Choosing the right grinding wheel from countless options can be a challenge. The global market for these wheels is growing, projected to reach USD 4.0 billion by 2033, driven by a need for greater precision. A systematic method simplifies this selection.

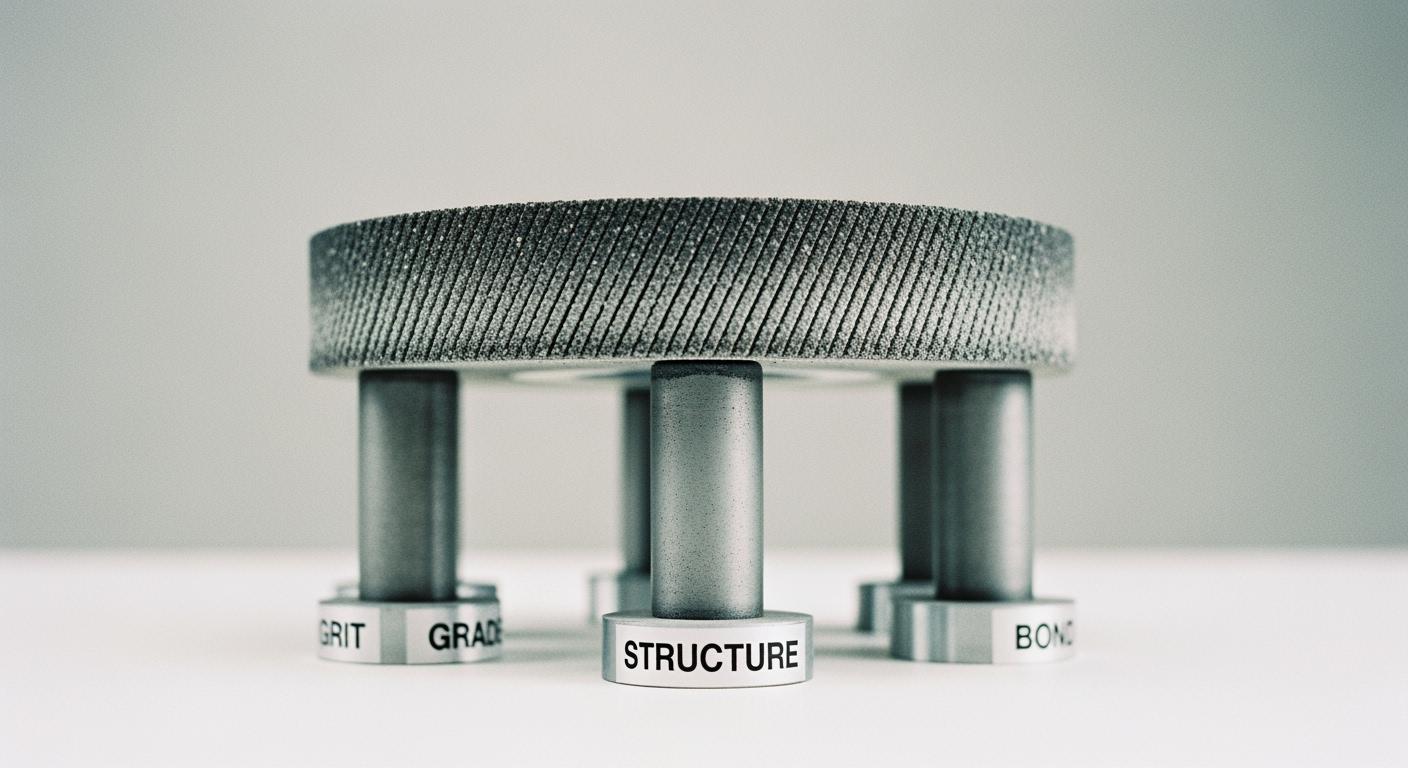

This approach relies on the 4 pillars of aluminum oxide wheel selection: grit, grade, structure, and bond.

