Grinding force is affected by many things. These include abrasive type, grit size, bond type, wheel structure, wheel hardness, workpiece material, and grinding settings. Knowing these things is important for grinding. They change how much material is removed, the surface finish, wheel wear, and machine stability.

Operators who watch grinding force can change the wheel, pressure, and coolant. This helps control heat, stops tool damage, and makes work better. Choosing the right wheel and settings makes grinding safer and more efficient.

Key Takeaways

Picking the right abrasive type and grit size helps control grinding force. It also makes the surface smoother.

Matching wheel hardness and bond type to the workpiece keeps grinding efficient. It also stops damage from happening.

Using the right wheel structure and controlling contact area lowers grinding force. It also helps keep the wheel cool.

Changing grinding pressure, wheel speed, and coolant use balances force, heat, and quality.

Keeping the system strong and checking grinding conditions makes grinding safer. It also makes it smoother and last longer.

Grinding Wheel Factors

Abrasive Type

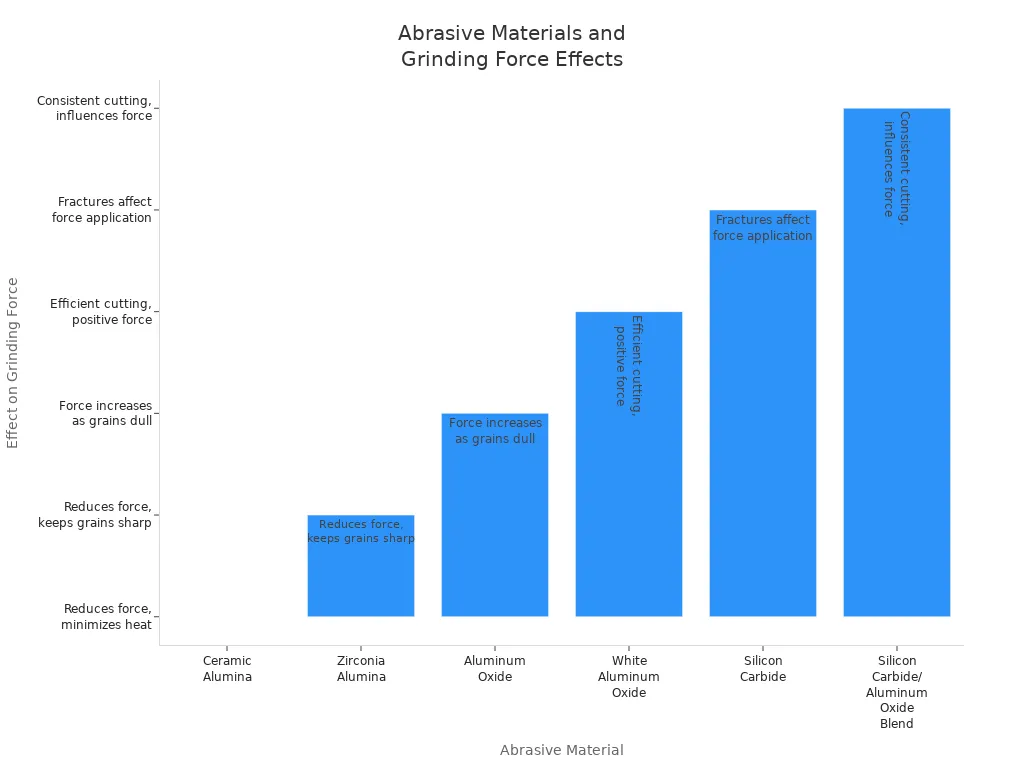

The abrasive in a grinding wheel decides how it works with the workpiece. Abrasives like ceramic alumina, zirconia alumina, aluminum oxide, and silicon carbide are all different. The abrasive is the main part of the grinding wheel. It changes how chips form, how much friction there is, and how fast the wheel wears out. Harder abrasives like CBN and ceramic alumina keep their sharp edges longer. This can make grinding force lower and help the wheel cut better. Abrasives that break easily, like silicon carbide, crack and show new sharp edges. This helps keep grinding force low and makes the surface cooler.

Key Properties | Effect on Grinding Force and Performance | |

|---|---|---|

Ceramic Alumina | Self-sharpening, micro-fracturing crystals, low heat generation | Reduces grinding force by maintaining sharp edges and minimizing heat; suitable for hard metals |

Zirconia Alumina | Self-sharpening, fast cutting, long life under high pressure | Maintains cutting efficiency, reducing grinding force by keeping grains sharp |

Aluminum Oxide | Hard, durable, sharp initial cut but dulls over time | Grinding force may increase as grains dull and wear down |

White Aluminum Oxide | Fast cut-rate, long lifespan | Provides efficient cutting on hard steels, influencing grinding force positively |

Silicon Carbide | Very hard, sharp, but friable (brittle) | Friability causes grains to fracture, affecting how grinding force is applied and maintained |

Silicon Carbide/Aluminum Oxide Blend | Combines properties for soft alloys like aluminum | Offers fast, consistent cutting with extended life, influencing grinding force accordingly |

Tip: Pick ceramic or zirconia alumina wheels for hard metals. These wheels give lower grinding force and last longer. For softer materials, use a mix of silicon carbide and aluminum oxide.

