What are the best abrasives for aluminum? For most applications, your choices are clear and effective.

Quick Answer: Use a silicon carbide grinding wheel for heavy grinding on aluminum. For finishing aluminum, choose zirconia or ceramic flap discs.

These abrasives are designed to prevent “loading.” This is the main problem when grinding a soft metal like aluminum. This guide helps you select the best grinding wheel. You can achieve professional results safely and efficiently with the right tool.

Key Takeaways

- Use a silicon carbide grinding wheel for heavy aluminum removal. This wheel prevents clogging and cuts fast.

- Choose a ceramic flap disc for finishing aluminum. It keeps the surface cool and creates a smooth finish.

- Never use a grinding wheel on aluminum if it has touched steel. This prevents dangerous fires.

- Always use light pressure and special lubricants when grinding aluminum. This stops the wheel from loading up.

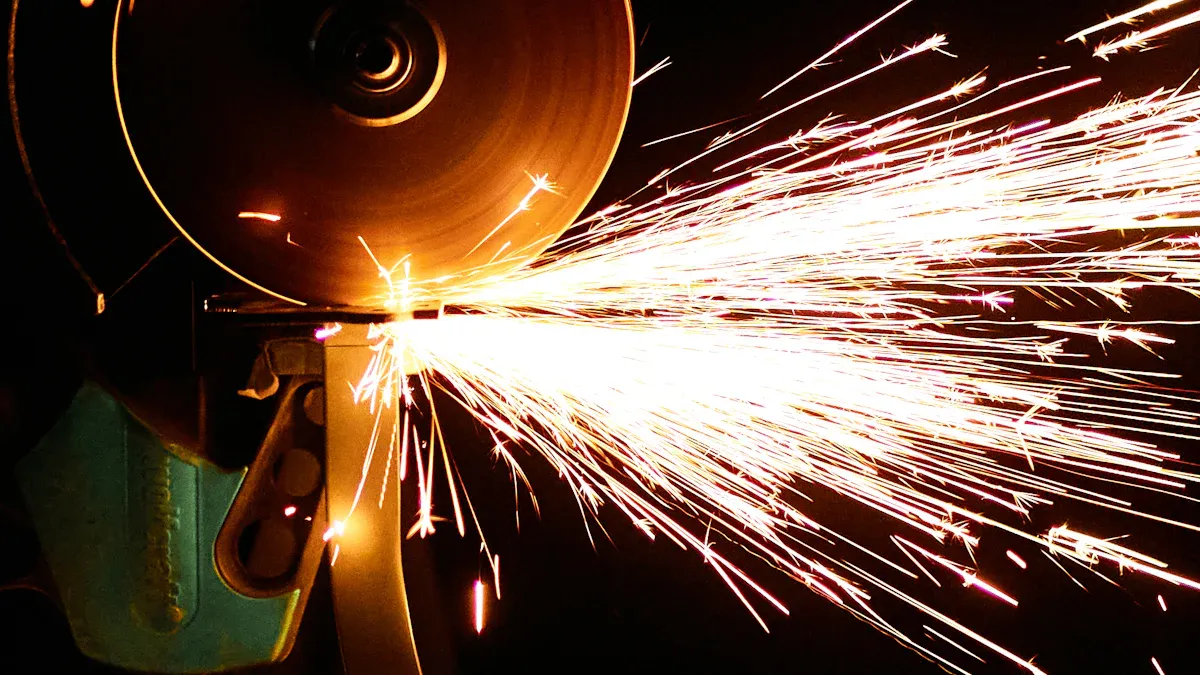

Why standard grinding wheels fail on aluminum

You might have a standard grinding wheel in your shop, likely made of aluminum oxide. These wheels work great on hard metals like steel. However, you will run into serious problems if you use one on aluminum. The unique properties of aluminum require a different approach.

The problem of wheel loading

The biggest issue is “wheel loading.” Aluminum is a soft metal with a low melting point. The friction from grinding creates intense heat. This heat melts the surface of the aluminum. The soft, gummy metal then gets smeared into the pores of the abrasive wheel.

