High-speed grinding is growing fast in industries like automotive and aerospace. You must master five key grinding wheel characteristics for success. Your success in any grinding application depends on understanding these five points.

The 5 Keys to High-Speed Grinding:

- Abrasive Type

- Grain Size

- Bond Type

- Grade

- Structure

Understanding these grinding wheel characteristics helps you choose the perfect grinding wheel. This guide gives you practical steps to select the right grinding tool. A proper abrasive choice boosts productivity and delivers superior results for your specific grinding tool.

Key Takeaways

- You must understand five key things about grinding wheels. These are the abrasive type, grain size, bond type, grade, and structure. They help you choose the right wheel for your job.

- Always pick the right abrasive for your material. Use CBN for hard metals and diamond for very hard non-metals. Use aluminum oxide for tough metals and silicon carbide for brittle materials.

- Match the grain size to your goal. Use coarse grains for fast material removal. Use fine grains for a smooth finish. The bond, grade, and structure also help the wheel work best.

- Always check the grinding wheel’s speed limit. Never run it faster than its maximum speed. This keeps you safe. Use reinforced wheels for tough jobs or when you hold the grinder by hand.

Understanding Grinding Wheel Characteristics

Choosing the right type of abrasive is your first step toward better grinding performance. The abrasive is the cutting material in your grinding wheel. Each abrasive type has unique properties. Your choice of abrasive directly impacts cutting efficiency and the final finish on your workpiece. These grinding wheel characteristics determine the tool’s overall performance.

Superabrasives: CBN and Diamond

You should use a superabrasive for grinding extremely hard materials. This category includes Cubic Boron Nitride (CBN) and diamond.

- CBN (Cubic Boron Nitride): This abrasive is your best choice for grinding hard ferrous metals like hardened steel. CBN has excellent thermal stability. It does not react chemically with the iron in the metal at high temperatures. This allows for faster, cooler cutting and extends the life of your grinding tool.

- Diamond: As the hardest known material, diamond excels at grinding hard, non-ferrous materials. Use a diamond abrasive for materials like carbide, ceramics, composites, and glass. The right diamond grinding wheel delivers superior precision and performance.

Pro Tip: For a perfect match, specialized suppliers like Aimgrind offer customized diamond grinding wheels. Their formula design service ensures your grinding tool is optimized for your specific material and application, boosting efficiency.

Conventional Abrasives: Aluminum Oxide and Silicon Carbide

Conventional abrasives are excellent for general-purpose grinding on a wide range of materials. Your two main options are aluminum oxide and silicon carbide.

- Aluminum Oxide: This is a tough and durable abrasive. You can use it for grinding high-tensile materials like stainless steel and other high-strength metal alloys. It offers a great combination of cutting speed and grinding tool life. Its versatility makes it a popular abrasive for many metal grinding tasks.

- Silicon Carbide: This abrasive is harder than aluminum oxide but also more brittle. Its sharp cutting action makes it ideal for grinding hard, brittle materials. Use this abrasive for grinding cast iron, aluminum, copper, and other soft non-ferrous metal. It provides fast cutting for these applications. The right abrasive is key for precision grinding.

Determining Optimal Grain Size (Grit)

After selecting your abrasive, you must determine the optimal grain size, also known as grit. The grit size of an abrasive refers to the size of the individual cutting particles on your grinding wheel. This choice directly controls your material removal rates and the final finish on your workpiece. A lower grit number means a larger, more aggressive abrasive particle. A higher grit number indicates a smaller, finer abrasive particle.

Coarse Grains for High Material Removal

You should choose a coarse grit abrasive when your main goal is rapid stock removal. These larger abrasive particles create deeper scratches for faster cutting.

- Heavy Grinding: Use coarse grits (like 24 to 36) for heavy grinding jobs. This includes grinding welds or preparing surfaces for welding.

- Large Contact Area: A coarse grit is also effective when your grinding tool has a large contact area with the workpiece.

The aggressive cutting action of a coarse abrasive makes this type of grinding tool perfect for shaping and roughing operations where finish is not the primary concern.

Fine Grains for Precision Finishing

You need a fine grit abrasive for applications that demand precision and a high-quality finish. The smaller abrasive particles take smaller bites, resulting in a smoother surface finish. This type of grinding is essential for final passes.

Did You Know?

The final finish is measured in Ra (Roughness average). When grinding hardened steel, you can achieve an Ra value below 0.2 µm. With multi-stage grinding using progressively finer wheels, you can even reach an Ra as low as 0.05 µm.

Processes like cylindrical and surface grinding often use a fine grit grinding tool to achieve a superior finish. The right grit size is crucial for your cutting and finishing goals. A fine abrasive ensures your grinding produces a part that meets exact specifications. Your choice of abrasive grit size is a key step in successful grinding.

Selecting the Perfect Grinding Tool: Bond, Grade, and Structure

You have chosen your abrasive and grit size. Now, you must master three more grinding wheel characteristics: bond, grade, and structure. These elements work together to control your grinding tool’s cutting action, lifespan, and overall performance. Making the right choices here is key to selecting the perfect grinding tool for high-speed work.