Understanding these key factors to consider when selecting a wheel transforms the process. It empowers users to pick the perfect wheel for any grinding task, boosting performance, durability, and longevity.

Key Takeaways

- Choosing the right grinding wheel is easy when you understand its four main parts: grit, grade, structure, and bond.

- Grit size tells you how rough or smooth the wheel cuts. Use coarse grit for fast material removal and fine grit for a smooth finish.

- Wheel grade shows how hard the bond is. Soft wheels work well on hard materials, and hard wheels are good for soft materials.

- Structure is about how close the abrasive grains are. Open structures help with heavy grinding, and dense structures give a fine finish.

- The bond holds the wheel together. Different bonds offer different strengths and flexibility for various grinding tasks.

The 4 Pillars of Aluminum Oxide Wheel Selection

Excellent grinding performance depends on a wheel perfectly matched to the job. The selection process becomes simple when users understand the core components of a grinding wheel. These components provide the key to unlocking optimal precision and efficiency for all grinding applications.

The 4 pillars of aluminum oxide wheel selection are:

- Abrasive Grit

- Wheel Grade

- Structure

- Bond

A deep knowledge of these pillars guarantees better performance, durability, and longevity from your tools. This framework helps users choose the right wheel for any task.

What is Abrasive Grit?

Abrasive grit refers to the size of the individual cutting particles on the wheel. The grit size directly impacts the material removal rate and the final surface finish. Industry standards like ANSI, FEPA, and JIS classify grit size using a numbering system. A lower number indicates a coarse grit for rapid grinding, while a higher number signifies a fine grit for precision finishing. Choosing the correct grit size is the first step toward achieving the desired performance.

Understanding Wheel Grade

The wheel grade measures the hardness of the bonding agent holding the abrasive particles. An alphabetical scale from A (soft) to Z (hard) defines the grade.

- Soft Grades (A-H) work best on hard materials.

- Medium Grades (I-P) offer balanced performance for general use.

- Hard Grades (Q-Z) provide excellent durability on softer metals.

A correct grade ensures the wheel wears at an optimal rate, exposing new, sharp grit for consistent grinding.

The Role of Structure

Structure describes the spacing or density of the abrasive grains in a wheel. An open structure has wide spacing, which helps with chip clearance and cooling during heavy grinding. A dense structure has grains packed closely together. This is ideal for applications requiring high precision and a very smooth surface finish. The structure influences the wheel’s cutting action and overall performance.

Choosing the Right Bond

The bond is the adhesive material that holds the abrasive grit together. Common types include vitrified, resin, and rubber bonds. Each bond type offers different characteristics of strength, flexibility, and heat resistance. The right bond enhances the wheel’s durability and ensures it can handle the stress of specific grinding operations. The 4 pillars of aluminum oxide wheel selection work together to deliver superior precision and performance.

Pillar 1: Understanding Grit Size

The first pillar in selecting the right grinding wheel is understanding grit size. This single factor dramatically influences the wheel’s performance, the speed of the job, and the quality of the final surface finish. A solid grasp of understanding grit size is essential for achieving both efficiency and precision in any grinding task.

What is Grit?

Grit refers to the size of the individual abrasive particles that perform the cutting action. The grit size is rated with a number. This number comes from a standard grading method that uses a sieve, or mesh, to sort the particles. A lower number, like 24, indicates a coarse grit with larger abrasive particles. A higher number, such as 180, signifies a fine grit with smaller particles. This system provides a reliable way to define the cutting potential of a wheel. The correct grit size selection is the first step toward excellent grinding performance.

How to Choose the Right Grit

Choosing the right grit size involves balancing material removal speed with the required finish. The choice depends entirely on the goals of the grinding applications.

- Coarse Grit (16-24): Use a coarse grit size for rapid material removal. These wheels are perfect for heavy grinding on softer materials like mild steel or for quickly shaping a workpiece. They offer great performance but leave a rougher surface.

