Upgrade your work with a diamond grinding wheel for lapidary tasks like the CabKing diamond resin wheels. You get smoother cabbing and easier contour grinding because of their balanced design. Their performance stays the same every time you use them. Many people say these wheels last a long time and cost less. You can pick from many different grits, so your grit choices always fit your project. These wheels work with popular lapidary machines, so they are easy to use. Try these wheels and notice the change in your finished stones.

Key Takeaways

-

Diamond grinding wheels work faster and last longer. They make smoother finishes than other tools. This helps your lapidary work be easier and better.

-

Pick the right grit size for each step. Use coarse grit for shaping. Use medium grit for smoothing. Use fine grit for polishing. This makes your stone shiny and perfect.

-

Choose the right wheel type for your project. Use metal-bonded wheels for hard grinding. Use resin-bonded wheels for gentle polishing. Match the wheel to your stone type.

-

Always use water when you grind. Water keeps the wheel cool. It lowers dust and protects your stones and tools. This helps them last longer.

-

Install your wheels the right way. Clean them often and follow safety rules. This keeps your wheels working well. It helps you enjoy lapidary work safely and easily.

Why Choose Diamond Grinding Wheels?

Performance Benefits

You want your lapidary work to look great. Diamond grinding wheels help you do better work. These wheels have strong, sharp diamond grains. They cut faster and last longer than other tools. You get smooth stones without scratches each time. The resin bond in some wheels keeps your stones cool. This helps stop overheating and damage. You will see less chipping, even if you are just starting. The wheels run quietly and smoothly, so your work is more fun. You can use them for cabbing, shaping, or glass art. Many people say they save time and get better results with these wheels.

-

Industrial-grade diamonds cut hard materials easily.

-

Resin bonds show new diamonds for steady work.

-

Wheels fit many machines and stone types.

-

You get a flat, true surface for careful work.

-

The wheels help you avoid flat spots and sharp corners.

Durability and Longevity

You want tools that last a long time. Diamond grinding wheels last five to eight times longer than regular abrasives. You do not need to replace them as often, so you save money. The wheels keep their shape and sharpness, so you do not need to fix them much. They handle heat well, which protects your stones and your machine. Even though they cost more at first, you get more value because you buy fewer wheels and spend less time fixing them.

Tip: Buying diamond grinding wheels means you stop less and spend more time making nice stones.

What else abrasive tools except diamond grinding wheels

You might wonder about other tools for lapidary work. Here is a quick look:

|

Abrasive Tool |

Common Use in Lapidary Work |

Performance Characteristics |

Suitable Materials |

Finish Quality |

Cost and Durability |

|---|---|---|---|---|---|

|

Diamond Grinding Wheels |

Finish grinding, hard materials |

Superior durability, faster cutting, finer finishes |

Hard stones, ceramics, gemstones |

Mirror-like, fine polish |

Higher cost, lasts much longer |

|

Silicon Carbide Wheels |

Rough grinding, softer stones |

More affordable, wears out faster, max grit ~1000 |

Softer stones (opal, turquoise) |

Decent polish on soft stones |

Lower cost, needs frequent replacement |

Diamond grinding wheels use strong diamonds on the edge. This makes them last longer and cut faster, especially for gemstones and hard stones. Silicon carbide wheels are good for rough shapes and softer stones, but they wear out fast and do not make stones as shiny. For careful work and long-term use, diamond grinding wheels are the best choice for lapidary artists.

Key Features to Consider

Grit Size

Picking the right grit size is very important. Coarse grits like 80 or 120 take off material fast. They help shape your stones quickly. Medium grits, such as 220 or 400, smooth out rough spots. They get the stone ready for more detailed work. Fine grits, from 600 up to 3000, make your stones shiny and glass-like. Use this table to see which grit and abrasive material work best for each step:

|

Abrasive Material |

Effective Stage in Lapidary Work |

Key Properties Supporting Effectiveness |

Practical Application Notes |

|---|---|---|---|

|

Silicon Carbide |

Initial coarse grinding |

Very hard, fast cutting |

Best for shaping hard stones like quartz |

|

Aluminum Oxide |

Medium to hard stones polishing |

Durable, thermally stable |

Good for wet/dry tumbling, wears faster on hard stones |

|

Cerium Oxide |

Final polishing on softer stones |

Fine polishing compound |

High-gloss finish on quartz and agate |

|

Tin Oxide |

Final polishing on glassy stones |

Mild abrasive |

Smooth, reflective finish on turquoise |

Tip: Begin with a coarse grit. Move to finer grits to get the best shine.

