Precision grinding presents a fundamental challenge. Manufacturers must balance wheel wear resistance against profile integrity. This balance ensures part quality and cost-effective grinding operations. A systematic approach to grinding wheel selection provides the solution. An informed decision rests on four key pillars for optimal performance.

Key Selection Criteria:

- Abrasive Type

- Grain Size

- Grade (Hardness)

- Bond Type

Key Takeaways

- Choose the right abrasive type for your workpiece material. Diamond wheels work best for very hard materials like tungsten carbide.

- Balance grain size and wheel hardness. Coarser grains remove material fast, while finer grains create a smooth finish.

- Select the correct bond type. Vitrified bonds hold shape well, and resin bonds absorb shock.

- Match wheel specifications to your material. Soft steels need different wheels than hard steels.

- Test and document everything. This helps you find the best grinding wheel for your specific job.

Core Factors in Grinding Wheel Selection

A successful grinding wheel selection process begins with understanding its four core components. Each factor plays a distinct role in the wheel’s overall performance. Aligning them with your application is the key to balancing wear resistance and profile integrity.

Abrasive Type: The Foundation of Performance

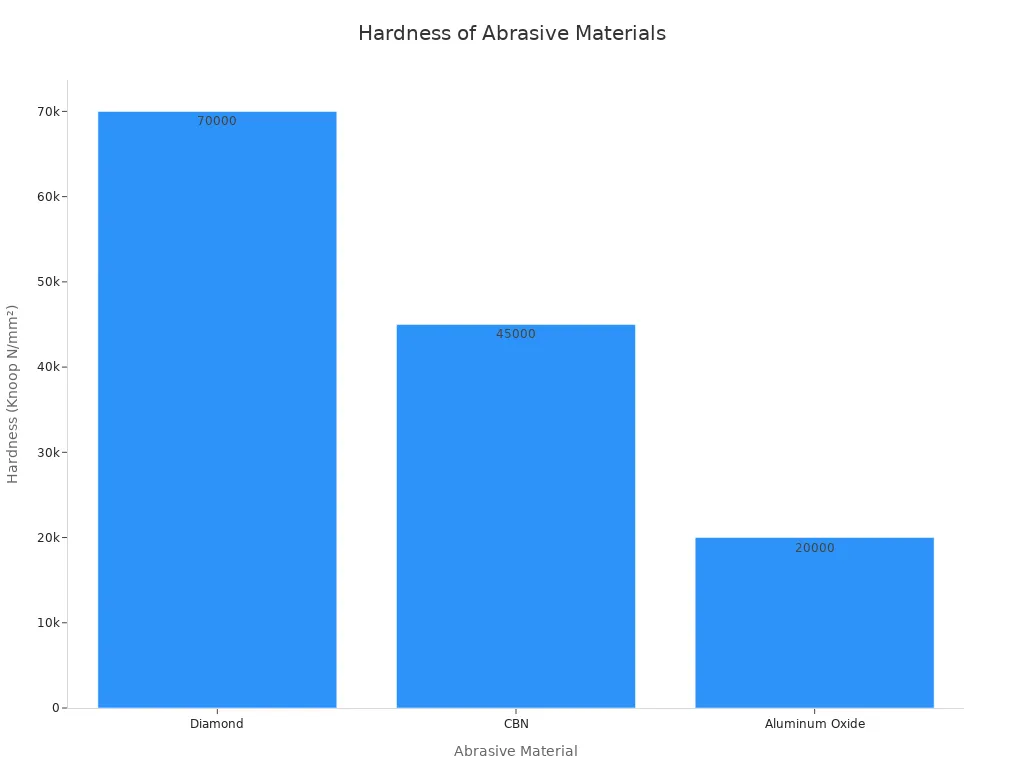

The abrasive material does the actual cutting. Your choice depends entirely on the workpiece material’s properties.

