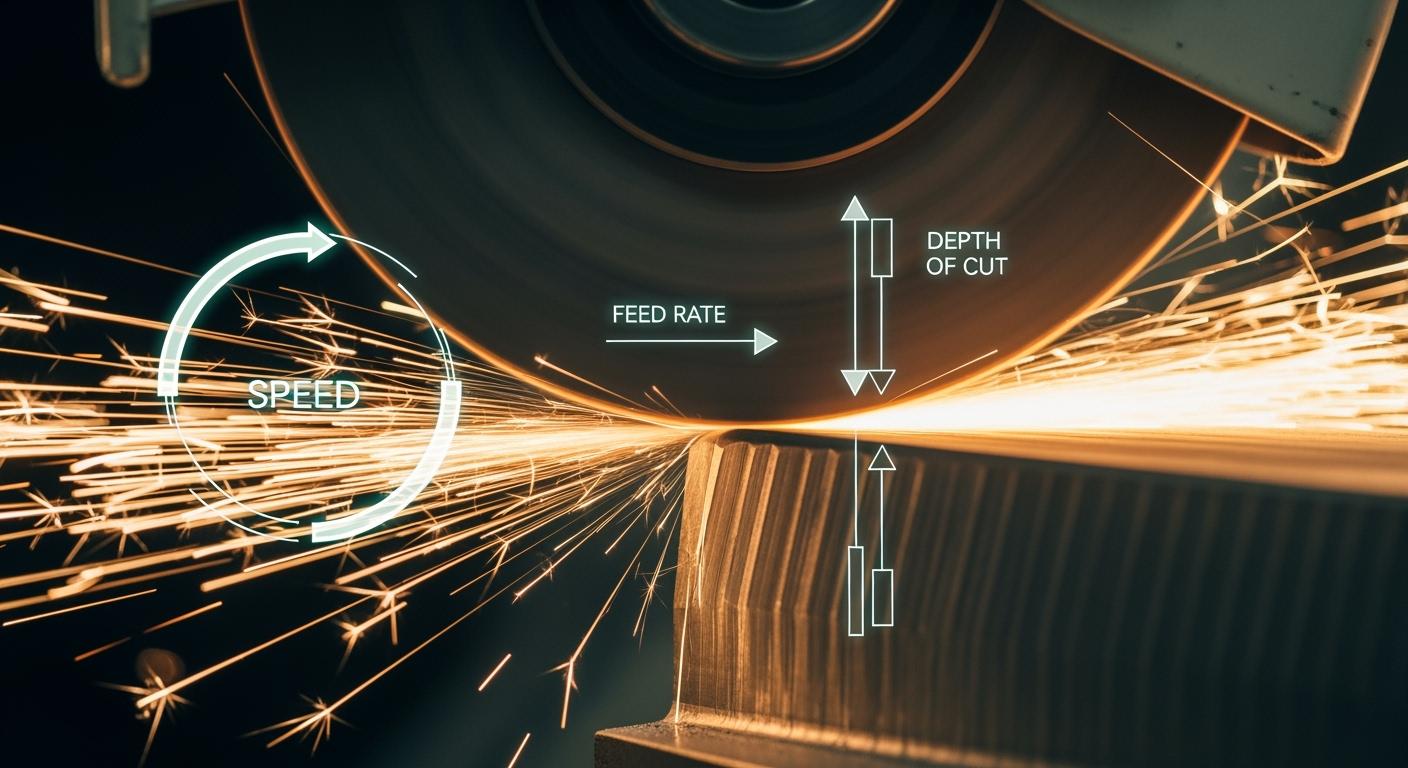

You want to improve your grinding work. Balancing quality, cost, and productivity in any grinding process can be difficult. Your main controls are the grinding wheel’s speed, feed, and depth. This guide helps you with optimizing speed for better efficiency and a higher material removal rate. A full grinding process optimization strategy delivers a huge boost in performance and cost savings. This process makes your grinding work more effective.

Key Takeaways

- Balance speed, feed, and depth of cut for good grinding results. Changing one setting means you must adjust the others.

- Measure your progress using Material Removal Rate (MRR) and G-Ratio. MRR shows how fast you remove material. G-Ratio shows how long your wheel lasts.

