A vacuum brazed diamond grinding wheel works very well and lasts long. People see that diamond pieces stick tightly to the wheel. This helps the wheel work smoothly and cut hard things well. Many skilled DIY users like these wheels because they cut fast and keep their shape. These wheels can cut many things, like granite and metal. So, one diamond tool can do the job of many tools. But, these wheels cost more at first and can get too hot. So, you need to use them with care. Even so, the wheel lasts a long time. This makes it a good buy for people who want to work neatly and waste less.

Key Takeaways

-

Vacuum brazed diamond wheels cut quickly and last a long time. They keep their shape well. This makes them good for many things like stone and metal.

-

These wheels do not get too hot and stay sharp. You do not need to fix them often. This saves you time and work.

-

They are very exact for small jobs in places like aerospace, cars, and electronics.

-

They cost more at first, but they last longer. You do not need to buy new ones often, so you save money later.

-

To stop them from getting too hot or breaking, always use water or coolant. Do not push too hard. Always check the wheel before you use it.

Strengths

High Grinding Efficiency

Vacuum brazed diamond wheels work very well for grinding. The diamond grit sticks tightly to the wheel. This lets the wheel cut fast and hard. Tests show these wheels make smoother chips than resin-bonded wheels. When used on Q345 steel, they made the surface about 20% smoother. They also lowered leftover stress by 8-12%. The steel core is strong and does not shake. This helps remove more material quickly. These wheels do not need to be dressed. So, people spend more time working and less time fixing the tool. The deep pockets and good heat flow stop the wheel from getting clogged. This keeps the wheel working well for a long time.

-

Vacuum brazed diamond wheels remove more material than other wheels.

-

They can cut deep and fast with sharp diamonds.

-

The wheels keep working well and do not get clogged.

Exceptional Durability

Vacuum brazed diamond wheels last a very long time. The special way they are made keeps the diamond grit stuck on tight. This makes them cut better and last longer. Tests show these wheels keep working well for a long time. They do not bend or break, even when used hard. The big diamond pieces help them last even longer. Compared to electroplated wheels, these last longer and cost less over time. The strong bond and tough build make them very durable.

-

The wheels can handle hard hits while cutting and grinding.

-

Their long life makes them good for big jobs and home projects.

Precision

Vacuum brazed diamond wheels are very precise. The strong bond between the diamond and steel keeps the diamond from breaking. It also stops the diamond from turning into graphite, even when hot. In metalwork, these wheels make smooth and exact cuts. In aerospace, they can grind to within ±5 microns. In cars, they make surfaces smoother than Ra 0.2 μm. In electronics, they do not crack wafer edges. This high precision is great for jobs that need fine detail.

|

Industry |

Application |

Surface Tolerance Achieved |

|---|---|---|

|

Aerospace |

Precision grinding of composites |

Surface tolerances within ±5 microns |

|

Automotive |

Deburring hardened steels & alloys |

Surface finish Ra < 0.2 μm consistently |

|

Electronics |

Sub-micron precision wafer edges |

Zero micro-cracking incidence |

Versatility

Vacuum brazed diamond wheels can be used in many ways. The making process spreads the diamond grit evenly. The braze layer is always the same thickness. This helps the wheel cut hard but use less power. The wheels can grind metal, stone, and fiberglass. Makers can change the wheel size and diamond size for different jobs. The strong grip lets the wheels take hard hits. This makes them good for many kinds of work.

-

These wheels can grind many iron types, like cast iron and steel.

-

They are used in cars, planes, building, stone work, and medical tools.

-

The wheels work for both dry and wet grinding at high speeds.

Heat Resistance

Vacuum brazed diamond wheels handle heat very well. The metal core and diamond grit move heat away fast. This is important when grinding hard things like WC-Co composites. The wheels keep their shape and work well, even when dry. Resin-bonded wheels do not handle heat as well. They can get too hot and damage the diamond. Metal-bonded wheels are better, but vacuum brazed wheels are best for heat. Tests show wheels brazed at 1010 °C stay strong and do not get damaged by heat.

Tip: Keep grinding below 1010 °C to stop heat damage and keep the wheel working well.

Safety and Reliability

Vacuum brazed diamond wheels are safe and meet strict rules. Makers follow RoHS, CE, and EPR rules to keep out bad chemicals. They also have MPA, SGS, and ISO9001:2015 safety checks. The strong bond keeps the diamond grit from falling off. This makes the wheels safer for fast and hard grinding. Their long life means you do not need to change them often. This also means fewer mistakes and less waste.

-

The wheels work safely and well for both big jobs and home use.

-

Green certifications help protect the environment.

