Cylindrical grinding is a vital precision grinding technique. The cylindrical grinding process uses a rotating abrasive wheel to shape a workpiece, delivering superior surface finishes and exceptional roundness. This method achieves extremely tight tolerances and high precision, ensuring the dimensional accuracy required for component reliability and performance. Its ability to create parts with unmatched quality makes cylindrical grinding essential in modern manufacturing. The growing demand for this precision grinding is reflected in market projections.

| Metric | Value |

|---|---|

| Market Size (2024) | US$ 1,998.51 million |

| Projected Market Size (2031) | US$ 2,828.91 million |

| CAGR (2025–2031) | 5.20% |

Key Takeaways

- Cylindrical grinding is a precise way to shape parts. It makes surfaces very smooth and parts perfectly round.

- This method uses a spinning wheel to remove material. It helps make parts that fit together well and work correctly.

- Cylindrical grinding is important for many industries. It helps make parts for cars, airplanes, and medical tools.

- It can shape very hard materials. This process makes strong parts that last a long time.

The Cylindrical Grinding Process

The cylindrical grinding process achieves precision through a set of controlled mechanical actions. Understanding these fundamentals is key to appreciating its capabilities in modern manufacturing.

Fundamental Principles

Effective cylindrical grinding relies on four primary motions working in harmony. These coordinated movements ensure consistent material removal and create perfectly round parts.

- The workpiece rotates continuously on its central axis.

- The grinding wheel rotates at a high speed in the opposite direction.

- The grinding wheel moves toward and away from the workpiece to apply pressure.

- Either the workpiece or the wheel traverses along the part’s length.

The ratio between the wheel speed and workpiece speed directly impacts the material removal rate and final surface finishes. A higher wheel speed generally produces a finer finish, making this relationship critical for achieving desired specifications in precision grinding.

Key Grinding Components

A cylindrical grinding machine integrates several core components to execute its function. The most critical tool in this setup is the grinding wheel, which performs the material removal. Other essential parts include:

- Headstock: Securely holds and rotates the workpiece.

- Spindle and Feed Mechanism: Controls the wheel’s movement and force.

- Controls: Allow for micro-level adjustments to ensure accuracy.

The choice of grinding wheel is vital. While standard abrasives work well for many metals, machining hard materials like ceramics or hardened steel requires specialized tools. For such demanding applications, Aimgrind provides custom diamond grinding wheels. These advanced wheels are engineered to deliver optimal performance and longevity when shaping the toughest materials.

Automated Cylindrical Grinding Process

The automated cylindrical grinding process uses Computer Numerical Control (CNC) technology to elevate precision. CNC systems control every machine movement with digital instructions. This automation ensures extreme accuracy and perfect repeatability, which is essential for high-volume production runs. By minimizing human error, CNC technology makes cylindrical grinding a highly reliable method for creating identical parts with tight tolerances. This level of control is fundamental to achieving the highest standards in precision grinding.

Types of Cylindrical Grinding

Cylindrical grinding is a versatile process with several specialized methods. Each type is designed to meet specific manufacturing needs, from shaping outer surfaces to refining internal bores. Understanding the differences between internal and external cylindrical grinding is key to selecting the right technique for a component.