- Adjust settings for your goal. Use higher depth and feed for fast material removal. Use lower depth and feed for a smooth finish.

- Follow a step-by-step plan to improve grinding. Start with a baseline. Change one setting at a time. Then, check the results.

- Coolant and a strong machine are important. Coolant keeps things cool and clean. A strong machine prevents wobbling and bad surfaces.

Foundations of the Grinding Process

To master your grinding work, you must first understand the core principles. The grinding process removes material through microscopic interactions between the abrasive wheel and the workpiece. These interactions happen in three main ways:

- Cutting: Abrasive grains act like tiny cutting tools to shear away material.

- Plowing: Grains push material aside without creating a chip, deforming the surface.

- Rubbing: Dull grains slide across the workpiece, generating friction and heat.

The undeformed chip thickness model helps explain the relationship between your parameters and the material removed. Understanding these fundamentals is key to achieving efficient grinding work.

Optimizing Speed (SFM) for Finish and Efficiency

Your wheel speed, measured in Surface Feet per Minute (SFM), is critical for performance. Optimizing speed helps you control the grinding action. A higher speed often improves the surface finish and boosts efficiency. However, finding the optimal speed is a balance. The right speed ensures abrasive grains fracture correctly, exposing new, sharp edges for a clean cutting action. This is one of the most important techniques for any grinding application, including cylindrical, centerless, and internal grinding. Proper speed management is essential for precision manufacturing.

Adjusting Feed Rate for Cycle Time and Quality

The feed rate is how fast you move the workpiece past the grinding wheel. Increasing the feed rate directly shortens your cycle time, which is great for productivity in manufacturing. For operations with long cycle times, like grinding large gears, adjusting parameters can cut the time in half. However, an excessive feed rate can cause problems. It may leave a rough surface finish and create visible scallop marks. This happens because a high feed rate increases chip load and can cause vibrations, hurting the quality of your grinding work.

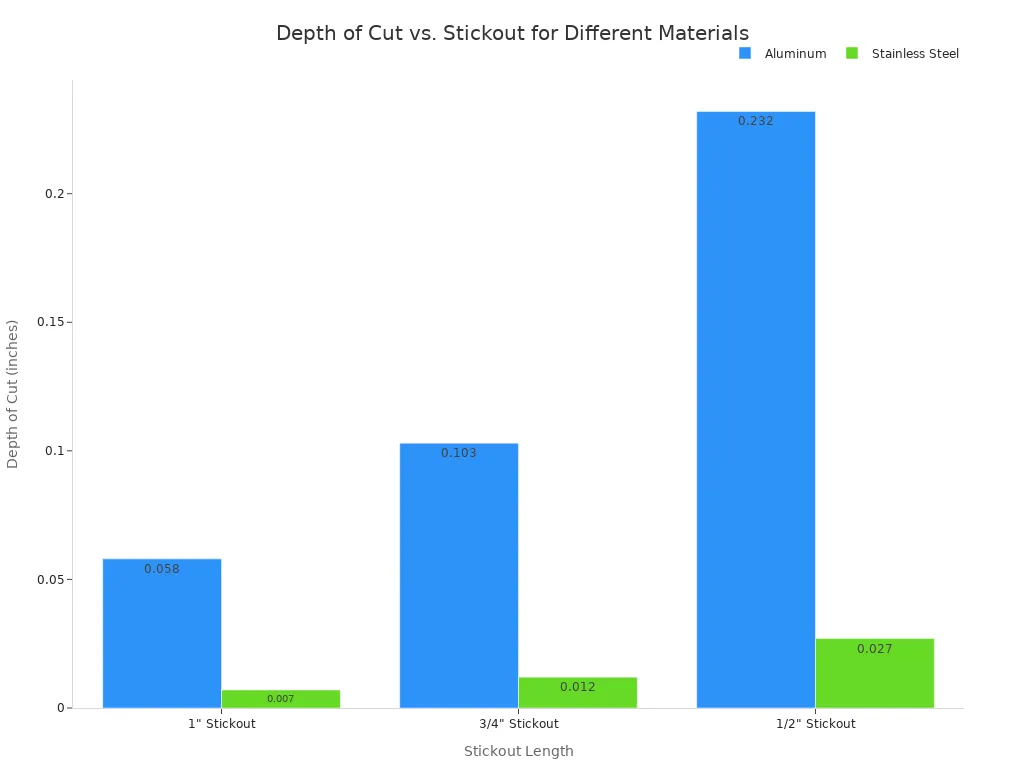

Managing Depth of Cut for Material Removal

The depth of cut is how deep the grinding wheel penetrates the workpiece on each pass. A deeper cut removes more material faster. However, the material you are grinding dictates the maximum depth. Harder materials like stainless steel require a much shallower cut than softer materials like aluminum.

