Grinding wheel grit size shows how rough or smooth the tiny pieces are on a grinding wheel. You can see this number printed on grinding wheels. It helps you pick the right wheel for your work. A coarse grit size takes off material fast but makes the surface rough. A finer grit size makes the surface smoother and helps lower roughness and stress. Picking the right grinding wheel grit size gives you more control over how much material you remove and how the surface looks. This guide gives you easy steps to find grit size and choose the best grinding wheel for your job.

Key Takeaways

Grit size tells you how big the abrasive pieces are. It changes how fast you can remove material. It also changes how smooth the surface will be.

Coarse grits take away material fast. They make the surface rough. Fine grits make the surface smooth. Fine grits are good for polishing and careful work.

You can see grit size on the wheel label or code. This helps you choose the right wheel for your job.

There are different grit size standards. Some are ANSI, FEPA, and JIS. Always check which standard your wheel uses. This helps you get the finish you want.

Pick the grit size that matches your material hardness. Also match it to your grinding method and the finish you want. This helps you work well and avoid errors.

Grinding Wheel Grit Basics

What Is Grit Size

When you look at a grinding wheel, you see tiny particles stuck to its surface. These particles are called grit. The grit size tells you how big or small these particles are. If you choose a lower grit size, you get larger, rougher particles. These help you remove material quickly during grinding, but they leave a rough finish. If you pick a higher grit size, you get smaller, finer particles. These make the surface smoother and give you a polished look.

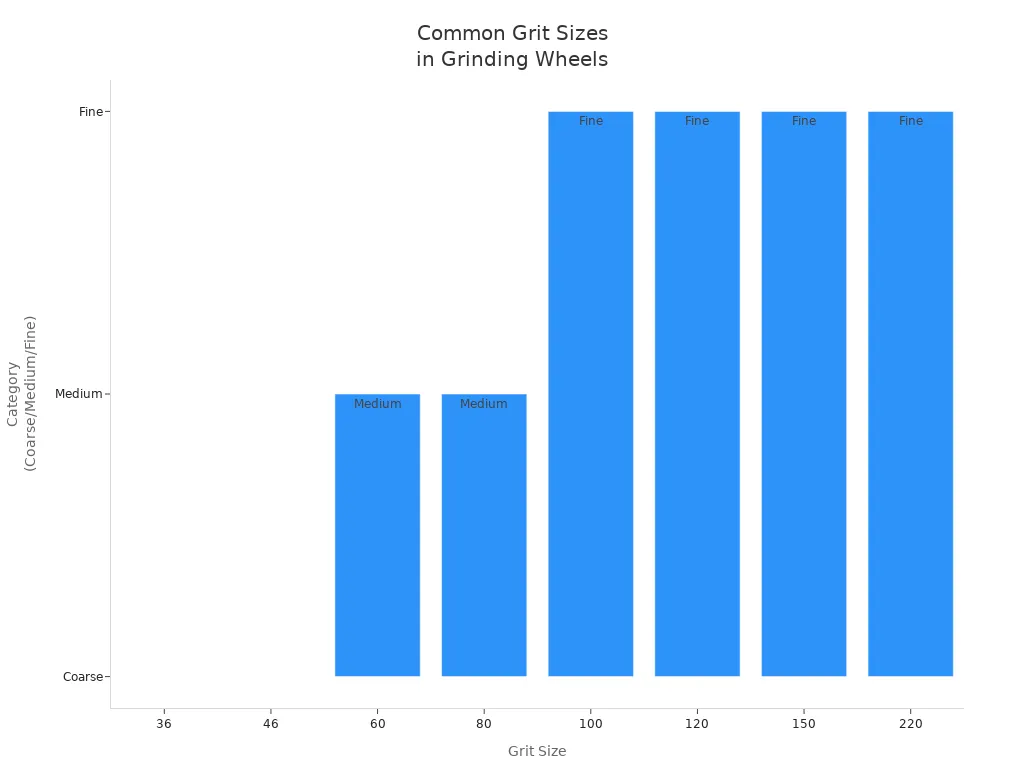

Grit size is important because it affects how your grinding wheel works. You need to match the grit size to your job. For example, coarse grit sizes like 36 or 46 work best when you want to grind away a lot of material fast. Medium grit sizes such as 60 or 80 are good for general grinding tasks. Fine grit sizes like 100, 120, 150, or 220 help you get a smooth or mirror-like finish. The table below shows common grit sizes and their uses:

