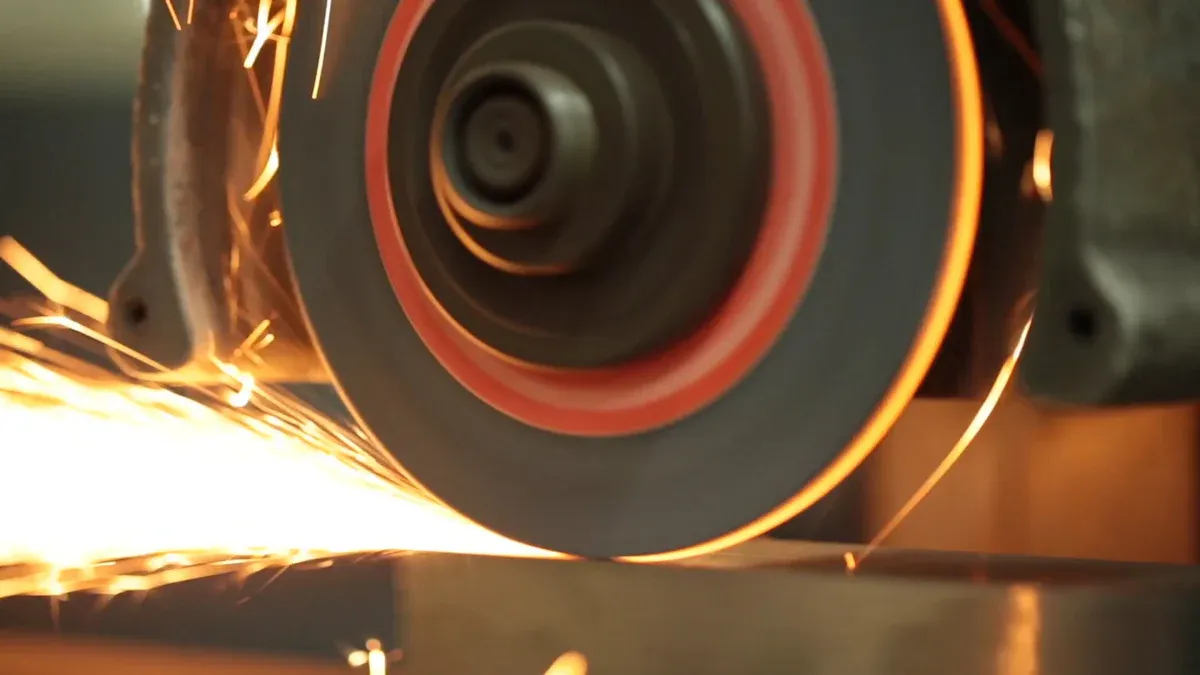

Five costly mistakes in your grinding process are shortening your wheel life. These mistakes include:

- Incorrect wheel selection

- Improper dressing

- Wrong parameters

- Poor coolant management

- Machine neglect

Avoiding these costly errors improves your surface grinding machine efficiency. Correcting these grinding mistakes enhances surface quality, extends wheel life, and prevents future costly mistakes.

Key Takeaways

- Choose the right grinding wheel for your material. This prevents fast wear and poor surface quality.

- Dress your grinding wheel often. This keeps it sharp and working well.

- Set the correct speeds and feeds for your grinding machine. This stops heat damage and makes parts better.

- Use enough clean coolant. This cools the wheel and stops scratches on your parts.

- Take care of your grinding machine. Regular checks make it work better and last longer.

Mistake 1: A Costly Wheel Selection Error

The Problem: A Mismatched Wheel

Using the wrong grinding wheel for your material is one of the most common mistakes. A mismatched wheel leads to rapid wear, poor surface quality, and wasted time. Each material, from soft steel to hard ceramic, requires a specific wheel composition for effective grinding. When the wheel’s abrasive, grit, or bond is not suited for the job, you force the tool to work inefficiently. This not only shortens the life of your wheel but also risks damaging the workpiece, leading to costly rework. These mistakes can halt your production and hurt your bottom line.

The Solution: Correct Wheel Specification

You must use the right abrasive wheel to achieve optimal results. Matching the wheel’s specifications to your material is critical for extending its life and ensuring a high-quality surface finish.

Four key elements determine a wheel’s performance:

- Abrasive: The cutting material (e.g., aluminum oxide, silicon carbide, diamond).

- Grit: The size of the abrasive particles, which affects the finish.

- Grade: The hardness of the bond holding the abrasives.

- Bond: The material holding the wheel together (e.g., vitrified, resin, metal).