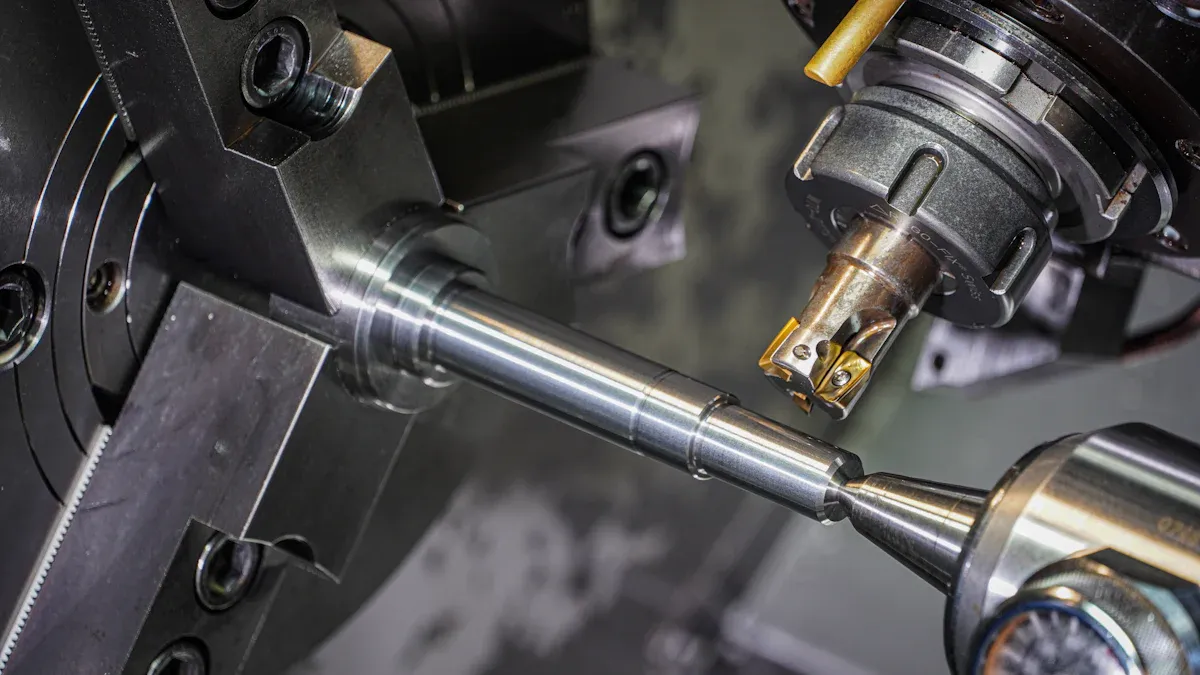

External (OD) Grinding

External cylindrical grinding shapes the outer diameter of a workpiece. This is the most common form of cylindrical grinding. The process creates precise cylindrical surfaces and can produce complex profiles. Many industries rely on this method for critical components.

- Shafts and rods

- Pistons and valve tappets for the automotive industry

- Drills, cutters, and step drills

- Bearing seats of camshafts

Two primary techniques exist within external grinding: traverse and plunge grinding. Each offers distinct advantages.

| Feature | Plunge Grinding | Traverse Grinding |

|---|---|---|

| Movement | Wheel feeds directly into the part | Part moves side-to-side across the wheel |

| Best For | Shorter parts or specific sections | Longer parts requiring straightness |

| Cycle Time | Generally shorter | Typically longer |

| Finish | Efficient for quick stock removal | Excellent for final finishing and correction |