Grit Range | Typical Use |

|---|---|

36, 46 | Coarse grinding, rapid material removal |

60, 80 | Medium grinding, general purpose |

100, 120, 150, 220 | Fine to mirror finish grinding |

How Grit Size Is Measured

You can measure grit size in several ways. Manufacturers often print the grit size right on the grinding wheel label. You can check this label to find out if the wheel is coarse or fine. Sometimes, you can use a grit gauge, which is a special tool that helps you match the gaps between particles to a grit number.

If you want to be more precise, you can use digital microscopes to look at the abrasive grains closely. Some experts use contact methods like stylus profilometers or coordinate measuring machines to get a 3D view of the wheel’s surface. Non-contact methods, such as scanning electron microscopy or laser techniques, also help measure grit size without touching the wheel.

You can also estimate grit size by looking at the wheel. Coarse grit wheels have bigger, more spaced-out particles. Fine grit wheels look smoother and have tightly packed grains. Always check the manufacturer’s chart or standards like ANSI B74.1 to confirm the grit size before you start grinding.

Grit Categories

Coarse, Medium, Fine

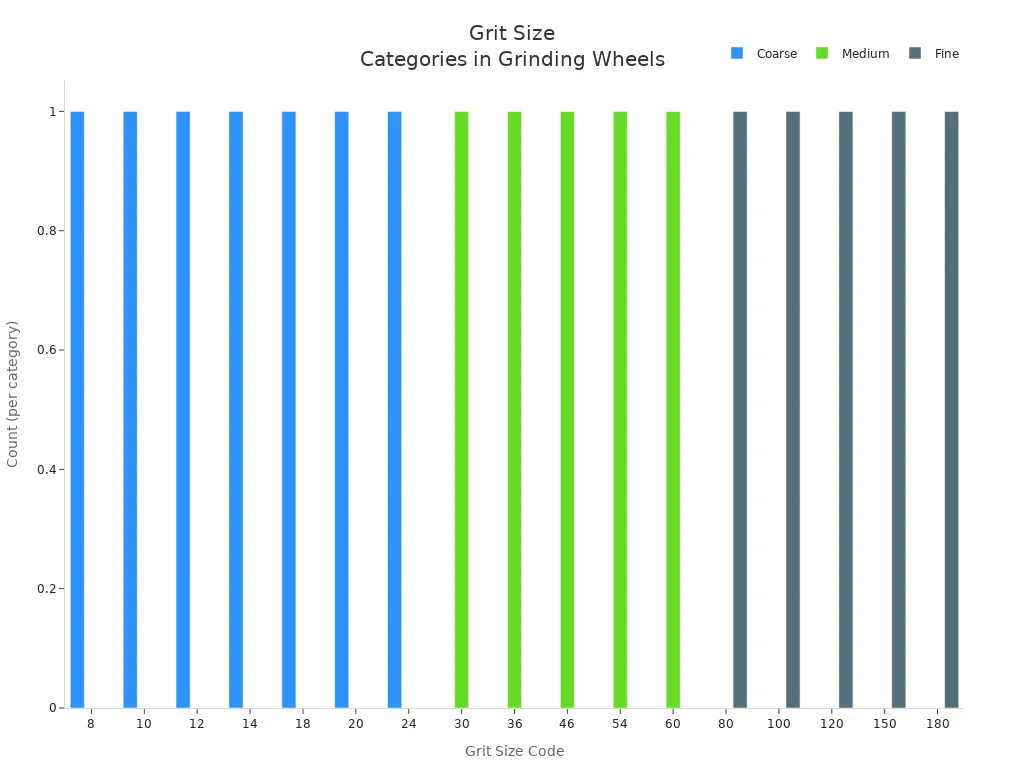

Grit sizes fit into four groups: coarse, medium, fine, and very fine. Each group is good for a different job. The table below shows grit numbers and what they are used for:

