce labor time and the need for frequent replacements.

Key Factors in Grinding Wheel Performance

You must understand the core components of a grinding wheel to make a cost-effective choice. The right combination of abrasive, grit, and bond determines the wheel’s performance and overall value for your grinding applications. Choosing the correct types of grinding wheels is essential for efficient grinding.

Abrasive Grain Type

The abrasive grain does the cutting. Different types of grinding wheels use different grains, each with a unique price and performance level.

- Aluminum Oxide: This is the most common and least expensive abrasive. It is a durable choice for general-purpose grinding but dulls over time.

- Zirconia: This grain is tougher than aluminum oxide. It works best under high pressure for aggressive grinding on metals.

- Ceramic: This is the highest-performance abrasive. Its microcrystalline structure self-sharpens, providing a fast, consistent cut. Ceramic grinding wheels offer superior durability, often lasting 2-4 times longer than aluminum oxide wheels.

Pro Tip: For demanding jobs, a ceramic grinding wheel delivers the best performance. Its long life and fast cut rate reduce labor time and wheel changes, improving your cost-performance ratio.

| Abrasive Type | Material Removal Rate Characteristics |

|---|---|

| Ceramic | Fast cut rate and quick material removal due to self-sharpening ability. |

| Zirconia | Aggressive and suitable for heavy stock removal under high pressure. |

| Aluminum Oxide | Less effective for heavy-duty applications; dulls during use. |

Grit Size and Finish Quality

Grit size refers to the size of the abrasive particles on the grinding wheel. This choice creates a trade-off between speed and finish.

- Coarse Grits (Low Numbers): These remove material quickly. You save time and labor costs on heavy grinding tasks.

- Fine Grits (High Numbers): These remove material slowly. You get a smooth, high-quality surface finish for precision applications.

Choosing the right grit helps you complete the job efficiently. You can balance speed and quality for optimal grinding performance.

Bond Hardness and Wheel Lifespan

The bond holds the abrasive grains together in the grinding wheel. Its hardness is graded on an A-Z scale, where ‘A’ is the softest and ‘Z’ is the hardest. The bond controls how quickly the wheel wears. A key rule for grinding is to match the bond to your material.

Use a softer bond for hard materials. The bond releases dull grains more easily, exposing new, sharp edges. This self-sharpening action prevents the wheel from glazing and ensures consistent performance.

Using the correct bond for your metal grinding wheel types extends the life of the wheel. This reduces your replacement costs for abrasive grinding wheels and grinding wheels. There are many types of grinding wheels, so choosing the right one is important. This is a key factor in grinding wheel applications.

Choosing a Grinding Wheel for Your Material

The best method for choosing a grinding wheel involves matching it to your specific material. A wheel that excels on steel may fail completely on aluminum. Making the right choice prevents wasted time, money, and materials. This section gives you actionable advice for choosing a grinding wheel for common material types.

Wheels for Soft Metals

You face unique challenges when grinding soft metals like aluminum. Using a standard grinding wheel often leads to serious problems. The low melting point of aluminum causes it to stick to the wheel’s surface during grinding.

Common Issues with Standard Wheels on Aluminum:

- Loading/Clogging: The wheel surface quickly gums up with melted aluminum. This stops the grinding wheel from cutting.

- Ineffective Grinding: A loaded wheel just rubs against the workpiece. This creates excessive heat and a poor finish.

- Safety Risk: The buildup of heat and pressure can cause the grinding wheel to overheat and break apart.

- Cross-Contamination: If you use a wheel previously used on steel, it can embed steel particles into the aluminum, causing corrosion later.

To avoid these issues, you need a specialized grinding wheel for aluminum. Look for grinding wheels with a non-loading formula. These often use a blend of silicon carbide and aluminum oxide grains. Silicon carbide is a very hard abrasive. Its grains are friable and sharp, which helps them break down before clogging. This design ensures your grinding wheel for aluminum maintains a fast, consistent cut throughout its life, making your grinding process efficient and safe. Choosing a grinding wheel designed for the job is key.

The Sweet Spot for Standard Steels

For common materials like carbon steel, you can find an excellent balance of price and performance. Choosing a grinding wheel for these metals does not mean you must buy the most expensive option. Zirconia and high-quality aluminum oxide grinding wheels represent the cost-performance “sweet spot.”