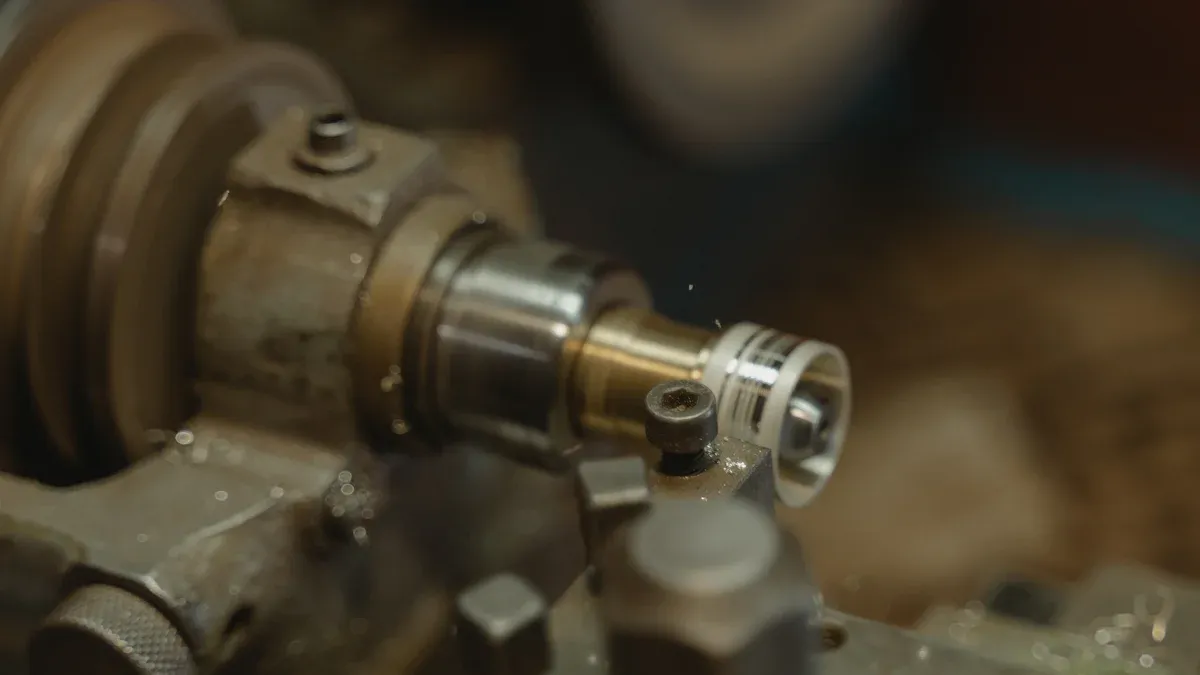

Internal (ID) Grinding

Internal cylindrical grinding finishes the inner diameter (bore) of a workpiece. A small grinding wheel enters the part to remove material from the inside surface. This precision grinding method is essential for parts that must fit together perfectly. Common applications include:

- Bearings, where it creates a smooth surface to reduce friction.

- Bushings, ensuring precise and consistent dimensions.

- Engine components requiring exact internal tolerances.

Centerless Grinding

Centerless grinding is a highly efficient type of cylindrical grinding for mass production. The workpiece is not held between centers. Instead, it rests on a work blade and is supported by a regulating wheel. This setup allows for continuous feeding and automation, which significantly increases production throughput. This method is ideal for producing large quantities of small cylindrical parts that require tight tolerances. While both internal and external cylindrical grinding offer high accuracy, centerless grinding excels in speed for high-volume jobs like rollers, tubes, and long bars.

Role in High-Precision Manufacturing

Cylindrical grinding is more than just a finishing step; it is a cornerstone of high-precision manufacturing. The process provides capabilities that are impossible to achieve with conventional machining methods. It plays a critical role in producing components that meet the strictest standards for accuracy, finish, and performance.

