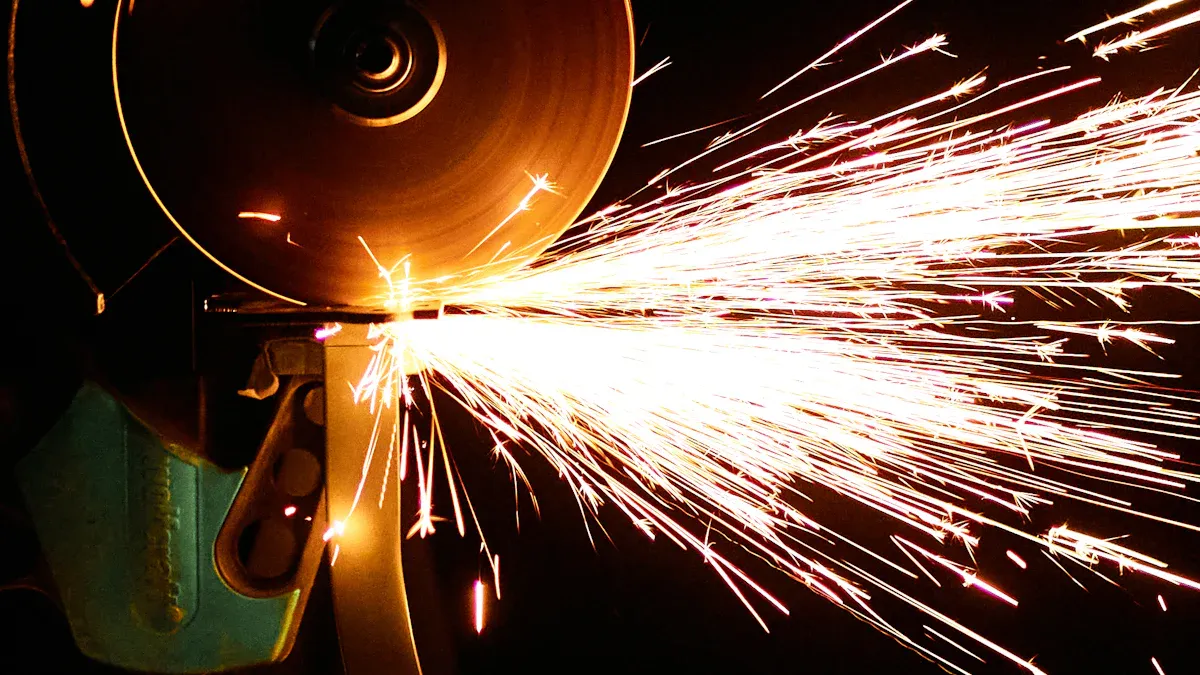

For professional grinding wheel operators, true mastery in grinding involves three key areas. You must understand your grinding wheels. You need to match the correct grinding wheels to your grinding task. You must execute every job with a focus on safety.

Did You Know?

The need for expert grinding is clear. Tools like angle grinders are linked to over 5,400 injuries each year, making them one of the most dangerous tools in the workplace.

This guide is the essential resource for any operator. You can enhance your skills, boost efficiency, and achieve superior results in all your grinding work.

Key Takeaways

- Understand your grinding wheels. Learn about abrasive grains, bond hardness, and grit size. This helps you choose the right wheel for each job.

- Always pick the correct grinding wheel. Match the wheel to your tool, size, and task. This ensures safety and good results.

- Follow safety rules. Always check your wheel for damage. Mount it correctly. Use guards. This keeps you and your coworkers safe.

- Improve your grinding process. Dress and true your wheels. Balance them. Adjust speeds and feeds. This makes your work better and faster.

Understanding Grinding Wheels

To master your craft, you must first understand your tools. Grinding wheels are more than just simple discs. They are complex tools engineered for specific grinding tasks. Knowing the components of grinding wheels helps you choose the right one and improve your grinding performance.