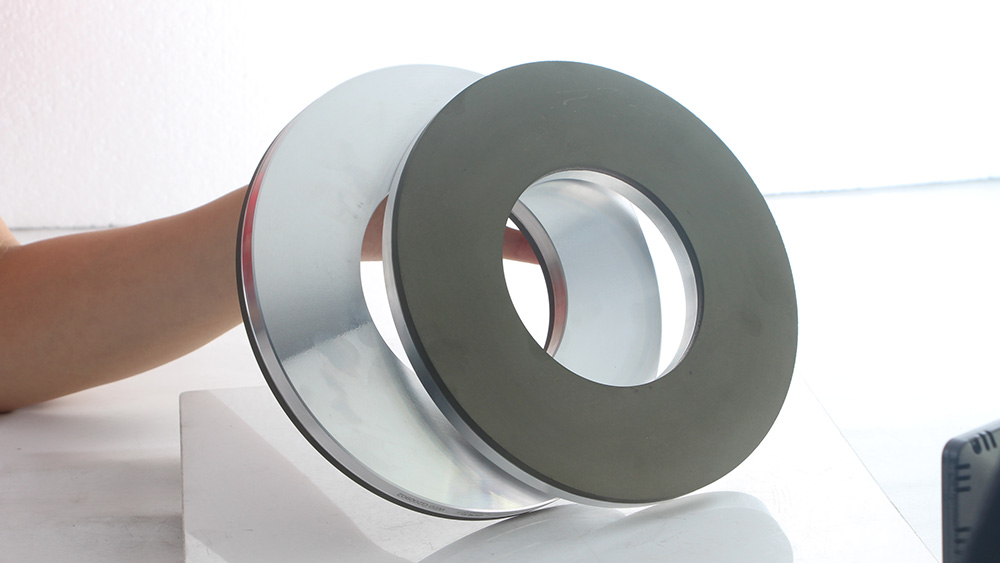

Wheel Construction

You should choose the right wheel construction for your job. Metal-bonded diamond wheels last a long time and are strong. They cut quickly and clear away debris well. But they can get hot and make a lot of noise. Resin-bonded wheels stay cooler and are quieter. They are good for delicate stones and give a smooth finish. Resin wheels are easier for beginners and help stop chipping.

-

Metal-bonded: Great for tough grinding and shaping.

-

Resin-bonded: Best for gentle work and polishing.

Machine Compatibility

Always check if the wheel fits your machine. Most wheels come in common sizes like 6-inch or 8-inch. Make sure the arbor hole is the right size for your machine. Using the correct size keeps your work safe and smooth.

Wet vs. Dry Use

Wet grinding works better for lapidary projects. Water cools the wheel and makes it last longer. It also lowers friction and helps your tools last. Wet grinding keeps dust down and gives a smoother finish. Dry grinding is easy but can make stones too hot and dusty. Here is a comparison:

|

Aspect |

Wet Grinding Advantages |

Dry Grinding Disadvantages |

|---|---|---|

|

Cooling & Lubrication |

Reduces heat, extends tool life |

Overheating, thermal damage risk |

|

Surface Finish |

Smoother, finer finish |

Rougher finish, more imperfections |

|

Dust & Debris |

Less dust, safer workspace |

More dust, needs filtration |

For the best results, use water with your diamond wheels if you can.

Abrasive Tools for Lapidary: Top Recommendations

To get great lapidary results, you need the right abrasive tools. The right diamond grinding wheel for lapidary makes your work faster and smoother. It also makes the process more fun. Let’s look at the best tools for each step. This way, you can pick what works best for you.

Cutting Stage

Metal-Bonded Diamond Cutting Blades

You need a tough blade for first cuts. Metal-bonded diamond cutting blades last a long time. They cut hard stones, glass, and ceramics easily. You get straight cuts and less waste. These blades are good for rough and fine grinding. They fit most 6-inch and 8-inch lapidary machines.

Cold-Pressed Ultra-Thin Slicing Blades (Straight/Beveled Teeth)

If you want thin slices or gentle cuts, use cold-pressed ultra-thin slicing blades. These blades have straight or beveled teeth for different jobs. You get less chipping and smoother edges. They are great for gemstones, glass, and fragile materials.

Rough Grinding & Shaping

-

Electroplated Diamond Grinding Wheels (Coarse Grit: 80#-400#):

These wheels take off material fast. You can shape stones quickly. Electroplated wheels have sharp points and do not need dressing. They work best for hard stones and fit most lapidary machines. -

Resin-Bonded Diamond Grinding Wheels (Medium Grit: 200#-600#):

Use resin-bonded wheels to smooth rough shapes. They run cooler and quieter than metal wheels. The soft resin bond helps stop chipping, especially on delicate stones like opal or turquoise.

Tip: Start with a coarse grit to shape your stone. Then use a medium grit to smooth it out.

Fine Grinding & Pre-Polishing

-

Electroplated Diamond Laps (Fine Grit: 600#-3000#):

These laps give you a smooth finish and high precision. Use them for fine sanding and pre-polishing. They work well on flat surfaces and are good for faceting gemstones.