Increasing the depth too much raises cutting forces. This can cause tool deflection or chatter, leading to poor precision and a damaged surface. You must manage this parameter carefully for successful surface grinding, cylindrical grinding, centerless grinding, and internal grinding. These techniques ensure both efficiency and quality in your manufacturing process.

Achieving Optimal Grinding Performance

Achieving the best results in your grinding work is a balancing act. Speed, feed, and depth of cut are interdependent. Changing one parameter forces you to adjust the others to maintain control over the process. For example, increasing the depth of cut to remove material faster might require you to reduce the feed rate to avoid excessive tool pressure. Understanding this relationship is the key to moving from basic operation to true optimization. By mastering these trade-offs, you can tailor your grinding techniques for any goal, whether it’s boosting performance for high-volume manufacturing or achieving delicate precision.

Key Metrics: MRR and G-Ratio

To optimize your grinding work, you need to measure your success. Two critical metrics are the Material Removal Rate (MRR) and the G-Ratio.

Material Removal Rate (MRR): This metric tells you how quickly you are removing material from the workpiece. You can calculate it with a simple formula:

MRR = Depth of Cut x Width of Cut x Feed Rate. A higher MRR means greater productivity, which is crucial in manufacturing environments. For more complex jobs like cylindrical grinding, the calculation is more involved but follows the same principle of measuring the volume of material removed over time.G-Ratio: This metric measures grinding efficiency by comparing the volume of material removed from the workpiece to the volume of wheel wear. A higher G-Ratio means your wheel is more durable and cost-effective. For instance, conventional abrasives might have a G-Ratio of 30–40, while advanced superabrasives like CBN can reach G-Ratios as high as 2441 on hardened steel. A high G-Ratio directly translates to lower tooling costs per part, as the wheel lasts longer and requires fewer changes.

Scenario 1: Roughing for Maximum Material Removal

When your primary goal is to remove a large amount of material quickly, you need to configure your parameters for maximum MRR. This process, known as roughing, prioritizes speed over surface finish.

To achieve a high material removal rate, you will generally increase both the depth of cut and the feed rate. For example, when grinding tough materials like AISI 316L stainless steel, you can use aggressive settings to maximize output.

| Parameter | Setting for Maximum MRR |

|---|---|

| Cutting Speed | 150 m/min |

| Feed Velocity | 250 mm/min |

| Depth of Cut | 2 mm |

Note: While these aggressive parameters boost productivity, they also create significant heat and stress. This can lead to premature wheel wear if not managed correctly. You must ensure adequate coolant flow to prevent thermal damage to both the wheel and the workpiece. The trade-off is clear: you gain speed but risk higher tool consumption and a rougher surface.

Scenario 2: Finishing for a Superior Surface

When the final surface quality is your top priority, your approach changes completely. For finishing passes, you will reduce the depth of cut and feed rate while often maintaining or increasing the wheel speed. This creates smaller chips, reduces cutting forces, and results in a smoother, more precise surface. These optimal grinding techniques are essential for applications demanding tight tolerances and a flawless appearance.

Achieving a mirror-like surface on hard materials like ceramics or composites often requires specialized tools. This is where high-quality Aimgrind diamond grinding wheels excel. Engineered for precision, these wheels can produce an exceptionally smooth surface, with some specialized wheels achieving a finish of 0.2 µm Ra. For the absolute finest finishes, such as those in optical components, grinding is the critical first step before final lapping and polishing. This level of precision is vital in advanced manufacturing and tooling.