Matching Bond Type to Application Speed

The bond is the adhesive that holds the abrasive grains together in a grinding wheel. The bond’s strength is critical. It must hold the grains long enough for effective cutting but release them once they become dull. Your choice of bond type directly impacts the wheel’s suitability for your application speed and material.

There are three primary bond types you will encounter:

Vitrified Bonds: You should consider a vitrified (glass-like) bond for most precision grinding tasks. Its rigidity and strength securely hold abrasive grains, which is essential for maintaining the accurate shape of your workpiece. The natural porosity of this bond creates tiny pockets for chip clearance and coolant flow. This design reduces heat buildup, making vitrified bonds a top choice for high-speed precision grinding.

Technology Spotlight: Advanced bonds like the Norton Vitrium3 are engineered for high-strength, high-speed operation. This technology uses less bond material, which increases porosity. The result is a grinding tool that cuts cooler, consumes less power, and holds its form exceptionally well, boosting both efficiency and part quality.

Organic Bonds (Resin): You should use a resin bond when your grinding operation involves high stress or vibration. This bond offers more flexibility than a vitrified bond. It excels in heavy stock removal, cutting-off applications, and the precision grinding of ultra-hard materials like diamond and hard ceramics. Grinding wheels with organic bonds are often designed for speeds between 6,500 and 9,500 Surface Feet Per Minute (SFPM).

Metal Bonds: You need a metal bond for applications that demand extreme durability and form-holding. This is the toughest bond type. It offers excellent wear resistance, making it perfect for grinding jobs where maintaining the wheel’s profile is critical. A metal-bonded grinding tool provides a long service life in demanding cutting environments.

Selecting the Right Grinding Wheel Grade

The grade of a grinding wheel indicates the hardness of its bond. It does not refer to the hardness of the abrasive grains. The grade, typically noted by a letter from A (soft) to Z (hard), determines how tightly the bond holds onto the abrasive particles.

A simple rule helps guide your selection:

- Use a soft grade for hard materials.

- Use a hard grade for soft materials.

This might seem backward, but the logic is sound. When grinding hard materials like tool steel, a soft grade wheel allows dull abrasive grains to break away. This exposes fresh, sharp cutting points and maintains a high cutting rate. Conversely, a hard grade grinding tool holds onto its abrasives longer, which extends wheel life when grinding soft, easy-to-cut materials.

| When to Use a Soft Grade Grinding Wheel | When to Use a Hard Grade Grinding Wheel |

|---|---|

| Grinding hard, brittle materials (tool steels, carbides) | Grinding soft, ductile materials (mild steel, aluminum) |

| Jobs with a large area of contact | Jobs with a small or narrow area of contact |

| You need rapid stock removal | You need a longer wheel life |

| Your machine has lower horsepower | Your machine has higher horsepower |

Choosing the correct grade prevents your grinding wheel from acting too hard (glazing) or too soft (wearing out quickly), ensuring optimal cutting.

Specifying Wheel Structure for Chip Clearance

The structure of a grinding wheel refers to the spacing between the abrasive grains. This is identified by a number, typically from 1 (dense) to 16 (open). The structure number tells you how much space is available for chips and coolant within the grinding tool.

Dense Structure (Low Numbers): A dense structure has minimal space between grains. You should choose this for applications requiring a fine finish and precise form-holding. The higher concentration of cutting points produces a very smooth surface.

Open Structure (High Numbers): An open structure has significant space between grains. This design is essential for high-speed grinding and high material removal rates. The extra space provides excellent chip clearance, which prevents the grinding wheel from clogging, or “loading.”

Why Open Structure Matters in High-Speed Grinding:

An open structure allows coolant to flow freely into the cutting zone, which drastically reduces heat. This cooler grinding action minimizes the risk of burning the workpiece. It also lowers grinding forces, reduces wheel wear, and allows for deeper, more aggressive cutting. For soft materials like aluminum that tend to load a wheel quickly, an open structure is a necessity for continuous performance.

By carefully balancing bond, grade, and structure, you can customize your grinding wheels for any high-speed application, achieving superior results every time.

Safety First: Speed Ratings and Reinforcement

You have learned about the performance characteristics of a grinding wheel. Now, you must focus on the most important factor: safety. Proper selection and use of your grinding tool are essential for safe, successful grinding.

Verifying Your Grinding Tool’s Speed Rating (MOS)

You must never operate a grinding wheel faster than its Maximum Operating Speed (MOS). Exceeding the MOS can cause the wheel to shatter. Fragments can fly off at nearly half the speed of a bullet, creating a serious danger.

Always check the MOS before you start any grinding job.

- Find the speed marked on the grinding wheel or its packaging. This is often listed as a maximum velocity (V/Max) in meters per second.

- Compare this speed to your grinder’s RPM.

- Ensure your machine’s speed is at or below the MOS of the grinding tool.