- Conventional Abrasives: Aluminum Oxide is a versatile choice for grinding ferrous metals like steel. Silicon Carbide is harder and sharper, making it suitable for non-ferrous metals and non-metallic materials like glass and plastic.

- Superabrasives: For grinding hardened steels (>45 HRC), Cubic Boron Nitride (CBN) is the superior option. A cbn wheel offers excellent thermal stability and does not react with ferrous materials. Diamond is the hardest material available. It is the best grinding wheel for non-ferrous metals, ceramics, and composites.

Expert Tip from Aimgrind

For the most demanding applications on hard alloys and ceramics, specialists like Aimgrind provide advanced superabrasive grinding wheels. Our custom-engineered diamond wheel solutions deliver superior longevity and precision. This directly contributes to holding tight form tolerance and reducing overall wear.

Grain Size and Grade: A Delicate Balance

Grain size (grit) and grade (hardness) work together to control the material removal rate and final surface finish.

- Grain Size: Coarser grains (lower grit numbers) remove material quickly. Finer grains (higher grit numbers) produce a smoother surface finish, which is critical for achieving a tight form tolerance.

- Grade: The grade indicates the bond’s strength in holding abrasive grains. Harder materials often require a softer grade wheel that breaks down to expose new, sharp grains. Softer, ductile materials may need a harder grade to prevent premature wheel loading.

Bond Type: Holding It All Together

The bond acts as the structural support, holding the abrasive grains in place. The bond type influences the wheel’s strength, flexibility, and heat resistance during the grinding process. Common bonds include vitrified, resin, and metal. Each offers unique properties for specific grinding operations, affecting everything from coolant absorption to the wheel’s ability to maintain its shape under pressure. This choice is vital for consistent precision.

Abrasive Choice and Its Impact on Profile Integrity

The abrasive material is the heart of the grinding wheel. Its properties directly influence form holding, wear rates, and final part quality. Choosing the right abrasive is the first step toward achieving profile integrity.

Conventional Abrasives: Aluminum Oxide & Silicon Carbide

Conventional abrasives are common but have limitations in high-precision form grinding. Aluminum oxide works well for general-purpose steel grinding. However, it is prone to several wear mechanisms under pressure. These include grain fracture, adhesive wear, and the wearing flat of grits. This breakdown can compromise the wheel’s profile during a long production run.

Silicon carbide is harder and sharper than aluminum oxide. It is often preferred for grinding materials with low tensile strength, like aluminum and cast iron. Its sharpness provides efficient cutting. However, this same quality can risk poor surface integrity on softer metals. A careful balance is needed to prevent deep scratches and damage during the grinding process.

Superabrasives: The Aimgrind Diamond Wheel Advantage

Superabrasives offer a significant leap in performance for demanding applications. For hard materials like tungsten carbide, ceramics, and composites, diamond is the ultimate abrasive. Its unmatched hardness ensures minimal wheel wear and exceptional profile retention. This makes superabrasive grinding wheels the ideal solution for complex forms and tight tolerances.

The benefits are clear when comparing grinding performance on a hard material like tungsten carbide. Aimgrind’s diamond wheels provide a dramatic improvement over conventional options.

| Metric | Conventional Wheel | Aimgrind Diamond Wheel | Advantage |

|---|---|---|---|

| Wheel Life | 8 – 16 hours | 800 – 1,200 hours | ~100x Longer Life |

| Cycle Time per Part | 90 seconds | 60 seconds | 33% Faster |

| Downtime for Changes | High (Frequent) | Very Low (Infrequent) | Increased Uptime |

This data shows how choosing the right abrasive transforms an entire grinding operation. It boosts productivity, reduces costs, and guarantees the profile integrity of every part.

Optimizing Bond, Grain, and Grade

Beyond the abrasive, the bond, grain, and grade dictate how a wheel behaves under pressure. Proper optimization of these elements is crucial for achieving your desired balance of performance and precision.