Scenario 3: Balancing for Extended Wheel Life

In many real-world scenarios, especially in high-volume production, the goal is not just speed or finish but overall cost-effectiveness. This means finding a balance that extends the life of your grinding wheel, reducing downtime and tooling costs. Optimizing for wheel life involves a careful trade-off between cycle time and tool wear.

A company that analyzed its data over four years found that optimizing its tooling process reduced tooling costs by 59% and scrap by 58%, leading to annual savings of around $750,000. This shows the immense value of a balanced approach.

Here are some techniques to find that sweet spot:

- Use Moderate Parameters: Avoid pushing the depth of cut and feed rate to their absolute limits. A slightly more conservative approach can dramatically increase wheel life with only a minor impact on cycle time.

- Select the Right Abrasive: Using ceramic or superabrasive wheels can improve durability and form retention, allowing for higher efficiency without rapid wear.

- Focus on Stability: Ensure your machine is rigid and your coolant system is effective. Proper lubrication reduces friction and heat, which are primary causes of wheel degradation during surface grinding, cylindrical, and internal grinding operations.

Ultimately, the best balance depends on your shop’s specific needs. For long production runs, minimizing cost per part is key. For job shops, maximizing uptime and flexibility might be more important than saving a few cents on a single tool.

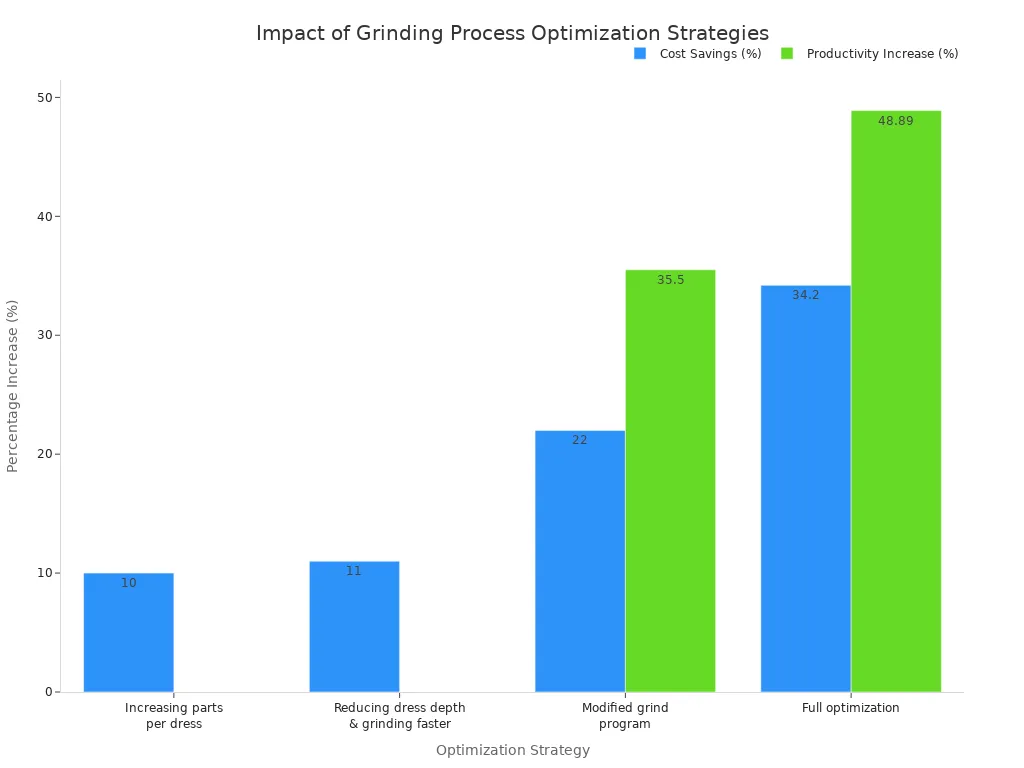

Your Guide to Grinding Process Optimization

You can achieve consistent, high-quality results with a structured approach to grinding process optimization. This process is about making smart, informed adjustments rather than guessing. These techniques will improve your grinding work and boost efficiency.

A Step-by-Step Optimization Method

Follow these steps to systematically improve your grinding operations. This method helps you isolate variables and understand their impact on your manufacturing process.

- Establish a Baseline: Start with the recommended parameters for your wheel and material. Run a test part and document the results, including cycle time, surface finish, and any visible issues.

