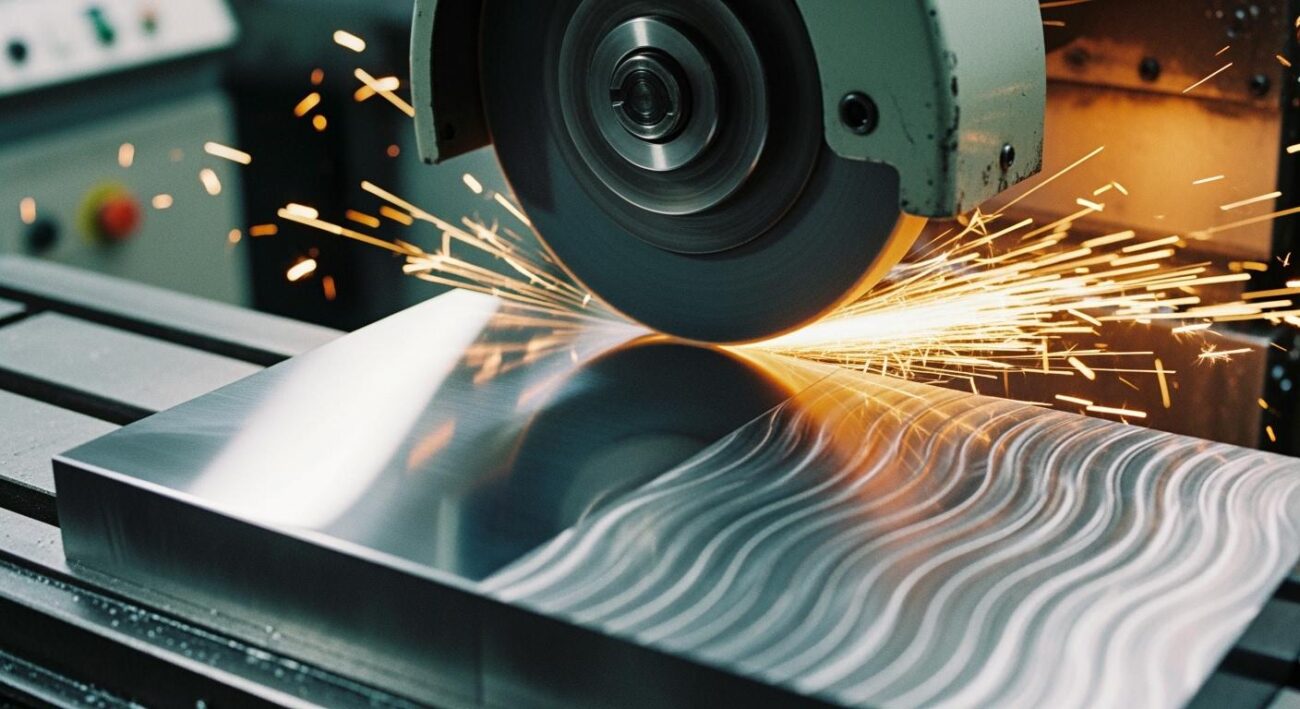

Finding a grinding wheel that matches your needs is crucial for quality surface grinding and your safety. The process of choosing a grinding wheel is straightforward when you understand five key factors. Your grinding success depends on the wheel’s abrasive, grit, grade, structure, and bond. Mastering these elements ensures every grinding job is efficient and precise.

⚠️ Safety First: Using an incorrect grinding wheel is a primary cause of dangerous incidents like wheel breakage and kickback.

Key Takeaways

- Match the grinding wheel’s abrasive type to your workpiece material. This is the most important step.

- Choose the right grit size based on your goal. Use coarse grit for fast material removal and fine grit for a smooth finish.

- Follow the ‘Golden Rule of Grinding’: use a soft wheel for hard materials and a hard wheel for soft materials.

- Consider the wheel’s structure and bond type. These affect how the wheel cuts and its durability for different tasks.

- Always prioritize safety. Wear protective gear and check the wheel before use.

Key Factors for Surface Grinding Selection

Before you select a wheel, you must analyze your specific job. There are several factors to consider when choosing the right wheel for your application. Your workpiece material, project goals, and machine specifications guide your decision. Understanding these elements ensures a successful surface grinding operation.

