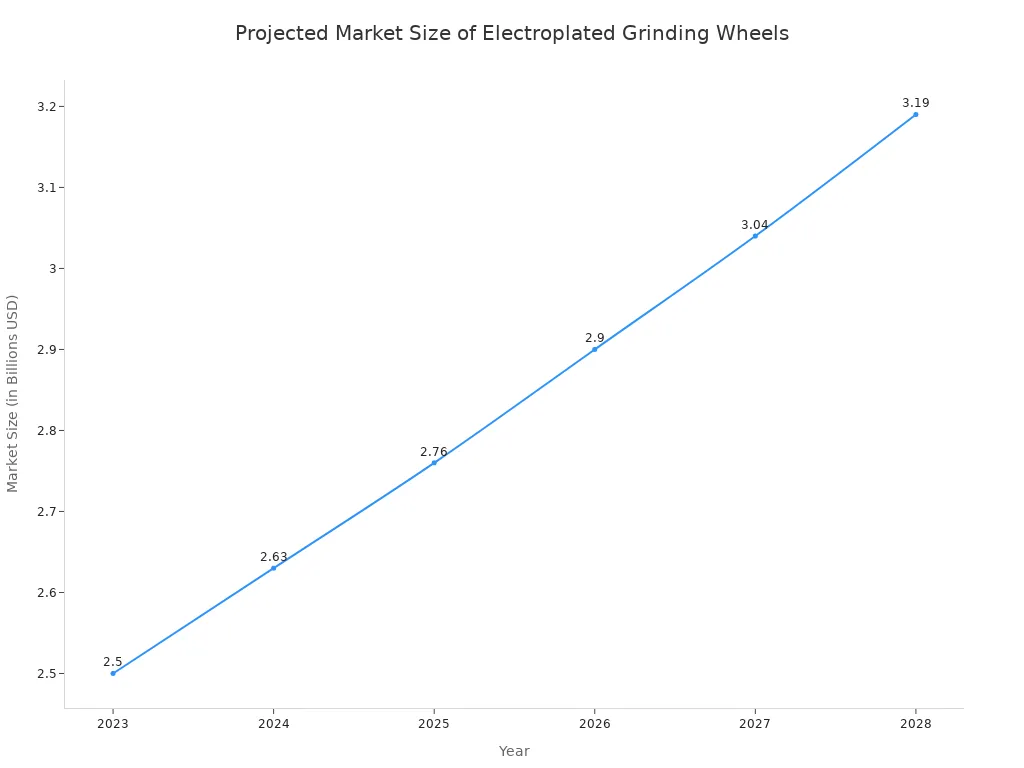

For applications demanding the highest accuracy, electroplated grinding whheir unique single-layer electroplated abrasive construction delivers aggressive cutting and unparalleled form-holding for precision grinding. This guide shows engineers the competitive edge of electroplated grinding technology, making these tools a strategic investment for complex machining. The market for precision grinding shows consistent growth, highlighting the industrial value of products like electroplated grinding wheels.

| Market Segment | CAGR | Timeframe |

|---|---|---|

| Precision Grinding Wheels Market | 2.29% | 2025 – 2035 |

| CNC Precision Grinding Machine Market | 6% | 2025 – 2033 |

| Precision Grinding Service Market | 6.2% | 2026 – 2033 |

Key Takeaways

- Electroplated grinding wheels offer great accuracy because they have a single, strong layer of abrasive material.s, making them useful for many industries.

- They save money over time because they last longer and can be renewed, which means less downtime and lower costs.

- Electroplated wheels are important for making precise parts in aerospace, medical, and electronics industries.

