Experts choose silicon carbide grinding wheels for processing hard and brittle materials. These powerful silicon carbide abrasives work well on cast iron, ceramics, glass, and stone. They are also effective for soft, non-ferrous metals like aluminum and brass. The right silicon carbide grinding wheel is key for top performance.

Note: The choice between a black wheel and a green wheel is critical. Each wheel type has specific properties for different materials. Selecting the correct wheel ensures the best results for your project.

Key Takeaways

- Silicon carbide grinding wheels work well on hard, brittle materials like glass and stone. They also work on soft metals like aluminum.

- Black silicon carbide wheels are good for soft metals and cast iron. Green silicon carbide wheels are better for very hard materials like ceramics.

- Always pick the right grinding wheel for your material. This helps you get the best results and finish your work well.

- Silicon carbide wheels are not for steel. Use aluminum oxide wheels for steel and other strong metals.

- For very tough jobs, consider special diamond or CBN wheels. These tools offer high precision and last longer than regular wheels.

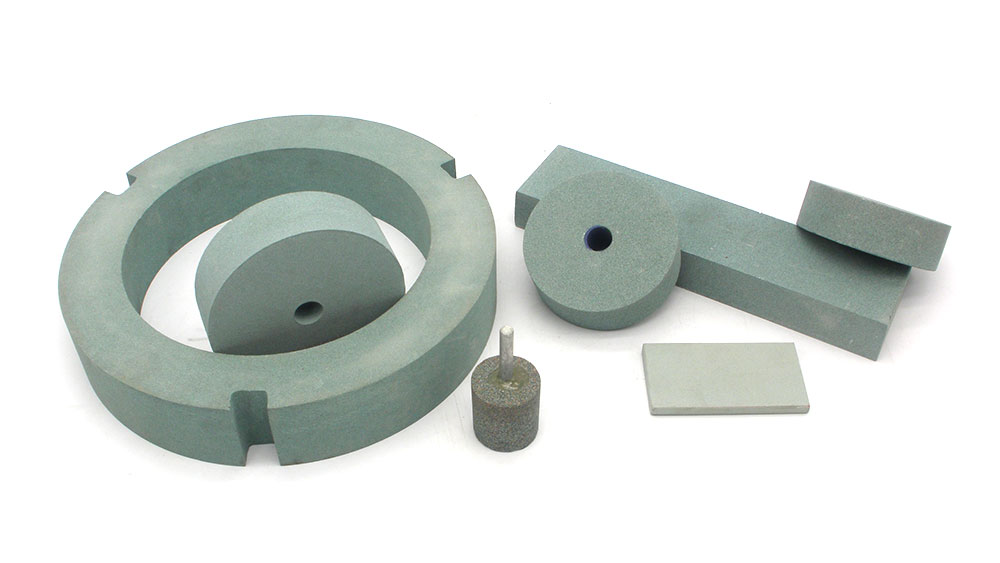

Types of Silicon Carbide Abrasives

Silicon carbide grinding wheels come in two main varieties: black and green. Each type has a unique composition and structure. These differences make each wheel ideal for specific tasks and materials. Understanding these types helps users select the perfect wheel for their job.

Black Wheels for Non-Ferrous Metals

Black silicon carbide wheels are known for their toughness and durability. They contain about 98% silicon carbide, making them a very economical choice for heavy-duty work. This toughness allows the wheel to withstand high pressure and mechanical shock. It is the go-to wheel for grinding materials with lower tensile strength.

Operators often choose black silicon carbide wheels for processing softer, non-ferrous metals. These metals include:

- Aluminum (Al)

- Copper alloys (Cu alloys) like brass and bronze

The wheel’s structure helps prevent loading, which is when material clogs the abrasive surface. This makes the wheel very effective for fast material removal on cast iron, stone, and ceramics. The physical properties of black silicon carbide explain its excellent performance.

| Property | Value |

|---|---|

| SiC Content | Around 98% |

| Mohs Hardness | 9.2 |

| Thermal Conductivity | High, for rapid heat dissipation |

| Key Properties | High wear resistance, good toughness |

Pro Tip: For general grinding on cast iron or aluminum, a coarse grit wheel (F36–F80) provides high removal rates. The open structure of the wheel helps it cut fast without clogging.

Green Wheels for Hardened Materials

Green silicon carbide wheels are harder and more friable than their black counterparts. They are made from higher-purity silicon carbide, often containing over 99% SiC. Manufacturers produce these silicon carbide abrasives in a special furnace at extremely high temperatures. This process removes more impurities, resulting in a harder and sharper abrasive grain.

The key feature of a green wheel is its friability. This means the abrasive grains fracture easily under pressure. This process is actually a benefit.

- Fracturing exposes new, sharp cutting edges.

- This self-sharpening action keeps the wheel cutting efficiently.

