Most grinding wheel breakage results from critical operational errors. Operators create many grinding problems by making simple mistakes. The most common mistakes include:

- Overspeeding the wheel

- Applying incorrect pressure during grinding

- Mounting the wheel improperly

- Using a damaged wheel for grinding

Understanding these preventable issues is the first step. It ensures a much safer grinding process for everyone in the workshop.

Key Takeaways

- Always check the grinding wheel’s speed limit. Never spin a wheel faster than its maximum RPM to prevent it from breaking apart.

- Use the right amount of pressure when grinding. Pushing too hard or grinding on the side of the wheel can cause it to shatter.

- Mount the grinding wheel correctly. Make sure the flanges are clean and tight, but do not overtighten them.

- Inspect the grinding wheel before each use. Do not use wheels that are damaged or make a dull sound when tapped.

Overspeeding: A Critical Grinding Error

Every grinding wheel has a maximum safe operating speed, measured in Revolutions Per Minute (RPM). Exceeding this speed is one of the most dangerous operational mistakes. The forces generated can cause the wheel to explode, sending sharp fragments flying at high velocity. Proper speed management is essential for a safe grinding operation.

How Centrifugal Force Causes Failure

A spinning grinding wheel creates powerful centrifugal force. This force pulls the wheel’s material outward from the center. As the speed increases, this force intensifies dramatically. Grinding wheels, especially vitrified types, are strong but brittle materials. They contain microscopic flaws or pores from the manufacturing process. High centrifugal force turns these tiny flaws into stress points. When the speed limit is surpassed, the stress becomes too great for the material to handle. A small flaw can rapidly grow into a large crack, causing the wheel to shatter instantly.

Common Overspeeding Scenarios

Operators can accidentally overspeed a wheel in several common situations. Understanding these scenarios is key to preventing failure.

- Using the wrong size wheel: An operator might mount a large-diameter wheel onto a smaller grinder designed for higher RPMs. A larger wheel must spin slower to remain safe.

- Ignoring the RPM rating: Every wheel is marked with its maximum safe RPM. Operators must always compare this rating to the grinder’s speed.

- Modifying the grinder: Some users might alter a grinder’s governor or controls to make it run faster. This is an extremely unsafe practice for any grinding work.

Safety Tip: Always match the wheel’s maximum RPM to the grinder’s operating speed. The grinder’s RPM must never exceed the wheel’s rated RPM. The grinding process depends on this simple check.

