Your grinding wheels can be safe, efficient, and cost-effective tools. Proper grinding wheel maintenance is the key to unlocking their full potential. This guide offers your ultimate checklist for essential maintenance, ensuring the durability of your grinding wheels.

Master these steps for excellent dry grinding maintenance. You will get the best performance and lifespan from all your grinding wheels.

Key Takeaways

- Always check your grinding wheel for cracks or chips before you use it. This keeps you safe.

- Do a ‘ring test’ on your wheel to find hidden damage. A clear ring means it is safe; a dull sound means you should throw it away.

- Clean your grinding wheel regularly. This is called dressing. It makes the wheel cut better and last longer.

- Make sure your grinding wheel is round and balanced. This is called truing. It helps you grind accurately.

- Store your grinding wheels carefully in a dry place. This prevents damage and keeps them working well.

The Essentials of Grinding Wheel Maintenance

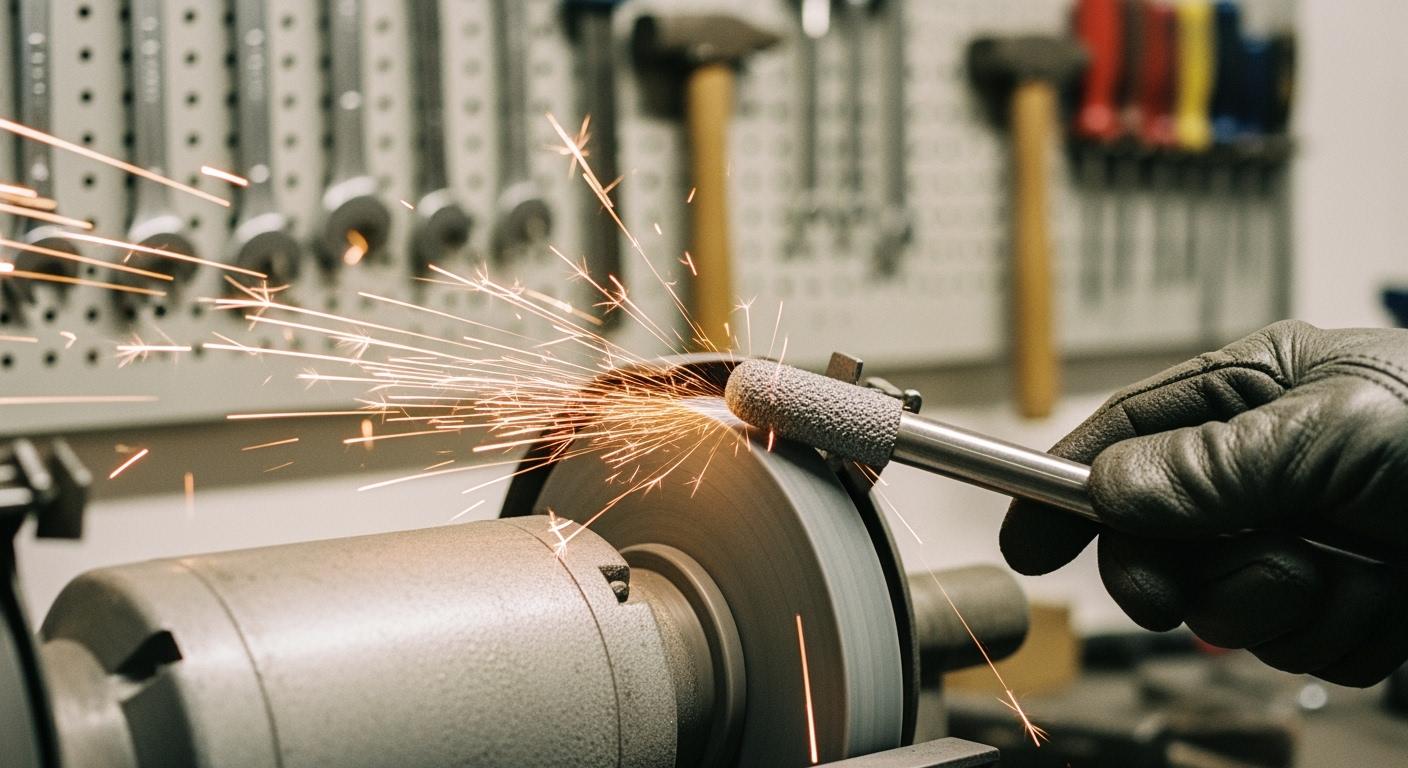

Proper grinding wheel maintenance begins with simple, consistent habits. You can ensure safety and efficiency by making a few checks part of your daily routine. These foundational steps prevent major issues and extend the life of your grinding wheels.

Daily Pre-Use Inspection

Your first step before any grinding task is a thorough visual check. This is one of the most important regular inspection procedures for your safety. A damaged wheel can fail at high speeds, creating a serious hazard. Take a moment to examine your grinding wheels for any signs of trouble.