Grit size directly impacts the surface finish. Finer grits produce a smoother finish, while coarser grits remove material faster but leave a rougher surface.

| Application | Recommended Grit Sizes |

|---|---|

| Rough Grinding | 24 to 36 |

| Intermediate Grinding | 46 to 60 |

| Fine Grinding | 80 to 120 |

| Super Fine Grinding | 150 to 600 |

Pro Tip: For challenging materials like ceramics or hard alloys, a standard wheel may not suffice. Partnering with a specialist like Aimgrind to get a custom-formulated diamond grinding wheel ensures a perfect match. This prevents premature wear and maximizes grinding performance and quality.

Mistake 2: Common Abrasive Mistakes in Dressing

The Problem: Incorrect Dressing Habits

Over time, your grinding wheel loses its cutting ability. This happens in two main ways: glazing and loading. These common abrasive mistakes reduce efficiency and can damage your workpiece. Understanding the difference is the first step to fixing the problem.

- Wheel Glazing: The wheel’s surface becomes smooth and shiny. The abrasive grains get dull, which reduces the wheel’s cutting ability.

- Wheel Loading: Grinding material gets stuck between the abrasive grains. This clogs the wheel and makes it less effective.

These mistakes often occur when grinding soft metals like aluminum without the right wheel or coolant.

| Feature | Glazed Grinding Wheel | Loaded Grinding Wheel |

|---|---|---|

| Cause | Abrasive grains become dull from wear. | Material chips clog the wheel. |

| Appearance | The surface looks smooth and shiny. | You can see material stuck on the wheel. |

| Effect | Reduced cutting efficiency. | Poor material removal and finish. |

Ignoring these issues leads to a poor surface finish and shortens the life of your wheel. These are common abrasive mistakes that cost you time and money.

The Solution: Proper Dressing Techniques

You fix a glazed or loaded wheel by dressing it. Dressing removes the dull or clogged layer to expose fresh, sharp abrasive grains. Using proper abrasive techniques is essential for effective grinding.

Here are some tips for better dressing:

- Choose the Right Tool: Your dressing tool must match your wheel. For many resin and vitrified bond wheels, a brake or motorized dresser works best. Using the wrong tool, like a single-point diamond on a vitrified CBN wheel, can destroy the tool quickly.

- Set Correct Parameters: A slow and steady pass with the dressing tool is often more effective than a quick one. A shallow depth of cut removes just enough material to restore the cutting surface without wasting the wheel.

- Dress Regularly: Do not wait for your grinding process to suffer. You must regularly dress the grinding wheel to maintain a clean cutting surface and consistent performance.

Adopting these dressing techniques will extend your wheel’s life and improve your part quality. Avoiding these common abrasive mistakes is key to an efficient operation. Proper abrasive techniques and dressing are not just maintenance; they are vital parts of the grinding process. These common abrasive mistakes are easy to avoid with the right techniques.

Mistake 3: Incorrect Speeds and Feeds

The Problem: Unbalanced Grinding Parameters

Setting the wrong speeds and feeds is one of the most common grinding mistakes. You might think faster is always better, but excessive wheel speed generates extreme heat. This heat can cause thermal damage to your workpiece, especially with hardened steels. High temperatures soften the material’s surface layer, reducing its hardness and strength. This can also lead to microcracks, ruining the part’s integrity.

When your grinding parameters are unbalanced, you sacrifice control for a speed that ultimately hurts your efficiency. The friction and heat from improper settings cause poor performance, leading to scrapped parts and a shorter life for your grinding wheel. These issues directly impact your operational costs and productivity.

The Solution: Optimizing Your Parameters

You can achieve optimal results when you optimize grinding parameters for your specific job. This involves balancing wheel speed with your feed rate to improve efficiency and part quality.

1. Calculate Your Wheel Speed Your wheel speed is best measured in Surface Feet Per Minute (SFPM), not just RPM. You can calculate it with a simple formula:

There is no single perfect speed. The ideal SFPM depends on your material and abrasive. However, knowing this value helps you operate within the recommended range for better performance.

2. Adjust Your Feed Rate You must also set an appropriate feed rate for the task. Grinding operations typically involve two stages:

| Pass Type | Goal | Recommended Feed |

|---|---|---|

| Roughing | High material removal speed | Deeper cut, faster feed |

| Finishing | Achieve the desired finish | Lighter cut, slower feed |

For the final pass, a slow feed rate is crucial to get a smooth surface finish. Making these adjustments for each stage of the grinding process ensures a high-quality finish and boosts your overall efficiency.

Mistake 4: Poor Coolant Management Mistakes

The Problem: Inadequate Cooling and Lubrication

You make costly mistakes when you overlook your coolant system. Inadequate cooling and lubrication during grinding create major problems for your wheel and workpiece. When you supply insufficient coolant, friction generates intense heat. This heat can damage the resin bond holding your wheel together, causing it to wear out quickly. The high temperature also harms the workpiece surface, leading to thermal damage and a poor finish.

Another issue is dirty coolant. If your filtration system is poor, small metal chips circulate back into the grinding zone. These particles get trapped between the wheel and the workpiece.