- Identify Your Goal: Decide what you want to improve. Are you aiming for a faster cycle time, a better surface, or longer wheel life?

- Adjust One Variable: Change only one parameter at a time (speed, feed, or depth). Make a small, controlled adjustment.

- Measure the Outcome: Run another test part and compare the new results to your baseline.

- Document and Repeat: Record your findings. Continue adjusting one variable at a time until you achieve your desired outcome.

Tip: This optimization process delivers the best results when you start with the correct tool. The selection of the appropriate grinding wheel for your material and machine is the most critical first step. This is a core service offered by experts like Aimgrind, ensuring your grinding work is built on a solid foundation for peak performance and safety.

The Critical Role of Coolant

Coolant does more than just cool the part; it is vital for precision and efficiency. It flushes away chips, reduces friction, and prevents thermal damage. Insufficient coolant flow can cause burn marks and a rougher surface. Using high-pressure delivery (5–10 bar) helps the fluid penetrate the grinding zone, which can improve the surface finish by 15-25%. The type of coolant also matters.

| Coolant Type | Key Characteristics | Best For Grinding… |

|---|---|---|

| Synthetics | Very low oil, excellent cooling. | Steel, Cast Iron, and Stainless Steel where cooling is the top priority. |

| Semi-synthetics | Balanced cooling and lubrication. | General grinding, including Steel and occasional nonferrous metals. |

The Impact of Machine Rigidity

The stability of your grinding machine directly affects your results. A machine with low rigidity can vibrate during the grinding process. This vibration, known as chatter, creates a repeating pattern of small waves on the workpiece surface, ruining your precision. Poor rigidity is one of the key factors that influence grinding outcomes in surface grinding, cylindrical, and internal grinding. Maintaining machine stability is essential for safety and quality.

Troubleshooting Common Grinding Issues

Even with careful setup, you may encounter problems. Here are two common issues in grinding work and how to address them:

- Wheel Glazing: The abrasive grains on your wheel become dull, causing it to rub instead of cut. This generates excess heat and can burn the workpiece. To fix this, dress the wheel to expose fresh, sharp abrasives or increase your feed rate to encourage wheel breakdown.

- Wheel Loading: Chips from the workpiece get clogged in the wheel’s pores. This reduces cutting efficiency and can cause scratches on the surface. This often happens with soft materials. Correct it by using a coarser grit wheel, improving coolant flow, or dressing the wheel.

Addressing these issues promptly ensures your cylindrical grinding, centerless grinding, and internal grinding operations run smoothly, maintaining both safety and part quality in your manufacturing environment. Optimizing speed is just one part of the complex puzzle of precision grinding.

Your grinding optimization is a systematic process, not guesswork. Your grinding work requires balancing material removal against your desired surface and wheel life. This grinding process improves precision and efficiency in manufacturing. For better performance, start with a baseline for your grinding. Adjust one variable at a time to improve your grinding work for a better surface. This improves precision in manufacturing. For the best surface quality, partner with experts. Aimgrind provides customized grinding solutions for your wheel and grinding needs.

Final Advice: Always prioritize safety. Your safety, your team’s safety, and machine safety are paramount. Safety in grinding is non-negotiable. Safety, safety, safety, safety, safety, safety.

FAQ

What is the first step to optimize my grinding work?

You should first establish a baseline. Run a test part with standard settings. This gives you a starting point for your grinding work. Documenting this initial grinding work is key to measuring future improvements in your grinding work.

How do I know if my wheel speed is too high?

You might see burn marks on your part. The wheel may also make a high-pitched sound. These signs indicate excessive heat from the grinding process. This can damage your workpiece and affect your overall grinding work.

Can I improve my grinding work without buying a new wheel?

Yes. You can often improve your results by adjusting your parameters. Change one variable at a time, like feed rate or depth of cut. This systematic approach to grinding helps you find the best settings for your current setup.

Why is my surface finish poor after grinding?

A poor finish often results from incorrect parameters. Your feed rate might be too high, or your wheel could be glazed. Proper grinding requires balancing speed, feed, and depth. Adjusting these can significantly improve your final surface quality.

Contact Us

For More Grinding Solution or Customized Abrasive Tools