- It also helps the wheel run cooler, preventing damage to the workpiece.

This makes green silicon carbide wheels perfect for grinding extremely hard and brittle materials. They excel at finishing cemented carbides and sharpening tungsten carbide tools. The sharp grains of the wheel create a fine, precise surface finish. For finishing tasks on hard alloys, a finer grit wheel (F150–F320) is the best choice. These silicon carbide abrasives deliver superior precision for the most demanding jobs.

Applications for Silicon Carbide Grinding Wheels

Silicon carbide grinding wheels have many uses across different industries. Their unique properties make them ideal for specific materials and tasks. These applications range from heavy-duty metal processing to precision finishing on delicate materials. Understanding these uses helps operators choose the right tool for the job.

Metalworking and Foundry Use

Foundries and metalworking shops rely heavily on silicon carbide for processing metals. Black silicon carbide wheels are particularly useful in these environments. Their toughness is perfect for metal grinding applications that demand high stock removal. Foundries use these wheels for snagging and rough grinding. This process removes unwanted parts like gates, risers, and flashing from non-ferrous castings. This is a common step when processing metals such as aluminum, brass, and copper.

The automotive industry also has many applications for these tools. Heavy-duty grinding wheels are essential for working on cast iron components. Common uses include:

- Engine blocks

- Cylinder heads

- Brake drums

- Housings

The wheel’s aggressive cutting action quickly smooths a rough surface. This efficiency makes it a top choice for metal processing tasks requiring fast, effective material removal. The durability of the wheel ensures a long service life in demanding industrial applications.

Grinding Ceramics and Glass

The sharp, friable nature of green silicon carbide makes it perfect for processing hard, non-metallic materials. These applications require precision and a fine surface finish. The glass industry uses green silicon carbide grinding wheels for grinding optical glass. The goal is to create a smooth and exact surface on lenses, mirrors, and other optical parts.

The grinding process often involves several stages.

- Rough Grinding: An operator uses a wheel to grind a glass lens. This step achieves a specific curve and surface texture.

- Fine Grinding: This stage improves the surface and prepares it for polishing. The self-sharpening action of the green wheel creates a clean surface without causing heat damage.

The excellent cutting efficiency of a silicon carbide grinding wheel ensures a high-quality finish. This makes it a vital tool for creating precise ceramic and glass components.

Stone and Masonry Applications

Silicon carbide is also a key material in stone processing and construction. Its hardness allows it to cut and shape tough materials like granite, marble, and concrete. Stone workers use silicon carbide cup wheels to grind and smooth hard stone surfaces. A coarse grit wheel provides high stock removal for initial shaping. A finer grit wheel creates a smoother surface, removing scratches and preparing the stone for polishing.

In construction, special silicon carbide grinding wheels cut concrete and masonry blocks. These wheels offer a good cutting rate and high stability for general-purpose cutting jobs. The right wheel makes stone and masonry applications much easier.

Safety First! 👷

Grinding stone creates dust and poses risks. Always use proper Personal Protective Equipment (PPE). This includes a respirator, safety goggles, and gloves. Before starting, check that the wheel is mounted correctly. Ensure the machine’s speed does not exceed the wheel’s maximum rating. A damaged wheel can be dangerous, so always inspect your tools before use.

Silicon Carbide vs. Other Abrasives

Choosing the right abrasive is crucial for any grinding project. Silicon carbide and aluminum oxide are two of the most common abrasives, but they have very different strengths. Understanding these differences helps operators select the best tool for their material and application, ensuring efficiency and a quality finish. The choice impacts everything from cutting speed to the final surface.

Choosing a Silicon Carbide Grinding Wheel

Operators select a silicon carbide grinding wheel for specific materials. These wheels excel at processing hard, brittle, or lower-tensile strength materials. The sharp, friable nature of silicon carbide abrasives makes them the ideal choice for these jobs.

Key materials for silicon carbide grinding wheels include:

- Cast iron

- Soft non-ferrous metals like aluminum and brass

- Hard non-metallic materials like ceramics, glass, and stone

For very hard materials, a softer grade wheel is often better. This allows dull abrasive grains to break away, exposing fresh cutting edges. This self-sharpening action keeps the wheel cutting effectively without generating excess heat.

When to Use Aluminum Oxide

Operators choose aluminum oxide abrasives for different jobs, primarily those involving high-tensile strength materials. Aluminum oxide is tougher and more durable than silicon carbide, making it perfect for grinding hard metals.

Pro Tip: 💡 Aluminum oxide is the preferred abrasive for grinding steel, stainless steel, and other ferrous alloys. Its durability allows it to withstand the high pressure needed to grind these tough materials effectively.

While silicon carbide would wear down too quickly on steel, an aluminum oxide wheel maintains its structure. This makes it a reliable and cost-effective choice for most metalworking applications involving high-strength alloys.