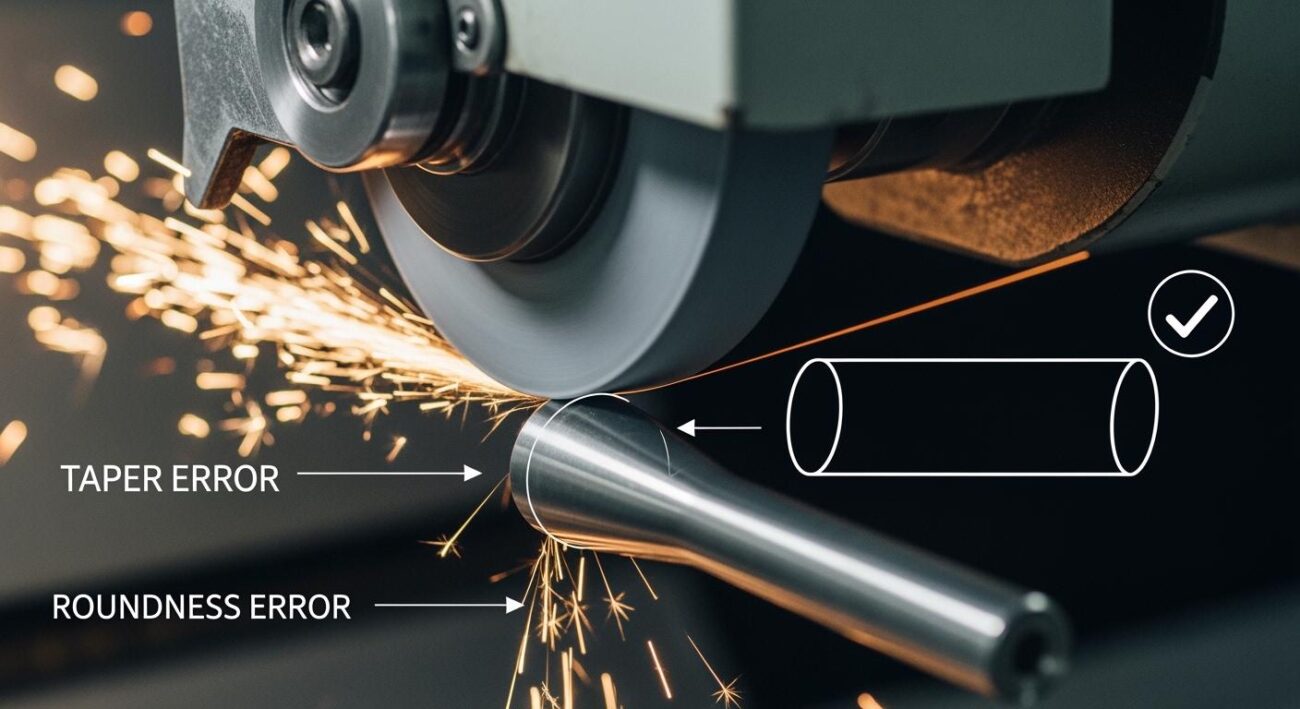

Achieving Precision Grinding

The primary role of cylindrical grinding is to deliver unparalleled accuracy. The process consistently achieves extremely tight tolerances, often as fine as ±0.0001 inches. This level of precision is essential for creating interchangeable, high-performance components. Several key factors enable such high levels of accuracy:

