Incorrect grinding wheel grit selection is a primary cause of poor surface finish. This choice creates significant surface roughness issues. A grit that is too coarse produces deep scratches. A very fine one leads to heat damage from rubbing. Successful grinding demands a proper diagnosis of these issues. This ensures the operator selects the correct grinding wheel for the job.

Key Takeaways

- Using a grinding wheel with grit that is too coarse creates deep scratches on metal surfaces.

- A grinding wheel with grit that is too fine causes too much heat and can burn the surface.

- The right grit size depends on the desired smoothness, the material type, and the grinding step.

- Always choose the coarsest grit that still gives the needed smooth finish to work best.

How Coarse Grits Cause Surface Roughness Issues

Using a grinding wheel with a grit that is too coarse is a direct path to significant surface roughness issues. While coarse grits excel at rapid material removal, their aggressive nature often compromises the final quality of the workpiece. This section explores the common grinding problems that arise from this specific selection error.

Deep Scratches and High Ra Values

A coarse grinding wheel creates deep scratches on a metal surface. The abrasive particles on the wheel function like miniature cutting tools. During the grinding operation, these particles aggressively engage the workpiece. They remove material by creating chips and causing substantial surface deformation. This action leaves behind deep grooves and a visibly rough texture.

These deep scratches directly result in a high Roughness average (Ra) value. An elevated Ra value indicates a poor surface finish, which is unacceptable for precision components. The primary goal of a finishing grinding pass is to reduce these imperfections, not create them.

Note: The aggressive cutting process of a coarse wheel is designed to remove large imperfections. However, this same action introduces new, deep scratches that a subsequent finishing pass must then remove.

Poor Dimensional Accuracy

Poor dimensional accuracy is another consequence of using an overly coarse grit for finishing operations. The aggressive nature of the grinding leads to a high material removal rate that is difficult to control with precision. This can cause several issues:

- Overshooting Tolerances: Operators may remove too much material too quickly. This makes it challenging to hold tight dimensional tolerances.

- Inconsistent Dimensions: The aggressive grinding can result in uneven material removal across the part’s surface.

- Increased Scrap Rate: Parts that fall outside of specified dimensions must be reworked or scrapped, increasing costs and reducing efficiency.

Ultimately, selecting the wrong wheel creates surface roughness issues and undermines the entire grinding operation’s precision.

Problems in Fine Grit Grinding

While a fine grit seems like the logical choice for a smooth finish, selecting a grit that is too fine can introduce a different set of serious grinding problems. Instead of cutting, the tiny abrasive particles begin to rub against the workpiece. This rubbing action generates excessive heat and friction, leading to several types of surface damage.

Surface Burn and Thermal Damage

Excessive heat from fine grit grinding is a primary cause of surface burn and thermal damage. High temperatures alter the workpiece’s surface metallurgy. This is especially true when combined with excessive pressure or inadequate coolant. These changes can severely compromise the part’s integrity. Key thermal defects include:

- Thermal Softening: The surface hardness reduces if grinding temperatures surpass the material’s tempering temperature.

- Re-hardening Burn: Extreme heat can create a brittle, re-hardened martensitic layer on the surface. This layer is prone to cracking.

- Residual Tensile Stress: High thermal stress can introduce residual tensile stress, which reduces the fatigue life of the component.

These issues create significant surface roughness issues and weaken the part from the outside in.

Wheel Loading and Glazing

Two common grinding problems with fine grits are wheel loading and glazing.

- Loading occurs when particles from the workpiece, especially soft materials like aluminum, clog the spaces between the abrasive grains. A loaded grinding wheel stops cutting effectively.

- Glazing happens when the cutting points of the abrasive grains become dull and smooth. The grinding wheel surface takes on a glassy appearance and loses its cutting ability.

Both conditions increase friction and heat. Operators can prevent loading by using open-coat abrasives or implementing wet grinding techniques. When a wheel becomes loaded or glazed, it must be dressed to expose fresh, sharp abrasives.