Grit Size Category | Grit Number Range | |

|---|---|---|

Coarse | 8 – 24 | Removes lots of material fast when finish is not important |

Medium | 30 – 60 | Good for both removing material and getting a better finish |

Fine | 70 – 220 | Makes surfaces smooth and helps with careful work |

Very Fine | 240+ | Used for polishing and making things shine |

Coarse grits take off a lot of material quickly. They have big particles and are good for shaping or cleaning metal. Medium grits help you remove material but also give a nicer finish. Fine grits make the surface smooth and help you meet strict rules for how it should look. Very fine grits are best for polishing and making the surface shiny.

Coarse abrasives have low grit numbers, usually from 10 to 70. You use them for tough jobs like taking off rust. Medium abrasives are in the middle and help you go from rough to smoother grinding. Fine abrasives have high grit numbers, from 70 up to 1000 or more. These are best for polishing and getting a really nice finish.

Grit and Surface Finish

The grit you pick changes how the surface looks. Coarse grits have big pieces and leave the surface rough. You use them when you do not care about the finish but need to remove a lot of material. Medium grits help you get both a good finish and remove material. Fine grits have small pieces and make the surface smooth. Finer grits have more cutting points, so they lower roughness and give a better finish.

The table below shows how grit size changes the surface and other things:

Aspect | Relationship/Effect |

|---|---|

Grit Size | Smaller grit makes smoother surfaces (lower Ra, RMS). |

Surface Roughness | Ra and RMS measure roughness; lower numbers mean smoother finish. |

Coarse Grits | Big particles, remove material fast, make rough surfaces. |

Medium Grits | Good balance between removing material and finish. |

Fine Grits | Small particles, make smooth, high-quality surfaces. |

Cutting-Point Density | Smaller grit means more cutting points, thinner chips, and better finish. |

Other things, like the bond type and using coolant, also change the final finish. Finer grits help you get the best finish and meet tight rules.

Grit Size Standards

Mesh and FEPA Ratings

There are different ways to measure grit size on grinding wheels. The two most common are mesh and FEPA ratings. Mesh size shows how many holes are in a sieve for every inch. If the mesh number is higher, the abrasive particles are smaller. FEPA stands for Federation of European Producers of Abrasives. FEPA uses a “P” before the number. This system also tells you about the number of mesh holes per inch. Both mesh and FEPA help you know the real size of the abrasive grains.

