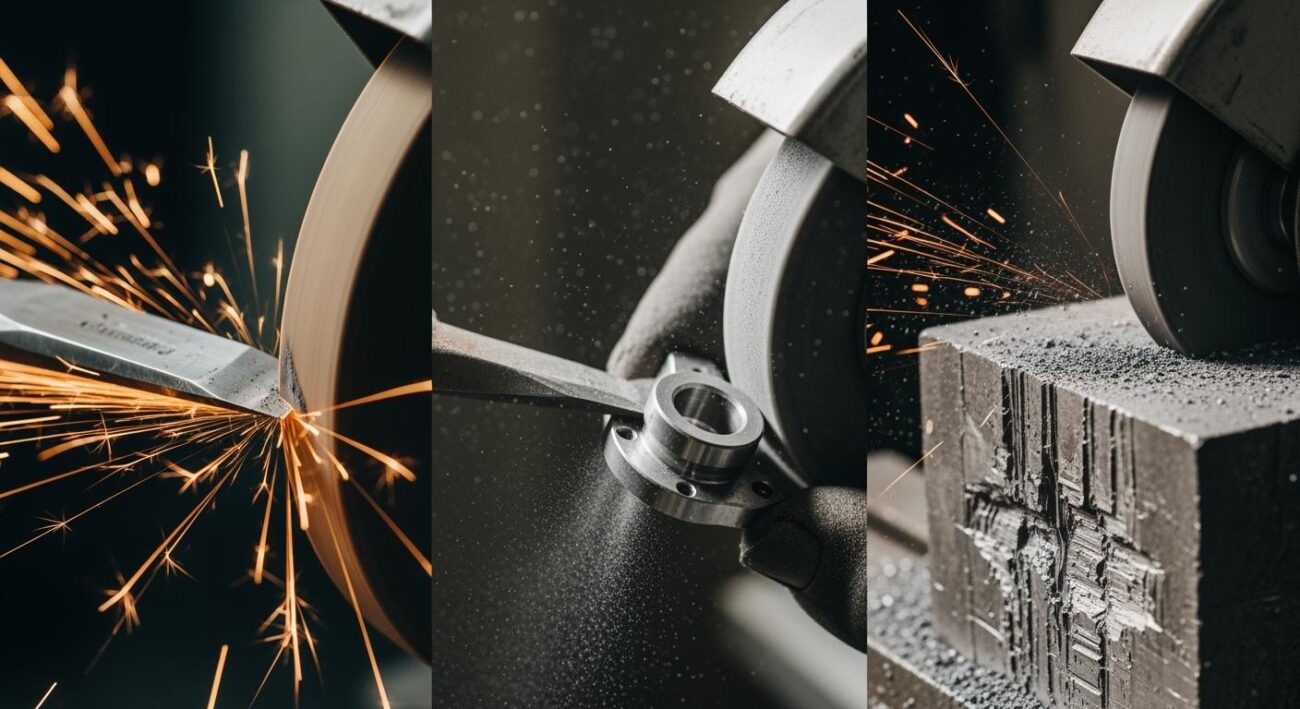

Professionals performing precision grinding on hard materials prefer superabrasive grinding wheels for their longevity. The market for these tools is growing 8% annually. The choice of grinding wheel depends on the material. A diamond grinding wheel is used for non-ferrous materials, while a CBN grinding wheel is for ferrous metals. Superabrasive wheels are the fastest-growing segment in abrasives. Their use in automated machining drives this trend. The two primary superabrasive types are diamond and CBN. The fundamental rule for grinding is choosing diamond for non-ferrous and CBN for ferrous applications.

Key Takeaways

- Professionals use superabrasive grinding wheels for hard materials. These wheels last a long time.

- Diamond wheels work best for non-ferrous materials like carbide and ceramics. CBN wheels are for hard metals like steel.

- Superabrasive wheels help achieve very precise results. They also save money over time because they last longer.

- These wheels make work faster. They also reduce machine downtime.

