You must select the correct grinding wheel for brittle materials to prevent fractures. Superabrasive grinding wheels are your best option for this task. A diamond grinding wheel is the top choice for these delicate materials. Successful grinding depends on understanding a few key elements.

Key Selection Factors:

- Abrasive Type: The superabrasive material, like diamond.

- Bond Material: The substance holding the abrasives.

- Grit Size: The coarseness of the abrasive particles.

Properly matching these factors protects valuable materials and optimizes your grinding process with the right superabrasive wheels.

Key Takeaways

- Use special grinding wheels for brittle materials to stop them from breaking.

- Diamond is the best material for grinding hard, brittle things like ceramics and glass.

- The bond holds the grinding wheel together; metal, vitrified, and resin bonds work differently.

- Grit size changes how smooth the surface becomes; smaller grit makes it smoother.

- Always use coolant when grinding to keep materials from cracking due to heat.

Understanding the Grinding Wheel for Brittle Materials

Key Grinding Wheel Components

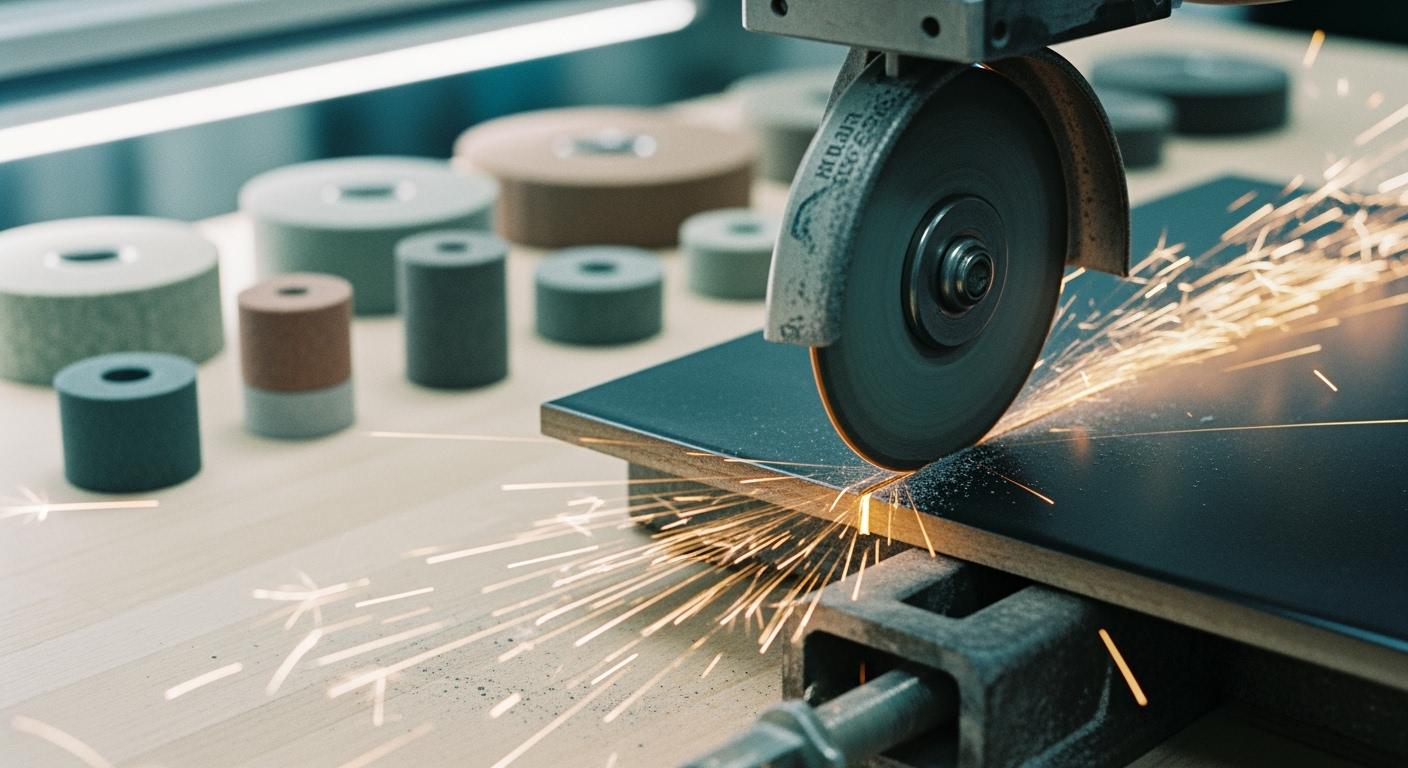

Grinding brittle materials presents a unique challenge. These materials do not bend or deform under pressure. Instead, they crack and fracture. The grinding process removes material by creating a series of micro-fractures. This can lead to subsurface damage and a rough finish if you use the wrong tool. A proper grinding wheel for brittle materials controls this process. Your choice of components—abrasive, bond, and grit—directly impacts the final quality.

