Every grinding wheel has a basic composition. It contains an abrasive grain that cuts a workpiece and a bond material that holds the grains together. The global market for these tools is growing significantly.

- The market is expected to increase by USD 6.29 billion.

- It will grow at a 5.2% rate between 2024 and 2029.

The main types of abrasive include aluminum oxide and silicon carbide. The specific grinding wheel composition, meaning the material from which the wheel is made, dictates its performance. Choosing the right grinding wheel materials for a grinding task is critical. The type of material selected ensures the best results.

Key Takeaways

- Grinding wheels have two main parts: an abrasive and a bond. The abrasive cuts the material. The bond holds the abrasive together.

- Different jobs need different abrasives. Aluminum oxide works well for steel. Silicon carbide is good for hard, brittle materials.

- The bond material affects how the wheel works. Vitrified bonds are rigid for precise work. Resinoid bonds are tough for fast cutting.

- Diamond and cubic boron nitride (CBN) are superabrasives. They grind the hardest materials. Diamond is for very hard materials. CBN is for hard metals like steel.

- Choosing the right grinding wheel is important. Match the wheel’s materials to the workpiece and the desired finish. This helps get the best results.

Key Grinding Wheel Materials: Abrasives

The abrasive is the component of a grinding wheel that performs the actual cutting. The choice of abrasive material is one of the most important factors in grinding. Different materials have unique abrasive grain properties. These properties determine how the grinding wheel will interact with the workpiece. The size of the abrasive grain, or abrasive grain size, also plays a key role. Let’s explore the most common abrasives used in grinding wheel materials.

Aluminum Oxide

Aluminum oxide is the most widely used abrasive in the world. It is a versatile and cost-effective material for many grinding applications. This abrasive is excellent for grinding ferrous metals and high-tensile strength materials. There are several types of aluminum oxide, each with distinct characteristics.

- Brown Aluminum Oxide: This is the toughest type of aluminum oxide. It is made by fusing bauxite. Its toughness makes it ideal for rough grinding tasks, like working on iron castings.

- White Aluminum Oxide: This type is much purer. It is more friable, meaning it breaks down to expose new sharp edges. This action provides a fast and cool cutting performance. Its high purity makes it suitable for applications where contamination is a concern, such as in the medical equipment and weapon industries.

- Pink & Ruby Aluminum Oxide: Manufacturers add chromium oxide to white aluminum oxide to create these types. The addition increases toughness. A darker color indicates more chromium and greater toughness.