⚠️ Warning: These trapped chips act like rocks in your shoe, causing deep scratches on the part’s surface. This ruins the finish and can compromise the structural quality of the final product. These coolant management mistakes directly reduce your grinding efficiency.

The Solution: An Effective Coolant Strategy

You can avoid these problems with an effective coolant strategy. Proper management protects your wheel, improves efficiency, and helps you achieve a high-quality surface finish. Your strategy should focus on three key areas.

- Maintain Correct Concentration: The coolant-to-water ratio must match the material you are grinding. Using the right concentration ensures proper lubrication and cooling. You can use a refractometer to check your levels.

| Metal Type | Recommended Coolant Concentration |

|---|---|

| Ferrous Metals (Steels, Iron) | 5% – 8% |

| Non-Ferrous Metals (Aluminum, Copper) | 8% – 12% |

-

Optimize Nozzle Position: The spinning wheel creates an air barrier that can block coolant. You should aim the nozzle just ahead of the grinding zone. This action peels away the air barrier, allowing fluid to reach the cut and cool it effectively.

-

Ensure Proper Filtration: You must keep your coolant clean to prevent scratches. A good filtration system removes harmful particles, ensuring a smooth finish and better overall quality. Following these steps will help you achieve optimal results in your grinding operations.

Mistake 5: How Neglect Can Improve Surface Grinding Machine Efficiency

The Problem: Machine Instability and Wear

You might have the perfect wheel and parameters, but you make critical mistakes if you ignore the health of your surface grinding machine. Machine instability is a hidden drain on your efficiency. A primary cause is spindle imbalance, which creates eccentric vibrations. These vibrations have serious consequences for your operation.

- They reduce the service life of both the grinding wheel and the spindle bearings.

- They force you to dress the wheel more often, consuming time and dressing tools.

- They ruin part quality, causing chatter marks and poor flatness on the finished surface.

This constant vibration causes uneven wear on the components of your surface grinding machine. An unlevel or warped machine table also leads to inaccurate grinding. These problems reduce your overall efficiency and can lead to expensive repairs.

The Solution: Essential Maintenance Checks

You can prevent these issues and improve surface grinding machine efficiency with a consistent maintenance schedule. A well-maintained surface grinding machine operates with greater precision and reliability. Regular checks help you catch small problems before they become major failures, boosting your long-term efficiency.

Maintenance Tip: Create a daily checklist to keep your surface grinding machine in top condition. This simple habit protects your investment and improves performance.

Your routine should include these essential tasks:

- Daily Cleaning: Wipe down the surface grinding machine to remove metal shavings and debris. A clean machine is easier to inspect.

- Lubrication Checks: Regularly lubricate spindle bearings, slides, and guides according to the manufacturer’s schedule. Proper lubrication is vital for smooth operation.

- Table Flatness Inspection: Periodically check that your machine table is perfectly flat. An uneven table makes it impossible to produce flat parts.

- Component Inspection: Look for signs of damage or wear on belts, guards, and spindles. This allows you to replace worn-out parts before they fail.

Following these steps ensures your surface grinding machine runs smoothly, extending wheel life and maximizing your production efficiency.

You can extend your grinding wheel life by avoiding five costly mistakes. These mistakes include incorrect wheel selection, poor dressing, wrong grinding parameters, bad coolant, and machine neglect. Correcting these errors improves your surface grinding machine efficiency and part quality. Proactive adjustments in these five areas are strategic decisions. They yield significant cost savings and a better finish, much like proper coolant management extends tool life. Fixing these costly mistakes in your grinding process prevents future costly mistakes and improves your final product quality.

Take a moment to audit your grinding process. For complex wheel selection challenges, contact a specialist like Aimgrind. We can help you find the perfect wheel to maximize its life and performance.

FAQ

How do I know if my wheel is glazed or loaded?

You can tell by looking at the wheel’s surface. A glazed wheel looks shiny and feels smooth because the abrasive grains are dull. A loaded wheel has visible material chips stuck in its pores, which clogs the cutting surface and reduces grinding efficiency.

Why is my workpiece getting burn marks?

Burn marks on your workpiece usually mean there is too much heat. You might be using the wrong wheel speed or feed rate. Another common cause is poor coolant flow, which fails to cool the grinding zone and leads to thermal damage.

How often should you dress a grinding wheel?

You should dress your wheel when you notice a drop in performance. Signs include a poor surface finish, increased grinding noise, or visible glazing. Regular dressing maintains sharpness and ensures consistent results. Do not wait for problems to appear.

Can you use one grinding wheel for different materials?

💡 For the best results, you should not use one wheel for all materials. Each material requires a specific abrasive, grit, and bond. Using the wrong wheel causes rapid wear and poor quality. For tough jobs, a custom wheel from a specialist like Aimgrind is your best solution.

Contact Us

For More Grinding Solution or Customized Abrasive Tools