The Workpiece Material

Your workpiece material is the single most important factor. Its properties, like hardness and thermal conductivity, dictate the best abrasive for the job. A general rule for grinding is to use a soft-grade wheel on hard materials and a hard-grade wheel on soft materials. This allows the wheel to break down correctly, exposing fresh, sharp grains for efficient grinding.

| Workpiece Hardness | Abrasive Type Recommended | Grinding Wheel Grade Recommended |

|---|---|---|

| Hard Steels & Alloys | Aluminum Oxide (A), Ceramic (SG) | Soft Grade (A-H) |

| Soft Metals & Non-Metals | Silicon Carbide (C) | Hard Grade (Q-Z) |

| General Purpose | Aluminum Oxide (A) | Medium Grade (I-P) |

Stock Removal vs. Surface Finish

You must decide between rapid stock removal and a fine surface finish. These two goals are opposites in grinding. Aggressive grinding for high stock removal leaves a rougher surface. Achieving a smooth, mirror-like finish requires a slower grinding process with a finer grit wheel. The science behind this involves chip size; fast material removal creates large chips and a rough surface, while slow, precise grinding creates tiny chips for a smoother finish.

Grinding Machine and Contact Area

Your grinding machine’s power and stability influence your wheel choice. A powerful, rigid machine can handle a harder wheel. The contact area—the amount of the wheel touching the workpiece at one time—is also critical. A larger contact area generates more heat.

💡 Pro Tip: For grinding operations with a large contact area, choose a softer grade wheel. This helps the wheel break down faster, preventing heat buildup and workpiece burn. A softer wheel also reduces the load on the grinding machine.

Abrasive Types for Your Material

The abrasive is the cutting material on your grinding wheel. You must match the abrasive to your workpiece material for effective grinding. Each abrasive type has unique properties. These properties make it suitable for specific materials and applications.

Aluminum Oxide (A) for Steels

Aluminum oxide is the most common abrasive you will find. It is a tough and versatile material. You should choose it for grinding most steel and ferrous alloys. Its durability makes it a reliable choice for many grinding tasks. It performs exceptionally well on materials with high tensile strength.

You can use aluminum oxide abrasive grinding wheels for:

- Carbon steel

- Alloy steel

- High-speed steel

- Annealed malleable iron

- Wrought iron

Silicon Carbide (C) for Non-Ferrous Metals

Silicon carbide is harder and sharper than aluminum oxide. However, it is also more brittle. You should use it for grinding materials with low tensile strength. This includes many non-ferrous metals. A common problem when grinding soft metals is “loading,” where chips clog the wheel. Silicon carbide wheels, especially a grinding wheel for aluminum, are designed to prevent this issue. This allows for grinding with less pressure and lower temperatures. You can find grinding wheels made for all metals, but silicon carbide is a top choice for:

- Aluminum

- Brass

- Copper

- Bronze

Silicon Carbide for Non-Metals and Concrete Grinding Wheel Use

Silicon carbide’s sharpness also makes it perfect for grinding hard, brittle non-metals. This includes materials like stone, ceramics, and glass. Its most prominent application in this category is the concrete grinding wheel. When selecting the right concrete grinding wheel, you must consider the concrete’s hardness. A good concrete grinding wheel uses silicon carbide to efficiently remove material. There are many types of concrete grinding wheels, but those with silicon carbide are excellent for surface preparation. A concrete grinding wheel is essential for smoothing rough surfaces. Selecting the right concrete grinding wheel ensures your project’s success. A quality concrete grinding wheel can handle tough jobs. The right concrete grinding wheel makes the work easier. You need a durable concrete grinding wheel for professional results. A concrete grinding wheel is a powerful tool.

Ceramic Alumina (SG) for Tough Alloys

Ceramic alumina is a premium, high-performance abrasive. You should choose it for the most demanding grinding jobs. It is ideal for a grinding wheel for hard-to-grind metals. This includes hardened tool steels and superalloys. The key to its performance is a unique micro-crystalline structure.

How it Works: Under pressure, the tiny grains in ceramic alumina fracture. This process constantly exposes new, sharp cutting edges. This self-sharpening action extends the wheel’s life and provides a faster cut rate.

This property means the wheel stays sharp longer and generates less heat. This is critical when working with heat-sensitive materials. A ceramic grinding wheel for stainless steel, for example, can last four to six times longer than an aluminum oxide wheel.

Superabrasives: Diamond and CBN

Superabrasives are materials at the top of the hardness scale. You use them for precision grinding on the toughest materials. The two main superabrasives are diamond and Cubic Boron Nitride (CBN).

Diamond (D) is the hardest material known. You should use a diamond wheel for grinding extremely hard, non-ferrous materials. It is indispensable for materials that resist conventional abrasives. A diamond abrasive excels where precision and longevity are critical.

| Material Type | Diamond Grinding Wheel Performance |

|---|---|

| Superhard Materials | Essential for tungsten carbide, ceramics, and PCD/PCBN tool blanks. |

| Composites | Critical for machining carbon fiber (CFRP) with minimal damage. |

| Non-Ferrous Metals | Ideal for high-precision applications on aluminum, titanium, and copper. |

For these demanding industrial applications, you need a specialized solution. Aimgrind‘s diamond grinding wheels deliver exceptional durability and precision. They are engineered for superior performance, ensuring efficient material removal and a high-quality finish. These wheels are available in resin, metal, and vitrified bonds to perfectly match your grinding process. You can explore these high-performance diamond options for your next project.