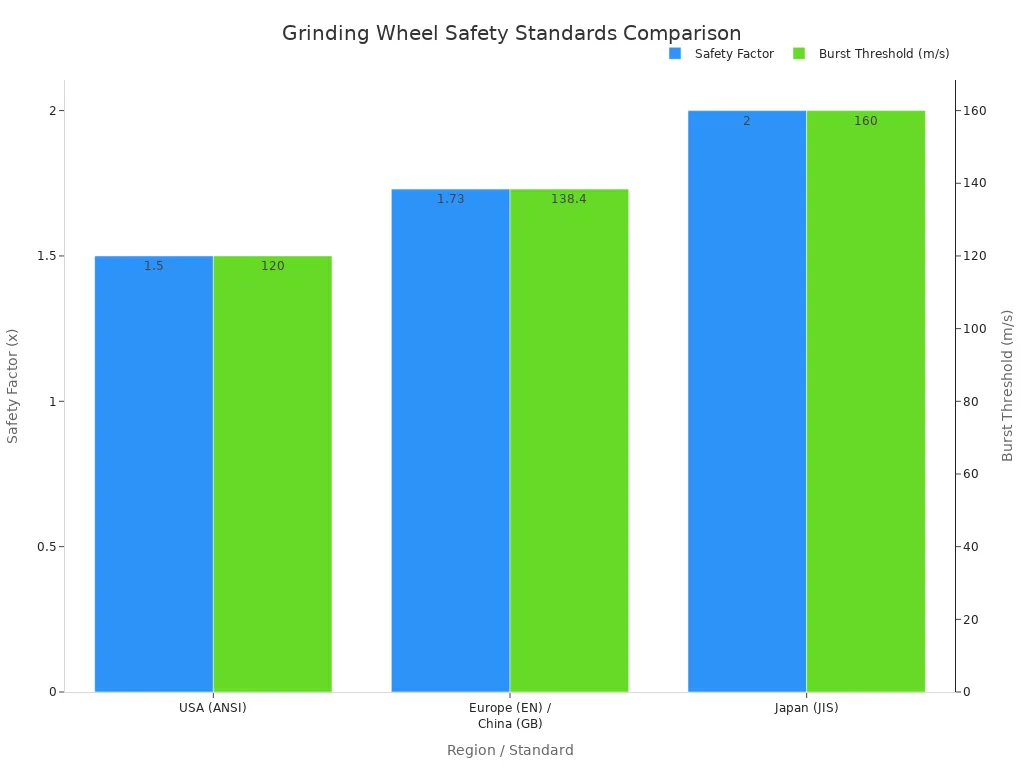

Safety standards govern these ratings. In the United States, the rules are based on the ANSI B7.1 standard. Different regions have different safety requirements.

Global Safety Standards at a Glance:

Japan’s JIS standard is the strictest, requiring a grinding tool to withstand twice its marked speed. Europe (EN) and China (GB) require a 1.73x safety factor, while the USA (ANSI) sets the factor at 1.5x.

Reinforced Grinding Wheels for High-Stress Operations

For high-stress jobs, you should use a reinforced grinding tool. These wheels contain layers of high-strength fiberglass mesh. This reinforcement adds structural integrity without slowing down the cutting speed. The added support helps prevent the wheel from breaking during tough grinding and cutting tasks.

This design is ideal for high-speed grinding operations. It reduces vibration and controls kickback, making your work safer and more stable. Manufacturers offer different levels of reinforcement.

- Single Reinforcement: Good for high-speed cutting and reducing burrs.

- Double & Triple Reinforcement: Designed for heavy-duty industrial grinding where vibration is high.

Safety Mandate! ⚠️

You must use reinforced grinding wheels for any operation where the grinder is hand-guided (portable) or when your workpiece is not securely clamped.

You now have a guide to the five critical grinding wheel characteristics. Use this checklist for your next high-speed grinding application:

- Abrasive

- Grain Size

- Bond Type

- Grade

- Structure

Always verify your grinding tool’s speed rating before you begin. Safety is your top priority. Choosing the right abrasive and grinding wheel boosts productivity and efficiency. For customized solutions that match your needs, consult with experts like Aimgrind.

Grind with Passion, Achieve with Aim.

FAQ

What is the most important safety check before grinding?

You must always verify the wheel’s Maximum Operating Speed (MOS). Check that your grinder’s RPM is at or below the speed marked on the wheel. Exceeding the MOS is extremely dangerous and can cause the wheel to break apart during operation.

How do I choose between a diamond and a CBN wheel?

You should choose based on the material you are grinding. Use a diamond wheel for hard, non-ferrous materials like carbide, ceramics, and glass. Select a CBN wheel for grinding hard ferrous metals, such as tool steels and hardened alloys.

Why is my grinding wheel wearing out so fast?

Your wheel’s grade might be too soft for the job. However, this can be intentional. When grinding very hard materials, you need a soft grade wheel. It breaks down to expose fresh, sharp abrasive grains, which maintains a high cutting efficiency.

Can I get a grinding wheel made for my specific job?

Yes, you can get a custom grinding wheel. Specialized suppliers like Aimgrind can design a wheel formula for your exact material, machine, and application. This ensures you achieve the best possible performance, efficiency, and surface finish for your project.

Contact Us

For More Grinding Solution or Customized Abrasive Tools