Think of it like stepping on chewing gum. The gum fills the treads of your shoe, making it smooth and useless. In the same way, the melted aluminum clogs the grinding wheel. The abrasive grains get covered, and the wheel can no longer cut effectively. This loading happens very quickly when grinding aluminum with the wrong abrasive.

Performance issues and safety risks

A loaded wheel doesn’t just stop working; it becomes dangerous. Since it can no longer cut, the wheel just rubs against the aluminum. This action generates even more heat. This extreme heat can warp or damage your aluminum workpiece.

More importantly, a loaded wheel poses a major safety hazard.

⚠️ Safety Alert: A Loaded Wheel is a Dangerous Wheel

The clogged surface traps heat inside the wheel itself. This intense thermal stress can cause the wheel to crack, fracture, or even explode during operation, sending sharp fragments flying at high speed. Never use a standard wheel on aluminum.

The risks are significant:

- Excessive heat buildup damages the aluminum part.

- The wheel loses its cutting ability completely.

- There is a high risk of the wheel shattering and causing serious injury.

Top abrasive choices for your grinding wheel

Now that you understand the dangers of using the wrong wheel, let’s focus on the right tools for the job. You need an abrasive that can handle the unique properties of aluminum. The best abrasives for aluminum are designed to cut efficiently without loading.

Silicon carbide for heavy grinding

For heavy stock removal on aluminum, silicon carbide is your best choice. Unlike the aluminum oxide found in standard wheels, silicon carbide has a different structure. It is harder, sharper, and more friable, or brittle.

This friable nature is its greatest strength when working with aluminum.

How it works: When you grind, the pressure causes the silicon carbide grains to fracture and break away. This action constantly exposes new, razor-sharp cutting edges. The wheel essentially sharpens itself, preventing the soft aluminum from clogging its surface.

This self-sharpening process allows for aggressive and efficient material removal. Silicon carbide wheels cut fast on non-ferrous metals. While some wheels are rated for speeds up to 8,000 RPM, you must always follow the maximum RPM listed on your specific grinding wheel for safe operation. This ensures you get the performance you need without compromising safety.

Advanced option: Aimgrind diamond wheels

For most projects involving standard aluminum alloys, a silicon carbide wheel is perfect. However, you may face more demanding applications. Modern industries often use advanced materials like hard aluminum composites, such as Aluminum-Silicon Carbide (Al-SiCP). Grinding these materials requires a more specialized tool.

This is where a premium aluminum grinding wheel becomes necessary. For high-precision industrial jobs or work on tough composites, you should consider diamond grinding wheels. Aimgrind specializes in customized abrasive solutions for these exact challenges. Our high-quality abrasives deliver superior performance where it matters most.

An Aimgrind diamond grinding wheel offers several key advantages for specialized aluminum work:

- Exceptional Longevity: Diamond is the hardest material, meaning the wheel lasts much longer, reducing downtime.

- Ultimate Precision: These wheels maintain their shape, ensuring consistent accuracy for critical parts.

- Superior Performance: They provide efficient material removal on even the most difficult-to-grind aluminum composites.

When your project demands the highest level of accuracy and tool life, investing in a specialized diamond wheel ensures you achieve professional-grade results.

The best flap discs for aluminum finishing

After heavy grinding, you need the right tool for blending welds and creating a smooth, clean surface. For this finishing work, you should switch from a grinding wheel to a flap disc. The best flap discs for aluminum give you control and a superior finish, making them essential for professional results.

Why choose flap discs for aluminum?

A flap disc is made from overlapping pieces of abrasive cloth, or “flaps,” arranged in a fan-like pattern. This design is the key to its success on aluminum. It allows air to flow between the flaps, which makes the disc run much cooler than a solid grinding wheel. This lower temperature is vital because it prevents the aluminum surface from melting and clogging the abrasive.

When you use flap discs for aluminum, you get several powerful advantages. The benefits of using abrasive flap discs help you work faster and achieve a better surface.

- Cooler Grinding: The flap design significantly reduces heat. This protects your aluminum workpiece from discoloration and warping.