Weaknesses

Higher Cost

Vacuum brazed diamond wheels cost more than most other wheels. A 4-inch wheel costs $79.99, no matter the grit size. This price is the same for coarse, medium, or fine grit. Other wheels, like resin-bonded or electroplated, usually cost less. Their prices can change if you order more or want special features.

|

Diameter |

Grit Size |

Price |

|---|---|---|

|

4 inch |

Coarse |

$79.99 |

|

4 inch |

Medium |

$79.99 |

|

4 inch |

Fine |

$79.99 |

Many people think the higher price is a problem, especially for small shops or hobby users. But these wheels last longer and have a strong diamond bond. This helps save money over time. You do not need to buy new wheels as often. You also spend less time changing tools, which saves money in the end.

-

Vacuum brazed diamond wheels cost more at first.

-

Their long life and fewer replacements can save money over time.

Overheating Risk

Vacuum brazed diamond wheels can get too hot if not used right. Overheating happens when you do not use enough water or coolant. Grinding too fast or pressing too hard also makes heat build up. Thick or tough materials, like some metals or stones, make the wheel hot faster. Wheels without cooling slots cannot get rid of heat well.

Tip: Always use water or coolant when grinding. Take breaks and do not push too hard. Pick wheels with cooling grooves to help control heat.

Common reasons for overheating are:

-

Not enough water or coolant during grinding.

-

Grinding too fast or pressing too hard.

-

Working on thick or tough materials without cooling.

-

Using wheels without cooling slots.

To stop overheating:

-

Use a water cooling system that sends coolant to the cutting area.

-

Check the coolant system often to keep the flow strong.

-

Use lots of water for long jobs.

-

For dry grinding, do not cut too deep and let the wheel cool down.

Handling Requirements

Vacuum brazed diamond wheels need careful handling to stay safe and last longer. You must wear gloves and eye protection. Fasten the workpiece before you start grinding. Mount the wheel the right way, so the blade turns with the tool. Before each use, check the wheel for dullness or damage. Slow cutting or visible wear are signs of trouble.

-

Check the wheel for chips or cracks before using it.

-

Clean and mount the wheel with the right alignment.

-

Tighten nuts to the correct torque so they do not loosen.

-

Run the wheel without load for 1-2 minutes to check for wobble.

-

Use coolant for jobs that get hot.

-

Clean the wheel after use and check for cracks or missing parts.

These steps help stop accidents and keep the diamond bond strong. Good handling also lowers the chance of wheel failure.

Limited Reconditioning

Vacuum brazed diamond wheels have only one layer of diamond grit. This makes them last a long time, but you cannot recondition them much. When the diamond layer is gone, you cannot add more diamond. Other wheels, like sintered types, have many layers and can be fixed more.

You can use a dressing stick to clean off debris and show new diamond. Truing can fix the wheel’s shape if it gets uneven. But once the diamond layer is gone, you must get a new wheel.

-

Truing fixes the wheel’s shape.

-

When the diamond layer is gone, you need a new wheel.

Not for All Applications

Vacuum brazed diamond wheels work best on softer stones, concrete, and some metals. Their design uses a mechanical bond to hold the diamond grit. This bond is not as strong as the one in sintered wheels. Because of this, these wheels do not work well on very hard materials like granite.

|

Aspect |

Vacuum Brazed Diamond Grinding Wheels |

Impact on Suitability |

|---|---|---|

|

Diamond Fixation |

Less effective on hard materials like granite |

|

|

Matrix Grip |

Weaker than sintered tools |

Not ideal for hard, abrasive materials |

|

Suitable Materials |

Marble, limestone, concrete, metals |

Good wear resistance and fast cutting |

|

Unsuitable Materials |

Granite |

Shorter tool life and reduced performance |

|

Abrasive Layer |

Single-layer |

Limits service life compared to multi-layer sintered tools |

Vacuum brazed diamond wheels remove material fast and are good for shaping and leveling softer stones. They do not last long on hard, rough materials. For those jobs, sintered wheels or other types work better.

Applications

Industrial Use

Many factories use vacuum brazed diamond wheels for hard jobs. Foundries use them to grind and cut tough metals like cast iron and steel. Tool and die shops use these wheels for fixing molds and sharpening tools. These wheels help workers finish jobs faster and more accurately. In big factories, tests show these wheels last three times longer than electroplated wheels. They also keep things cooler, which protects the tool and the material.