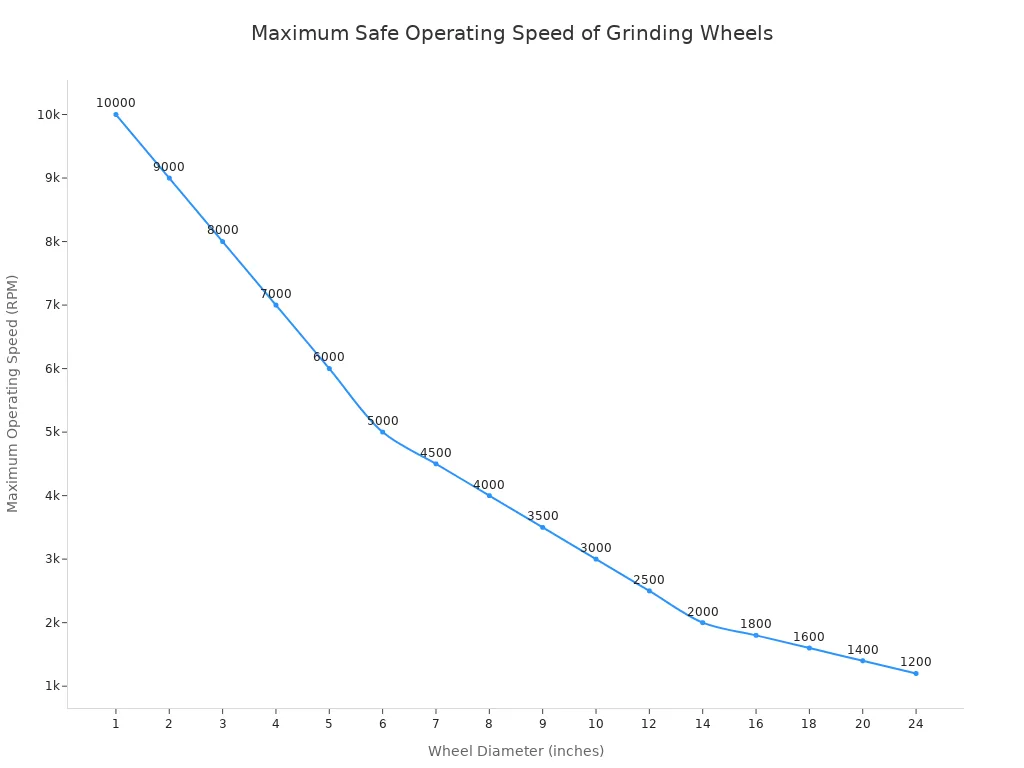

The relationship between wheel diameter and safe speed is critical. As the wheel gets bigger, its maximum safe speed decreases.

| Wheel Diameter (inches) | Maximum Operating Speed (RPM) |

|---|---|

| 6 | 5,000 |

| 8 | 4,000 |

| 10 | 3,000 |

| 12 | 2,500 |

Following these speed guidelines is a non-negotiable part of safe grinding.

Improper Pressure: A Key Cause of Grinding Wheel Breakage

Applying the correct amount of pressure is crucial for a safe and effective grinding operation. Too much force, or force applied incorrectly, creates immense stress on the wheel. This stress can lead to catastrophic failure. Operators must understand how excessive infeed, improper side grinding, and shock loads compromise wheel integrity.

The Impact of Excessive Infeed

Infeed is the rate at which an operator pushes the workpiece into the grinding wheel. Forcing the material too aggressively generates extreme heat and mechanical stress. This combination can weaken the wheel’s bonding structure. The excessive heat also damages the workpiece, a condition known as grinding burn. Operators can spot this damage by looking for specific visual signs.

Signs of Workpiece Burn from Excessive Grinding Pressure:

- Discoloration: The metal surface may turn straw, brown, or blue, indicating high temperatures.

- Surface Cracks: Tiny cracks can form on the workpiece from thermal stress.

- Changes in Surface Roughness: The burned area often feels different from the rest of the surface.

These signs show that the grinding process is out of control and the wheel is under dangerous strain.

The Danger of Side Grinding

Many operators make the mistake of using the side of a standard straight wheel for grinding. These wheels are designed for grinding only on their periphery (the outer edge). The sides are much weaker and are not built to handle grinding forces. Applying pressure to the side of a conventional wheel can cause it to bend and shatter. Only wheels specifically designed and labeled for side grinding are safe for such tasks.

Shock Loads from Workpiece Jamming

A shock load is a sudden, sharp impact on the grinding wheel. This happens when an operator accidentally bumps the workpiece against the spinning wheel. It can also occur if the workpiece jams between the wheel and the tool rest. This sudden impact creates intense mechanical and thermal shock that can instantly fracture the wheel. This type of failure is one of the most common causes of grinding wheel breakage, highlighting the need for a steady and controlled approach during every grinding task.

Incorrect Mounting and Wheel Imbalance

Proper mounting is a fundamental step in any safe grinding operation. Even a high-quality wheel, such as one of Aimgrind‘s precision diamond grinding wheels, will fail if mounted incorrectly. Correct mounting ensures that clamping pressure is distributed evenly across the wheel’s surface. This even pressure is critical for maintaining the wheel’s structural integrity during the high-speed rotation of the grinding process. An improperly mounted wheel creates an imbalance, leading to dangerous vibrations and concentrated stress that can cause it to shatter.

Overtightening the Mounting Flanges

Operators often think tighter is better, but this is a dangerous mistake in grinding. Flanges are the metal discs that hold the grinding wheel on the spindle. Overtightening the mounting nut applies excessive and uneven pressure to the center of the wheel. This concentrated force can create internal stress points or even crack the wheel near the arbor hole. The damage may not be visible, but the wheel can fail catastrophically once it reaches operating speed.

Using Damaged or Mismatched Flanges

The condition of the mounting flanges is just as important as the wheel itself. Flanges must be the correct type, the same diameter, and perfectly clean and flat.

- Damaged Flanges: Flanges with burrs, nicks, or warping will not apply pressure evenly. This creates high-stress areas on the wheel.

