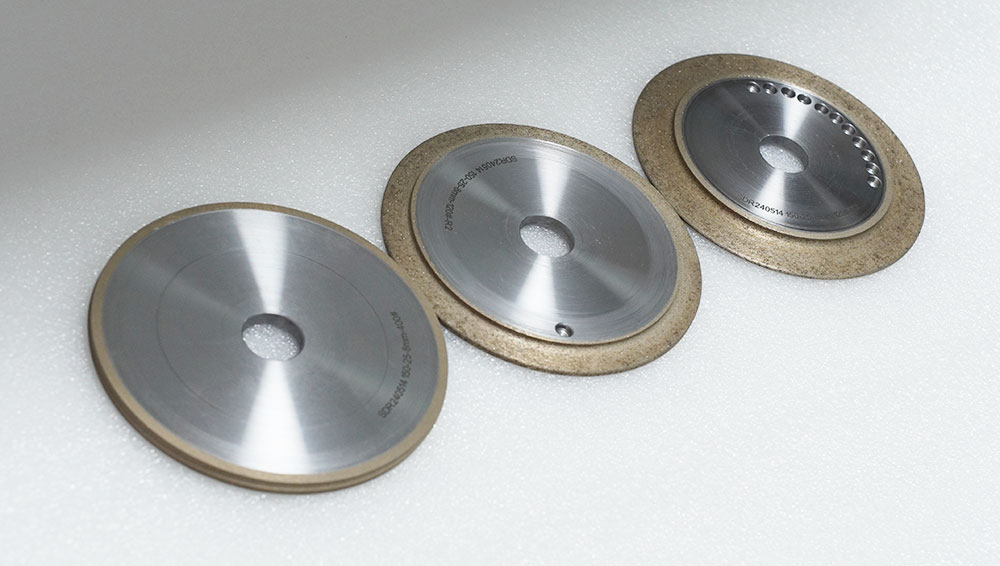

For demanding industrial applications, a metal bond grinding wheel provides unmatched durability and form retention. These characteristics directly translate to key business benefits, including longer wheel life and superior part accuracy, which lowers the total cost per piece. The market for these wheels continues to expand, driven by industries requiring consistent performance.

- Key growth drivers include high demand from the automotive, aerospace, and electronics sectors.

- The Asia Pacific region leads this expansion, accounting for over 42% of global revenue.

This exceptional performance in tough grinding applications makes them essential for operations focused on maximizing productivity and quality in specialized applications.

Key Takeaways

- Metal bond grinding wheels last a long time. They save money by reducing how often you need to replace them.

- These wheels are very precise. They help make sure finished parts are accurate and have a good surface.

- Metal bond wheels handle heat well. This stops your parts from getting damaged during grinding.

- These wheels work best for tough jobs. They are good for grinding hard materials and work well with cooling liquids.

Why a metal bond grinding wheel offers superior life

The exceptional durability of a metal bond grinding wheel stems from its unique manufacturing process and material composition. This advanced engineering results in significant operational advantages for demanding industrial applications.

The science behind extreme bond hardness

The hardness of a metal bond comes from a process called sintering. This high-temperature process “bakes” a mixture of metal powders, such as bronze, steel, and nickel alloys, under pressure. Sintering fuses the metal particles together, creating an incredibly dense and robust matrix. This process enhances the material’s tensile strength and impact toughness. The resulting bond securely holds superabrasive grains like diamond or CBN, preventing them from breaking out prematurely during tough grinding applications. This strong bond is essential for maintaining wheel integrity and delivering consistent performance.

Benefit: Lower downtime and replacement costs

The superior hardness of a metal bond directly translates to extended wheel life. While a typical resin bond wheel may last between 1,000 and 3,000 hours, metal bond wheels offer a much longer operational lifespan. This durability is especially noticeable when grinding hard materials like tungsten carbide.

Key Takeaway: Longer wheel life means fewer replacements. This simple fact leads to a significant reduction in machine downtime and lowers the total cost of ownership.