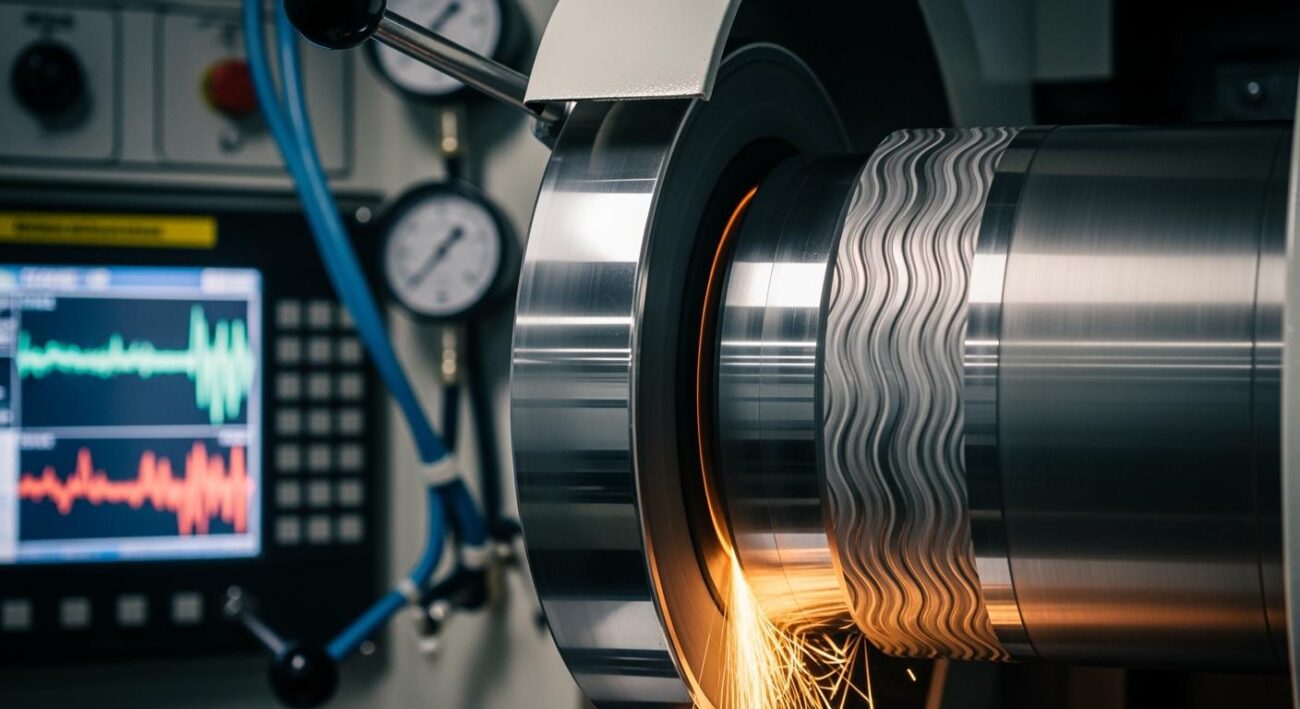

- CNC Controls: These systems offer exceptional accuracy and repeatability, which minimizes human error and maintains strict geometric control.

- Real-Time Monitoring: Advanced systems track variables like wheel wear and part temperature to optimize grinding conditions on the fly.

- Adaptive Speed Control: The machine adjusts grinding parameters based on real-time data, further enhancing part quality.

- Automatic Wheel Dressing: This feature maintains the grinding wheel‘s optimal condition, ensuring consistent precision throughout long production runs.

- Superabrasives: The use of diamond or CBN wheels provides superior wear resistance and uniform performance, contributing to exact material removal.

Creating Superior Surface Finishes

Beyond dimensional accuracy, cylindrical grinding creates exceptionally smooth surface finishes. A superior finish reduces friction, minimizes wear, and improves the overall function and lifespan of a part. The process can produce surfaces with very low roughness values, often measured in Roughness Average (Ra).

| Process Type | Roughness Average (Ra) |

|---|---|

| Fine Grinding | 0.1 µm |

| Grinding / Polishing | 0.2 µm |

| General Grinding | 0.05 – 0.2 Ra |

Achieving mirror-like surface finishes requires careful control over the precision grinding process. Manufacturers follow systematic steps to ensure uniformity and quality:

- They implement controlled processes with precise monitoring.

- They adjust parameters like wheel speed and feed rate as needed.

- They ensure the workpiece surface is properly prepared before the final grinding pass.

Enhancing Part Durability

The quality produced by cylindrical grinding directly enhances a component’s durability. The process removes microscopic surface imperfections left by other machining methods. These tiny flaws can act as stress concentrators, which are potential points of failure under load. By creating a smooth, uniform surface, cylindrical grinding distributes stress more evenly across the part. This improvement makes high-quality parts stronger and more resistant to fatigue, extending their operational life in demanding applications.

Machining Difficult Materials

Many modern industries rely on materials that are extremely difficult to machine. These include hardened steels, superalloys, and industrial ceramics. Conventional cutting tools often fail against these materials for several reasons:

- Their extreme hardness and high-temperature strength cause rapid tool wear.

- Their low thermal diffusivity traps heat in the cutting zone.

- Their abrasive nature leads to rapid insert wear.

- They tend to work-harden during machining, requiring higher cutting forces.

Note: Cylindrical grinding excels where other methods struggle. It is one of the few processes capable of shaping these advanced materials with high precision and excellent finish.

Success in this area depends on using the right abrasive. For materials like hardened steel or ceramics, specialized abrasive solutions are necessary. Aimgrind’s custom diamond grinding wheels are engineered for these demanding applications. These advanced wheels provide the durability and cutting efficiency needed to machine the toughest materials, making precision grinding possible across a wide range of advanced manufacturing sectors.