Unmatched precision and form holding

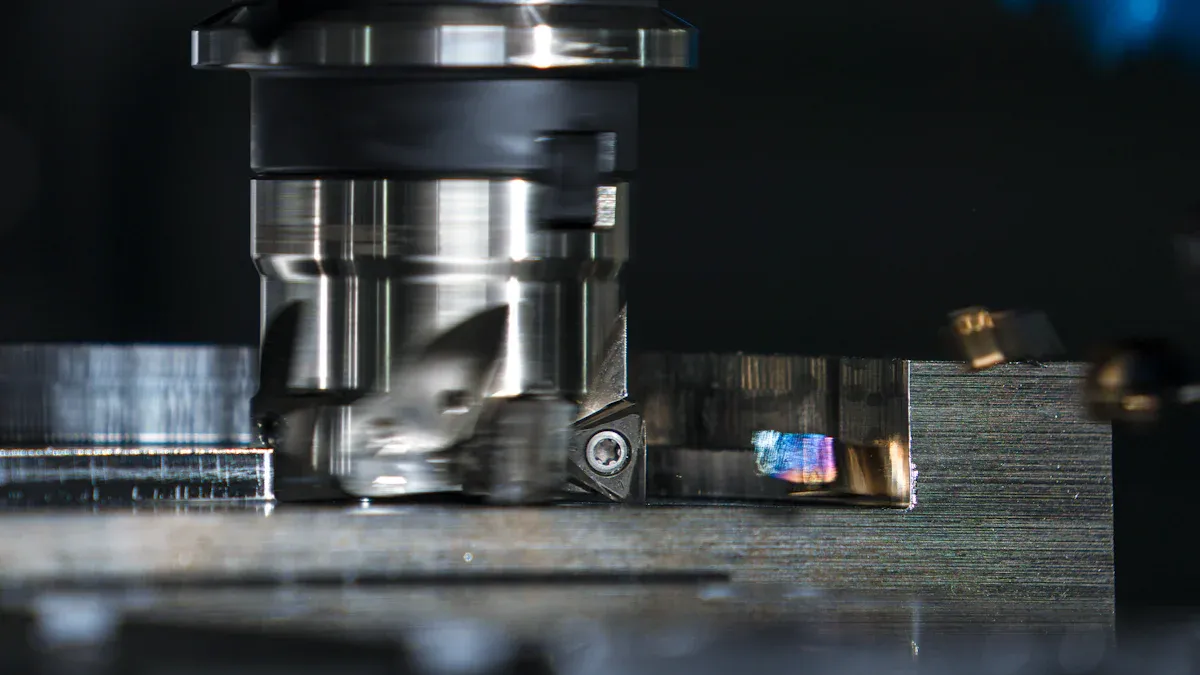

Electroplated grinding wheels offer unmatched precision because of their unique construction. The single, durable abrasive layer is bonded directly to a rigid core. This design ensures a sharp and efficient cutting edge for any grinding task.

The single abrasive layer advantage

The primary benefit of an electroplated wheel is its single abrasive layer. This layer provides a consistent distribution of abrasive particles across the wheel’s surface. The electroplated process securely holds each grain, leading to a superior surface finish and minimal material waste. This construction allows for aggressive cutting action while achieving excellent surface finishes. The consistent distribution of abrasive particles ensures uniform performance throughout the grinding operation.

Holding complex profiles without deviation

Manufacturers create electroplated wheels with incredible accuracy. The process often uses a pre-formed metal core, ensuring the wheel is made to a precise shape from the start. This allows for the creation of complex profiles for specialized machining jobs. Different manufacturing methods offer varying levels of profile complexity and accuracy.

| Manufacturing Method | Profile Complexity | Working Surface Accuracy |

|---|---|---|

| Positive Plating | Low | Low |

| Reversed Plating | Highest | Highest |

| Regular distribution | General | General |

Reversed plating, for example, achieves the highest level of precision for intricate designs. This ensures the wheel holds its exact profile until the abrasive layer wears away, producing consistent parts every time.

Eliminating the need for dressing

A key advantage of electroplated wheels is that they do not require dressing. Dressing is the process of reshaping or cleaning a grinding wheel, which causes downtime.