Operators spend less time changing and dressing wheels, which boosts overall productivity. Although the initial investment for a metal bond grinding wheel might be higher, the long-term savings are substantial. Reduced replacement frequency and fewer scrapped parts make it the most cost-effective solution for high-volume production and precision applications, ensuring reliable performance day after day.

Unmatched precision for complex machining

Precision is non-negotiable in advanced manufacturing. A metal bond grinding wheel delivers the accuracy required for complex machining operations. Its ability to hold a precise shape ensures that every part meets exact specifications, a critical factor for high-value industries.

How form retention ensures profile integrity

The rigid metal matrix gives these wheels exceptional form retention. This means the wheel’s edge and profile do not wear down or change shape easily, even during demanding grinding applications. This stability is vital when machining superhard materials. For example, Aimgrind customers grinding PCD and PCBN cutting tools rely on this feature. The wheel maintains its profile, ensuring the tool’s cutting edge is ground to the exact required geometry for clean cuts.

Aimgrind’s customized formula design further enhances this capability. By tailoring the bond to specific precision grinding tasks, such as sharpening tungsten carbide saws, operators can achieve perfect profile integrity. This prevents defects and ensures the final tool performs flawlessly.

Benefit: Consistent accuracy in finished parts

Excellent form retention directly produces consistent accuracy in finished parts. This consistency is essential for high precision machining, where even tiny deviations can lead to part failure. The result is a superior surface finish and the elimination of costly rework. Many industries depend on this level of precision.

| Industry | Precision Application |

|---|---|

| Aerospace | Grinding turbine blades and high-performance ceramic parts. |

| Medical | Manufacturing surgical tools and implants with a perfect finish. |

| Tool & Die | Sharpening cutting tools and creating molds with tight tolerances. |

| Electronics | Grinding semiconductor wafers and ceramic substrates. |

Aimgrind supports these applications by offering tailored solutions. Different wheel designs, like segmented or continuous rims, are engineered for specific machining needs. This customization helps customers achieve high-quality surface finishes and make clean cuts, delivering reliable performance across all their grinding applications.

Excellent thermal stability for hard materials

Managing heat is crucial when grinding hard materials. Excessive heat can ruin both the workpiece and the wheel. Metal bond grinding wheels excel in this area, offering superior thermal stability that protects your parts and preserves wheel life.

Efficient heat dissipation from the grinding zone

The excellent thermal conductivity of a metal bond wheel comes from its atomic structure. Metals possess a unique bond where electrons are not fixed to a single atom. Instead, they form a mobile ‘sea of electrons‘ that can move freely. This mobility allows them to transfer heat energy rapidly away from the grinding zone. This process is far more efficient than in other bond types.

Aimgrind enhances this natural property with smart engineering. Designs like segmented rim wheels feature gaps, or gullets, that serve two key purposes:

- They create airflow that provides air cooling during operation.

- They allow cutting fluids to flow more effectively into the grinding zone.

This combination of material science and design keeps the grinding interface cool, even during intense grinding applications.

Benefit: Preventing thermal damage to the workpiece

Efficient heat dissipation directly prevents thermal damage to the workpiece. High temperatures can cause serious defects that compromise the integrity and quality of the final part.

Key Benefit: A cooler grinding process protects against common heat-related defects, including:

- Metallurgical burns and discoloration

- Surface micro-cracks

- Warping or distortion of the part

By managing heat effectively, metal bond wheels ensure that hard materials retain their desired structural properties. This is vital in precision grinding applications where part quality is paramount. Operators can grind with confidence, knowing the workpiece is safe from thermal damage, which reduces scrap rates and improves overall production quality.

Designed for specialized grinding operations

Metal bond wheels are engineered for specific, challenging grinding applications. Their robust construction provides the versatility needed for high-performance grinding and advanced machining processes. This makes them a top choice for specialized applications requiring both power and precision.