- Mismatched Flanges: Using flanges of different sizes or types leads to an unstable mounting. This imbalance causes severe vibration during grinding.

Mounting Tip: Always inspect flanges before any grinding task. Ensure they are clean, flat, and identical. Never use a wheel if the flanges are damaged.

Forcing a Wheel onto a Spindle

A grinding wheel should slide onto the machine’s spindle smoothly. The fit should be snug but not tight. An operator should never have to force a wheel into place. Forcing a wheel onto a spindle that is too large can create tiny, invisible cracks around the arbor hole. These cracks become the starting point for a major fracture when the wheel spins up. This simple error turns a perfectly good wheel into a serious safety hazard for any grinding job.

Using a Damaged or Unsuitable Wheel

Selecting the right wheel and ensuring it is in perfect condition is essential for safe grinding. A compromised or incorrect wheel introduces significant risk into the grinding process. Operators must inspect every wheel before use and choose the correct type for the specific grinding application. Using a flawed wheel is a direct path to failure.

Skipping the Pre-Use ‘Ring Test’

The ‘ring test’ is a simple yet vital inspection method. It helps detect invisible internal cracks in a vitrified grinding wheel. An operator performs the test by tapping the wheel gently with a non-metallic object, like a plastic or wooden handle.

- A good wheel produces a clear, high-pitched ringing sound.

- A damaged wheel makes a dull thud or a dead sound.

Safety Alert: A dull sound indicates a hidden crack. The operator must immediately discard the wheel. Skipping this quick test means risking a catastrophic failure during the grinding operation.

Ignoring Cracks from Drops or Bumps

Grinding wheels are strong but brittle. Dropping a wheel or bumping it against a hard surface can create fine cracks that are difficult to see. These small fractures compromise the wheel’s structural integrity. The immense forces of a grinding operation can cause these tiny cracks to expand rapidly, leading to the wheel shattering. An operator should never use a wheel that has been dropped, no matter how minor the impact seems. The only safe action is to dispose of it properly. This simple rule prevents many serious grinding accidents.

Using the Wrong Wheel for the Job

Every grinding task requires a specific type of wheel. Factors like the material being ground, the desired finish, and the type of grinding machine all influence wheel selection. Using the wrong wheel creates unsafe conditions and poor results. For example, using a wheel designed for soft steel on a hard ceramic material will cause excessive heat and stress. This can lead to wheel glazing, loading, or even breakage. Operators must always match the wheel’s specifications (abrasive, grit, bond) to the job. Proper wheel selection is a cornerstone of effective and safe grinding.

Preventing grinding wheel breakage starts with the operator. Key errors like overspeeding, excessive force, poor mounting, and using damaged wheels are avoidable. Diligent operators who follow safety rules make every grinding task safer.

Investing in proper training and high-quality, customized solutions from Aimgrind is the best strategy. It improves both safety and productivity for all grinding work.

FAQ

Why is my grinding wheel not cutting?

A wheel not cutting often means it is glazed or loaded. Glazing happens when the abrasive grains become dull. Loading occurs when material clogs the wheel’s surface. Both issues are common grinding problems. Proper dressing can restore the wheel’s cutting ability.

What causes grinding wheel breakage?

Most grinding wheel breakage results from operational errors. These include overspeeding the wheel, applying too much pressure, or incorrect mounting on grinding machines. Using a damaged wheel also creates a high risk of failure during a grinding operation.

How can operators solve the problem of wheel life too short?

Operators can extend wheel life by using the correct grinding parameters. Avoiding excessive pressure and ensuring the wheel is right for the material helps. Proper storage and handling also prevent damage that leads to premature wear and other grinding problems.

What should an operator do if a wheel is not cutting?

An operator should stop the grinding process immediately. The wheel needs inspection for glazing or loading. Dressing the wheel with a proper tool will expose fresh abrasive grains. This simple step solves one of the most frequent grinding problems and restores performance.

How do operators prevent grinding wheel breakage?

Operators prevent breakage by following safety rules. They must match the wheel’s RPM to the grinding machines’ speed. They should also perform the ‘ring test’ before mounting and avoid using excessive force during grinding.

Contact Us

For More Grinding Solution or Customized Abrasive Tools