Chatter Marks and Poor Surface Finish

A glazed or loaded grinding wheel often leads to vibration during grinding. This vibration creates a distinct wave-like pattern on the workpiece known as chatter marks, resulting in a poor surface finish. The wheel’s inability to cut cleanly causes it to bounce or skip along the surface. While a fine grit can contribute to chatter, other factors can also be the cause, including:

- An unbalanced or excessively hard contact roll

- Worn machine bearings

- Incorrect belt tension or feed rate

- Machine vibrations from improper anchoring

Identifying the root cause is essential for eliminating chatter and achieving the desired surface quality.

Selecting the Right Grinding Wheel Grit

Choosing the correct grit is the most critical step in preventing surface roughness issues. Proper wheel selection balances material removal rates with the desired surface finish. This decision depends on the final part requirements, the workpiece material, and the specific grinding operation. A systematic approach ensures high-quality results and efficient production.

Matching Grit to Finish (Ra)

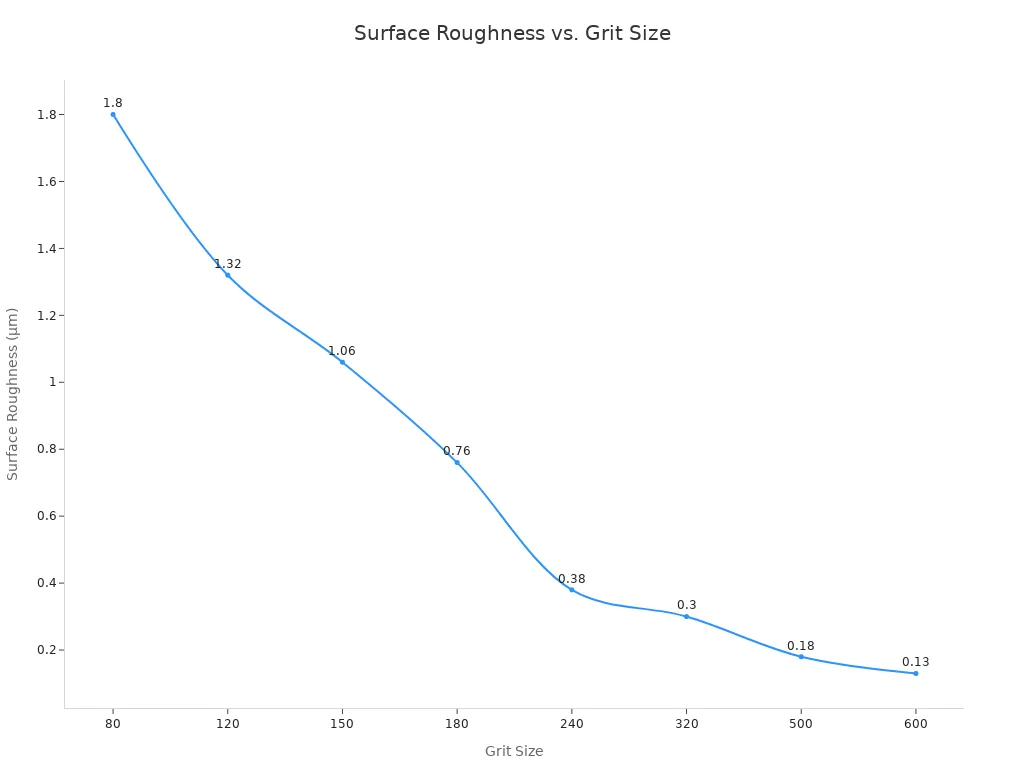

The grit size of a grinding wheel directly determines the final surface finish, measured in Roughness average (Ra). A lower Ra value signifies a smoother surface. Coarser grits have larger abrasive particles and leave deeper scratches, resulting in a higher Ra. Finer grits have smaller particles that create a smoother finish and a lower Ra.