Aluminum oxide is a great general-purpose choice for grinding carbon steel and even some alloy steels. For more demanding jobs, a zirconia wheel offers a significant upgrade.

| Brand/Product | Abrasive Type | Best For |

|---|---|---|

| DEWALT Zirconia | Zirconia Alumina | Aggressive grinding and heavy-duty material removal on various steels. |

| Makita | Aluminum Oxide | General-purpose steel grinding and finishing. |

| Standard Grinding Wheel | Aluminum Oxide | Deburring and shaping on carbon steel and structural steel. |

While a zirconia wheel has a higher initial price, its durability delivers long-term value. It excels at aggressive grinding and heavy-duty material removal on surfaces like carbon steel and grinding wheel for stainless steel applications.

| Feature | Aluminum Oxide Wheels | Zirconia Alumina Wheels |

|---|---|---|

| Pros | Inexpensive, widely available | Extremely durable, handles high pressure |

| Cons | Less effective on harder alloys | Higher initial cost |

| Price Range | $2–$6 each | $6–$15 each |

For heavy grinding tasks, the extended life and faster cut rate of a zirconia wheel reduce labor costs and wheel changeovers. This makes it a more cost-effective choice over time.

Aimgrind Diamond Grinding Wheels for Hard Materials

What about grinding hard, brittle, or exotic materials? When you work with ceramics, composites, hard alloys, or tungsten carbide, you need a grinding wheel for hard-to-grind metals. In these high-value applications, standard grinding wheels wear down too fast to be effective. This is where you get the best cost-performance ratio from a premium solution: Aimgrind diamond grinding wheels.

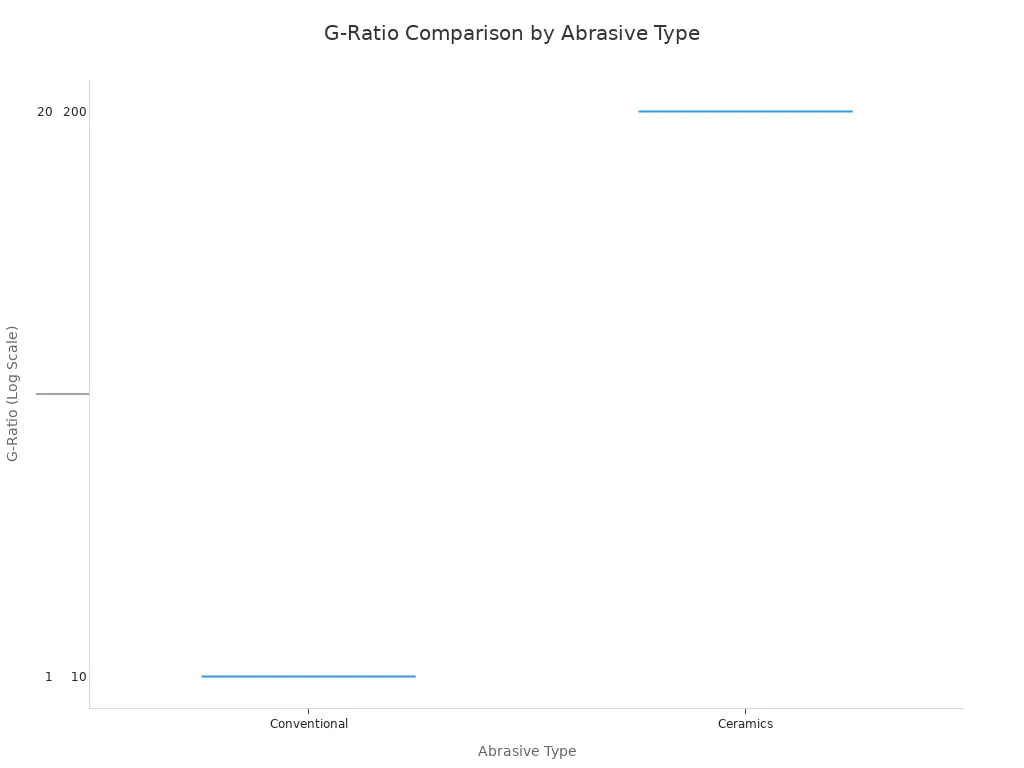

While there are no grinding wheels made for all metals, diamond is the top performer for the toughest materials. An Aimgrind diamond grinding wheel may cost 3 to 5 times more than a conventional wheel upfront. However, its performance and lifespan provide unmatched long-term value. The efficiency of a grinding wheel is measured by its G-Ratio, which is the volume of material removed divided by the volume of wheel wear. A higher G-Ratio means a more efficient wheel.