Diamond Wheels for Hard Non-Ferrous Materials

A diamond grinding wheel is the premier choice for shaping hard, non-ferrous materials. The exceptional hardness of diamond makes it perfect for difficult grinding applications. Professionals rely on this tool for its precision and durability.

Key Users: Tool, Electronics, and Ceramics Specialists

Specialists across several high-tech industries prefer diamond wheels. Toolmakers use them for sharpening and manufacturing tungsten carbide tools. In the electronics sector, technicians depend on diamond for the precision grinding of delicate components like silicon wafers. The process requires a fine surface finish and exact specifications. Ceramics specialists also use diamond for cutting and shaping extremely hard ceramic parts, where conventional abrasives fail. These users need a grinding wheel that delivers consistent performance for high-value components.

Common Applications: Grinding Carbide, Glass, and Composites

The applications for diamond grinding are extensive. A primary use is the grinding of tungsten carbide. The selection of the correct diamond grit size is critical for these tasks.

- Coarse grits are ideal for rapid stock removal.

- Medium grits balance stock removal with a good finish for general-purpose grinding.

- Fine grits are used for precision finishing and creating an ultra-sharp cutting edge on a cutting tool.

Resin bond wheels are often chosen for these grinding jobs. They provide a smooth cutting action and generate less heat. This protects heat-sensitive carbide grades. The diamond abrasive grains ensure efficient cutting and a long-lasting grinding wheel.

Core Benefit: Superior Finish Without Chemical Reaction

The main benefit of a diamond grinding wheel is its ability to produce a superior finish on non-ferrous materials. Diamond abrasive grains create an almost mirror-like polish on hard ceramics. This level of finish is impossible with other abrasives. The diamond itself is pure carbon. At high temperatures, carbon reacts with iron in ferrous metals. This chemical reaction, known as diffusion wear, causes the diamond abrasive grains to break down quickly. This makes a diamond grinding wheel unsuitable for grinding steel. For non-ferrous materials, however, no such reaction occurs. This allows for stable, high-speed cutting and exceptional results.

CBN Wheels for Hardened Ferrous Metals

When professionals need to grind hardened ferrous metals, they turn to Cubic Boron Nitride (CBN) grinding wheels. CBN is the second hardest material after diamond. It offers exceptional performance for tough grinding applications. Unlike diamond, CBN is chemically stable when grinding steel, making it the ideal choice for these materials.

Key Users: Automotive, Aerospace, and Gear Makers

Manufacturers in the automotive and aerospace industries rely heavily on CBN for precision grinding. In automotive production, CBN is essential for finishing critical components that demand tight tolerances.

- Camshafts and crankshafts

- Gears and transmission parts

- Fuel injector components

Aerospace engineers use CBN for grinding high-performance superalloys found in jet engines. These materials, like Inconel, are used for turbine blades and require a grinding wheel that can handle extreme heat and maintain its form. The superior cutting action of CBN abrasive grains ensures these parts meet strict safety and performance standards.

Common Applications: Grinding Tool Steels and Superalloys

The primary applications for CBN involve the grinding of hard, heat-sensitive ferrous metals. This includes tool steels like M2 and D2, which are used to make a cutting tool and dies. The choice of grit size is crucial for achieving the desired outcome.

| Application | Grit Size Range | Purpose |

|---|---|---|

| Heavy Stock Removal | 24-60 | For rapid material cutting. |

| General Purpose Grinding | 60-100 | A balance of stock removal and finish. |

| Precision Finishing | 120-220 | For achieving a fine surface. |

Proper grit selection ensures efficient stock removal and a superior final surface. The durable CBN abrasive grains provide a consistent cutting performance throughout the life of the grinding wheel.

Core Benefit: High-Speed Grinding With Thermal Stability

The core benefit of CBN is its remarkable thermal stability. During high-speed grinding, significant heat is generated at the point of contact. CBN abrasive grains excel at managing this heat. This prevents metallurgical damage such as surface burns or microcracks. The high thermal conductivity of CBN directs heat away from the workpiece, protecting its integrity. This stability allows for faster cutting speeds, which increases productivity.

| Abrasive Type | Temperature Stability |

|---|---|

| CBN | Maintains cutting edge up to 1000°C. |

| Diamond | Oxidizes above 600°C. |

| Aluminum Oxide | Transfers ~70% of heat into the workpiece. |

This makes CBN grinding wheels the superior choice for any high-performance grinding operation on hardened steels.