- Smoother Finish: A flap disc creates a finer, more consistent surface finish than a grinding wheel. This is perfect for smoothing surfaces and can reduce the need for extra polishing steps.

- Longer Tool Life: As the top layer of the flap wears down, a fresh layer of abrasive is exposed underneath. This self-renewing action means one flap disc lasts much longer than a traditional disc.

- Great Versatility: You can use the same flap disc for light grinding, blending, deburring, and finishing. By changing the angle of your grinder, you can control the aggressiveness of the cut.

Using a flap disc is a faster method for smoothing surfaces compared to finishing by hand. The unique construction of the flap disc gives you excellent control over the final surface.

Zirconia vs. ceramic grains

When you shop for flap discs for aluminum, you will mainly see two high-performance abrasive grains: zirconia and ceramic. Both are a major step up from standard aluminum oxide, but one has a clear advantage for aluminum.

Zirconia Alumina (Zirconia) is a tough and durable abrasive. It works well on steel because it requires high pressure to fracture the grains and expose new, sharp edges. However, this high pressure is not ideal for soft aluminum. Pushing too hard can dig into the surface and remove too much material, potentially gouging your workpiece.

Ceramic Alumina (Ceramic) is the top choice for aluminum. Ceramic grains are also very hard, but they are more friable. This means they fracture easily under lower pressure, constantly creating new, sharp cutting edges. This action gives you a faster rate of material removal with less heat buildup. The result is a quick, cool cut that leaves a beautiful surface.

Many premium flap discs for aluminum also include a special coating to improve performance.

These flap discs have a surface infused with a chemical grinding aid. The friction from grinding melts this coating, which lubricates the surface for an even cooler cut and helps prevent loading.

For maximum safety and performance, look for a quality flap disc built with a strong backing plate. These plates use multiple layers of high-tensile fiberglass mesh bonded together. A higher number of layers creates a more durable and stable flap disc, which is crucial for safe operation at high speeds. The number of layers often increases with the diameter of the disc to ensure stability.

Choosing a ceramic flap disc with a grinding aid and a strong fiberglass backer ensures you have the best tool for creating a perfect surface on your aluminum project.

How to select the right grinding wheels for aluminum

Choosing the right grinding tools for aluminum applications involves more than just picking the right abrasive. You also need to consider the grit size, wheel grade, and structure. Getting these three elements right ensures you can work efficiently and achieve a great surface finish on your aluminum workpiece.

Choosing the right abrasive material

As we covered earlier, silicon carbide is the best abrasive for grinding aluminum. Its particles are harder and sharper than standard aluminum oxide. This allows the abrasive to cut cleanly through the soft aluminum instead of smearing it. Silicon carbide is highly effective for low-tensile strength metals like aluminum. It helps you create an even surface while generating less heat, which is critical for preventing loading and damage to the aluminum surface.

A guide to grit size selection

Grit size determines how quickly you remove material and the quality of the final surface. The number refers to the size of the abrasive grains; a lower number means a coarser grit.

- Coarse (24-36 Grit): Use this for aggressive stock removal and shaping.

- Medium (40-80 Grit): This is your best choice for general-purpose work. It balances material removal with a decent surface finish. A 46-grit wheel is a popular and effective aluminum grinding wheel for many tasks. For removing weld beads on aluminum, a 60 or 80-grit disc works quickly and prepares the surface for a smoother finish.

- Fine (100+ Grit): Select a fine grit for finishing and creating a smooth surface.

The importance of wheel grade and structure

The grade of a grinding wheel tells you how strong its bond is. For a soft metal like aluminum, you need a softer wheel.

Pro Tip: Choose a soft grade wheel, typically in the G to L range. A soft bond breaks down easily. This action constantly exposes fresh, sharp abrasive grains and helps the wheel shed the aluminum particles before they can cause loading. This keeps your surface clean.

The wheel’s structure is also vital. You need an open structure wheel. This design provides more space between the abrasive grains. This extra space gives the aluminum chips a place to go, preventing them from clogging the wheel’s surface. An open structure helps the grinding wheel run cooler and cut more freely, giving you a better surface on your aluminum project.