Since an electroplated wheel has only one abrasive layer, it maintains its form throughout its operational life. This eliminates the need for intermediate reshaping. Operators can continue the grinding process without interruption, boosting productivity. This feature is crucial for applications demanding constant precision and high output, as it guarantees that the first part and the last part have the same exceptional surface finishes. The electroplated design delivers reliable cutting performance from start to finish.

Superior performance on hard materials

Electroplated grinding wheels excel at machining tough materials. Their unique design provides an aggressive yet controlled cutting action. This makes them ideal for industries working with ceramics, hard alloys, and composites. Brands like Aimgrind engineer their electroplated wheels with ultra-high grit retention, ensuring consistent performance during demanding grinding operations.

High-speed, free-cutting action

The single electroplated layer exposes the maximum amount of abrasive grit. This structure creates a free-cutting action that removes material quickly and efficiently. This capability is essential for high-speed machining applications where productivity is key. The electroplated bond securely holds each abrasive particle, allowing for aggressive cutting without sacrificing precision. This design ensures a fast and effective grinding process from start to finish.

Using electroplated diamond grinding wheels

Choosing the right abrasive is critical for success. Electroplated diamond grinding wheels are the top choice for non-ferrous hard materials. Diamond’s properties make it highly effective for this type of machining.

- Superior Hardness: Diamond is harder than materials like tungsten carbide, so it maintains a sharp cutting edge for longer.

- Efficient Cutting: The exposed diamond grains provide a high material removal rate.

- Complex Profiles: The electroplated process allows for precise application on pre-formed cores, perfect for creating intricate tool shapes.

For ferrous metals like steel, CBN is a better option due to its chemical stability at high temperatures.

| Feature / Material | Diamond Wheels | CBN Wheels |

|---|---|---|

| Ideal Materials | Non-ferrous metals, ceramics, glass | Ferrous metals (steel, cast iron) |

| Wear Resistance | Excellent on very hard materials | Outstanding on ferrous metals |

| Chemical Reaction with Iron | Reacts, causing degradation | Does not react, maintains stability |

Using electroplated diamond grinding wheels on the correct materials ensures optimal performance and tool life.

Preventing wheel loading and workpiece damage

Wheel loading occurs when material clogs the grinding wheel’s surface, reducing its cutting ability. This can lead to poor surface finishes and workpiece damage.

The structure of an electroplated wheel naturally resists loading. The ample space between abrasive grains provides clear channels for chip removal. Coolant flows easily into the grinding zone, washing away debris and dissipating heat. This clean cutting action prevents material from building up on the wheel. As a result, the wheel maintains its efficiency, protecting the workpiece and ensuring a high-quality finish.

Long-term cost-effectiveness

Investing in electroplated grinding wheels offers significant long-term financial benefits. While the initial cost may be a consideration, their durability and reusability deliver a lower total cost of ownership. This aligns with Aimgrind’s mission to provide high-quality, customized solutions that enhance productivity and deliver lasting value. The right grinding strategy reduces cycle times and boosts efficiency in any machining operation.

Reducing downtime with longer wheel life

A durable grinding wheel directly reduces machine downtime. High-performance electroplated wheels offer superior form holding and longer operational periods. This extended life means operators change wheels less frequently. Fewer wheel changes lead to more uptime for production. This reliability is crucial for maintaining a consistent and efficient manufacturing process. The strong electroplated bond ensures a long-lasting cutting surface for demanding tasks.

Aimgrind’s strip-and-replate value

Aimgrind offers a strip-and-replate service that provides exceptional value. This process renews a worn electroplated wheel, supporting a cost-effective and sustainable manufacturing strategy. The process is simple and effective:

- Technicians inspect the used wheel core for damage.

- They strip the old abrasive layer and re-inspect the core, making repairs if needed.

- A new electroplated layer of superabrasive is applied.

- The finished wheel undergoes a final inspection before shipment.

This service restores the wheel to its original cutting performance, extending the life of the initial investment.

