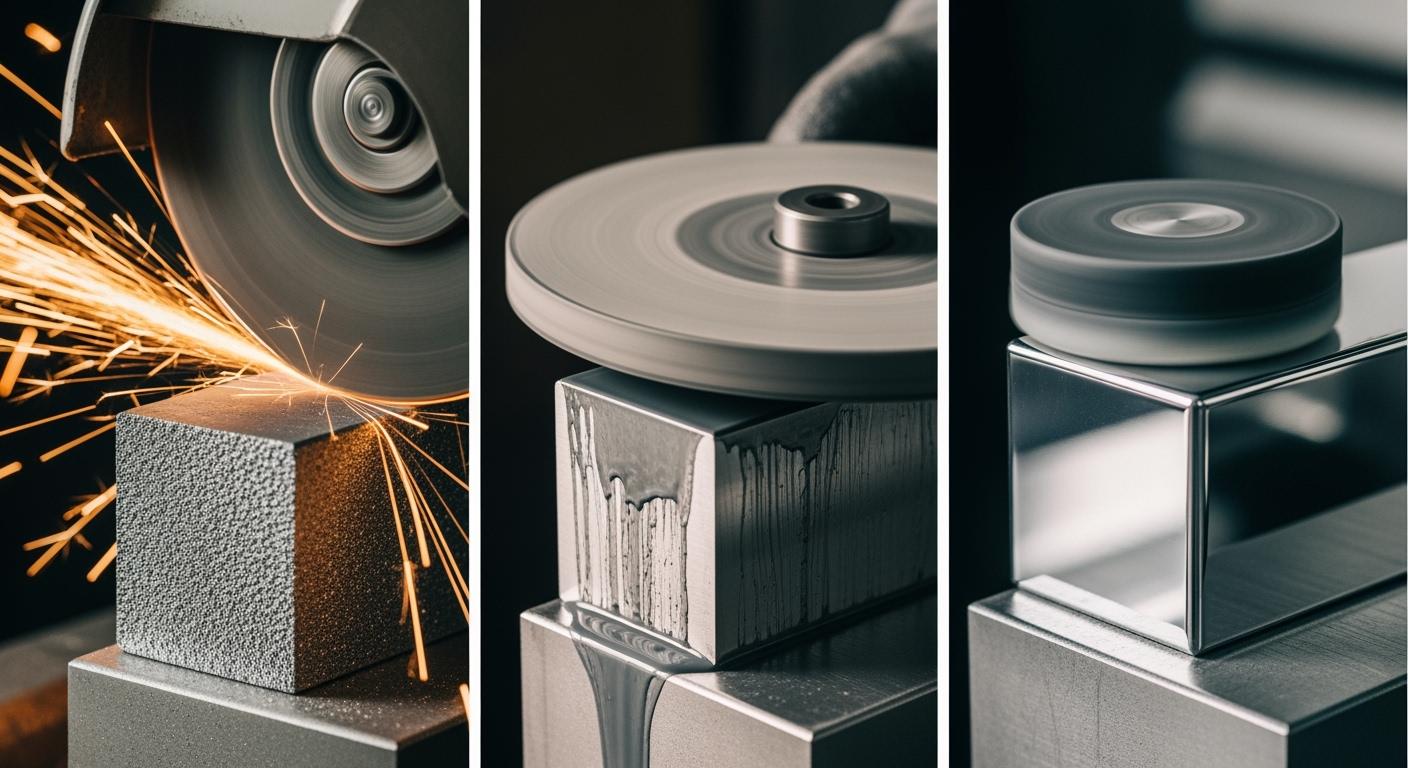

The grinding process gives a part its shape. The lapping process creates an extremely flat surface. The polishing process achieves a mirror-like finish.

These three methods are all part of creating high-quality finishes. The best process depends on your goals for dimensional accuracy and surface finish. Ultra-precision grinding, lapping, and polishing are often used in sequence. This combination helps achieve high precision and the best final accuracy. Using the grinding process first, then lapping, and finally polishing, delivers a perfect finish for any surface.

Key Takeaways

- Grinding shapes parts by removing a lot of material. It uses fixed abrasive wheels.