Abrasive Grains: The Cutting Element

The abrasive grains are the tiny cutting elements doing the work. Different types of grinding wheels use different abrasive materials. The choice of abrasive grain affects the wheel’s cutting ability and lifespan.

- Aluminum Oxide: This is a durable and tough abrasive. You can use it for grinding steel, iron, and other metals.

- Silicon Carbide: This abrasive is extremely hard and sharp. It is excellent for grinding non-metallic materials or metals with low tensile strength.

- Ceramic Alumina: These grains are self-sharpening. They are ideal for grinding hard-to-grind metals like stainless steel and titanium.

The right abrasive grain ensures efficient grinding and better results.

Bond Hardness and Wear Rate

The bond is the glue that holds the abrasive grains together in grinding wheels. The hardness of the bond, not the abrasive grit itself, determines how the wheel wears.

Operator’s Tip

A softer bond releases dull abrasive grains more easily. This exposes new, sharp grit, creating a self-sharpening effect ideal for hard materials. A harder bond holds the grit longer, which is better for softer materials and maintaining the wheel’s shape during grinding.

Understanding this helps you match the wheel’s wear rate to your grinding job for optimal performance.

Grit Size, Speed, and Finish

Grit size refers to the size of the individual abrasive particles. The grit number tells you how coarse or fine the abrasive is. This choice directly impacts your grinding results.

| Grit Type | Grit Number | Result |

|---|---|---|

| Coarse | Low (e.g., P24) | Fast material removal, rough finish |

| Fine | High (e.g., P240) | Slower material removal, smooth finish |

You should select the grit based on your goal. Use a coarse grit for heavy grinding and a fine grit for finishing. Adjusting grinding wheel speeds also plays a role. Proper speed combined with the right grit optimizes your grinding process. There are many types of grinding wheels, and understanding these grinding wheel materials and features is key to your success. These details make all the difference in your grinding wheels.

Selecting the Right Wheel for the Job

Choosing the correct grinding wheel is one of the most important decisions you will make. The right wheel ensures safety, efficiency, and a high-quality finish. The wrong wheel can lead to poor results, damaged workpieces, or even serious injury. This choice involves matching the wheel to your tool, size, and specific grinding task.

Expert Assistance is Key

The world of grinding wheels is vast. For complex grinding wheel applications, partnering with a specialist can make all the difference. Expert suppliers like Aimgrind specialize in customized grinding solutions. They can provide personalized selection and formula design to perfectly match your equipment and processes, ensuring optimal performance.

Matching Wheel Type to Your Tool

Your power tool dictates the type of grinding wheel you can safely use. Bench grinders and angle grinders are common tools, but they require different types of grinding wheels. Using the wrong type can be dangerous and ineffective.

| Grinder Type | Recommended Wheel Type | Key Feature / Application |

|---|---|---|

| Bench Grinder | Type 1 (T1) Straight Wheels | These are flat discs used for general-purpose grinding and sharpening on a fixed machine. |

| Angle Grinder | Type 27 (T27) Depressed-Center Wheels | The depressed hub allows you to use the wheel at an angle for grinding welds and shaping surfaces. |

Beyond the wheel’s shape, you must also consider its speed rating. The revolutions per minute (RPM) of your tool must never exceed the maximum RPM listed on the grinding wheel.

- Always check the RPM rating on the abrasive wheel’s label.

- Operating a wheel above its rated RPM can cause it to shatter, leading to catastrophic failure.

- Running a wheel too slowly results in poor grinding performance and premature wear on the abrasive.

- Matching the RPM to your material and task is essential for safe and efficient grinding.

Selecting the Right Size Grinding Wheel

Selecting the right size grinding wheel is a critical step for both safety and functionality. A wheel’s size includes its diameter and the arbor hole size. The arbor hole must fit your tool’s spindle perfectly. A loose fit can cause dangerous vibrations.

Using a wheel that is too large for your machine is a major safety hazard. It forces you to remove the safety guard, exposing you to potential wheel failure. An oversized wheel may also run at a surface speed higher than its rating, increasing the risk of it breaking apart during the grinding process. Conversely, a wheel that is too small will reduce your grinding efficiency and wear out quickly.