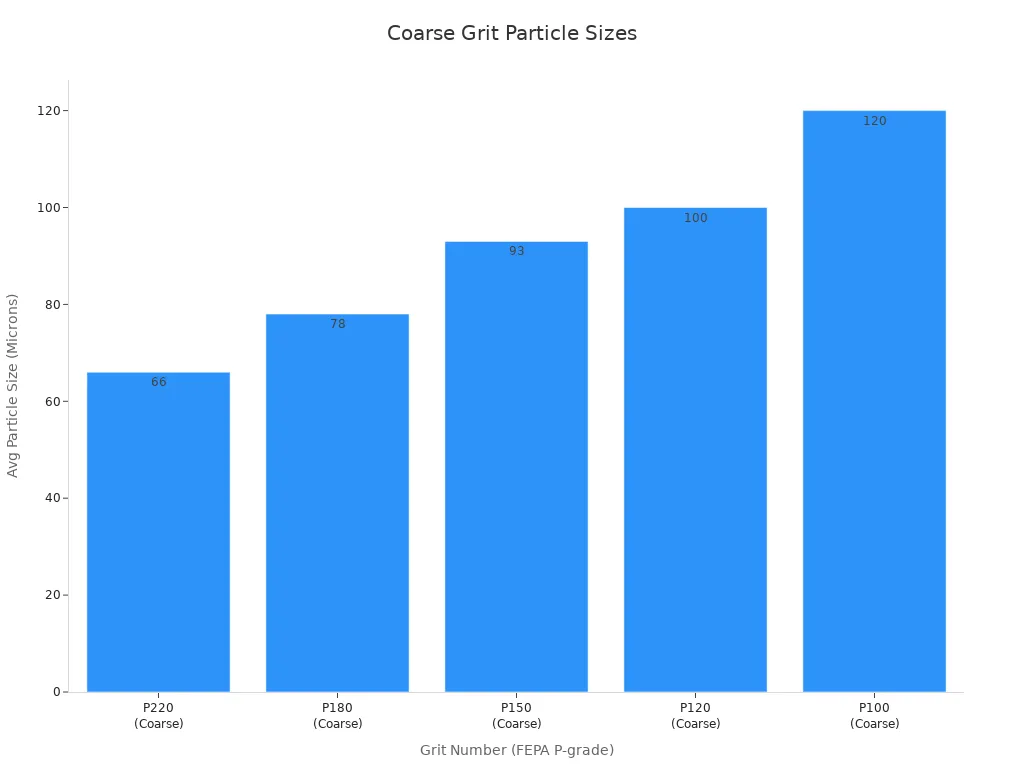

Here is a table that compares mesh and FEPA ratings with particle sizes:

FEPA Grit (P) | Mesh Size | Average Particle Size (Microns) |

|---|---|---|

60 | 265 | |

P120 | 120 | 125 |

P400 | 400 | 35 |

P1200 | 1200 | 15 |

Tip: Always look at the grit size rating before picking a grinding wheel. This helps you choose the right abrasive for your job and get the finish you want.

Comparing Standards

There are several grit size standards used in different countries. The main ones are:

ANSI (American National Standards Institute) in the United States

FEPA (Federation of European Producers of Abrasives) in Europe

JIS (Japanese Industrial Standards) in Japan

Micron graded standards

Each standard has its own way to define grit size. ANSI counts the number of lines in a sieve for each inch. FEPA and JIS use micron ranges or exact values. This means the same grit number can have different particle sizes in each standard.

Standard | Origin | Measurement Method | Grit Size Definition | Particle Size Representation |

|---|---|---|---|---|

FEPA | Europe | Sieve mesh and micron ranges | “P” or “F” numbers | Micron range with tolerances |

JIS | Japan | Own grit scale | J numbers | Specific micron values |

ANSI | USA | ANSI B74.12, sieve mesh | Mesh numbers | Sieve and micron values |

You should always check which standard your grinding wheel uses. This helps you pick the right abrasive grain and get the finish you need for your project.

Grinding Wheel Markings

Reading Grit Size Codes

When you look at a grinding wheel, you see a code printed on the label. This code tells you important details about the wheel. You can use this code to find out the grit size, abrasive type, bond type, and other features. Understanding these codes helps you pick the right grinding wheel for your job.

A typical grinding wheel code looks like this: A36-L5-V23. Each part of the code has a meaning:

Code Element | Meaning | Example/Explanation |

|---|---|---|

Letter | Abrasive type | ‘A’ = Aluminum oxide |

Number | Grain size | ’36’ = Grain size number indicating abrasive size |

Letter | Grade or hardness | ‘L’ = Medium hardness grade |

Number | Structure (spacing of grains) | ‘5’ = Structure rating indicating grain spacing |

Letter | Bond type | ‘V’ = Type of bond holding the abrasive grains |

If you see a code like C60, the ‘C’ stands for silicon carbide abrasive, and ’60’ is the grit size. For aluminum oxide grinding wheels, ‘A’ means aluminum oxide, and the number tells you the grit size. You can use this information to choose between coarse, medium, or fine grit.