Key Differences in Performance

The primary differences between the two abrasives come down to hardness, brittleness, and material suitability. A silicon carbide grinding wheel is harder and sharper, but an aluminum oxide wheel is tougher and more durable. This simple cost and performance comparison helps clarify the best use for each wheel. The abrasive grinding ability of each wheel is tailored for specific tasks. The following table breaks down the key distinctions for these silicon carbide grinding wheels and their counterparts.

| Material | Silicon Carbide | Aluminum Oxide |

|---|---|---|

| Best For | Low-tensile materials (cast iron, aluminum) | High-tensile materials (steel, bronze alloys) |

| Hardness | Harder and sharper | Tougher and more durable |

| Brittleness | More brittle (self-sharpening) | Less brittle (longer life on hard metals) |

| Common Non-Metal Use | Glass, ceramics, stone | Bare wood, painted surfaces |

Ultimately, the material of your workpiece dictates the correct wheel. Using the right silicon carbide abrasives or aluminum oxide wheel ensures optimal results.

Beyond Silicon Carbide: Aimgrind’s Advanced Solutions

While silicon carbide abrasives are excellent for many jobs, some tasks demand superior performance. Aimgrind specializes in customized grinding solutions, offering everything from conventional abrasives to the most advanced tools available. For the highest precision, longest tool life, and toughest materials, an upgrade is often necessary.

When to Upgrade Your Abrasive

Operators should consider upgrading when working with ultra-hard materials like PCD/PCBN tools or when seeking major efficiency gains. Conventional silicon carbide abrasives work by plowing material away, which can lead to faster wear. In contrast, super hard abrasives like diamond and CBN use a true shearing action. This superior cutting method reduces heat and extends tool life significantly.

Upgrading provides measurable benefits.

- Bearing manufacturers see faster cycle times and better surface quality.

- Studies show that upgrading can reduce machine run times by nearly 40%.

This level of performance is essential for any high-precision grinding operation that requires consistency and speed. The right tool makes demanding processing jobs much more efficient.

Aimgrind’s High-Performance Tools

Aimgrind’s diamond and CBN wheels are the ultimate high-performance tools for industries that require absolute precision. The aerospace industry relies on these tools for the precision grinding of turbine blades and strong alloys. The medical field uses them for processing surgical instruments where flawless accuracy is critical. These advanced abrasives deliver the extreme precision needed for such demanding applications.

For industries where every micron matters, Aimgrind’s super hard abrasives offer unmatched performance. They provide the tight tolerances and superior finishes required for complex processing tasks. This makes them the top choice for any precision grinding job. Aimgrind’s expertise in precision grinding ensures customers get the perfect tool for their specific needs.

Silicon carbide grinding wheels are the expert choice for hard, brittle, and non-ferrous materials. The correct wheel selection is vital. A black wheel works best on cast iron, while green silicon carbide wheels excel on cemented carbide. The right silicon carbide grinding wheel ensures efficiency. For the most demanding jobs, however, a different wheel is needed. While silicon carbide abrasives are effective, Aimgrind’s super hard abrasives like diamond and CBN offer the next level of performance, especially when green silicon carbide wheels are not enough.

FAQ

What is the difference between black and green silicon carbide?

Green silicon carbide wheels are purer and harder. Operators use them for grinding hard materials like cemented carbide. Black silicon carbide wheels are tougher. They are the better choice for grinding softer, non-ferrous metals and cast iron, offering great durability for heavy work.

Can operators use a silicon carbide wheel on steel?

No, operators should avoid using silicon carbide wheels on steel. Aluminum oxide is the correct abrasive for high-tensile strength metals like steel and its alloys. An aluminum oxide wheel is tougher and withstands the pressure of grinding hard ferrous metals more effectively.

Which grit size is best for a project?

The choice of grit depends on the task.

- Coarse grits (e.g., F24–F60) remove material quickly.

- Fine grits (e.g., F150–F320) create a smooth surface finish.

Tip: Start with a coarse grit for rough shaping. Then, switch to a fine grit for final finishing.

When should someone choose a super hard abrasive?

Users should upgrade to a super hard abrasive for the toughest jobs. Aimgrind’s diamond and CBN wheels are perfect for ultra-hard materials like PCD/PCBN tools. They offer the highest precision, longest life, and best performance for demanding industrial applications.

See Also

Selecting the Optimal Grinding Wheel for Your Carbide Tooling Needs

Exploring Various Grinding Wheel Types and Their Real-World Uses

Selecting the Perfect Grinding Wheel for Your Circular Saw Blade

Mastering Safe and Effective Usage of Your Dremel Grinding Wheel

Understanding CBN Grinding Wheels: Their Function and Operational Principles

Contact Us

For More Grinding Solution or Customized Abrasive Tools