You should never use standard grinding wheels for grinding soft non-ferrous metals, wood, plastics, or rubber. These are materials cannot be ground safely with a conventional wheel. Attempting this kind of grinding is extremely dangerous.

Safety Alert! ⚠️ Improper grinding techniques contribute to over 5,000 injuries annually in the U.S. A shattering wheel can cause severe or fatal harm.

The primary risks of grinding improper materials include clogging the wheel, extreme heat causing fires, and the release of toxic fumes. This guide is essential for your safety when using grinding wheels.

Key Takeaways

- Do not use standard grinding wheels on soft metals, wood, plastics, or rubber. These materials are unsafe to grind.

- Grinding the wrong materials can clog the wheel, cause extreme heat, release toxic fumes, and lead to serious injuries.

- Always match your grinding wheel to the material you are working on. Different materials need different types of abrasive wheels.

- Use hand tools like files and sandpaper for soft materials like wood and aluminum. This is safer and gives better results.

- Specialized tools, like diamond grinding wheels, are needed for very hard materials such as ceramics. They ensure safety and good quality.

Key materials cannot be ground safely

You must understand which materials are unsafe for your grinder. Standard grinding wheels are designed for specific tasks, and using them on the wrong workpiece can lead to disaster. Let’s explore the key materials cannot be ground safely and understand why they pose such a risk.

Soft non-ferrous metals: Aluminum and copper

You might think a soft metal like aluminum would be easy to shape. However, grinding soft, non-ferrous metals is a recipe for trouble. These materials do not grind away cleanly. Instead, they melt from the friction and get smeared into the pores of the grinding wheel. This is a dangerous condition known as “loading.”

A loaded wheel loses its cutting ability. It stops grinding and starts rubbing, which generates extreme heat. This can cause the workpiece to overheat and may even lead to the wheel shattering. When grinding copper, for example, you will face several problems:

- The copper’s ductility causes it to quickly block the wheel’s surface.

- This blockage prevents the wheel from dissipating heat effectively.

- Soft copper material sticks to the abrasive grains, making them useless.

- The adhered copper can create deep scratches on your workpiece as the wheel spins.

Wood and wood composites

You should never attempt to use a bench grinder on wood, plywood, or MDF. Wood is one of the most dangerous materials cannot be ground on a standard wheel. The high speed of the grinder generates immense friction, which will quickly scorch and burn the wood, creating a serious fire hazard in your workshop.

Instead of a clean cut, the grinding wheel will tear and shred the wood fibers. This can cause the workpiece to be violently ripped from your hands, leading to a dangerous kickback event. The correct tools for shaping wood are sanders, files, and saws, not grinding wheels.

Plastics, polymers, and rubber

Plastics, polymers, and rubber have very low melting points. When you press them against a fast-spinning abrasive wheel, they instantly melt and smear across its surface. This ruins the grinding wheel materials and makes the wheel completely ineffective.

More importantly, the heat from grinding releases hazardous fumes from these different materials.

Health Warning: Toxic Fumes ☣️ Grinding plastics can release invisible but highly toxic chemicals. For example:

- ABS plastic releases fumes containing styrene and benzene, which are known or probable carcinogens.

- PVC plastic can produce hydrogen chloride, formaldehyde, and dioxins. These substances can cause severe respiratory damage, skin burns, and even cancer with prolonged exposure.

Always use proper ventilation and the correct cutting tools for these different materials.

Certain heat-sensitive steels

While grinding wheels are made for steel, you must be careful with certain types. High-carbon tool steels, used for knives and cutting tools, are heat-treated to achieve a specific hardness, or “temper.” Aggressive grinding generates intense heat that can ruin this temper.

If you see the steel’s edge turn straw-colored, purple, or blue, you have overheated it. This discoloration shows that the steel has softened, destroying its ability to hold a sharp edge. While a small amount of bluing at the very tip can sometimes be sharpened away, consistent overheating will ruin the tool. The extreme heat from grinding softens the thin cutting edge, making it dull quickly. This is why many professionals prefer water-cooled grinding systems or hand-sharpening methods for their high-carbon tools.