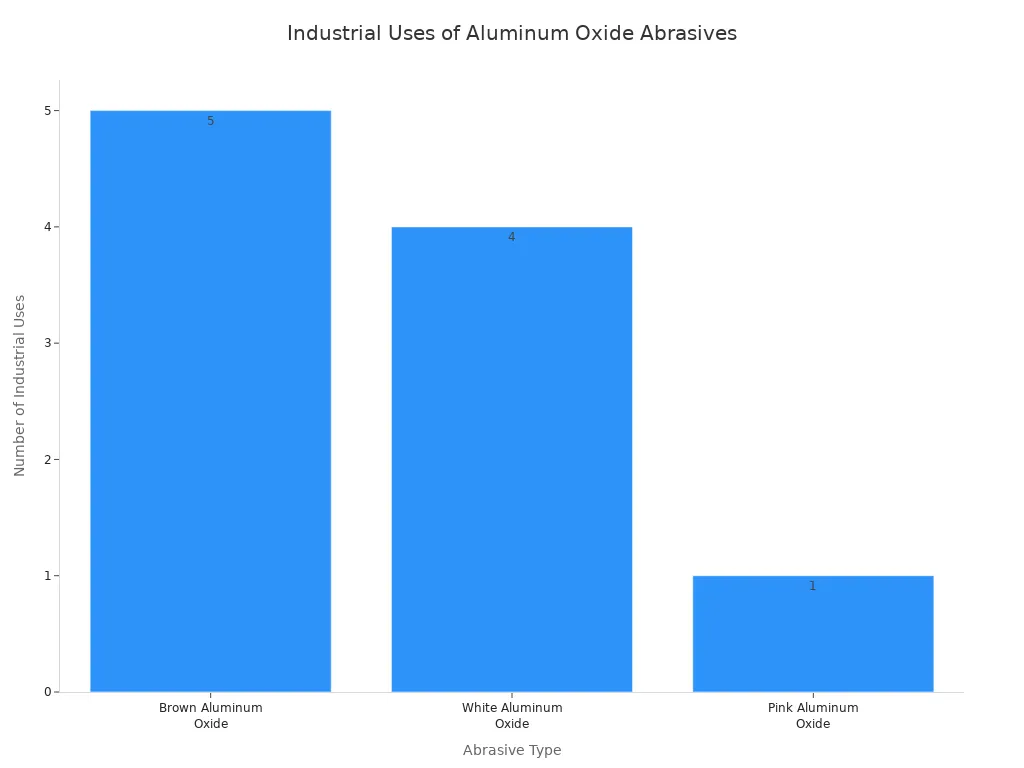

The chart below shows the number of industrial uses for each type of aluminum oxide.

The hardness of an abrasive material is a key factor in its performance. Here is a comparison of the hardness for different aluminum oxide types.

| Abrasive Type | Mohs Hardness | Knoop Hardness (kg/mm²) |

|---|---|---|

| Brown Fused Aluminum Oxide | 9 | ~2450 |

| White Fused Aluminum Oxide | 9 | ~20500 N/mm² (approx. 2090 kg/mm²) |

| General Aluminum Oxide | 9 | 2000 |

Silicon Carbide

Silicon carbide is harder and sharper than aluminum oxide. This abrasive material is an excellent choice for grinding low-tensile strength materials. This includes non-ferrous metals like aluminum and brass. It is also effective on extremely hard materials like cemented carbide. There are two main types of silicon carbide.

Note: The primary difference between green and black silicon carbide is purity and friability. Green silicon carbide is purer and more friable, making it better for precision finishing. Black silicon carbide is tougher and more economical for general-purpose grinding.

| Property | Black Silicon Carbide | Green Silicon Carbide |

|---|---|---|

| Purity (SiC %) | 97–99% | 99–99.9% |

| Hardness (Mohs) | ≈9.2 | ≈9.4 |

| Toughness | Higher (less friable) | Lower (more friable) |

| Typical Use | Grinding cast iron, stone, non-ferrous metals | Precision grinding of hard alloys, ceramics, glass |

Zirconia Alumina

Zirconia alumina is a very tough and durable abrasive. It is a mixture of aluminum oxide and zirconium oxide. The typical ratio is 10-40% zirconium oxide. This combination creates a material with exceptional durability. It is mainly used for aggressive stock removal in steel and stainless steel applications.

A key feature of this abrasive is its self-sharpening mechanism. During high-pressure grinding, the abrasive grains fracture in a controlled way. This process constantly exposes new, sharp cutting edges. This action allows the grinding wheel to maintain a high cutting rate and extends its life.

Ceramic Aluminum Oxide

Ceramic aluminum oxide represents a leap in abrasive technology. This material is not found in nature; it is created through a gel-sintering process. The result is an abrasive with a unique microcrystalline structure. Each grain is composed of billions of tiny abrasive particles.

During grinding, these tiny particles break away. This exposes fresh, sharp cutting points. This self-sharpening action leads to a superior abrasive grain performance. A grinding wheel with this abrasive cuts faster and lasts much longer than those with conventional abrasives. It is a premium choice for precision grinding on difficult-to-grind materials.

Aimgrind Diamond Grinding Wheels & CBN

When grinding the hardest materials, conventional abrasives are not enough. This is where superabrasives come in. Superabrasive materials like diamond and cubic boron nitride (CBN) offer unmatched performance. As experts in customized grinding solutions, Aimgrind specializes in harnessing the power of these advanced materials.

Diamond is the hardest known material. This makes it the ultimate abrasive for grinding extremely hard and brittle materials.

- Unmatched Hardness: Diamond cuts materials like tungsten carbide, advanced ceramics, and hard composites with ease.

- Thermal Conductivity: It quickly dissipates heat from the grinding zone. This prevents thermal damage to the workpiece.

- Wear Resistance: Diamond grinding wheels maintain their shape and precision for a very long time, reducing downtime.

Aimgrind provides high-performance diamond grinding wheels engineered for these demanding jobs. They are available with resin, metal, and vitrified bonds to perfectly match any application.

Cubic Boron Nitride (CBN) is the second-hardest material on Earth. Cubic boron nitride is the preferred abrasive for grinding hard ferrous metals. This includes hardened tool steels and superalloys.