Lowering total cost per part

Replating a wheel core is much cheaper than buying a new one. Manufacturers can save up to 50% on the cost of a new wheel by choosing this service. These savings directly lower the total cost per part produced. Fewer wheel changes also reduce setup times. Shorter setups increase machine capacity and flexibility without extra cost. This efficient approach to machining improves cash flow and allows a company to better utilize its workforce for complex grinding jobs.

Applications requiring precision grinding

Electroplated grinding wheels are essential tools in industries that demand the highest levels of precision. Their ability to hold complex forms and cut hard materials makes them ideal for creating critical components. The unique construction of an electroplated wheel supports high-speed machining and delivers superior results in various demanding applications.

Aerospace and automotive components

The aerospace and automotive industries rely on high precision parts for safety and performance. Electroplated grinding wheels are crucial for the high precision machining of components made from tough materials like titanium alloys. The grinding process must be exact to meet strict industry standards.

Key aerospace components manufactured with this technology include:

- Turbine blades and vanes

- Aero-engine parts

- Structural components

The aggressive cutting action of an electroplated wheel allows for efficient material removal. This is vital for shaping hard metal engine parts without causing thermal damage, ensuring the final product’s integrity and reliability.

Medical instruments and implants

In the medical field, precision can mean the difference between success and failure. The manufacturing of surgical tools and implants requires flawless surfaces and exact dimensions. Electroplated diamond and CBN wheels are used for the form grinding of prosthetics and joint replacements. For example, specialized wheels shape artificial knee slots and hip joint broaches.

Surgical instruments also benefit from this technology. The grinding process is used to sharpen blades made from materials like hardened stainless steels and alloy steels. This ensures that every tool performs perfectly during a procedure.

Electronics and tool manufacturing

The electronics industry uses electroplated tools for slicing hard, brittle materials like silicon and sapphire into wafers. This process is fundamental to producing semiconductors. The precision of the grinding wheel ensures minimal material waste and creates the smooth surfaces necessary for electronic components.

In tool manufacturing, electroplated wheels perform critical operations like flute grinding and gashing on drills and end mills. These processes create the helical grooves that allow for chip removal during a machining operation. This type of precision grinding is essential for producing high-performance cutting tools used in high-speed cnc machining.

In summary, electroplated grinding wheels deliver unparalleled precision, aggressive cutting, and long-term value. The market’s projected growth underscores their importance in modern grinding.

For industries requiring tight tolerances, these electroplated tools are essential for efficient machining. To enhance your operations, explore Aimgrind’s customized electroplated solutions to optimize your precision grinding process and achieve superior grinding results. ⚙️

FAQ

What are electroplated grinding wheels used for?

Electroplated grinding wheels perform precision grinding on hard alloys and ceramics. Industries like tool manufacturing, aerospace, and electronics use them for demanding tasks. Their design ensures high accuracy and excellent surface finishes on difficult materials.

How do electroplated wheels differ from other grinding wheels?

These wheels feature a single abrasive layer bonded by metal electroplating. This process provides ultra-high grit retention. It results in a longer lifespan and superior cutting performance compared to many traditional grinding wheels.

What materials can electroplated wheels grind?

Electroplated wheels are highly effective on hard, brittle materials. The choice of abrasive is key.

| Abrasive | Best For |

|---|---|

| Diamond | Ceramics, glass, non-ferrous alloys |

| CBN | Hard ferrous metals (steel, cast iron) |

This ensures optimal performance and prevents premature wheel wear.

Are electroplated grinding wheels cost-effective?

Yes, they are highly cost-effective. Their strong grit retention provides a long operational life. Services like Aimgrind’s strip-and-replate option also allow users to renew worn wheels at a lower cost than buying new ones. 💰

See Also

Selecting the Perfect Metal Grinding Wheel for Your Specific Project

Picking the Optimal Grinding Wheel for Your Stainless Steel Work

Identifying the Best Bench Grinding Wheel Material for Your Requirements

Discovering the Ideal Grinding Wheel for Sharpening Carbide Tools

Understanding Various Grinding Wheel Types and Their Real-World Uses

Contact Us

For More Grinding Solution or Customized Abrasive Tools