Grit Size

Grit size means how big the abrasive grains are. It controls grinding force and how smooth the surface is. Coarse grits have bigger grains. They remove material fast but make rougher surfaces and higher grinding force. Fine grits have smaller grains. They cut gently and make smoother surfaces. But they need more energy and work slower.

Studies show that smaller abrasive grains change how grinding works. It goes from pushing and rubbing to real cutting. This lowers grinding force and makes the surface better. But fine grits can make more force on each grain because they touch more area. So, you need to pick the right grit size for your job.

Note: Use coarse grit wheels when you want to remove a lot of material fast. Use fine grits when you want a smooth finish.

Bond Type

The bond holds the abrasive grains together. It is important for controlling grinding force. Resin bonds are soft and bendy. They let the wheel grind with less pressure. This helps lower grinding force and stops shaking. Resin-bonded wheels are good for careful grinding and fast speeds. Vitrified bonds are hard and glass-like. They hold grains tight but can make grinding force higher. They do not absorb shocks well.

Resin bonds help control force and stop chatter.

Vitrified bonds are stiff but can raise grinding force and cause burning.

Softer bonds let old grains fall off sooner. This keeps the wheel sharp and lowers force.

Tip: Pick resin-bonded wheels for jobs needing careful force and smooth finishes. Use vitrified bonds for tough grinding where you need the wheel to keep its shape.

Wheel Structure

Wheel structure means how the grains and spaces are arranged. Wheels with more open spaces let chips and coolant move better. This stops the wheel from getting clogged. It lowers grinding force and keeps things cool. Porous wheels also sharpen themselves more easily. This helps the wheel last longer and work better.

Microstructured wheels have special grain patterns. They lower grinding force and make grinding more stable, especially for careful jobs.

Good pore spacing helps cooling and removes waste, so the wheel does not clog.

Note: For careful or heat-sensitive jobs, pick wheels with more pores or special designs.

Wheel Hardness

Wheel hardness depends on how strong the bond is. It changes grinding force and how long the wheel lasts. Hard wheels hold grains longer. They keep their shape and cutting power. This is good for soft materials or when you need the wheel to stay the same shape. But if the wheel is too hard, it can get hot and burn the surface. Soft wheels let grains fall off more easily. This shows new sharp edges and lowers grinding force. Soft wheels are better for hard-to-grind materials.

For hard workpieces, use soft wheels. They sharpen themselves and stop burning.

For soft workpieces, use hard wheels. They last longer and keep their shape.

Change wheel hardness for grinding pressure. High pressure needs tough wheels. Light pressure works better with soft wheels.

Tip: Always match the wheel hardness to the workpiece and grinding job. This gives the best results and makes the tool last longer.

Workpiece and Contact

Material Properties

The material being ground affects grinding force a lot. Hardness and toughness are important. Hardness means how well something resists scratches or dents. Toughness means how much impact it can take before breaking. These things change how the grinding wheel works with the workpiece.

Harder materials make grinding force go up. They are harder to cut.

Tougher materials take more hits without breaking. This can make grinding smoother. But if a material is hard and tough, more force is needed.

The grinding tool must be harder than the material. This helps the tool keep its shape and stay sharp.

If the material is very hard, grinding force gets higher. This can make the surface rougher and change how smooth it is.

Operators should pick the right grinding wheel for the material. This helps get a good finish and keeps grinding force under control.

Area of Contact

The contact area between the wheel and workpiece changes grinding force. A bigger area spreads force over more grains. But it also means more total force is needed. The shape and size of the contact zone matter for grinding, tool wear, and finish.

When the wheel touches a bigger area, grinding force goes up. This can make more heat and wear out the wheel faster. If chips block the area, grinding force and shaking both rise. Friction in the contact zone is the main force. Operators can change the contact area by changing the depth of cut or wheel structure.

Using a smaller depth of cut makes the contact area smaller. This lowers grinding force.

Picking the right grain size and wheel structure helps control the contact zone.

Special methods like ultrasonic help or force control can lower grinding force and make grinding more accurate.

By controlling the contact area, operators can grind better, wear tools less, and get a nicer finish. Changing the depth of cut and wheel structure also keeps grinding steady and the surface smooth.