Did You Know? 💡 Diamond is not suitable for grinding steel because the carbon in the diamond reacts with the iron in the steel at high temperatures. Cubic boron nitride is chemically inert to iron, making it the perfect choice.

The aerospace and automotive industries rely heavily on cubic boron nitride. In aerospace, a grinding wheel with cubic boron nitride shapes jet engine components made from superalloys. In automotive, it is essential for finishing engine parts that require extreme precision. The high thermal stability of cubic boron nitride ensures consistent quality and safe machining. These superabrasives are key to modern manufacturing.

The Grinding Wheel Bond: Holding It All Together

The abrasive grains in a grinding wheel do the cutting, but the bond material holds them together. This bond material determines the wheel’s strength, structure, and how it wears during use. The type of bond material is just as important as the abrasive. Each type of bond material offers unique properties for different grinding jobs. The right bond material ensures the grinding wheel performs correctly. Let’s explore the main types of bond material used to make a grinding wheel.

Vitrified Bond

Vitrified bonds are the most common type of bond material used in grinding wheels. They are made from a mixture of clays and other ceramic materials. Manufacturers fire this mixture at high temperatures to create a strong, glass-like structure. This process makes the grinding wheel rigid and porous.

Newer vitrified bonds are engineered for lower firing temperatures. Some modern vitrified bonds soften between 500°C and 520°C and are fired below 900°C. This innovation reduces energy use while keeping the mechanical properties of the bond material strong.

The porosity of vitrified bonds is a key factor in their performance.

Optimal Strength: The impact strength of a grinding wheel with vitrified bonds is highest when porosity is around 40.5%. If porosity is too low or too high, the strength decreases. This shows how carefully engineers design the material structure.

This type of bond is excellent for precision grinding because it is very rigid and does not flex under pressure. Vitrified bonds are also resistant to water, oil, and acids, making them suitable for many grinding environments.

Resinoid Bond

Resinoid bonds use synthetic resins, like phenolic or polyimide resins, as the bonding agent. This type of bond material creates a grinding wheel that is tough and less rigid than vitrified bonds. This flexibility allows it to absorb shock, making it ideal for rough grinding and cutting operations.

However, this bond material is less resistant to very high temperatures. Excessive heat from grinding can cause the resin to soften or char. This leads to faster wear. It is important to choose a resinoid bond formulated for the specific grinding temperature.

Resinoid bond wheels excel in high-speed applications.

- They are used for cut-off wheels that can operate at speeds up to 100 m/s.

- Operators use them for fast cutting of castings and tempered parts.

- They are also used in high-speed grinding wheels for cleaning welds and metal surfaces in industries like shipbuilding.

Rubber Bond

Rubber bonds use natural or synthetic rubber as the primary bond material. This type of bond creates a grinding wheel that is smooth and flexible. The elasticity of the rubber bond provides excellent shock absorption. This quality is perfect for grinding delicate parts or creating very fine surface finishes.

The flexibility of this material also helps reduce heat buildup during the grinding process. This is vital when working with heat-sensitive materials. The rubber bond’s natural damping properties reduce vibration, which improves grinding precision. These features make rubber bond wheels a top choice for achieving tight tolerances in the aerospace and medical industries. This type of grinding wheel is often used for “regulating wheels” on centerless grinding machines.

Metal Bond

Metal bonds use various metal powders to hold the abrasive grains. This bond material creates an extremely strong and durable grinding wheel. It is the best choice for grinding with superabrasives like diamond and CBN. The metal bond holds these expensive grains securely, extending the life of the grinding wheel.

Common metals used to create this bond material include:

| Metal Type | Composition | Common Use |

|---|---|---|

| Bronze | Copper, Tin, Phosphorus (CuSn10) | High-density parts, bearings |

| Steel | Iron, Nickel, Chromium (FeNiCr) | Strong, durable applications |

| Stainless Steel | Iron, Chromium, Nickel, Molybdenum (316L) | Corrosion-resistant parts |

Manufacturers use several processes to create a metal bond grinding wheel. Each process offers different advantages for a specific grinding task.

Sintering: Metal powders are pressed and heated to form a very strong bond. This creates a durable grinding wheel that holds its shape well.Electroplating: A single layer of abrasive is attached to the wheel’s surface. This method is great for detailed work but has a shorter lifespan.Vacuum Brazing: This technique uses a filler metal to create a very strong chemical bond between the abrasive and the wheel. It results in a robust grinding wheel for heavy-duty grinding.