Why metal bonds excel in wet grinding

Metal bonds show exceptional performance in wet grinding applications. The metal matrix is naturally resistant to chemical reactions from coolants. This durability allows for techniques like flood cooling, where large volumes of fluid immerse the grinding zone. This process removes heat and lubricates the surface, improving the final finish and extending tool life.

Efficient coolant delivery is critical for high-performance grinding. Wheel designs with internal channels can accelerate fluid flow, reducing temperatures significantly and boosting overall process performance.

This makes metal bond wheels ideal for demanding operations like creep-feed grinding. The combination of a strong bond and effective cooling allows for rapid material removal without compromising part integrity. The versatility of these wheels in wet environments is essential for many modern machining tasks.

Unlocking the power of diamond and metal bond cbn wheels

Choosing the right superabrasive is key to optimizing performance. The choice between diamond and Cubic Boron Nitride (CBN) depends entirely on the workpiece material. Metal bond CBN wheels are the correct choice for grinding hard ferrous materials like steel. Iron causes diamond abrasives to break down chemically, leading to rapid wear. Therefore, metal bond CBN wheels provide superior results for these applications. In contrast, electroplated diamond grinding wheels excel on non-ferrous materials.

The versatility of these wheels is unmatched. For example, electroplated diamond grinding wheels are used for high-speed CNC machining. Other options like resin bond CBN wheels, vitrified bond CBN wheels, and electroplated CBN wheels serve different needs. Hybrid bond CBN wheels offer unique properties for specific tasks. For high-speed grinding applications, electroplated diamond grinding wheels provide excellent results. The stability of electroplated diamond grinding wheels is crucial for high-speed machining. Many industries rely on electroplated diamond grinding wheels for their specialized applications. The performance of electroplated diamond grinding wheels in high-speed machining is well-documented. For rapid material removal, electroplated diamond grinding wheels are a go-to solution. The precision of electroplated diamond grinding wheels supports complex machining. Ultimately, electroplated diamond grinding wheels, metal bond CBN wheels, resin bond CBN wheels, vitrified bond CBN wheels, and electroplated CBN wheels offer a wide range of solutions. The durability of electroplated diamond grinding wheels makes them suitable for many specialized applications. The combination of resin bond CBN wheels, vitrified bond CBN wheels, and electroplated CBN wheels covers nearly all grinding needs.

A metal bond grinding wheel delivers superior durability, unmatched precision, and excellent heat management. These wheels perform ideally with coolants and superabrasives in specialized operations. While the initial price is higher, the long-term savings are significant. Companies reduce costs through less downtime, fewer wheel changes, and the elimination of part defects. This makes them the most cost-effective choice for demanding industrial applications.

For any operation focused on maximizing productivity and quality, choosing Aimgrind’s metal bond wheels is a strategic investment in superior performance.

FAQ

What makes metal bond wheels so durable?

Their durability comes from a sintered metal matrix. This process creates a very hard bond. The bond securely holds abrasive grains, which reduces wear during tough grinding applications and extends the wheel’s operational life.

When should I use a metal bond CBN wheel?

A metal bond CBN wheel is the best choice for the precision machining of hard ferrous materials like steel. It prevents chemical reactions that cause rapid wear, ensuring efficient and clean results for your machining process.

Can these wheels be used for both wet and dry machining?

Metal bond wheels excel in wet machining because their bond resists coolant chemicals. Wet grinding cools the workpiece and improves surface finish. Dry machining is possible but less common for these wheels.

How do metal bond wheels compare to other types?

Metal bond wheels offer superior durability for heavy material removal. In contrast, electroplated diamond grinding wheels provide excellent performance for high-speed, precision tasks where less material is removed per pass.

See Also

Selecting the Optimal Metal Grinding Wheel for Your Specific Project

Picking the Best Bench Grinding Wheel Material for Your Requirements

Guiding Your Choice of Grinding Wheels for Stainless Steel Applications

Identifying the Ideal Grinding Wheel for Your Carbide Tool Sharpening

Understanding Various Grinding Wheel Types and Their Real-World Uses

Contact Us

For More Grinding Solution or Customized Abrasive Tools