You should look for these specific issues:

- Cracks and Chips: Carefully inspect the entire surface and edges. Even small cracks can lead to catastrophic failure under operational stress.

- Discoloration and Glazing: Dark spots or discoloration may show that the wheel has been overheated. A shiny, smooth surface, known as glazing, indicates the abrasive grains are dull and will not cut effectively.

These regular inspection procedures are your first line of defense. Never use a wheel that shows any visible damage. Your personal safety is the top priority.

The ‘Ring Test’ for Hidden Cracks

Sometimes, a wheel has internal damage that you cannot see. The ‘ring test’ is a simple and effective method to detect these hidden flaws in vitrified and silicate grinding wheels. Performing this test correctly is a critical part of your maintenance and safety precautions.

Follow these steps in a quiet area to get a clear result:

- Make sure the wheel is dry and clean. Suspend it on your finger or a small pin through the center hole so it can hang freely.

- Take a non-metallic object, like a plastic screwdriver handle or a wooden mallet.

- Gently tap the wheel about one to two inches from the edge.

- Listen closely to the sound. A healthy, undamaged wheel will produce a clear, metallic ringing tone.

- Rotate the wheel 45 degrees and tap it again. A consistent ring confirms the wheel is sound.

A cracked or damaged wheel will make a dull “thud” or a dead sound instead of a clear ring. If you hear this, the wheel is unsafe. You must discard it immediately and never attempt to use it.

Proper Wheel Cleaning Methods

Over time, your grinding wheels will become “loaded” with material from the workpiece or “glazed” as the abrasive particles wear down. This reduces cutting efficiency and increases heat buildup. Proper cleaning, also known as dressing, restores the wheel’s cutting surface. This is a key task in both dry grinding maintenance and general grinding disc maintenance.

Dressing exposes fresh, sharp abrasive grains. The method you use depends on the wheel’s bond type.

| Wheel Bond Type | Dressing Needs | Recommended Tools |

|---|---|---|

| Resin Bond | These softer bonds wear easily. Dressing focuses on cleaning loaded material and gently exposing new diamonds. | Use standard silicon carbide (SiC) or aluminum oxide (Al₂O₃) dressing sticks. |

| Metal Bond | This bond is very hard and wear-resistant. It requires more force to break down and expose fresh abrasive. | Use impregnated diamond rotary dressers or specialized hard abrasive blocks for effective dressing. |

| Vitrified Bond | This hard, brittle bond needs a controlled dressing process to fracture the bond without causing damage. | Impregnated diamond rotary dressers offer the best control for these grinding wheels. |

Effective maintenance ensures your tools perform at their best. Following these safety precautions and maintenance steps will keep your grinding wheels in top condition for every job.

Mastering Dry Grinding Maintenance

Beyond daily checks, mastering dry grinding maintenance means learning how to properly condition your wheel’s surface. This involves two key processes: dressing and truing. These techniques ensure your grinding wheels operate at peak performance, giving you precise results every time.

Why Wheel Dressing is Crucial

Dressing your grinding wheel is essential for productivity and quality. Over time, the wheel’s surface can become loaded with material or glazed with dull abrasives. Dressing cleans and sharpens this surface. This process is a core part of your maintenance routine.

A properly dressed wheel offers several key benefits:

- It restores the wheel’s cutting efficiency.

- It removes loaded materials and glazed areas.

- It exposes fresh, sharp abrasive grains.

- It helps you achieve a smoother, more accurate surface finish.

A new wheel often has a smooth surface. You should dress it before its first use. This exposes the abrasive grains and prevents poor cutting performance right from the start. Proper dressing reduces heat buildup and extends the life of your grinding wheels.

A Guide to Wheel Truing

People often confuse truing with dressing, but they serve different purposes. Truing restores the shape of the grinding wheel, while dressing sharpens its surface. You perform truing less often than dressing. It is necessary when you first mount a wheel or when it loses its shape.

Here is a simple breakdown of the differences:

| Aspect | Truing | Dressing |

|---|---|---|

| Purpose | Restores the wheel’s geometric shape and ensures it is concentric. | Cleans and sharpens the wheel’s cutting surface. |

| When to do it | After mounting a new wheel or when the wheel becomes unbalanced. | When cutting efficiency drops or as part of routine maintenance. |

| Outcome | An accurate, perfectly round wheel profile for precise grinding. | A sharp, clean cutting surface for better efficiency. |

To true your grinding wheels correctly, follow these steps for better safety and results:

- Preparation: Put on your safety gear. Make sure the grinder is turned off and secure.

- Inspection: Check the wheel for damage. This helps you know how much material to remove.

- Execution: Mount your truing tool securely. Turn the grinder on and let it reach full speed. Gently bring the tool into contact with the wheel until its surface is uniform and smooth.

- Evaluation: Turn the grinder off. Inspect the wheel to ensure it is perfectly round and concentric.

Choosing Your Dressing Tool

The tool you choose for dressing and truing directly impacts your results. While simple tools like star dressers exist for coarse work, they can leave an uneven surface. For precision, nothing beats high-quality diamond dressing tools. They use industrial-grade diamonds to reshape and sharpen grinding wheels with incredible accuracy.