Cubic Boron Nitride (CBN) is the second-hardest material. You should use a CBN wheel for grinding hard ferrous materials. It is the clear winner for grinding High-Speed Steel (HSS). CBN grinds cool, which prevents overheating. Overheating can ruin a tool’s temper and make it soft. Using a CBN wheel guarantees you can sharpen tools without damaging your expensive equipment.

Grit, Grade, and Structure Explained

You have matched the abrasive to your material. Now you must fine-tune your wheel selection. The wheel’s grit, grade, and structure are the three elements that control its performance. Understanding these factors helps you balance cutting speed with surface finish for any grinding job.

Selecting Grit Size for Finish

The grit refers to the size of the individual abrasive particles in the wheel. A numbering system classifies the grit size. A smaller number means larger, coarser abrasive particles. A larger number indicates smaller, finer particles. Your choice of grit directly impacts both the material removal rate and the final surface quality.

Coarse grit wheels (10-24) remove material very quickly. You should use them for rough grinding and heavy stock removal. They will, however, leave a rough surface. Fine grit wheels (70-220) remove material slowly. You use them for precision grinding and achieving a smooth finish. Medium grit wheels (30-60) offer a balance between speed and finish for general-purpose work.

💡 The Finish-Speed Trade-Off: Achieving a smooth finish requires a slower material removal rate. Rapid stock removal always sacrifices surface quality. You must choose the grit that best matches your project’s primary goal.

This table provides a general guide for selecting a grit for your grinding application.

| Grit Size | Suitable Materials | Typical Application |

|---|---|---|

| 10-24 | Stainless steel, cast iron, hard steel | Rough grinding, heavy stock removal |

| 30-60 | Mild steel, aluminum, general metals | General purpose, shaping |

| 70-220 | Carbide, high-speed steel | Precision grinding, tool sharpening, finishing |

Determining Wheel Grade (Hardness)

The grade of a grinding wheel measures the strength of the bond holding the abrasive grains. It does not refer to the hardness of the abrasive itself. The industry uses an A-Z scale, where ‘A’ is the softest grade and ‘Z’ is the hardest. The grade determines how quickly the wheel breaks down to expose new, sharp cutting edges. This is known as the “self-sharpening” effect.

A softer grade wheel (A-H) releases dull grains easily. This constant exposure of fresh grit prevents heat buildup and is ideal for grinding hard materials. A harder grade wheel (Q-Z) holds onto its grains longer. You should use it for grinding soft materials to extend the life of the wheel.

The Golden Rule of Grinding:

- Use a soft grade wheel for hard materials.

- Use a hard grade wheel for soft materials.

This counterintuitive rule is essential for efficient grinding. A soft wheel on a hard material self-sharpens effectively. A hard wheel on a soft material resists premature wear.

- Soft Grade (A-H): For hard materials, large contact areas, and rapid stock removal.

- Medium Grade (I-P): A versatile choice for general-purpose grinding applications.

- Hard Grade (Q-Z): For soft materials, small contact areas, and jobs requiring high form retention.

Understanding Wheel Structure

Structure refers to the spacing between the abrasive grains in the wheel. A number from 1 to 20 or higher indicates the structure. A low number signifies a dense structure with grains packed closely together. A high number indicates an open structure with more space between the grains. This spacing, or porosity, creates chip pockets that are crucial for effective grinding.

Dense Structures (1-7): You should choose a dense structure for fine finishing, holding intricate forms, and grinding hard, brittle materials. The close grain spacing provides more cutting points for a smoother surface.

Open Structures (8+): You need an open structure for high stock removal and for grinding soft, ductile materials like aluminum. The extra space prevents chips from clogging the wheel, which reduces heat and loading. This makes for a cooler, faster grinding operation.

The Role of the Bond Type

The bond is the adhesive that holds the abrasive grains together in a grinding wheel. It determines the wheel’s strength, flexibility, and resistance to heat. Your choice of bond directly influences the wheel’s performance in different grinding applications.

Vitrified (V) for Precision

You should choose a vitrified bond for precision grinding jobs that demand rigidity and a consistent form. This bond is a glassy substance created at very high temperatures. Its chemical inertness makes it resistant to oils and coolants, ensuring predictable grinding performance. Vitrified bonds also have excellent thermal stability, so the wheel will not soften or break down during aggressive grinding operations. This makes it a reliable choice for maintaining tight tolerances.