Essential tips for grinding aluminum

Selecting the right wheel is only half the battle. Your technique is just as important for achieving a clean, professional finish on aluminum. Following these tips for getting the best results will help you work safely and efficiently.

Use light pressure and proper angles

Let the grinding wheel do the work. When grinding aluminum, you should always use light, consistent pressure. Applying too much force is a common mistake. It causes the soft aluminum to clog the wheel, a problem known as “loading.” This makes your wheel ineffective and can overheat your grinder.

Warning: Pushing too hard on the grinder can cause uneven material removal and may even damage your workpiece. It also leads to quicker wear on the grinding disc itself.

Maintain a proper grinding angle, typically between 15 and 30 degrees to the surface. This allows the abrasive to cut efficiently without digging in too deeply.

Apply lubricants and coolants

Heat is the enemy when working with aluminum. Using a lubricant is one of the best ways to manage it. For most jobs, a grinding wax stick is an excellent choice. Simply apply the wax directly to the spinning wheel or disc before you start grinding.

A quality lubricant offers several benefits:

- Eliminates heat buildup and prevents loading.

- Extends the life of your abrasive wheel.

- Provides a smoother, cooler cut.

In industrial settings, you might use a liquid coolant. Water-based coolants are highly effective for aluminum. Ensure the nozzle directs a steady flow of fluid onto the grinding area. This not only cools the workpiece but also flushes away chips for a cleaner grind.

Dedicate your wheels to aluminum only

Never use a grinding wheel on aluminum if it has been used on steel or other ferrous metals. This is a critical safety rule. Using a wheel on steel embeds tiny iron particles into the abrasive. When you then grind aluminum, the friction and heat can ignite these particles, causing a dangerous chemical reaction.

🔥 Fire Hazard: This reaction, known as an aluminothermic reaction, can create a ‘Class D’ fire with sparks reaching up to 4,500°F.

To prevent this, dedicate specific wheels and discs for aluminum only. Here are some simple tips for getting the best results with organization:

- Label Everything: Clearly mark your wheels with “ALUMINUM ONLY.”

- Color-Code: Use a specific color marker or tape for all your aluminum abrasives.

- Store Separately: Keep your aluminum wheels on a dedicated shelf or in a separate bin to avoid mix-ups.

This simple habit prevents cross-contamination and ensures a safe working environment.

You now have the knowledge to grind aluminum correctly. For the best results, match your tool to the task.

Quick Guide for Aluminum:

- Heavy Grinding: Use a silicon carbide grinding wheel.

- Finishing & Blending: Use the best flap discs for aluminum.

Always use light pressure and a soft-grade wheel to prevent loading. The unique flap design of a disc, where each flap, flap, flap, flap, flap, flap, flap, flap, flap, flap works to cool the surface, is ideal for heat-sensitive aluminum. For specialized aluminum projects, brands like Aimgrind offer custom solutions.

FAQ

What is the best wheel for heavy aluminum grinding?

You should use a silicon carbide grinding wheel. Its sharp grains cut cleanly through soft aluminum. This abrasive prevents the wheel from clogging. It is the best choice for fast, heavy material removal.

Can I use a standard steel grinding wheel on aluminum?

No, you must never use a wheel meant for steel on aluminum. The wheel will clog instantly with melted aluminum. This creates intense heat and a serious safety risk. The wheel could shatter during use.

What is the best tool for finishing aluminum?

You should choose a ceramic flap disc for finishing work. The flap design keeps the surface cool. This prevents warping and leaves a smooth, clean finish. It is perfect for blending welds and preparing surfaces.

Why do I need to dedicate wheels to aluminum only?

You must keep your aluminum wheels separate to prevent fires. 🔥 A wheel used on steel picks up iron particles. These particles can ignite when grinding aluminum, creating a dangerous reaction. Always label your wheels “ALUMINUM ONLY.”

Contact Us

For More Grinding Solution or Customized Abrasive Tools