Using a superior tool ensures a perfectly dressed and true wheel face for optimal performance. Specialized tools, like Aimgrind‘s diamond grinding wheels, are designed for such demanding tasks. These tools expertly restore cutting action, reduce heat, and improve surface finish. This aligns with Aimgrind’s commitment to quality and efficiency, helping you achieve professional results. Investing in a quality diamond tool is an investment in the life and performance of all your grinding wheels.

Safe Techniques for Dry Grinding

Your safety is the top priority during any grinding operation. Following established safety precautions protects you from injury and ensures the machine operates correctly. Good dry grinding maintenance includes a safe work environment.

Before you begin, always perform these regular inspection procedures and safety checks:

- Secure the Grinder: Ensure the grinder is securely anchored to prevent it from moving during operation.

- Check Guards: The work rest should be within 1/8-inch of the wheel. The tongue guard should be within 1/4-inch. Never adjust them while the wheel is moving.

- Wear Protective Gear: You must wear protective gear. This includes ANSI-approved safety glasses and a face shield to protect you from sparks and debris.

- Stand Aside: When starting the grinder, stand to the side, not directly in front of it. Let the wheel get to full speed before you start grinding.

- Apply Gentle Pressure: Move the workpiece smoothly across the face of the wheel. Do not use the side of the wheel for grinding.

- Power Down Safely: Turn off the grinder when you are finished. Wait for the wheel to stop on its own. Never use an object to force it to stop.

Following these rules creates a culture of safety and keeps your equipment in excellent condition.

Long-Term Durability and Storage

Proper care for your grinding wheels extends beyond daily use. Your storage and handling practices are critical for long-term durability and safety. Good maintenance habits protect your investment and ensure every wheel performs reliably.

Proper Wheel Storage Rules

You should store your grinding wheels in a controlled environment. Extreme temperatures or humidity can damage them. High humidity makes a wheel absorb moisture, which can weaken its structure. Low humidity can make it brittle.

Storage Tip: Aim for a temperature between 60°F and 80°F (15°C to 27°C) with 35% to 50% relative humidity. Keep grinding wheels away from direct sunlight or moisture to maximize their operational lifespan.

Organize your storage area to prevent damage. Different types of grinding wheels have specific needs.

- Store large-diameter wheels in racks that support them in at least two places.

- Keep smaller wheels, cones, and plugs in their original boxes or in separate bins.

- Place straight cup wheels base-to-base and rim-to-rim to prevent chipping.

Safe Handling and Mounting

Always handle grinding wheels with care. Never roll them or bump them against hard surfaces. Use a cart or truck to move wheels that are too heavy to carry by hand. This simple step prevents hidden cracks that create a major safety hazard.

When you mount a wheel, proper setup is essential.

- Perform the ‘ring test’ on a new wheel before mounting it.

- Check that the work rest is adjusted correctly. The gap between the rest and the wheel face must be 1/8-inch or less. This prevents the workpiece from getting jammed.

The Role of Flanges and Blotters

Flanges and blotters are small parts that play a big role in safe grinding. Flanges are the metal discs that hold the wheel on the spindle. They must be a matched pair and at least one-third the diameter of the wheel.

Blotters are the paper or composite discs that go between the flange and the wheel. You should always use them. They serve three important functions:

- Distribute Pressure: They spread the clamping force evenly across the wheel.

- Dampen Vibration: They act like a cushion to reduce vibration during use.

- Protect the Wheel: They create a barrier that stops the hard metal flange from cracking the abrasive wheel.

Your grinding wheel maintenance relies on three key actions: consistent inspection, regular dressing, and proper storage. This proactive approach to dry grinding maintenance unlocks the full potential of your grinding wheels. You ensure maximum efficiency and long-term durability for every task.

Achieve maintenance excellence. You can grind with passion and confidence, knowing your tools are built for durability and performance.

FAQ

How often should you dress a grinding wheel?

You should dress your wheel whenever you notice a drop in cutting performance. A glazed or loaded surface is a clear sign. There is no fixed schedule. Your grinding results will tell you when it is time to dress the wheel.

Can you use a wheel with a small crack?

No, you must never use a wheel with any crack, no matter how small. A small flaw can cause the wheel to break apart at high speed. This creates a serious safety risk. Always discard a damaged wheel immediately for your protection.

What is the main difference between truing and dressing?

Truing and dressing are two different tasks.

- Truing corrects the wheel’s shape, making it perfectly round.

- Dressing cleans and sharpens the wheel’s cutting surface.

You true a wheel when mounting it. You dress it to improve performance.

Why is the ‘ring test’ so important?

The ‘ring test’ helps you find hidden internal cracks. A visual check can miss these dangerous flaws. Performing this simple test before mounting a wheel is a critical safety step. It prevents a potentially catastrophic failure during operation.

Contact Us

For More Grinding Solution or Customized Abrasive Tools