Here is a table that shows common grit size categories and their numbers:

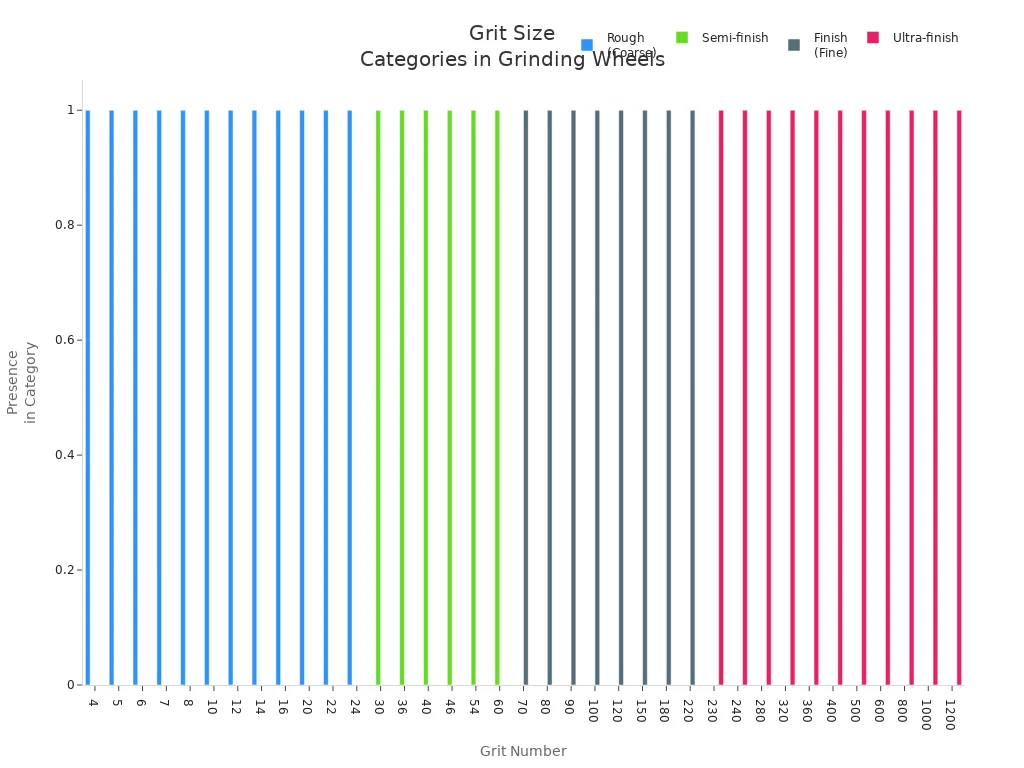

Category | Grit Numbers (Examples) |

|---|---|

Rough (Coarse) | 4, 5, 6, 7, 8, 10, 12, 14, 16, 20, 22, 24 |

Semi-finish | 30, 36, 40, 46, 54, 60 |

Finish (Fine) | 70, 80, 90, 100, 120, 150, 180, 220 |

Ultra-finish | 230, 240, 280, 320, 360, 400, 500, 600, 800, 1000, 1200 |

Smaller grit numbers mean the wheel is coarse and removes material quickly. Larger grit numbers mean the wheel is fine and gives a smoother finish. You can use this chart to match the grit size to your grinding task.

You will also see codes for diamond wheels and cbn wheels. For example, ‘D120‘ means a diamond grinding wheel with a grit size of 120. ‘B80’ means a cbn wheel with a grit size of 80. These codes help you select the right wheel for hard materials.

Tip: Always check the grit size number in the code. This number tells you how rough or smooth the grinding wheel will be.

Decoding Wheel Labels

You can find the grit size on the grinding wheel label. The label usually shows the abrasive type first, then the grit size number. For diamond wheels, you see a ‘D’ followed by the grit size, like ‘D120’. For cbn wheels, you see a ‘B’ followed by the grit size, such as ‘B80’. For aluminum oxide grinding wheels, you see an ‘A’ and a number, like ‘A36’.