Abrasive Types: Diamond and cBN

Superabrasives are necessary for the effective grinding of hard materials. The two primary superabrasives are diamond and cubic boron nitride (cBN).

- Diamond: With a Knoop hardness of over 70,000 N/mm², diamond is the hardest known material. It is the ideal choice for grinding non-ferrous brittle materials like ceramics, tungsten carbide, and glass. However, diamond can react with iron at high temperatures, making it less suitable for steel.

- CBN: As the second-hardest material, cBN has superior thermal stability. It remains hard at temperatures above 800°C, where diamond begins to degrade. This makes cBN perfect for grinding hardened ferrous metals.

For most brittle materials, diamond and cbn wheels offer the best solutions, but diamond is often the top choice. Choosing between these superabrasive wheels depends entirely on the material you are grinding.

Bond Materials: Vitrified, Resin, and Metal

The bond holds the superabrasive particles in the grinding wheel. Each type offers a different performance.

Bond Types at a Glance:

- Metal Bond: Offers the longest wheel life and excellent durability. It is ideal for high-volume grinding operations where maintaining the wheel’s shape is critical.

- Vitrified Bond: Provides high precision and porosity. This allows coolant to flow effectively, reducing heat during grinding and preventing thermal damage.

- Resin Bond: A softer bond that allows for a fast cutting action. It is less resistant to heat, which can shorten the life of the grinding wheel.

Grit Size and Concentration

Grit size and concentration fine-tune your grinding wheel’s behavior.

- Grit Size: This refers to the size of the abrasive particles. The number is inversely related to the finish; a higher number (e.g., 400 grit) means finer particles and a smoother surface. A lower number (e.g., 80 grit) means coarse particles for rapid material removal.

- Concentration: This defines the amount of superabrasive in the bond. A higher concentration means more cutting points, which can improve grinding efficiency.

Selecting the right combination of these elements is the key to success with any grinding wheel for brittle materials.

Matching the Wheel to the Material

Selecting the right wheel means pairing its components with the specific brittle material you are grinding. Different materials have unique properties. Your choice of abrasive, bond, and grit size will determine the success of your operation. This section guides you through matching a grinding wheel to four common brittle materials.

Grinding Advanced Ceramics

Advanced ceramics like Alumina and Zirconia are extremely hard and wear-resistant. You need a robust tool for effective grinding. Diamond wheels are the best choice for this job. Specialized wheels with advanced bond technologies can reduce grinding forces by up to 30% and increase tool life significantly. For these demanding applications, you need a customized solution. Experts like Aimgrind provide tailored diamond grinding wheels designed specifically for hard and brittle materials.

When grinding ceramics, you must control the parameters carefully to avoid damage.

Recommended Grinding Parameters for Ceramics

| Parameter | Value |

| :— | :— |

| Spindle/Wheel Speed | 20–35 m/s |

| Feed Rate | 0.01–0.05 mm/pass |

| Depth of Cut | 0.02–0.5 mm |

| Coolant | Water-based |

You should use a coarse-grit wheel for initial material removal. Then, switch to a fine-grit wheel for finishing. This two-step process helps you achieve a very smooth surface. With the right diamond wheel, you can achieve a surface roughness (Ra) as low as 0.1 μm on ceramics.

Grinding Glass and Quartz

Glass and quartz are highly susceptible to thermal shock and cracking. Your grinding process must be precise and gentle. Metal bond diamond wheels are an excellent choice for grinding glass. They offer high abrasion resistance and a long service life. This is especially true for optical components like lenses and prisms, where sintered metal-bonded wheels provide superior performance and consistency.

Grit size selection is critical for your desired finish.

- Rough Grinding: Use a coarse grit for rapid shaping.

- Fine Finishing: Use finer grits (170–325 mesh) for a smooth, polished surface.

💡 Pro Tip: Use Coolant Correctly

You must use coolant to prevent thermal shock when grinding glass. Apply a generous amount of flood coolant, like a synthetic fluid mixed with water. This keeps the temperature stable and washes away debris. Avoid random splashes of coolant, which can cause micro-cracks.

Brands like Aimgrind offer a variety of bond types, including resin, metal, and vitrified options. This allows you to find the perfect grinding wheel for your specific glass or quartz application, ensuring optimal grinding performance.

Grinding Silicon Wafers

The electronics industry relies on perfectly smooth silicon wafers. The backgrinding process thins these wafers to their final thickness. This step is delicate. Any subsurface damage can ruin the component. The right grinding wheel is essential to prevent wafer breakage.