Why standard grinding wheels fail

Using the wrong material on a standard grinder causes specific failures that are dangerous and destructive. You need to understand these failure modes to stay safe and protect your tools. The wrong grinding wheel composition for a job guarantees poor results and high risk.

Understanding wheel loading and clogging

When you attempt the grinding of a soft material like aluminum, the wheel’s pores get clogged. This is called “loading.” A loaded wheel stops cutting effectively. Instead of removing material, the wheel starts to rub against the workpiece, which creates intense friction and heat.

This failure happens for several reasons:

- The clogged wheel cannot remove material efficiently.

- Dull cutting edges on the wheel increase friction.

- You might push harder to compensate, which generates even more heat.

Regular cleaning can expose sharp abrasive parts, but grinding the wrong material makes loading happen almost instantly.

The dangers of improper grinding heat

The heat from improper grinding can permanently damage your workpiece. Certain tool steels are very sensitive to heat and can be damaged at temperatures as low as 350°F. This thermal damage, or “burning,” ruins the steel’s temper.

Heat Damage in Steel 🔥 Excessive grinding heat causes different types of damage as temperatures rise:

Temperature Range Effect on Steel Around 600°C Temper Burn: The surface softens and loses hardness. Above 720°C Rehardening Burn: A brittle layer forms, making the steel weak.

This damage makes a tool unable to hold a sharp edge.

Shattering, kickback, and other safety risks

A loaded or improperly used wheel is a major safety hazard. The buildup of heat and pressure can cause the grinding wheel to shatter, sending sharp fragments flying at high speed. Another serious risk is kickback. This happens when the wheel suddenly grabs or jams on the workpiece, violently throwing it out of your hands. Common causes of kickback during grinding include:

- The wheel snagging on the material.

- Applying too much pressure, causing the wheel to dig in.

- Holding the workpiece at an improper angle.

Damaging the workpiece temper and finish

Even if you avoid injury, using the wrong grinding technique will ruin your workpiece. A loaded or glazed wheel causes burning, which appears as discoloration on the material’s surface. This is not just a cosmetic issue; it indicates thermal damage that can change the material’s hardness. The rubbing action from a clogged wheel also creates a rough, uneven finish and can cause deep scratches, destroying the precision of your work. The two grinding wheels will not produce a quality result if one is loaded.

Choosing the right abrasive for the job

After learning what not to grind, you need to know the right tools for the job. Using the correct abrasive prevents accidents and ensures a quality finish. While standard grinding wheels are unsuitable for many tasks, specialized tools exist for almost any material.

Matching grinding wheel materials to the task

You must match your grinding wheel materials to your workpiece. Standard wheels are often made of aluminum oxide, which is great for steel. However, other materials require different abrasives. For example, silicon carbide is a better choice for grinding cast iron or ceramics. Using the wrong wheel leads to poor results and danger.

Abrasive Type Best For Grinding… Aluminum Oxide Steel, iron, and other ferrous metals Zirconia Alumina Stainless steel and hard steels Silicon Carbide Cast iron, aluminum, ceramics, glass Ceramic Alumina Titanium, hard nickel alloys, tool steel

Files and sanders for wood and soft materials

You should never use a grinder for wood or soft metals like aluminum. Instead, you can use hand tools for safe and effective shaping.

- For Wood: Use sandpaper. A medium 80-grit paper is good for initial shaping, while a finer 150 or 220-grit paper prepares the wood for finishing.

- For Aluminum: Use a single-cut file. This type of file removes material smoothly and is less likely to clog than a double-cut file.

These simple tools give you far more control and eliminate the risks of fire or a shattering wheel.

Specialized abrasives for hard materials

Some jobs involve grinding extremely hard or heat-sensitive metals. For these tasks, you need specialized abrasives. For instance, grinding hardened tool steels or tough nickel alloys requires a superabrasive like Cubic Boron Nitride (CBN). These advanced grinding wheel materials cut efficiently without generating excessive heat, protecting the workpiece from damage. This type of precision grinding is common in the aerospace and automotive industries.