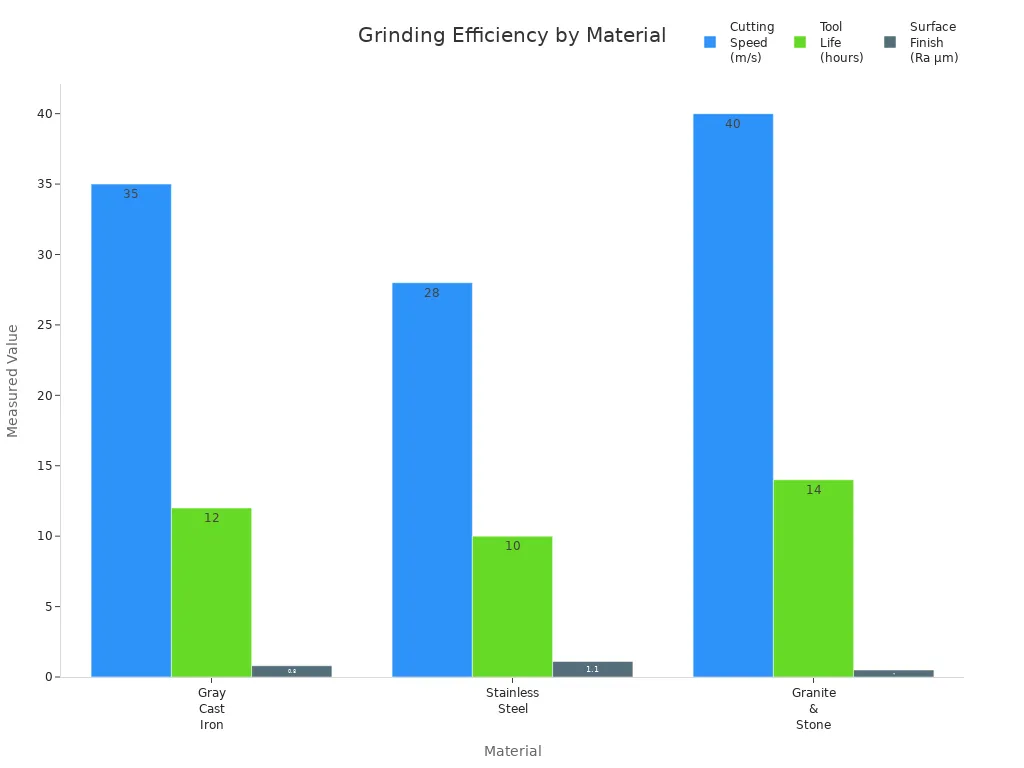

In one real example, workers used these wheels to cut granite slabs. They saw 30% less chipping and smoother edges. When cutting stainless steel, the wheels made the job 25% faster and needed fewer replacements.

|

Material |

Application |

Outcome |

|---|---|---|

|

Granite slabs |

Precision cutting and grinding |

30% less chipping, smoother edges |

|

Stainless steel |

High-speed trimming |

25% shorter cycle, fewer tool changes |

|

Concrete panels |

Finishing |

20% less dust, better smoothness |

DIY Projects

Vacuum brazed diamond wheels are good for home projects too. Many people use them to shape and grind stone, glass, and ceramics. The diamond grit helps make a smooth finish and removes material fast. These wheels work for both dry and wet grinding, so they are flexible. People use them with angle grinders to shape granite, marble, and concrete. The strong diamond bond means the wheels last longer and need fewer replacements. Users say they are easy to use for building, fixing, and masonry work.

-

Good for shaping and grinding stone, glass, and ceramics.

-

Work with tools like angle grinders.

-

Lower heat to protect the workpiece.

Material Compatibility

Vacuum brazed diamond wheels work well on many materials. They can be used with aluminum alloys, alumina, cemented carbide, and magnesium alloys. These wheels also handle granite, marble, basalt, quartzite, and travertine. The diamond layer cuts hard and brittle materials easily. This makes the wheels useful for simple and tough jobs. Makers say these wheels are good for many stones and metals.

-

Work with cast iron, granite, marble, and concrete.

-

Can handle very hard materials like cemented carbide.

-

Good for both factory and home use.

Note: Always check your material before grinding to make sure the diamond wheel is right.

Vacuum brazed diamond grinding wheels are very strong and last long. They cut fast and make smooth surfaces. These wheels cost more and can get too hot. So, you must use them carefully.

-

People should pick a wheel that fits their project.

-

Think about what you need to grind and how much you can spend.

Looking at the good and bad points helps you pick the best grinding wheel for your work.

FAQ

What materials can vacuum brazed diamond grinding wheels cut?

These wheels can cut many materials. They work well on granite, marble, concrete, cast iron, and some metals. Users also use them for glass, ceramics, and hard stones. Always check the material before starting.

How long does a vacuum brazed diamond wheel last?

A vacuum brazed diamond wheel lasts much longer than standard wheels. Many users report three to five times more life. The strong diamond bond helps the wheel keep working well over time.

Can users use these wheels for dry grinding?

Yes, users can use these wheels for dry grinding. The wheel handles heat well. For best results, use water or coolant to keep the wheel cool and extend its life.

What safety steps should users follow?

Users should wear gloves and eye protection. They must check the wheel for cracks or chips before use. Always mount the wheel correctly. Run the wheel without load for a short time to check for wobble.

Are vacuum brazed diamond wheels easy to maintain?

These wheels need little maintenance. Users should clean the wheel after each use. They should check for damage and store the wheel in a dry place. A dressing stick can help remove debris.

Contact Us

For More Grinding Solution or Customized Abrasive Tools