-

Resin-Bonded Diamond Laps (Fine Grit: 800#-5000#):

For a shiny, glass-like look, use resin-bonded laps. They are gentle and help you get a flawless surface before the final polish.

Polishing Stage

-

Resin Flexible Polishing Wheels (with Diamond/Ceria Polish):

These wheels bend to fit your stone’s shape. You get even contact and a bright shine. They work with diamond or ceria polish for the best results.

-

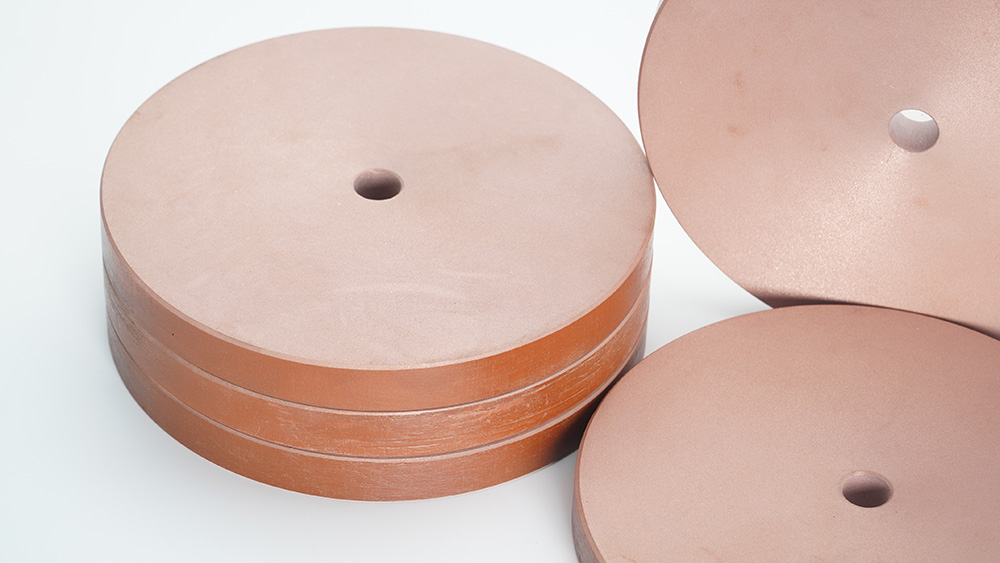

Pure Copper Wheels (with Diamond Powder):

If you want a mirror finish, try pure copper wheels with diamond powder. They are perfect for the last step when polishing hard stones.

Supplementary Tools for Special Cases

-

Ceramic-Bonded Grinding Wheels:

Use these for special materials that need extra care. They balance hardness and smoothness. -

Felt Wheels + Cerium Oxide:

For the final touch, felt wheels with cerium oxide give a high-gloss finish on glassy stones.

Top Diamond Grinding Wheel Recommendations

You want the best diamond grinding wheel for lapidary. Here is a table to help you compare top choices:

|

Product Name |

Bond Type |

Grit Range |

Key Features |

Machine Compatibility |

Pros |

Cons |

Ideal Use Cases |

|---|---|---|---|---|---|---|---|

|

Resin-bonded |

60-14000 |

Foam-backed, soft, absorbs vibration, universal fit, heat control |

6″ machines (adapters included) |

Smooth finish, less chipping, easy fit |

Needs break-in |

Shaping, pre-polishing, delicate stones |

|

|

Kingsley North Diamond Grinding Wheel |

80-600 |

High efficiency, durable, strong abrasive resistance |

6″ and 8″ machines |

Fast material removal, long life |

Louder, can get hot |

Rough grinding, shaping |

|

|

Nova Resin-Bonded Diamond Wheel |

Resin-bonded |

280-3000 |

Soft resin, flexible, smooth finish |

6″ and 8″ machines |

Quiet, cool, great for curves |

Wears faster on hard stones |

Pre-polishing, fine shaping |

|

Electroplated Diamond Grinding Wheel |

Electroplated |

80-400 |

Sharp, high removal rate, no dressing needed |

6″ and 8″ machines |

Fast, precise, easy to use |

Less info on durability |

Hard stones, precision grinding |

Note: Most diamond grinding wheels for lapidary come in 6-inch and 8-inch sizes. These fit standard lapidary machines. You can upgrade or replace wheels easily.

Typical Grit Progression for Lapidary

You need to use the right grit order for a smooth finish. Each step removes scratches from the last one. Here is a simple order to follow:

-

Start with coarse diamond grit (175) for shaping.

-

Use medium grit (325) for smoothing.

-

Use 600 grit for rough sanding.

-

Try 400 grit wet-or-dry sandpaper for fine sanding.

-

Use 600 grit wet-or-dry sandpaper for pre-polishing.

-

Use 800 grit wet-or-dry sandpaper for final pre-polishing.