Key Industry Applications

The capabilities of cylindrical grinding make it indispensable across industries where precision is non-negotiable. From aerospace to medicine, this process ensures components perform reliably under extreme conditions.

Aerospace Components

The aerospace industry relies on cylindrical grinding to manufacture flight-critical parts. Components like landing gear axles and turbine shafts must withstand immense stress and temperature. This process is ideal for shaping the high-temperature nickel alloys and hard-coated metals used in aircraft.

- It allows multiple operations in a single clamping, which boosts precision.

- It creates complex tooth forms on engine shafts with perfect pitch tolerances.

- The rigidity and stability of cylindrical grinding machines ensure process reliability.

This method delivers the accuracy required for these demanding cylindrical components, making it a cornerstone of aerospace manufacturing.

Automotive Parts

In the automotive sector, cylindrical grinding is essential for engine and transmission parts. The process shapes crankshafts and camshafts, removing tiny amounts of material to create flawless surfaces. This precision ensures engine components operate synchronously and last longer. For transmission gears, precision grinding produces superior surface finishes that reduce friction and wear. Research shows that polish-ground gears can have a fourfold service life and improve fuel economy. This makes cylindrical grinding a key factor in high-efficiency production and vehicle longevity.

Medical Tools and Implants

The medical field uses cylindrical grinding to produce surgical tools and orthopedic implants with exceptional quality. Surgical drills and reamers made from titanium or stainless steel achieve extremely smooth finishes (as fine as Ra 0.2 µm), which reduces friction and prevents corrosion. For implants like hip stems, cylindrical grinding is vital. It creates the flawless surfaces and exact dimensions needed for biocompatibility, ensuring the implant fits perfectly and functions safely within the body. The process can even create micro-textures that encourage bone growth, improving patient outcomes.

Cylindrical grinding is a fundamental technique for achieving the highest quality standards in manufacturing. The cylindrical grinding process delivers unparalleled precision, flawless surface finishes, and the versatility to machine hard materials. As industries integrate AI and advanced abrasives, this precision grinding method remains indispensable for creating components with smooth finishes. Success in cylindrical grinding ultimately relies on high-quality tools, like those from Aimgrind, to meet modern demands for precision grinding. This makes cylindrical grinding a cornerstone of advanced manufacturing.

FAQ

### What makes cylindrical grinding different from turning?

Turning uses a single-point cutting tool to shear material from a workpiece. Cylindrical grinding, however, uses a multi-point abrasive wheel for material removal. This allows grinding to achieve far superior surface finishes and much tighter dimensional tolerances than turning.

### What materials can be cylindrically ground?

Cylindrical grinding works on a wide range of materials. It excels at shaping very hard substances like hardened steels, superalloys, and industrial ceramics. These materials are often too difficult for conventional machining methods to process effectively.

### How do you choose the right grinding wheel?

The ideal wheel depends on the workpiece material and required finish. For hard materials like ceramics or hardened steel, specialized wheels are essential. Aimgrind offers custom diamond grinding wheels designed for these demanding applications, ensuring optimal results.

Tip: Matching the wheel to the material is crucial for achieving both precision and efficiency. ⚙️

### What are the main benefits of cylindrical grinding?

Cylindrical grinding offers three primary advantages. It delivers exceptional dimensional accuracy and creates superior surface finishes. The process also provides the unique capability to effectively machine extremely hard or abrasive materials with high precision.

See Also

Understanding CBN Grinding Wheels: Their Functionality and Operational Principles

Selecting the Optimal Grinding Wheel for Your Carbide Tooling Needs

Finding the Ideal Grinding Wheel Dresser for Your Specific Requirements

Exploring Diverse Grinding Wheel Varieties and Their Real-World Uses

Discovering the Most Economical Crankshaft Grinding Wheel for Your Needs

Contact Us

For More Grinding Solution or Customized Abrasive Tools