Why Choose Superabrasive Grinding Wheels?

Professionals choose superabrasive grinding wheels for their superior performance and value. These tools provide solutions for the most demanding grinding challenges. The decision to use a diamond or CBN grinding wheel delivers significant advantages over conventional abrasives.

To Achieve Unmatched Precision and Finish

Superabrasive wheels excel at achieving tight geometric tolerances. Precision grinding operations often require accuracy below 10 microns. A diamond or CBN grinding wheel consistently meets these demands, achieving tolerances in the 2–5 µm range. This level of precision is critical for high-value components in aerospace and medical manufacturing. The exceptional hardness of diamond ensures a superior quality of finish. This makes a diamond grinding wheel ideal for cutting hard, brittle materials. The result is a smooth surface that meets strict specifications.

For Long-Term Grinding Wheel Value and Cost Savings

While the initial cost of a superabrasive grinding wheel is higher, its extended life delivers significant long-term savings. The longevity of diamond and CBN abrasives means fewer wheel changes and less downtime.

Studies show wheel costs are only 2-5% of total grinding operation costs. Proper selection can reduce overall grinding costs by 25-45%.

This longevity and durability translate to a lower cost per part. The superior cutting action of a diamond grinding wheel also reduces scrap rates, further enhancing its value. Choosing the right grinding wheel is a strategic investment in efficiency.

To Increase Productivity and Reduce Downtime

Superabrasive grinding wheels boost productivity by enabling faster cutting speeds and higher material removal rates. The exceptional hardness of diamond allows for aggressive yet controlled grinding. This reduces cycle times and increases throughput. For example, a CBN grinding wheel requires dressing far less frequently than conventional wheels, sometimes allowing for over 1,000 parts per dress. This remarkable performance minimizes machine downtime.

For professionals seeking to optimize their grinding performance, partnering with an expert is key. A specialized brand like Aimgrind uses its nearly two decades of experience to provide customized grinding solutions. Aimgrind offers personalized formula design to match the perfect grinding wheel to a specific application. Their super hard abrasives product line, featuring both diamond and CBN options, is engineered to deliver this unmatched precision, longevity, and cutting performance.

The preference for superabrasive grinding wheels is clear for any professional grinding hard materials. The selection rule for every grinding job remains straightforward.

Selection Rule Recap:

- Diamond Grinding Wheel: For non-ferrous grinding (e.g., diamond for carbide, diamond for ceramics).

- CBN Grinding Wheel: For ferrous metal grinding.

Choosing the right superabrasive grinding wheel is a strategic investment. This decision impacts every grinding process. Partnering with an expert like Aimgrind ensures you select the best diamond grinding wheel for your specific grinding application, optimizing your entire grinding operation with the right superabrasive diamond.

FAQ

What is the main difference between diamond and CBN wheels?

Diamond wheels excel at grinding hard, non-ferrous materials like carbide and ceramics. CBN wheels are the superior choice for grinding hard ferrous metals, such as tool steels and superalloys, because they are chemically stable at high temperatures.

How important is selecting the correct grit size?

Choosing the correct grit size is critical for success. A coarser grit removes material quickly, while a finer grit produces a superior surface finish. The selection depends on the specific requirements of the job, balancing speed with precision.

Are superabrasive wheels worth the higher initial cost?

Yes, they provide excellent long-term value. Their extended lifespan reduces the frequency of wheel changes, which minimizes machine downtime. This durability leads to a lower cost per part and boosts overall productivity in demanding grinding operations.

What materials are best for superabrasive applications?

Superabrasive wheels handle a wide range of difficult materials.

- Diamond: Best for tungsten carbide, glass, ceramics, and composites.

- CBN: Ideal for hardened tool steels, high-speed steels (HSS), and aerospace superalloys.

Contact Us

For More Grinding Solution or Customized Abrasive Tools