- Medium Grit (30-60): This grit size offers a good compromise between speed and finish. It is a versatile choice for general-purpose grinding on various metals, providing good durability and consistent performance.

- Fine Grit (70-220): Select a fine grit size when precision and a smooth surface finish are the top priorities. These wheels are ideal for sharpening tools, finishing hard materials like carbide, or any task requiring high precision. Their longevity in precision tasks makes them valuable.

Pro Tip: Always start with the coarsest grit that achieves the desired material removal without damaging the workpiece. Then, move to a finer grit to achieve the final precision and surface quality.

The material being worked on also dictates the ideal grit size for optimal performance and durability.

| Grit Size | Common Applications & Materials |

|---|---|

| Coarse | Fast stock removal on cast iron and stainless steel. |

| Medium | General grinding on mild steel and aluminum. |

| Fine | Finishing and sharpening on carbide and high-speed steel. |

Properly understanding grit size ensures the wheel delivers the best performance for the job.

Pillar 2: The Grade or Hardness

The second pillar, wheel grade, refers to the hardness of the bond holding the abrasive grains together. This factor does not describe the hardness of the abrasive itself. Instead, it measures the bond’s strength. A correct grade ensures the wheel wears at an optimal rate. This self-sharpening action exposes new, sharp grit for consistent grinding performance and precision. Understanding grade is crucial for balancing wheel longevity with cutting efficiency.

What is Grade?

The grade of a grinding wheel indicates the relative strength of its bond. A standard alphabetical scale defines this property. The scale provides a simple way to identify the bond’s holding power.

The grade of a grinding wheel is denoted by an alphabetical scale, ranging from A to Z. ‘A’ signifies the softest grade, and ‘Z’ represents the hardest.

A softer bond breaks down faster. This action releases dull abrasive grains and reveals fresh ones. A harder bond holds onto grains longer, which increases durability. The right grade choice directly impacts the wheel’s performance and the quality of the grinding work.

How to Choose the Right Grade

Choosing the right grade involves a simple but important rule: use a soft grade wheel for hard materials and a hard grade wheel for soft materials. A soft wheel on hard material prevents clogging by shedding grains easily. This exposes new sharp edges for effective grinding. A hard wheel provides the durability needed for grinding softer materials.

- Soft Grades (A-H): These are best for hard materials like tool steel and carbides. They are also used for applications requiring high precision.

- Medium Grades (I-P): This range offers versatile performance for general-purpose grinding on various steels.

- Hard Grades (Q-Z): These wheels have excellent durability. They work well on softer materials like aluminum and mild steel.

The following table compares the performance of soft and hard grade wheels for different applications.

| Feature | Soft Grade Wheels | Hard Grade Wheels |

|---|---|---|

| Abrasive Renewal | Faster renewal rate; exposes new grit | Slower renewal rate; retains grit longer |

| Cutting Action | More aggressive cutting | Less aggressive cutting |

| Best For | Hard materials, precision grinding | Soft materials, rough grinding |

| Effect | Prevents wheel loading and glazing | Maximizes wheel durability |

Selecting the correct grade optimizes the grinding process, ensuring superior performance and precision.

Pillar 3: The Structure and Spacing

The third pillar, structure, focuses on the spacing between the abrasive grains within a grinding wheel. This element is a critical factor that influences chip clearance, coolant flow, and the final finish. Proper structure selection enhances the wheel’s performance and ensures it is well-suited for specific grinding applications. A deep understanding of structure helps users achieve greater precision and efficiency.

What is Structure?

Structure describes the density of the abrasive grains in a wheel. A numerical scale from 1 to 17 defines this property. A low number like 1 indicates a dense structure with grains packed closely together. A high number like 17 represents an open structure with wide spacing between grains. This number reflects the ratio of abrasive material and bond to the amount of air space within the wheel.

A dense structure offers more cutting points per area, which is ideal for fine finishing. An open structure provides ample room for chips, preventing the wheel from loading during heavy grinding.