Choosing the Right Materials for Your Job

Proper grinding wheel selection is crucial for success. The right combination of grinding wheel materials ensures efficiency and quality. The choice depends heavily on the workpiece material and the desired outcome, whether it’s aggressive material removal or a fine surface finish.

Grinding Ferrous Metals

Grinding ferrous metals requires a specific type of abrasive. Aluminum oxide is a common choice for these materials. The correct abrasive and grit size are essential for effective grinding.

- Mild Steel: Most general-purpose aluminum oxide wheels perform well on this material.

- Stainless Steel: This material needs a special grinding wheel. The abrasive must be free of iron, sulfur, and chlorine to prevent contamination.

- Cast Iron: A silicon carbide abrasive is the best choice. Its hardness effectively grinds this brittle material.

The grit size of the abrasive in the grinding wheel also matters for different metals.

| Grit Size | Grinding Wheel Grades | Suitable Materials |

|---|---|---|

| 10-24 | Soft-Medium | Stainless steel, cast iron, hard steel |

| 30-60 | Medium-Hard | Mild steel and general metals |

| 70-220 | Medium-Hard | Carbide, high-speed steel |

Grinding Non-Ferrous Metals

Grinding non-ferrous metals like aluminum presents a unique challenge: wheel loading. The soft material can clog the abrasive pores of the grinding wheel. Using a silicon carbide abrasive helps prevent this issue. An aluminum oxide abrasive should not be used for grinding aluminum. A coarse-grit grinding wheel also helps reduce loading.

Pro Tip: Applying a water-soluble coolant directly to the grinding wheel can further prevent the material from sticking. This keeps the abrasive sharp and effective.

Grinding Hard & Brittle Materials

Grinding hard and brittle materials like ceramics, glass, or silicon wafers demands extreme precision. The process can cause surface damage and cracks. Solutions involve using specific grinding technologies and optimizing the grinding process. Multi-step grinding with different abrasive grit sizes can remove damage from previous steps. Precise diamond grinding wheels are essential for processing these advanced materials, ensuring a high-quality surface finish without compromising the material’s integrity.

Cutting vs. Precision Finishing

The goal of the grinding operation determines the ideal grinding wheel materials. Rough cutting and precision finishing require very different wheels. Rough cutting prioritizes high material removal rates. Precision finishing focuses on achieving a smooth surface finish.

| Feature | Rough Cutting Wheels | Precision Finishing Wheels |

|---|---|---|

| Grit Size | Coarse (16-60) for rapid material removal | Fine (150-600+) for a smooth surface finish |

| Bond Type | Resinoid for aggressive, high-speed removal | Vitrified for rigidity; Rubber for a high-gloss finish |

A quality grinding wheel on a rigid machine can produce a surface finish with a roughness around 0.25 microns Ra. This level of precision shows the importance of matching the abrasive and bond to the job. The right choice improves the material removal rate and the final surface finish.

A grinding wheel’s performance depends on the specific pairing of an abrasive grain and a bond material. The right choice of materials is critical for any job. It depends on the workpiece material and the grinding goal, from rough cutting to fine finishing.

Selecting the correct abrasive ensures the wheel is used to its full life. This choice improves efficiency and helps achieve superior results with less rework.

FAQ

What are the two main materials in a grinding wheel?

Every grinding wheel consists of two primary materials. The first is the abrasive, which performs the cutting action during grinding. The second is the bond material, which holds the abrasive grains together. The combination of these materials defines the wheel’s function.

How does the bond material affect grinding?

The bond material controls how the grinding wheel wears. A hard bond material retains abrasive grains longer, which is ideal for precision grinding. A softer bond material releases dull grains faster. This action exposes new, sharp abrasive for aggressive grinding tasks.

Why are there different abrasive materials?

Different workpiece materials require a specific abrasive for effective grinding. For instance, silicon carbide is excellent for grinding hard, brittle materials. Aluminum oxide works best for grinding steel. The correct abrasive material ensures optimal performance and prevents damage to the workpiece.

Can one grinding wheel work for all grinding jobs?

No single grinding wheel is suitable for every application. The specific combination of the abrasive and the bond material is engineered for a particular grinding task. Selecting the right grinding wheel with the correct bond material ensures efficiency and a high-quality finish.

Contact Us

For More Grinding Solution or Customized Abrasive Tools