Grinding Force Parameters

Grinding Pressure

Grinding pressure is the force between the wheel and workpiece. When you push harder, grinding force goes up. This affects how much material is taken away. It also changes how well the job gets done. If you use more pressure, you can remove more material. This works well for steels and alloys. For example, if you make the pressure four times higher, you can take off two to five times more steel. But too much pressure can hurt the abrasive grains. It can make the wheel dull and wear out tools faster. Operators need to find the right pressure. This helps remove material fast but keeps the surface nice and the tool working longer. The grinding force ratio compares two types of force. This ratio changes with bond hardness. Harder bonds make the ratio higher. This can help remove material better but may also make cutting force go up.

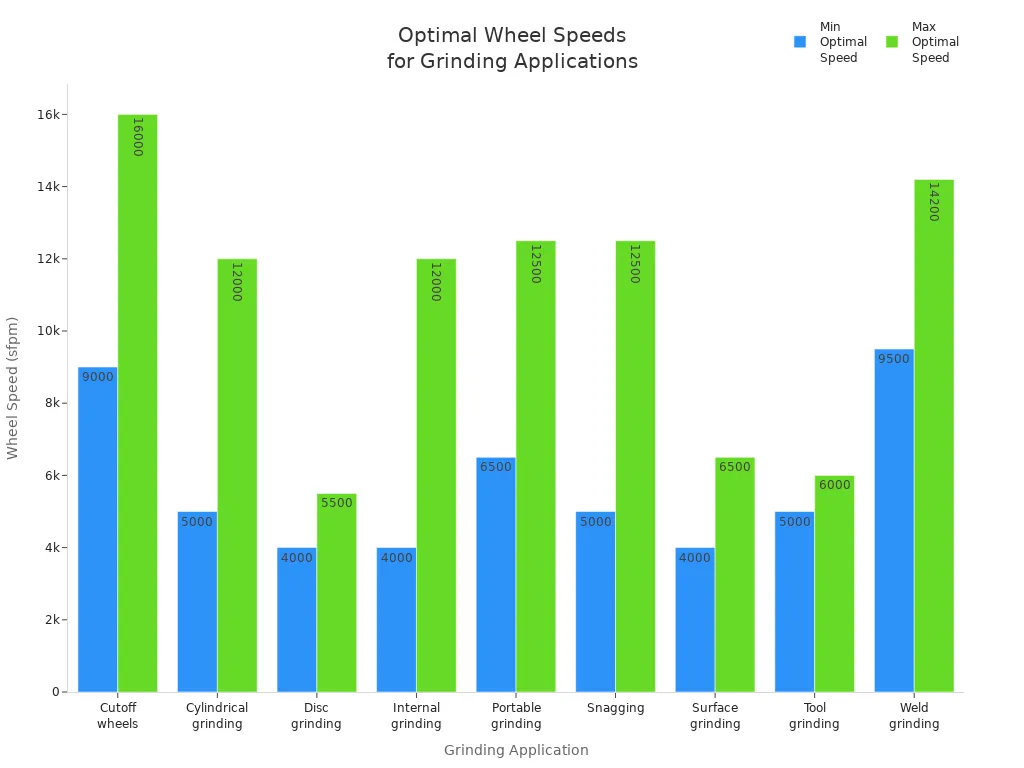

Wheel Speed

Wheel speed is important for grinding force and surface finish. Faster wheel speeds can make surfaces smoother. They help stop cracks and damage under the surface. For example, when grinding monocrystalline silicon, a faster wheel speed makes cracks smaller and fewer. But going too fast can make more heat. Sometimes, it can make the surface rougher. Operators must pick the best speed for each job. This keeps grinding force, heat, and finish balanced. The table below shows the best wheel speeds for different jobs:

Grinding Application | Optimal Wheel Speed Range (sfpm) | Notes on Force and Heat Control |

|---|---|---|

Cutoff wheels | 9,000 – 16,000 | High speeds need special wheels |

Cylindrical grinding | 5,000 – 12,000 | Speed affects force and heat |

Disc grinding | 4,000 – 5,500 | Lower speeds control heat |

Surface grinding | 4,000 – 6,500 | Lower speeds for heat-sensitive jobs |

Tip: Always use the right wheel speed for your job and material. This helps control grinding force and stops overheating.

Coolant Use

Coolant is very important in grinding. It cools the area where grinding happens. It also makes the wheel and workpiece slippery and washes away chips. Using coolant the right way lowers grinding force. It does this by making less friction and heat. Coolant also stops heat damage, like cracks or changes in the workpiece. Oil-based coolants, like neat oils, are very slippery. They lower grinding force in fast jobs. Water-mixed coolants take away heat well but need more care. Operators should pick the best coolant, flow, and pressure. This gives the best cooling and slippery action. If the coolant jet moves as fast as the wheel, it gets to the grinding area better. This lowers grinding force and makes the surface nicer.

Coolant makes things slippery and lowers grinding force.

Using coolant the right way helps tools last longer and work better.