How to Choose the Right Structure

Choosing the correct structure depends on the material and the goals of the grinding operation. The key is to match the wheel’s spacing to the demands of the job for the best performance. An open structure wheel works best on soft, ductile materials that produce large chips. A dense structure wheel provides the durability and fine finish needed for hard, brittle materials. Excellent precision is achievable with the right choice.

This table compares the performance of dense and open structure wheels.

| Feature | Dense Structure Wheel | Open Structure Wheel |

|---|---|---|

| Grain Spacing | Less space between grains | More space between grains |

| Chip Clearance | Less clearance; for small chips | More clearance; for large chips |

| Finish Quality | Finer, smoother finish | Rougher finish |

| Heat Generation | Generates more heat | Cooler grinding performance |

| Best For | Hard, brittle materials | Soft, ductile materials |

Selecting the right structure is essential for optimizing the grinding process. It ensures the wheel delivers the required precision and longevity for various applications, leading to superior results.

Pillar 4: The Bond for Precision Grinding

The final pillar, the bond, is the adhesive that holds the abrasive grains together in a grinding wheel. The type of bond determines the wheel’s strength, flexibility, and heat resistance. Choosing the correct bond is essential for maximizing grinding precision and achieving optimal performance. A wheel’s longevity and durability depend heavily on this crucial component.

What is Bond?

The bond acts as the structural framework for the abrasive wheel. It secures the grit, allowing it to cut effectively. The bond’s composition dictates how the wheel behaves under the stress of grinding operations. There are three common bond types, each suited for different applications.

- Vitrified (V): This is a hard, rigid bond made from fired clay. It offers excellent grain retention and is unaffected by coolant. It is the most common bond for general-purpose precision grinding.

- Resinoid (B): This bond uses synthetic resins. It is more elastic than a vitrified bond, making it great for high-speed cutting and rough grinding applications. It provides a cooler cutting action.

- Rubber (R): This is a highly elastic bond. It produces an exceptionally smooth finish and is often used for tasks like polishing bearing races or for wet cutting applications.

Aimgrind’s Vitrified Bond Wheels

For users focused on maximizing grinding precision, the right wheel makes all the difference. Aimgrind‘s vitrified bond grinding wheels are a leading example for demanding precision grinding tasks. These wheels showcase features designed for superior performance and durability.

Aimgrind’s wheels offer exceptional hardness and thermal stability. These features make them ideal for the precision grinding of hard metals and ceramics. Their advanced bond technology ensures consistent performance and longevity, reducing downtime.

The unique bonding system provides excellent wear resistance, which is critical for applications in precision grinding. This makes them a valuable tool for industries requiring high-quality results. Their design supports efficient heat dissipation, protecting the workpiece and ensuring a flawless finish. These wheels have many applications in precision grinding, delivering reliable and efficient solutions.

Putting It All Together: A Practical Guide

An exceptional grinding wheel is the cornerstone of any successful grinding project. The key to unlocking its full potential lies in understanding the 4 pillars of aluminum oxide wheel selection: grit, grade, structure, and bond. These are the essential factors to consider when selecting a wheel. By mastering these concepts, users can transform a complex choice into a simple, logical process, ensuring optimal performance, durability, and longevity for every task.

This guide will now synthesize this knowledge into a practical framework. It will demonstrate how to read a grinding wheel’s label and provide a quick reference for common applications. This will empower users to confidently select the perfect wheel, maximizing grinding precision and efficiency.

Decoding Wheel Labels for Grinding

At first glance, the string of letters and numbers on a grinding wheel can seem like a secret code. However, this marking system is a standardized label that clearly communicates the wheel’s characteristics. Each character corresponds directly to one of the four pillars, providing a complete specification of the wheel’s design and intended performance.

Example Marking:

A 46 H 8 V

This standard marking provides all the necessary information to match a wheel to a specific job. Understanding this code is the final step in applying your knowledge of grit, grade, structure, and bond.