The grit size is printed after the shape and size details. You can look for the section on the label that lists the abrasive and grit. For example, a label might read:

A36-L5-V23

‘A’ stands for aluminum oxide.

’36’ is the grit size.

‘L5’ shows the hardness and structure.

‘V23’ is the bond type.

If you use diamond grinding wheels, you might see:

D120-V

‘D’ stands for diamond.

‘120’ is the grit size.

‘V’ is the bond type.

For cbn wheels, the label could be:

B80-V

‘B’ stands for cbn.

’80’ is the grit size.

‘V’ is the bond type.

You can use these codes to compare wheels and pick the best one for your job. The grit size helps you know if the wheel will remove material quickly or give a smooth finish. You can use the chart below to see how grit size affects grinding wheels:

You should always check the label before you start grinding. The grit size number is a key part of the wheel specification. It helps you understand the abrasive particle size and the expected grinding performance.

Note: The grit size on the label guides you in choosing the right grinding wheel, diamond wheels, or cbn wheels for your application. You can use this information to get the finish you want and work more efficiently.

Choosing Grit Size

Material Type

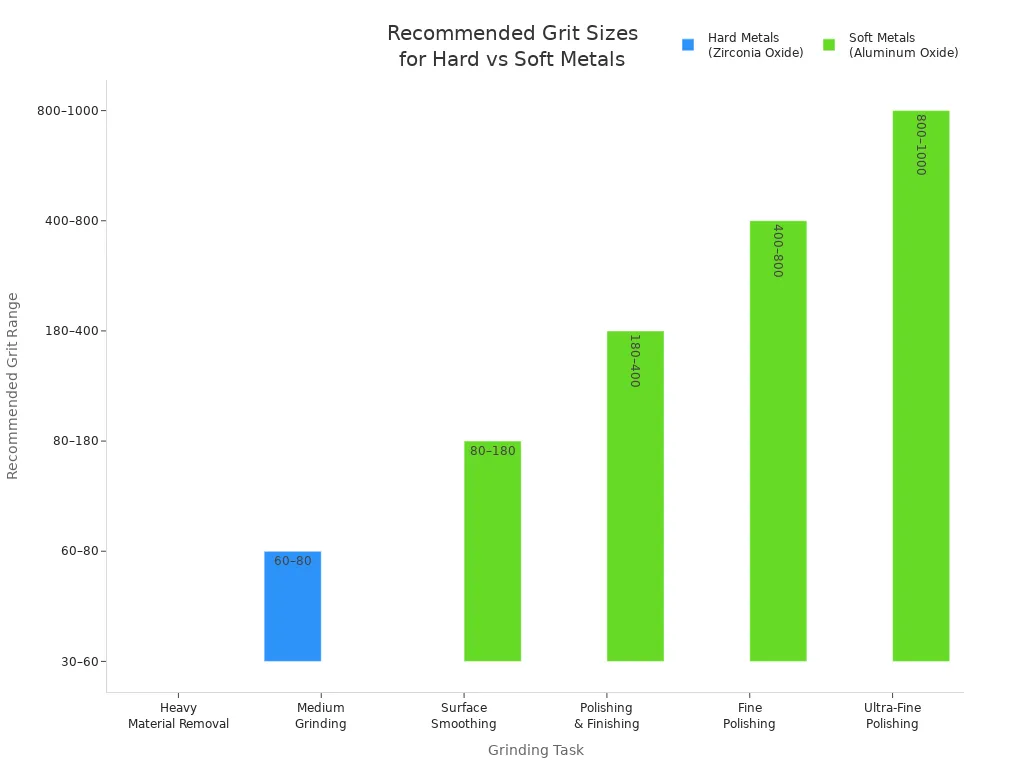

You need to pick the right grit for your material. Hard metals like hardened steel or cast iron need a different grit than soft metals. For hard metals, use coarser grits and strong abrasives like zirconia oxide or cbn. These wheels take off material fast and work well with hard surfaces. For soft metals like aluminum or brass, finer grits and softer abrasives such as aluminum oxide are better. They help you avoid scratching the surface and make it smoother.