System Rigidity

System rigidity means how stiff the machine and setup are. Stiff machines shake less and keep grinding force steady. This makes the surface look better. Machines that are not stiff shake more. This can make the finish uneven and wear out tools faster. Operators can make things stiffer by picking strong machines and good fixtures. Using microstructured wheels also helps stop shaking. These wheels keep grinding force steady. Robots can be programmed to use the right speed and pressure. This helps keep the system stiff and the cutting force steady.

Make machines and fixtures stiffer to stop shaking.

Use microstructured wheels to keep force steady.

Program grinding systems well for the best results.

Optimizing Grinding Force

Balancing Factors

Operators need to balance many things to get the best grinding force. Sometimes, they want to remove a lot of material but also keep the surface smooth. This can be hard to do at the same time. Skilled machinists use different ways to solve these problems:

Buying advanced machines, like multi-axis ones, gives more options and helps with tough designs.

Making part designs simpler cuts down on problems and lowers force issues.

Figuring out External Removed Material Ratio (ERMR) and Internal Removed Material Ratio (IRMR) shows if parts are strong and can be made easily.

Using 3D printing for test parts or tricky shapes makes machining easier and needs less force.

Using Deep Reinforcement Learning (DRL) in CNC machines lets them change feedrate, spindle speed, and toolpath as they work. Actor-Critic systems in DRL help machines learn and get better, so grinding force and quality improve.

Operators also change wheel shape and texture. Laser texturing makes big and small patterns that help grinding work better and lower force. Watching sensor data, like vibration and temperature, keeps things steady.

Tip: Good machinists and flexible methods are needed to fix problems and balance forces in hard grinding jobs.

Application Selection

Picking the right grinding wheel and settings depends on what the workpiece needs. Operators look at the material, how hard it is, and what finish they want. The table below shows what to use for different jobs:

Material Type | Process Parameter Considerations | |

|---|---|---|

Steel, Aluminum | Use coarser grit and harder bonds for easy grinding | Use higher wheel speed and medium pressure |

Hardened Steel | Use finer grit and softer bonds to keep sharpness | Use lower pressure and careful speed |

Ceramics, Glass | Pick special abrasives and the right wheel | Use exact speed and very little pressure |

Composites | Use special wheels with the right grit and bond | Change feed rate and watch temperature |

Operators change wheel position, how deep it goes, and how it is dressed to get the best grinding force. They use just enough pressure, hold the workpiece tight, and check for shaking before starting. If the force is too high, they pick a harder wheel, make sure it is mounted right, and swap out broken wheels fast.

Note: Checking and changing things often helps stop burning and gets the best grinding ratio, so the grinding job meets all the important needs.

Grinding force changes because of many things. These include abrasive type, grit size, bond, wheel structure, and workpiece properties. When operators manage these things well, they get good results. The table below shows how careful control helps tools last longer, makes more products, and improves quality:

Aspect | Impact on Efficiency and Quality |

|---|---|

Tool Condition Monitoring | Makes tools last longer and stops extra replacements |

Optimized Wheel Life | Cuts tool costs and uses wheels better |

Productivity Improvements | Helps make more parts and have less machine stops |

Surface Condition Control | Makes parts more accurate and keeps surfaces smooth |

Adaptive Tools and Diagnostics | Lets workers fix problems fast and control the process better |

Grinding teams who use these ideas work safer, faster, and make better products.

FAQ

What causes high grinding force during operation?

High grinding force can happen for a few reasons. If the wheel is dull, it does not cut well. Using the wrong grit size can also make force go up. Pushing too hard when grinding is another cause. Operators should look at the wheel to see if it is sharp. They need to pick the right abrasive for the job. Lowering the pressure can help reduce the force.

How does coolant affect grinding force?

Coolant helps lower grinding force by making things less hot and slippery. It keeps the grinding area cool and stops burning. Coolant also helps the wheel last longer. Operators should always use the right coolant for the job and material.

Can wheel speed change the grinding force?

Yes, wheel speed can change grinding force. Going faster with the wheel often makes force lower. It can also make the surface smoother. But if the wheel goes too fast, it can get too hot. Operators should always use the speed the maker says is safe.

Why does wheel hardness matter in grinding?

Wheel hardness is important for grinding. A soft wheel lets grains fall off easily. This keeps the force lower. A hard wheel holds onto grains longer. This can make the force and heat go up.

What should operators do if grinding force is too high?

Operators should check if they are using the right wheel. They can try using less pressure. Making sure coolant is used the right way helps too. Dressing the wheel or picking a softer bond can also lower the force and make grinding better.

See Also

Selecting The Best Metal Grinding Wheel For Your Needs

Different Grinding Wheel Varieties And Their Uses Explained

Finding The Most Effective Grinding Wheel Dresser For You

Contact Us

For More Grinding Solution or Customized Abrasive Tools