Operators should select a grit size that aligns with the target Ra value specified in the engineering drawing. The following chart provides a general guide for matching grit size to the expected surface finish.

| Grinding Category | Grit Size Range (FEPA) | Target Ra Range (µm) |

|---|---|---|

| Rough Grinding | F36 – F60 | > 1.8 |

| Medium Grinding | F80 – F120 | 0.8 – 1.8 |

| Fine Finishing | F150 – F240 | 0.4 – 0.8 |

| Super Finishing | F320 – F600+ | < 0.4 |

Pro Tip: Always start with the coarsest grit that can achieve the required Ra value. This approach maximizes efficiency without sacrificing part quality. For example, achieving an Ra of 0.8 µm on hardened steel often requires a grit of F240 or finer.

Considering Material Type

The workpiece material significantly influences the ideal grit size. Material properties like hardness and ductility dictate how the abrasive will interact with the surface. Proper material compatibility is key to avoiding defects.

- Soft, Ductile Materials: Materials like aluminum and copper tend to load the grinding wheel. A coarser grit (F36-F60) provides more space between abrasive grains. This clearance helps prevent clogging and allows for efficient material removal.

- Hard, Brittle Materials: Hardened tool steels, ceramics, and carbides require a finer grit (F80 and higher). The smaller abrasive particles take smaller chips from the material. This action minimizes the risk of chipping, micro-cracks, and subsurface damage, ensuring a clean and precise finish.

For a wide range of applications, a reliable and cost-effective solution is essential. Aimgrind‘s conventional bonded abrasives offer excellent performance across various materials. With nearly two decades of experience, Aimgrind’s experts help customers with wheel selection. They ensure the perfect grit from their product line matches specific material and finish requirements, guaranteeing optimal grinding results.

Differentiating Roughing vs. Finishing

Grinding operations are often divided into two main stages: roughing and finishing. Each stage has a distinct objective that requires a different grit size. Understanding this difference is fundamental to an effective grinding process.

Roughing is the first stage. Its primary goal is to remove a large amount of material quickly. Precision and surface finish are secondary concerns.

Finishing is the final stage. Its goal is to achieve the final dimensions, tolerances, and required surface finish. Material removal is minimal.

| Feature | Rough Grinding | Finish Grinding |

|---|---|---|

| Primary Goal | High material removal rate | Smooth surface finish |

| Grit Size | Coarse (e.g., F36-F80) | Fine (e.g., F120-F600+) |

| Surface Finish | Rough (High Ra) | Smooth (Low Ra) |

| Tolerances | Loose | Tight |

Selecting the right grit for each stage optimizes the entire grinding workflow. It reduces cycle times, minimizes wheel wear, and consistently produces parts that meet specifications.

Incorrect grit selection creates significant grinding problems. Coarse grits leave deep scratches, while overly fine grits cause thermal damage and loading. Operators prevent these surface roughness issues by considering three key factors. They must evaluate the target surface finish (Ra), workpiece material, and the specific grinding operation.

A proactive review of the grinding process prevents defects. It improves part quality and avoids suboptimal results, ultimately reducing scrap.

FAQ

How often should an operator dress a grinding wheel?

Operators should dress a wheel when it shows signs of loading or glazing. This action restores its cutting ability. Regular grinding wheel maintenance ensures consistent performance and prevents surface defects. The frequency depends on the material and the intensity of the grinding operation.

Can grinding speed affect surface finish?

Yes, wheel speed significantly impacts surface finish. Higher speeds generally produce a smoother finish because the abrasive grains take smaller cuts. However, excessive speed can increase heat and cause thermal damage. Operators must balance speed with other grinding parameters for optimal results.

What is the difference between open-coat and closed-coat abrasives?

Open-coat abrasives have more space between the grains. This design helps prevent clogging when working with soft materials. Closed-coat abrasives have full grain coverage for a finer finish on hard materials. The choice depends on the material and application.

Should I always use the finest grit for the best finish?

No, an overly fine grit can cause rubbing instead of cutting. This action generates excessive heat, leading to surface burn and chatter marks.

Tip: Select the coarsest grit that can still achieve the required Ra value. This approach improves efficiency and avoids heat-related defects.

Contact Us

For More Grinding Solution or Customized Abrasive Tools