You must choose a wheel size that matches your machine. Here are some common sizes you might encounter:

| Type of Wheel | Arbor Hole Size | Outside Diameter (in) |

|---|---|---|

| Grinding Wheel | 7/8″ | 4.5″ |

| Grinding Wheel | 5/8-11″ | 4.5″ |

| Cut-Off Wheel | 20.0 mm | 14.0″ |

Making the correct choice when selecting the right size grinding wheel prevents damage to your machine and ensures a better finish on your workpiece.

Application-Specific Wheel Choice

The final step is choosing a wheel designed for your specific application. Different grinding jobs require different abrasive materials, grades, and densities. As professional grinding wheel operators, understanding these variables helps you achieve superior results.

Abrasive Material: The abrasive does the cutting. Your choice depends on the material you are grinding.

- Aluminum Oxide: A versatile and durable abrasive for grinding ferrous metals like carbon steel.

- Silicon Carbide: A very hard and sharp abrasive ideal for grinding nonferrous metals and materials like cast iron.

- Zirconia Alumina: A tough abrasive suited for heavy material removal on carbon and stainless steels.

- Ceramic Alumina: A premium, self-sharpening abrasive that excels at precision grinding of hard alloys.

Abrasive Grade: The grade refers to the coarseness of the abrasive particles. Coarse grades remove material quickly, while fine grades produce a smooth finish. An operator must choose the right abrasive grade for the desired outcome.

The specific grinding task also dictates the ideal operating speed. This ensures the abrasive works effectively without damaging the workpiece.

| Task | Recommended Speed (SFPM) |

|---|---|

| Deburring | 5000-6500 SFPM |

| Decorative Finishing | 500-3000 SFPM |

| Blending/Polishing | 6000-8000 SFPM |

By carefully considering your tool, wheel size, and application, you can confidently select the perfect grinding wheels for any job.

Critical Safety and Operational Best Practices

Technical skill is only half the battle. Your commitment to safety and best practices defines you as a true professional. Following correct procedures for every grinding task protects you, your coworkers, and your equipment. It also ensures you produce high-quality work consistently. This section covers the essential habits every operator must master.

Pre-Operation Wheel Inspection

You should never start a grinding job without first inspecting your wheel. A damaged wheel can fail at high speed, causing serious injury. A quick visual check and a simple sound test can prevent a disaster.

First, look for obvious signs of damage. A careful visual inspection is your first line of defense. You should check for:

- Cracks: Look for any small fissures or lines on the wheel’s surface.

- Chips: Check for small pieces broken off the wheel, especially around the edges.

- Uneven Wear: Notice any inconsistent wear patterns across the grinding surface.

- Stress Fractures: Pay close attention to the area near the mounting hole.

Next, you must perform the “ring test” on vitrified grinding wheels to find hidden cracks. This test is a requirement under OSHA standard 1910.215.

- Make sure the wheel is dry and clean. Suspend it using a pin or your finger through the center hole.

- Use a light, nonmetallic tool, like a plastic screwdriver handle. Gently tap the wheel about 1 to 2 inches from its edge.

- Tap the wheel at points 45 degrees to each side of the vertical centerline.

- Listen to the sound. A clear, bell-like ring means the wheel is safe for grinding. A dull thud indicates a hidden crack.

- If you hear a thud, you must discard the wheel immediately. Do not attempt to use it.

Operator’s Note

Organic bonded wheels may not produce a clear ring like vitrified wheels. Always combine the ring test with a thorough visual inspection. When in doubt, get a new wheel.

Proper Mounting and Guarding

Properly mounting grinding wheels is critical for safe operation. An improperly mounted wheel can vibrate, wear unevenly, or even break apart. You must also ensure all safety guards are in place and correctly adjusted.