- Lapping makes surfaces very flat. It uses loose abrasives in a liquid.

- Polishing creates a shiny, mirror-like finish. It uses very fine loose abrasives.

- These three processes often work together. Grinding comes first, then lapping, then polishing.

- Choose the right process based on your goal. Do you need to shape, flatten, or shine a surface?

Grinding vs. Lapping vs. Polishing: A Comparison

Choosing the right finishing process is critical for manufacturing. Each method serves a unique function. The grinding process shapes a part. The lapping process creates extreme flatness. The polishing process delivers a mirror shine. Understanding their differences helps you select the best technique for your project.

Purpose: Shaping vs. Flattening vs. Shining

Each process has a distinct primary goal that defines its application.

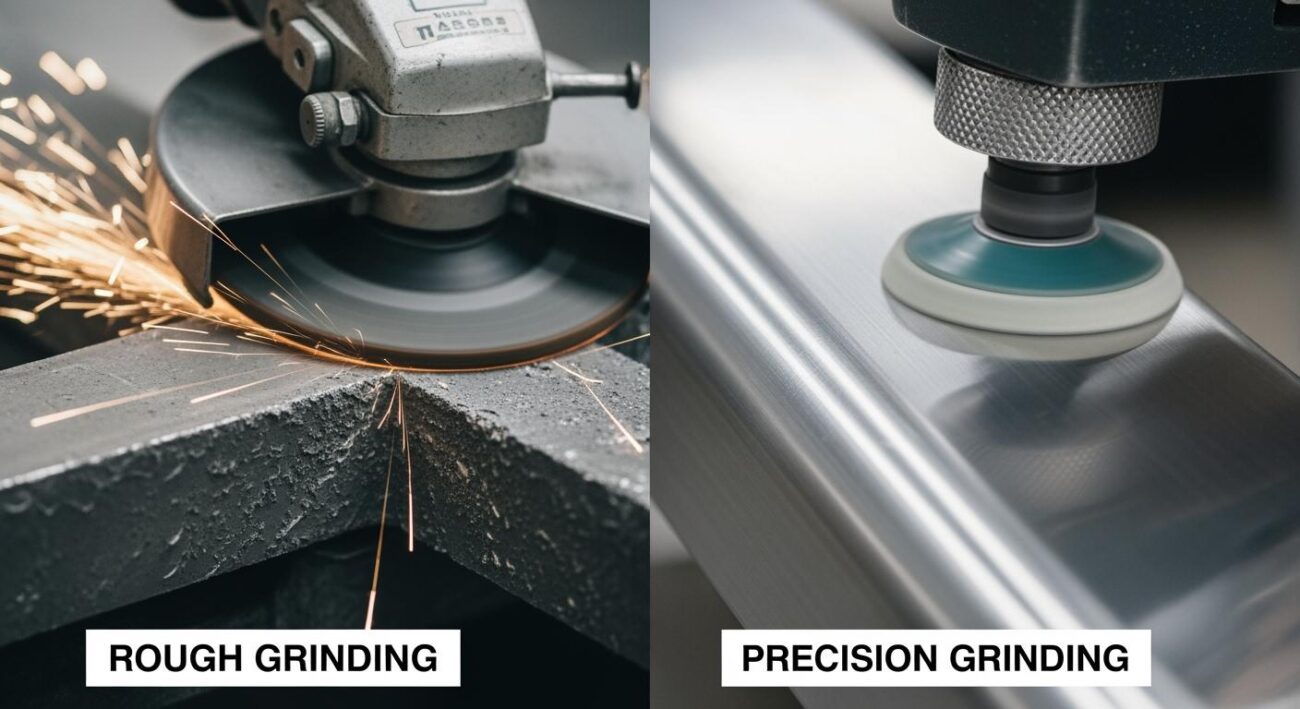

Grinding: The Goal is Shaping. The grinding process is the most aggressive of the three. Its main purpose is to remove significant material to define a part’s basic shape and size. Industries like aerospace, automotive, and medical devices rely on this process. They need components with tight tolerances and specific dimensions. For example, grinding shapes critical automotive parts like brake cylinders and engine components.