If you work with non-ferrous materials like carbide, glass, or ceramics, diamond abrasives are best. For ferrous materials, cbn abrasives work better. The bond type matters too. Metal bonds go with blockier diamond or cbn. Resin bonds use sharper, breakable powders. If you need high accuracy, like in tool making, pick a finer grit. This helps you keep shapes exact and meet tight rules.

Here is a chart to help you choose grit for different jobs:

Task | Recommended Grit Range | Abrasive Material | Application Notes |

|---|---|---|---|

Heavy Material Removal | 30 – 60 | Zirconia Oxide, cbn | Best for hard metals like hardened steel; aggressive stock removal. |

Medium Grinding | 60 – 80 | Zirconia Oxide, cbn | Used for leveling and blending on hard metals. |

Surface Smoothing | 80 – 180 | Aluminum Oxide | Good for soft metals; prepares for finishing. |

Polishing & Finishing | 180 – 400 | Aluminum Oxide | For soft metals to achieve smooth, mirror-like finishes. |

Fine Polishing | 400 – 800 | Aluminum Oxide | For very smooth finishes on soft metals. |

Ultra-Fine Polishing | 800 – 1000 | Aluminum Oxide | For ultra-fine polishing, especially on soft metals. |

Tip: Harder materials often need finer grits to cut well and stay in control. Softer materials can use coarser grits to work faster.

Grinding Method

The way you grind also changes which grit you need. If you use surface grinding for big, flat areas, a medium grit gives both speed and a nice finish. For cylindrical grinding, which shapes round parts, you often need a finer grit to keep the shape right. Centerless grinding holds parts between wheels and usually needs superabrasive wheels like cbn or diamond. These wheels stay sharp longer and help you get exact sizes.

If you want to take off a lot of material fast, pick a coarse grit. This is good for rough grinding or when the finish does not matter much. For careful grinding, like sharpening tools or making exact parts, use a finer grit. This gives you more control and a smoother finish. The bond and abrasive type matter too. For example, cbn wheels with fine grit are common for grinding hard steels with high accuracy.

Desired Finish

You need to think about how you want the surface to look. If you want a rough finish, use a coarse grit. This takes off material quickly but leaves the surface rough. For a smooth or shiny finish, use a finer grit. Finer grits have more cutting points and make the surface smoother. For fine grinding, use a grit size of 150 or higher.

To get a mirror finish on steel, start with 120 grit. Then move up to 240, 400, 600, and even 1200 or 2000 grit. After sanding, use a buffing wheel and polishing compound to make it shine. Always sand at a 90° angle to the last step to stop scratches.

Here is a chart for common grinding jobs and the best grit sizes:

Grinding Application | Recommended Grit Size Range | Description |

|---|---|---|

Rough Grinding | 24 to 36 | Heavy material removal and shaping. Coarse grit removes material quickly. |

Intermediate Grinding | 46 to 60 | Balances material removal and surface finish. |

Fine Grinding | 80 to 120 | Precise material removal and smooth finishes, such as tool sharpening or finishing precision parts. |

Super Fine Grinding | 150 to 600 | Finest finishes like polishing or preparing surfaces for final coating. Produces smooth, polished surfaces. |

Note: Your grit choice depends on how smooth you want the surface. If you want a high-quality finish, always use a finer grit and do not rush.

Steps for Achieving a Mirror Finish on Steel

Start sanding with 120 grit to remove marks and make the surface flat.

Move to 240, 400, 600, and 1200 grit for smoother sanding.

Use a buffing wheel with polishing compound to make it shine.

Change sanding direction by 90° with each grit to stop scratches.

Remember: Skipping grits or picking the wrong grit can give bad results. Always match your grit to the material, grinding method, and finish you want.