When mounting a wheel, always use blotters. These are compressible paper washers that go between the wheel and the flanges. They help distribute clamping pressure evenly. The blotter must be equal to or larger than the flange diameter. You should be able to see it sticking out slightly.

You must also use the correct flanges for your wheel. They should be of equal diameter to provide even pressure. Follow these steps for secure mounting:

- Slide the inner flange onto the spindle.

- Place the blotter and grinding wheel onto the spindle. Ensure a snug fit.

- Add the second blotter and the outer flange.

- Tighten the nut by hand first, then use a wrench to secure it. Do not overtighten, as this can crack the wheel.

Guarding is a non-negotiable part of grinding safety. OSHA requires guards to protect the operator from flying debris if a wheel breaks. Never operate a grinder without a guard. The guard must enclose most of the wheel. For bench grinders, the exposure of the wheel periphery should not exceed 90 degrees. The guard must also be adjustable. As the wheel wears down, you must move the guard to maintain protection.

Safe Angles and Pressure for Grinding

Your technique during grinding directly affects the outcome and your safety. Using the correct angle and pressure ensures efficient material removal and a quality finish. Applying the wrong pressure or angle can damage the workpiece, wear out the wheel, and create hazards.

The angle of your grinding depends on the task. Holding the grinder at a consistent, appropriate angle is key to achieving the desired result. For example, sharpening blades requires specific angles for an effective edge.

| Task / Blade Type | Recommended Grinding Angle |

|---|---|

| Standard Mower Blade | 20-30° |

| Gator Mulching Blades | 35° |

| Weld Preparation | Varies (often 30-37.5°) |

Applying the right amount of pressure is just as important. You should let the wheel do the work.

Pushing too hard on the workpiece is a common mistake. Excessive pressure overheats the metal, causing discoloration. It also overloads the abrasive grains, shortening the wheel’s life. This does not speed up the grinding process and increases operator fatigue. Use moderate, steady pressure for the best results.

Machine Checks and Tooling Setup

Before you begin any grinding work, you must perform a quick check of your machine. A properly set up grinder is a safe grinder. As professional grinding wheel operators, this daily routine is essential. The two most important adjustments are the tool rest and the spark arrester.

The tool rest supports your workpiece during grinding. It must be positioned correctly to prevent the workpiece from being pulled into the gap between the rest and the wheel.

The spark arrester, or tongue guard, is the upper guard that deflects sparks away from you. It also provides protection if the wheel breaks.

You must check and adjust these components as the wheel wears down. An incorrect gap is a major safety hazard.

| Component | Maximum Gap |

|---|---|

| Tool / Work Rest | 1/8-inch |

| Tongue Guard / Spark Arrester | 1/4-inch |

Always check these gaps before turning the machine on. A small adjustment takes only a moment but can prevent a serious accident. This simple habit is a hallmark of a skilled and responsible operator.

Mastering Grinding Process Optimization

Beyond safety, a skilled operator focuses on grinding process optimization. You can improve your work by fine-tuning your methods. Optimizing grinding processes leads to better results, longer tool life, and greater efficiency. This is where you move from a good operator to a great one.

The Importance of Wheel Dressing and Truing

Over time, your grinding wheels will wear down or become loaded with material. You must perform two key maintenance tasks: truing and dressing. While they sound similar, they serve different purposes for your grinding.

| Aspect | Truing | Dressing |

|---|---|---|

| Purpose | Restores the wheel’s original shape and ensures it runs true on its axis. | Cleans and sharpens the wheel’s surface by removing debris and exposing fresh abrasive grains. |

| Outcome | Ensures accuracy and precision in your grinding operations. | Restores the wheel’s cutting performance and improves surface finish. |

You can use several tools for these jobs. Common dressing tools include:

- Diamond Dressers

- Star Wheel Dressers

- Abrasive Stick Dressers

Properly maintaining your grinding wheels is the first step toward peak efficiency.