Lapping: The Goal is Flattening. Lapping refines the geometry of a surface. Its purpose is not major shaping but creating exceptional flatness, parallelism, and surface finish. This process is essential for parts that require a perfect seal or uniform contact. The lapping process corrects minor imperfections left by grinding.

Polishing: The Goal is Shining. Polishing is the final step. Its goal is to create a smooth, mirror-like finish. This process removes a microscopic amount of material to eliminate the final traces of surface texture. A polished surface has high reflectivity and minimal light scatter, which is vital for optics and high-performance electronics.

Material Removal and Abrasive Types

The way each process removes material is directly related to the type of abrasives used. The rate of material removal decreases from grinding to lapping and then to polishing.

The grinding process uses fixed abrasives. These abrasives are bonded together to form a solid wheel. The particles act like tiny cutting tools, plowing through the material to create micro-grooves. This method allows for a high rate of material removal.

Lapping and polishing, in contrast, typically use loose abrasives.

These abrasives are suspended in a liquid to create a slurry. The particles roll and slide between the workpiece and a lapping plate. This action causes microscopic chipping and abrasion, resulting in a much lower rate of material removal. This three-body wear process is gentle and controllable.

The choice of abrasives is also critical.

- Grinding often uses superhard abrasives like Diamond and Cubic Boron Nitride (CBN) for hard materials.

- Lapping may use abrasives like Aluminum Oxide for a fine finish on softer materials or Silicon Carbide for harder materials.

- Polishing uses the finest abrasives, such as micro-graded diamond powder or cerium oxide, to achieve the final luster.

Surface Finish and Geometric Accuracy

The final quality of a part is measured by its surface finish and geometric accuracy. Each process delivers a different level of precision.

Ultra-precision grinding can achieve an excellent surface finish, but its primary strength is dimensional accuracy. It sets the foundation for subsequent steps.

Lapping dramatically improves geometric form. It can produce surfaces that are flat to within fractions of a wavelength of light. A flatness of 1/10 wave is achievable, which is necessary for high-precision optical and mechanical components.

Polishing provides the best possible surface finish. While lapping creates a matte finish, polishing creates a specular, mirror-like surface. This process can reduce surface roughness to incredibly low levels. A super mirror finish can have a surface roughness (Ra) of 0.025 µm or even less. Some advanced methods can achieve a surface roughness below 0.01 µm.

To make these differences clear, here is a simple comparison:

| Feature | Grinding | Lapping | Polishing |

|---|---|---|---|

| Primary Purpose | Shaping & Sizing | Form Correction (Flatness) | Final Finish (Shine) |

| Material Removal Rate | High | Low | Very Low |

| Abrasive Type | Fixed (Bonded Wheel) | Loose (Slurry) | Loose (Fine Slurry/Paste) |

| Resulting Surface Finish (Ra) | Good (e.g., >0.1 µm) | Very Good (e.g., >0.05 µm) | Excellent (e.g., <0.025 µm) |

| Geometric Accuracy | Good (Sets Shape) | Excellent (Creates Flatness) | Maintains Form |

Ultimately, these three processes work together. Grinding provides the shape, lapping perfects the form, and polishing delivers the ultimate finish, ensuring parts meet the highest standards of high precision.

A Detailed Look at Each Finishing Process

Understanding each finishing method helps in selecting the right one. The grinding process, lapping, and polishing each play a specific role in creating precision components. Let’s explore what makes each process unique.

The Ultra-Precision Grinding Process: Shaping and Sizing

The ultra-precision grinding process is the first step in creating a part’s fundamental shape. This technique uses a fixed abrasive wheel for aggressive material removal. It is a system where the machine itself is key to ensuring accuracy.

- Common Machines: External, plane, and internal grinding machines are frequently used.

- Key Materials: This grinding process works well on hard materials like ceramics, tool steels, and tungsten carbide.

- Achievable Precision: It can achieve a surface roughness of less than 0.025 μm and dimensional accuracy of 0.1μm.

This grinding process sets the foundation for later steps that require even higher precision.