Resinoid (B) for High Speeds

Resinoid bonds are made from synthetic resins. They offer more flexibility and shock absorption compared to rigid vitrified bonds. This makes a resinoid wheel ideal for high-speed grinding. You will find this bond in wheels used for:

- Cut-off Operations: Slicing through metal bars and pipes.

- Snagging and Rough Grinding: Removing excess material from castings.

- High-Speed Grinding: Smoothing weld beads under high pressure.

The flexibility of a resinoid wheel allows it to handle vibrations and impacts without shattering, making it perfect for portable grinding tools.

Metal (M) for Durability

You need a metal bond for the most durable and long-lasting grinding wheel. These bonds excel at holding superabrasives like diamond and CBN. This combination is essential for tough applications. Among the various metal grinding wheel types, these are used for grinding hard materials where form retention is critical. Common applications include:

- Glass and ceramic processing

- Tool cutting and forming

- Internal grinding operations

This bond provides the longest wheel life, especially in wet grinding conditions.

Electroplated (E) for Intricate Shapes

Electroplated bonds are unique. They consist of a single layer of abrasive, often diamond or CBN, attached to a pre-shaped steel core. This process allows for the creation of a wheel with very specific and intricate shapes for a custom application.

How it Works: The electroplating process bonds the abrasive directly to a precisely machined core. This means you can get a custom-designed wheel for unique grinding tasks.

Once the single abrasive layer wears out, the wheel cannot be re-dressed and must be replaced or sent for replating. This makes it best for specialized, high-precision grinding.

A Quick Guide to Choosing a Grinding Wheel

You can simplify the process of choosing a grinding wheel by following a systematic approach. This four-step guide helps you make the right decision for any surface grinding project. Following these steps for choosing a grinding wheel ensures you are matching the wheel to the task.

Step 1: Match Abrasive to Material

Your first step in choosing a grinding wheel is to consider your workpiece. The material you are grinding dictates the correct abrasive type.

- Steel and Ferrous Alloys: Use an Aluminum Oxide wheel.

- Non-Ferrous Metals (Aluminum, Copper): Choose a Silicon Carbide wheel.

- Hard Alloys and Carbides: Select a superabrasive like Diamond or CBN.

This initial choice is the most critical part of choosing a grinding wheel for successful grinding.

Step 2: Pick Grit for Your Goal

Next, you must decide on your primary grinding goal. This decision determines the grit size of your wheel. The grit you select directly impacts both speed and finish.

- Fast Stock Removal: Use a coarse grit (10-24).

- General Purpose Grinding: A medium grit (30-60) works well.

- Fine Finishing: Select a fine grit (70-220).

Choosing a grinding wheel with the right grit is essential for efficient work.

Step 3: Select Grade for Hardness

The third step in choosing a grinding wheel involves the wheel’s grade, or hardness. You should follow the “Golden Rule of Grinding” for this selection.

Remember: Use a soft grade wheel for hard materials and a hard grade wheel for soft materials. This rule helps the wheel self-sharpen correctly during the grinding process.

Step 4: Choose Structure and Bond

Finally, your application’s demands will guide your choice of structure and bond. This last part of choosing a grinding wheel refines your selection for optimal performance.

- Structure: Use an open structure for high stock removal and a dense structure for fine finishing.

- Bond: Choose a vitrified bond for precision grinding, a resinoid bond for high-speed grinding, or a metal bond for maximum durability with superabrasives. This completes your wheel selection for any surface grinding job.

Systematically evaluating the five key factors is the most reliable way to select the correct wheel. This comprehensive process helps you avoid bias and achieve superior results. Your material dictates the abrasive, while your desired finish and speed determine the grit, grade, and structure for the application.

For specialized applications or further assistance, Aimgrind offers customized solutions to help you Grind with Passion, Achieve with Aim.

FAQ

What are the most important safety precautions?

You must always wear proper personal protective equipment (PPE), including safety glasses. Inspect the wheel for damage before mounting it. Ensure the machine’s speed does not exceed the wheel’s maximum RPM. Following these safety precautions is essential for your safety.

How should I store my grinding wheels?

You should store wheels in a dry, protected area. Avoid extreme temperatures. Place them on a flat surface or in their original packaging to prevent warping or damage. Proper storage is a key part of overall workshop safety.

What is wheel “dressing” and why is it necessary?

Dressing is the process of cleaning or re-sharpening a wheel’s surface. You do this to remove clogged material (loading) or to restore its shape. It exposes fresh abrasive grains, which ensures the wheel cuts efficiently and safely.

Where can I learn more about specific grinding techniques?

You can find detailed guides on specific applications and best practices from manufacturers like Aimgrind. Following expert advice ensures you achieve the best results. Proper technique is just as important for safety as following basic safety precautions.

Contact Us

For More Grinding Solution or Customized Abrasive Tools