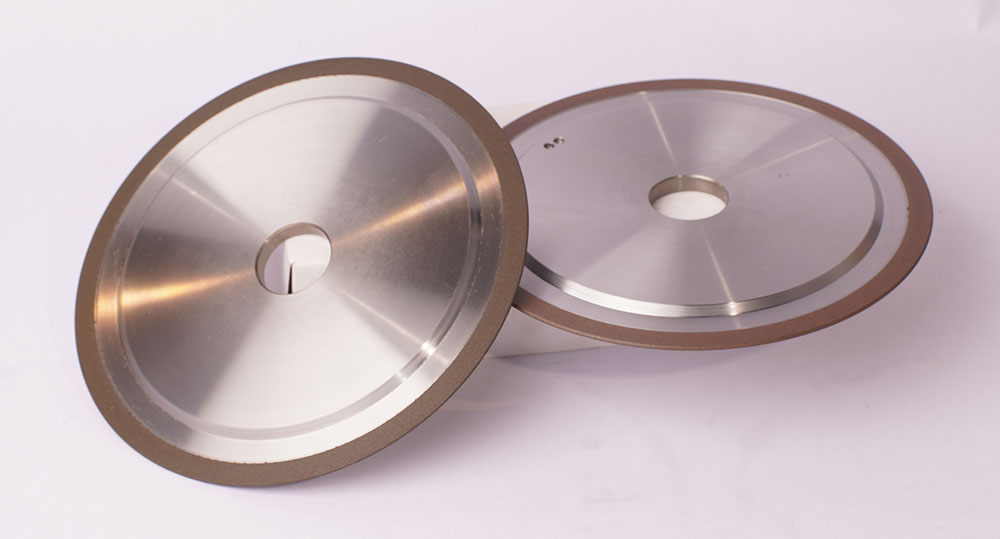

Aimgrind’s diamond grinding wheels for ceramics

When you are grinding extremely hard and brittle materials like ceramics, a standard wheel is not just ineffective—it’s dangerous. These different materials require an abrasive that is even harder. This is where diamond, the hardest material known, becomes essential for the grinding process.

Industries from medical device manufacturing to electronics rely on the precision of diamond grinding. For these demanding applications, you need a tool engineered for the task. Aimgrind‘s diamond grinding wheels are specifically designed for the high-precision grinding of ceramics, glass, and hard alloys. The synthetic diamonds on the wheel provide exceptional cutting power and dissipate heat, preventing cracks and ensuring a perfect finish. Choosing a specialized wheel from Aimgrind for these different materials guarantees both safety and superior results.

You now know the key materials cannot be ground with standard grinding wheels, including aluminum, wood, and plastics. Safe grinding depends on matching your material to the correct abrasive. Proper grinding prevents accidents and ensures quality results. For any challenging grinding, you must use the right tool. This is a core rule of safe grinding practices. When your grinding task involves tough materials cannot be ground with conventional tools, invest in specialized solutions. For superior grinding performance and safety, professional grinding wheels from a brand like Aimgrind are your best choice for successful grinding.

FAQ

What happens if I grind aluminum for just a second?

Even a brief touch can load your wheel. Aluminum melts instantly and clogs the abrasive surface. The wheel stops cutting and starts rubbing, which generates dangerous heat. This action quickly creates a safety hazard for you and your grinder.

How can I tell if my grinding wheel is loaded?

You can inspect your wheel for shiny metallic specks embedded in its surface. A loaded wheel also cuts poorly and generates excessive heat. You may notice a change in sound or feel more vibration while you work.

Can I use a wire wheel to shape aluminum?

You should not use a wire wheel for shaping. Its purpose is cleaning rust and paint. The wires can snag soft metals like aluminum, causing them to break and fly off. Always use a hand file for shaping aluminum.

Is it ever safe to grind wood on a bench grinder?

No, you must never grind wood. 🚫 The wheel’s high speed creates intense friction. This friction burns the wood and creates a major fire hazard. The wheel also tears wood fibers, which can cause a dangerous kickback event.

Contact Us

For More Grinding Solution or Customized Abrasive Tools