-

Polish with leather laps and 15,000 grit diamond paste.

-

Finish with leather laps and 50,000 grit diamond paste for a shiny look.

Following these steps helps you avoid scratches and get a shiny, smooth stone every time.

How to Choose the Right Wheel for Your Machine

You need a diamond grinding wheel for lapidary that fits your machine. Most wheels come in 6-inch and 8-inch sizes. These sizes work with almost all lapidary machines. The universal fit lets you use these wheels for jewelry, stone art, or hobbies. A soft resin bond gives better contact and a smoother finish, especially on curves and delicate stones. Picking the right size and bond type helps you get professional results at home.

Quick Comparison Table: Wheel Types and Their Best Uses

|

Type of Diamond Grinding Wheel |

Performance Characteristics |

Best Use Cases |

|---|---|---|

|

Metal-bonded |

High efficiency, self-sharpening, strong, durable |

Rough and fine grinding of glass, stone, ceramic |

|

Resin-bonded |

Fine grinding, polishing, cool running, gentle on stones |

Polishing, sharpening, delicate stones |

|

Electroplated |

Sharp, high removal rate, no dressing needed |

Precision grinding, hard stones |

Pick the right wheel for each step. You will get better results and save time.

Tips for Use and Maintenance

Installation

You want your diamond grinding wheel to work perfectly from the start. Follow these steps to avoid common mistakes:

-

Always match the wheel size and arbor hole to your machine.

-

Mount the wheel securely. Loose or uneven mounting can cause vibration or even breakage.

-

Inspect the wheel for chips or cracks before installation. Never use a damaged wheel.

-

Do not use too much force when tightening. Over-tightening can damage the wheel.

-

After mounting, spin the wheel by hand to check for wobbling.

-

Dress the wheel if needed to expose fresh diamonds and keep the surface even.

Tip: Regularly check your wheel during use. Early detection of problems keeps you safe and your equipment running smoothly.

Cleaning and Care

Proper care extends the life of your diamond grinding wheel and keeps your results sharp.

-

Use a side-to-side motion when grinding. This helps the wheel wear evenly.

-

Keep water flowing over the wheel to prevent overheating and damage.

-

Clean the wheel after each use to remove debris and sludge.

-

Store your wheels in a dry, well-ventilated place. Moisture can cause rust and resin breakdown.

-

Check for wear and replace parts as needed.

-

Lubricate moving parts and keep cords away from water.

Note: Dressing your wheel with a silicon carbide stick keeps it sharp and ready for your next project.

Safety Tips

Stay safe every time you work. Protect yourself and your workspace with these habits:

-

Always wear safety glasses or a face shield to guard against flying debris.

-

Use hearing protection if the machine is loud.

-

Inspect wheels before use. Replace any that show cracks or chips.

-

Stand to the side of the wheel during startup.

-

Wear gloves and sturdy shoes to protect your hands and feet.

-

Work in a well-ventilated area or use wet grinding to control dust.

-

Keep your workspace clean and organized to avoid accidents.

|

Common Hazard |

Prevention Method |

|---|---|

|

Eye injuries |

Wear goggles or face shields |

|

Inspect wheels, mount correctly, never remove guards |

|

|

Dust inhalation |

Use masks, wet grinding, and good ventilation |

|

Hearing damage |

Use hearing protection |

Remember: Safe habits protect you and help you enjoy your craft for years to come.

Upgrading to diamond grinding wheels gives you smoother results, longer tool life, and less mess in your workspace. You save time because these wheels cut faster, last for years, and need little maintenance.

-

You get better edge quality and a cleaner finish on every stone.

-

Choosing the right grit and wheel type lets you control the shine and strength of your stones.

Take a moment to check your machine and wheel setup. Pick the best diamond wheel for your goals, and you will see your lapidary work reach a new level.

FAQ

What grit diamond wheel should you start with for shaping stones?

You should start with a coarse grit, like 80 or 120. This grit removes material quickly and shapes your stone fast. You save time and get a better base for finer grits.

Can you use diamond grinding wheels on any lapidary machine?

Most diamond wheels fit standard 6-inch or 8-inch lapidary machines. Always check your machine’s arbor size before buying. You get the best results when the wheel matches your machine.

How do you clean a diamond grinding wheel?

Use water and a soft brush to remove debris after each use. For stubborn buildup, use a dressing stick. Clean wheels cut better and last longer.

Do you need to use water with diamond grinding wheels?

Yes, you should use water. Water cools the wheel, reduces dust, and gives you a smoother finish. You protect your stones and your health by keeping things wet.

How long does a diamond grinding wheel last?

A quality diamond wheel can last years with proper care. You save money because you replace wheels less often. Always follow cleaning and storage tips to extend the life of your wheel.

Contact Us

For More Grinding Solution or Customized Abrasive Tools