Balancing Wheel Packs for Accuracy

An unbalanced wheel creates serious problems. It causes vibrations that harm your machine’s spindle and bearings. This imbalance also leads to poor surface finishes and reduces the accuracy of your grinding. You will notice faster tool wear and may even experience unexplained failures during a job. As an operator, you must ensure your wheel packs are balanced. This simple check protects your equipment and guarantees a precise, high-quality result every time.

Adjusting Speeds and Feeds

Expert grinding wheel operators know how to adjust machine parameters for maximum performance. The two most important settings are wheel speed and feed rate. Your goal is to find the perfect balance for each job. This is a core part of grinding process optimization.

You use a slow feed rate to achieve a fine surface finish. At the same time, you need a high cutting speed to reduce grinding time.

Adjusting these settings helps you control the material removal rate. For production grinding, maximizing q-prime (the material removal rate) is key to efficiency. By skillfully managing speed and feed, you are maximizing q-prime and completing jobs faster without sacrificing quality. This control is essential for optimizing grinding processes and achieving superior outcomes.

Advanced Grinding Solutions

When you face tough materials, standard tools may not be enough. Advanced solutions can elevate your grinding performance and help you tackle the most demanding jobs. This is where specialized tools and knowledge give you a professional edge.

Aimgrind’s Diamond Grinding Wheels

For hard materials like ceramics, composites, and hard alloys, you need a high-performance solution. Aimgrind’s diamond grinding wheels deliver exceptional durability and precision. Unlike conventional abrasives, diamond wheels last much longer and provide a superior finish. This means less downtime and more consistent results for your grinding application.

These wheels come with different bond types to match your specific needs:

- Resin Bond: Offers a cooler cutting action, perfect for materials sensitive to heat.

- Metal Bond: Provides extreme abrasion resistance and long life, ideal for grinding glass or composites.

- Vitrified Bond: Gives you a free-cutting action with excellent shape retention for precision work.

Grinding Hard and Brittle Materials

Grinding brittle materials like glass or ceramic requires a special technique to prevent chipping. You must use light pressure and let the tool do the work. Using a fine grit size helps you create a smooth surface without causing cracks. The goal is to carefully remove material without applying excessive force. This careful approach to grinding ensures a high-quality outcome on every delicate application. The superior cutting ability of diamond abrasives makes this process more efficient and reliable.

Custom Solutions for Industry Needs

Every industry has unique challenges. That is why custom solutions are so important. For industries like aerospace or cutting tool manufacturing, a standard wheel might not deliver the required performance. Expert suppliers like Aimgrind can design a custom grinding solution for your specific application. Whether you need a special wheel profile for tool sharpening or a unique bond for a new composite material, a personalized approach guarantees the best possible performance and efficiency.

Mastery for professional grinding wheel operators rests on four pillars: understanding your wheel, correct selection, operational safety, and process optimization. As an operator, applying this knowledge directly improves your work. You will achieve greater efficiency in your process and better efficiency from your tools. This commitment to excellence boosts your overall efficiency and ensures top-tier safety.

Grind with Passion, Achieve with Aim.

FAQ

What should you do if you drop a grinding wheel?

You must inspect any dropped wheel for damage. Perform the “ring test” to check for hidden cracks. A dull thud means the wheel is unsafe. You should discard it immediately. Never use a wheel that you suspect is damaged. Your safety is the top priority.

Why is your workpiece turning blue?

A blue or discolored workpiece indicates excessive heat. You are likely applying too much pressure during grinding. You should reduce the force and let the wheel do the work. This prevents overheating and ensures a better quality finish on your material.

When should you use a diamond grinding wheel?

You should choose a diamond grinding wheel for very hard or brittle materials. They are perfect for grinding ceramics, hard alloys, and composites. Brands like Aimgrind offer these wheels for jobs that demand high precision and a superior finish.

How often should you dress a grinding wheel?

You should dress your wheel whenever you notice a drop in cutting performance. If the wheel seems glazed or loaded with material, it is time to dress it. Regular dressing exposes fresh abrasive grains and keeps your grinding process efficient.

Contact Us

For More Grinding Solution or Customized Abrasive Tools