The table below breaks down what each part of the example marking means.

| Character | Meaning | Interpretation for ‘A 46 H 8 V’ |

|---|---|---|

| A | Type of Abrasive | Fused aluminum oxide, a versatile abrasive. |

| 46 | Grit Size | Medium grit, balancing material removal and finish. |

| H | Grade of Hardness | Medium-soft grade, good for hard materials. |

| 8 | Structure | Medium density, offering a balance of finish and chip clearance. |

| V | Bond | Vitrified bond, ideal for precision grinding. |

By decoding this label, a user can quickly determine that this specific wheel is a medium grit, medium-soft grade aluminum oxide wheel with a vitrified bond. This configuration makes it suitable for general-purpose grinding on harder metals where precision is a goal.

Application Cheat Sheet

Selecting the right grinding wheel involves balancing multiple factors to avoid common mistakes. Using a wheel with a bond that is too hard can cause glazing, while choosing the wrong grit size can lead to inefficient grinding or a poor finish. This “cheat sheet” provides recommended starting points for several common grinding applications, helping users achieve excellent performance and durability.

| Application | Recommended Grit Size | Recommended Grade | Recommended Structure | Recommended Bond |

|---|---|---|---|---|

| Rough Grinding Soft Steel | Coarse (10-24 grit) | Hard (Q-Z) | Open (9-12) | Resinoid (B) |

| General Purpose Grinding | Medium (30-60 grit) | Medium (I-P) | Medium (7-9) | Vitrified (V) |

| Finishing Hardened Tool Steel | Fine (46-80 grit) | Soft (K-L) | Dense (4-6) | Vitrified (V) |

| Sharpening Carbide Tools | Fine (80-220 grit) | Soft (G-J) | Dense (4-6) | Vitrified (V) |

| Grinding Non-Ferrous Metals | Medium (36-60 grit) | Medium (I-P) | Open (9-12) | Silicon Carbide (C) |

Pro Tip: 💡 For finishing hardened tool steel, a 46 grit aluminum oxide wheel is often sufficient for achieving good precision. The final finish quality also depends heavily on how the wheel is dressed and the care taken during the final passes.

This table serves as a strong starting point. For tasks requiring the highest level of precision, such as applications in precision grinding, users should always consider the specific material and machine parameters. Maximizing grinding precision often involves fine-tuning these recommendations to perfectly match the job’s unique demands. This approach ensures the best possible performance and longevity from your grinding wheel.

Selecting the right grinding wheel is a logical process. It relies on the interplay of the 4 pillars of aluminum oxide wheel selection. Understanding these factors transforms a frustrating task into a strategic decision. This knowledge enhances grinding efficiency and quality. It ensures superior performance, precision, and durability for every wheel.

For your next precision grinding project, explore high-quality solutions like Aimgrind’s specialized wheels. Use this guide to achieve excellent grinding performance, precision, and the best longevity and durability from your tools.

FAQ

How do users maintain a grinding wheel?

Proper maintenance is essential for any grinding wheel. Users follow maintenance tips for optimal performance. This includes regular sharpening (dressing). Good maintenance and sharpening ensure safety. This process is crucial for minimizing wear and extending lifespan during grinding.

What features matter for different grinding jobs?

A wheel’s features must match the specific grinding applications. Key features like grit and grade determine performance. Users select a wheel based on the material and desired finish for their grinding applications.

What are some basic maintenance tips for sharpening?

Good maintenance includes regular sharpening. Users should inspect the wheel before each grinding task. These maintenance tips for optimal performance help with sharpening. Proper maintenance and sharpening prevent glazing. This is key for minimizing wear and extending lifespan and effective sharpening.

Why is wheel sharpening important for grinding?

Wheel sharpening, or dressing, exposes new grit. This maintenance step is vital for efficient grinding. Consistent sharpening ensures better grinding performance. This maintenance is part of a good maintenance routine for sharpening tools. Following maintenance tips for optimal performance includes this sharpening.

Contact Us

For More Grinding Solution or Customized Abrasive Tools