For this task, you should choose a resin-bonded diamond wheel. The flexibility of a resin bond helps absorb grinding forces. This reduces the risk of subsurface damage. You should also use a wheel with finer diamond grains. The depth of damage in silicon increases with larger abrasive particles. A fine-grit, resin-bond grinding wheel gives you a smooth finish while protecting the wafer’s integrity. This careful approach to grinding ensures high-quality results for sensitive electronic materials.

Grinding Tungsten Carbide

Tungsten carbide is a very hard composite material. It is widely used for cutting tools and wear-resistant parts. You need the hardest abrasive available for grinding it effectively. Diamond is the clear winner for this job. A diamond grinding wheel cuts through tungsten carbide with ease.

You might wonder why not cBN. The answer lies in chemistry.

- Diamond: It is the hardest known material. It excels at grinding non-ferrous materials like tungsten carbide.

- cBN: It is ideal for ferrous metals (containing iron). Diamond reacts chemically with iron at high temperatures, causing it to degrade.

Since tungsten carbide contains no iron, diamond maintains its superior hardness without any chemical breakdown. This makes it the most efficient and effective superabrasive for all your tungsten carbide grinding needs. Choosing the right grinding wheel for brittle materials ensures you get the best results every time.

Common Grinding Wheel Applications

Understanding the different grinding wheel applications helps you choose the right tool for the job. Your choice of grinding wheel directly impacts the quality of your finished product. Let’s explore three common grinding wheel applications for brittle materials.

Surface Grinding for Flatness

You use surface grinding to create perfectly flat and smooth surfaces. This process is vital in industries where precision is non-negotiable. A proper grinding wheel ensures you achieve tight tolerances without causing damage. This type of grinding is one of the most critical grinding wheel applications.

Many high-tech industries rely on surface grinding for brittle components:

- Aerospace: You can produce parts like ceramic turbine blades and structural panels that need exceptional surface finishes to perform under extreme stress.

- Medical: You can manufacture precise medical implants, such as joint replacements and dental prosthetics, where biocompatibility and a perfect fit are essential for patient safety.

Cylindrical Grinding (OD/ID)

Cylindrical grinding shapes the outside diameter (OD) or inside diameter (ID) of a workpiece. This process requires extreme precision to maintain roundness and concentricity. When working with brittle materials, you must prevent clamping forces from deforming the part.

Keys to Successful Cylindrical Grinding

To achieve the best results, you need a stable process. This includes using a rigid machine, a well-balanced grinding wheel, and proper workpiece alignment. Any flaw in your setup can lead to errors in the final part. This is one of the most demanding grinding wheel applications.

Cutting and Dicing Operations

Cutting and dicing are essential grinding wheel applications, especially in electronics. You use ultra-thin diamond blades to slice materials like silicon wafers and ceramic substrates into individual components. The goal is to make clean cuts with minimal material loss or chipping. For delicate materials, a resin bond blade offers good elasticity, which absorbs vibration during high speed grinding. This reduces stress on the workpiece. A softer bond on your grinding wheel can improve cut quality, but it may also wear faster. This grinding process is key to modern manufacturing.

Your success in grinding brittle materials depends on a smart choice. You must match the superabrasive, bond, and grit to your specific materials and grinding application. A proper grinding wheel for brittle materials, like a specialized diamond wheel, is key. Choosing the right grinding wheel from experts like Aimgrind boosts your grinding performance. This selection improves efficiency, enhances surface finish, and prevents costly material waste. For your next grinding project, consult an expert to find the perfect customized diamond grinding wheel. This ensures your grinding process protects valuable materials.

FAQ

What is the most important factor for grinding brittle materials?

You must control the grinding forces. Brittle materials crack easily under pressure. Your grinding wheel choice directly impacts these forces. A proper wheel ensures a smooth grinding process without causing fractures, protecting your valuable material from damage.

Can I use one wheel for all my grinding needs?

No, you should not use one wheel for every task. Different materials and grinding operations require specific wheels. A wheel for rough grinding is very different from one used for finish grinding. Matching the wheel to the job ensures the best results.

Why is coolant so important during the grinding process?

Coolant manages the intense heat generated during grinding. For brittle materials, this heat can cause thermal shock and cracks. Proper coolant use is essential for a successful grinding operation, as it prevents damage and clears away debris.

How do I improve my surface finish when grinding?

You can improve your finish by using a multi-step grinding process. Start with a coarse-grit wheel for material removal. Then, switch to a fine-grit wheel for the final grinding passes. This method gives you a much smoother and more precise surface.

What makes diamond wheels good for grinding hard materials?

Diamond is the hardest material, making it extremely efficient for grinding. It cuts through hard materials like ceramics with less effort. This efficiency reduces grinding time and produces a superior finish, making diamond the top choice for demanding grinding jobs.

Contact Us

For More Grinding Solution or Customized Abrasive Tools