Vitrified vs. Resin Bonds for Form Holding

The bond holds the abrasive grains. Its properties directly impact the wheel’s ability to maintain its shape. Vitrified bonds are strong and rigid, making them excellent for holding a precise profile. Resin bonds are softer and more flexible, offering shock absorption.

| Bond Type | Key Characteristics for Profile Retention |

|---|---|

| Vitrified | Strong, rigid, porous, excellent form-holding |

| Resin | Softer, more elastic, shock-absorbing |

While vitrified bonds excel at maintaining a tight form tolerance, the elasticity of resin bonds is beneficial in certain grinding operations. Resin’s gentler action helps prevent chipping and thermal damage. It is often preferred for:

- Grinding brittle materials like tungsten carbide and ceramics.

- Operations on heat-sensitive steels.

- Finishing glass and quartz where surface integrity is critical.

Metal and Hybrid Bonds for Extreme Durability

For maximum durability and wheel life, metal bonds are the top choice. They securely lock superabrasive grains, leading to minimal wear. This makes them essential in high-volume industries like aerospace, automotive, and medical device manufacturing.

Hybrid bonds represent a significant advancement. They combine the free-cutting nature of resin with the durability of metal bonds. This fusion delivers ultra-fast cutting and exceptional corner retention. Hybrid wheels enable high stock removal while generating less heat, extending tool life and boosting the material removal rate.

Fine vs. Coarse Grain for Profile Accuracy

Grain size selection involves a direct trade-off.

- Coarse Grains (low grit numbers) remove material quickly but leave a rougher finish.

- Fine Grains (high grit numbers) create a smoother surface and are essential for achieving a precise form tolerance.

For intricate profiles, a finer grain is necessary to accurately shape the workpiece without compromising detail. The final choice depends on balancing the need for speed with the required level of precision.

A Practical Guide to Wheel Specification

Theory provides a foundation. Practical application is where success is forged. This guide translates knowledge into actionable steps for selecting the right wheel specification. It helps you match the wheel to your material and process parameters perfectly.

Matching Specs to Soft and Hardened Steels

Steel’s properties change dramatically with heat treatment. Your grinding wheel selection must adapt accordingly. Soft, unhardened steels are gummy and require a different approach than hard, brittle steels.

For softer materials, grains from 36 to 46 are common. A harder grade wheel is often needed to prevent the wheel from loading up with material.

Hardened tool steels (>45 HRC) demand a more sophisticated approach. The abrasive must be harder and more friable to ensure a cool cut and prevent thermal damage.

Common Grinding Defects & Causes

- Surface Burn: This thermal damage often indicates the wheel is too hard or its pores are clogged. A softer grade or a dressing cycle is the solution.

- Chatter Marks: These vibrations can result from an unbalanced or overly hard wheel. Rebalancing the wheel or choosing a softer grade can resolve the issue.

Consider grinding hardened D2 tool steel (60-62 HRC). A standard aluminum oxide wheel will experience rapid wear. This leads to frequent dressing and loss of the required form tolerance.

| Material | Recommended Abrasive | Grade | Bond |

|---|---|---|---|

| Soft Steel | Aluminum Oxide | Medium-Hard | Vitrified |

| Hardened D2 Steel | Seeded Gel (SG) or CBN | Soft-Medium | Vitrified |

Using advanced abrasives like seeded gel (SG) or CBN is critical for hardened steels. They provide a cooler cutting action. This allows for an increased material removal rate without burning the workpiece.

Finding the Best Grinding Wheel for Your Material

Finding the best grinding wheel for a new material involves a systematic process. It is not about guesswork. It is about methodical testing and documentation. An unsuitable wheel specification can cause pores to clog quickly. The grain sharpness can be lost in just a few passes.

Follow these steps to validate wheel performance:

- Initial Verification: Check the wheel’s dimensions, abrasive type, grit, and bond against the manufacturer’s specifications. Ensure it meets safety standards like ANSI or OSHA.