Tips for Grinding Wheels

Selection Advice

Choosing the right grinding wheel grit size makes your work easier and gives better results. You should always match the wheel to your material and the job you want to do. Here are some expert tips to help you select the best grit size:

For harder materials, pick a softer grinding wheel. This helps the wheel stay sharp and cut better.

If you need to remove a lot of material quickly, use a coarser grit wheel. Coarse grits work fast but leave a rougher finish.

To get a smooth or shiny surface, choose a finer grit wheel. Finer grits make the surface smoother and reduce scratches.

For grinding sharp corners or small details, select a harder and finer grit wheel. This gives you more control and a cleaner edge.

Tip: Always check the abrasive type. For example, aluminum oxide works well for steel, while silicon carbide is better for non-ferrous metals like aluminum or brass.

You can also use this table to match abrasive types and grit size tips:

Abrasive Type | Best Use | Grit Size Tip |

|---|---|---|

Aluminum Oxide | General grinding, ferrous metals | Use various grits, replace often |

Silicon Carbide | Non-ferrous, non-metals | Use finer grits for smooth finishing |

Zirconium Alumina | Metal, hardwoods | Match grit to material hardness |

Ceramic | Heavy metal removal | Coarse for removal, fine for finishing |

Common Mistakes

Many people make simple mistakes when choosing grinding wheel grit size. You can avoid these problems by following a few easy rules:

Do not pick a grit size just because it is available. Always match it to your material and the finish you want.

Using a grit that is too coarse for a fine finish can leave scratches and cause too much heat.

Skipping grit steps can lead to gouges or uneven surfaces. Move up in grit sizes step by step.

Using the wrong abrasive type for your material can cause the wheel to wear out fast or even fail.

Not checking the grinding machine speed or feed rate can damage the wheel and the workpiece.

Note: If you are not sure, ask an expert or check the manufacturer’s chart. This helps you get the best results and keeps your grinding safe.

You can find the right grinding wheel grit size by doing these things: First, look at the wheel’s code to see the grit size and abrasive type. Next, pick a grit size that fits your material and how you will grind it. Think about if you want the surface to be rough or smooth. Check a quick chart to help you choose. Always follow what the manufacturer says for the best results.

Picking the correct grit size helps your tool last longer and gives you the finish you want. Use coarse grit if you need to remove material quickly. Medium grit is good if you want both speed and a nicer finish. Fine grit is best for making the surface very smooth. Always use the chart and follow the guidelines to get the best finish.

Grit Size Range | Application | Expected Surface Finish |

|---|---|---|

Rapid removal | Rough surface | |

30-60 | Intermediate | Moderate finish |

Fine grinding | Smooth surface finish | |

200+ | Polishing | Ultra-smooth finish |

Tip: If you match the grit size to your material and grinding method, you will have more control and get the finish you want.

FAQ

What does the grit number mean on a grinding wheel?

The grit number shows the size of the abrasive particles. A lower number means bigger, rougher grains. A higher number means smaller, finer grains. You can use this number to pick the right wheel for your job.

How do you find the grit size on a grinding wheel?

You can look at the label or code printed on the wheel. The number after the abrasive type, like “A36” or “C60”, tells you the grit size. Always check this before you start grinding.

Can you use the same grit size for all materials?

You should not use the same grit size for every material. Hard metals need finer grits for control. Soft metals work better with coarser grits for faster grinding. Always match the grit to your material.

What happens if you pick the wrong grit size?

If you choose a grit that is too coarse, you may scratch the surface. If you pick one that is too fine, you may not remove enough material. You should always match the grit size to your task.

Do grit size standards differ in other countries?

Yes, grit size standards can change by country. You may see ANSI, FEPA, or JIS ratings. Always check which standard your wheel uses so you get the right finish.

See Also

Finding The Most Effective Grinding Wheel Dresser For You

Different Grinding Wheel Varieties And Their Common Uses

Choosing The Best Grinding Wheel For Stainless Steel Work

Contact Us

For More Grinding Solution or Customized Abrasive Tools