As you can see, superabrasives like diamond offer a G-Ratio that is hundreds or even thousands of times higher than conventional grinding wheels.

| Abrasive Type | G-Ratio Range |

|---|---|

| Conventional | 1 to 20 |

| Ceramics | 10 to 200 |

| Superabrasives (Diamond) | 500 to 10,000+ |

Investing in an Aimgrind diamond wheel pays off by dramatically reducing wheel changes, minimizing machine downtime, and delivering superior precision. For demanding industries where quality and productivity are critical, choosing a grinding wheel from Aimgrind is an investment that enhances efficiency and lowers your total grinding cost.

Calculating the Best Cost-Performance Ratio

You can move beyond guesswork and use simple math to find the best cost-performance ratio. The sticker price of a grinding wheel is only one part of the equation. True cost includes your time and labor, which are often the most expensive parts of any grinding job.

The Simple Cost Formula

To understand the true expense, you can use a straightforward formula. This calculation helps you see the bigger picture of your grinding operation.

Total Job Cost = Wheel Price + (Labor Cost per Hour x Hours Worked)

This formula shows that a wheel with a high cut rate can significantly lower your total cost, even if its initial price is higher. Faster grinding means fewer labor hours.

Factoring in Labor Savings

Labor is a major expense. Skilled machine operators in the US can earn between $20 and $50 per hour. A faster, more efficient grinding wheel directly reduces this cost. Let’s look at an example of a one-hour grinding job with a labor cost of $30/hour.

| Metric | Standard Wheel | High-Performance Wheel |

|---|---|---|

| Wheel Price | $5 | $15 |

| Time to Complete Job | 1 hour | 0.5 hours |

| Labor Cost | $30 | $15 |

| Total Cost | $35 | $30 |

In this case, the high-performance wheel saves you $5 on a single job. Its rapid cut rate cuts the grinding time in half, making it the more economical choice. This demonstrates how a better wheel delivers a superior performance.

The G-Ratio in Efficient Grinding

For a more technical measure, you can look at the G-Ratio. This value measures grinding efficiency.

- Definition: The G-Ratio compares how much material you remove from your workpiece to how much of the grinding wheel you use up.

- Meaning: A higher G-Ratio means your wheel is more durable and efficient. It removes more material with less wheel wear.

A high G-Ratio directly translates to lower costs. You spend less time changing the wheel and more time on productive grinding. A wheel with a high G-Ratio offers excellent performance and helps you achieve the best cost-performance ratio by maximizing material removal and minimizing downtime.

You now know the cheapest wheel is rarely the most cost-effective for your grinding jobs. You achieve the best cost-performance ratio by strategically matching your grinding wheels to the job. Consider the material, required finish, and grinding pressure for your specific applications.

Final Tip: Think of high-performance grinding wheels as an investment. A premium wheel from a brand like Aimgrind pays for itself by reducing labor time, minimizing wheel changes, and boosting overall grinding productivity for demanding applications.

FAQ

How do I choose the right size grinding wheel?

You must match the wheel to your grinder’s specifications. Selecting the right size grinding wheel ensures safety and optimal performance. An incorrect size can damage your tool and make your grinding work unsafe. Check your grinder’s manual for the correct diameter and arbor size.

What is the most important factor for cost-effective grinding?

The most vital factor is matching your wheel to the material. A correct match improves your grinding speed and wheel lifespan. This simple step reduces overall costs more than just buying a cheap wheel. Proper selection is key for any grinding task.

When should you replace a grinding wheel?

You should replace your wheel when you see cracks, chips, or significant wear. A damaged wheel is a major safety hazard during grinding. Also, replace it if your grinding performance drops. A worn wheel makes your grinding work slow and inefficient.

Can you use one wheel for all grinding jobs?

No, you cannot use a single wheel for every grinding job. Soft metals, hard steels, and ceramics each require a specific type of wheel. Using the wrong one leads to poor results, damages the material, and makes your grinding process less effective.

Contact Us

For More Grinding Solution or Customized Abrasive Tools