- Machine Compatibility: Assess your equipment. High-tech wheels may underperform on older, less rigid machines. A traditional wheel might be more effective in such cases.

- Trial Runs: Conduct performance tests on sample material. Monitor cutting efficiency, heat generation, and the quality of the surface finish.

- Document Everything: Record all parameters and results. Note the wheel speed, feed rate, depth of cut, and final part quality. This data is invaluable for optimization.

This structured approach helps you identify the best grinding wheel for your application. It moves you from trial-and-error to a data-driven decision process.

Specs for Carbide, Ceramics, and Composites

Grinding advanced materials pushes the limits of conventional abrasives. Materials like tungsten carbide, industrial ceramics, and carbon fiber composites require high-performance solutions. Here, superabrasive grinding wheels are not just an option; they are a necessity.

Tungsten Carbide Tungsten carbide is extremely hard and wear-resistant. Grinding it effectively requires a diamond wheel. The specification depends on the operation.

- Abrasive: Diamond is the only choice for grinding tungsten carbide.

- Grit Size:

- Coarse (60/80): For rapid stock removal on wear parts.

- Medium (120/150): A balance for general sharpening of tungsten carbide tools.

- Fine (320/400): For achieving a keen edge and high surface integrity on precision tungsten carbide wear parts.

- Bond Type:

- Resin: Good for fine finishes on heat-sensitive tungsten carbide.

- Metal: The most durable option for high-volume grinding of tungsten carbide wear parts.

- Vitrified: Excellent form-holding for precision components made of tungsten carbide.

- Electroplated: An aggressive, free-cutting bond for complex tungsten carbide profiles.

Ceramics and Composites Industrial ceramics (alumina, zirconia) and composites (CFRP) present unique challenges. Ceramics are exceptionally hard. Composites are prone to delamination.

Aimgrind Expert Solution 💡

For challenging materials like tungsten carbide, ceramics, and composites, a standard wheel rarely delivers optimal results. The risk of part rejection and low productivity is too high. Partnering with a solutions provider like Aimgrind allows you to design a custom formula. We ensure the wheel is perfectly matched to your material and process, maximizing performance and guaranteeing a precise form tolerance.

Specialized diamond wheels are essential for these materials. For CFRP, electroplated or vitrified bond diamond wheels used with coolant can prevent delamination and maintain a high-quality finish. For ceramics, a rigid machine paired with a diamond wheel is required to achieve the necessary precision and material removal rate.

Achieving the ideal balance between wear resistance and profile integrity is not about finding a single “magic” wheel. It is about a methodical grinding wheel selection process. Aligning the abrasive, grain, grade, and bond with your material is the key to success. This systematic approach minimizes wear and ensures precision.

Adopting this strategy helps you find the best grinding wheel for your needs. For unique challenges, partnering with an expert like Aimgrind can refine this process, leading to enhanced productivity and superior high-performance parts.

FAQ

What is the most critical factor when selecting a form grinding wheel?

The most critical factor is the workpiece material. The material dictates the best abrasive type, such as diamond for carbide. All other specifications—grain, grade, and bond—are then selected to support that primary choice and achieve your specific goals.

How do I prevent my wheel from losing its profile?

Profile retention depends on several factors. Use a wheel with a strong, rigid bond like vitrified or metal. Select the correct grade for your material. Regular and proper wheel dressing is also essential to maintain the wheel’s sharpness and shape.

When should I choose a diamond wheel over a conventional one? 💎

Choose a diamond wheel for grinding extremely hard, non-ferrous materials. This includes tungsten carbide, industrial ceramics, and composites. Diamond wheels provide superior wear resistance and profile integrity, making them essential for precision work on these challenging materials.

Can a grinding wheel be customized for a specific job?

Yes. Customization is key for optimal performance on difficult materials or unique applications. Partners like Aimgrind can design a custom formula. This process matches the abrasive, bond, and other specs perfectly to your machine and process for the best results.

Contact Us

For More Grinding Solution or Customized Abrasive Tools