The Lapping Process: Achieving Ultimate Flatness

The lapping process focuses on geometric form, not major material removal. It uses loose abrasives in a slurry to create exceptionally flat surfaces. The machine moves parts in a planetary motion, where they revolve and rotate at the same time. This action creates a random, non-directional surface finish. After lapping, flatness is often checked with interferometry, a method that uses light patterns to detect tiny surface variations. This process is essential for parts needing a perfect seal.

The Polishing Process: Creating a Perfect Finish

Polishing is the final touch. This process uses very fine abrasives for minimal material removal. Its goal is to eliminate microscopic defects like scratches and grinding lines, reducing surface roughness to create a mirror-like shine. The polishing process is what gives a surface its final aesthetic and functional quality. For optical parts, this high-quality finish is critical for performance.

The Role of Aimgrind Polishing Wheels

Achieving a perfect finish requires the right tools. Aimgrind Polishing Wheels are designed for this final, critical stage.

Made from soft and elastic materials, our polishing wheels adapt to the workpiece surface. This ensures a smooth, consistent result on materials like glass and metal.

For industries that demand high-quality finishes, from optics to precision machining, using a specialized tool is key. Aimgrind provides the polishing solutions needed to achieve that ultimate shine and high precision. Explore our range of Polishing Wheels to find the perfect match for your application.

Real-World Applications and Process Selection

Understanding the theory is one thing; seeing these processes in action reveals their true value. The choice between grinding, lapping, and polishing depends entirely on the final product’s requirements. Let’s look at a few key industries.

Fabricating High-Performance Optics

Creating a high-power laser mirror or a precision lens requires a multi-step approach to achieve high precision.

For a high-power laser mirror, the journey begins with the grinding process to create the initial curve. This step handles the bulk material removal. Next, lapping refines the surface, making it perfectly uniform and geometrically correct. The final polishing process uses very fine abrasives to produce a flawless, reflective finish with minimal surface roughness.

This sequence ensures the optic performs its function without distortion.

Manufacturing Semiconductor Wafers

The world of electronics relies on perfectly flat silicon wafers. A specialized polishing technique called Chemical-Mechanical Polishing (CMP) is critical here. This process is essential for creating multi-layered integrated circuits.

- Chemical Action: A slurry with chemical agents softens the wafer surface.

- Mechanical Action: A polishing pad uses tiny abrasives for material removal, grinding the wafer flat.

This combination of chemical and mechanical material removal creates an ultra-smooth, defect-free surface. This extreme flatness is necessary for building complex circuits layer by layer, ensuring high-quality finishes and reliable device performance.

Finishing Precision Cutting Tools

The performance of precision components like carbide cutting tools depends on the quality of their edges. The grinding process is fundamental. Ultra-precision grinding creates a sharp, stress-free cutting edge, which extends the tool’s life and improves the quality of precision machining. A superior surface finish on the tool reduces friction and wear. The final edge geometry, with a low surface roughness, directly impacts the finish of the part being cut. A precise grinding process followed by lapping or polishing ensures the tool performs optimally, delivering high precision with every use.

Remember the core functions: grinding creates shape, lapping perfects form, and polishing delivers the final finish. Achieving high precision often requires combining these methods. For example, manufacturing complex precision components like hydraulic fittings involves a sequence:

- Surface grinding

- Lapping the surface

- Final polishing for a smooth finish

To select the right process, match your needs to standards like ISO 2768-2 for surface finish. This ensures your parts meet exact specifications. The path to high precision and high-quality finishes depends on choosing the correct process and tools.

FAQ

Which process is best for my project?

Your choice depends on your goal.

- Use grinding to create the main shape of a part.

- Use lapping to make a surface extremely flat.

- Use polishing to get a mirror-like shine.

Do I always need to use all three processes?

No, not always. The required steps depend on your final needs. A part may only need grinding for shape. High-precision optics, however, often require all three processes in sequence to achieve the perfect result.

What makes a good polishing wheel?

A good polishing wheel uses soft, elastic materials. It should adapt to the workpiece surface to create a smooth, even finish. Quality wheels, like those from Aimgrind, ensure consistent results on materials like glass and metal.

How is surface finish measured?

Surface finish is often measured using a value called Surface Roughness (Ra). A special tool called a profilometer moves a fine stylus across the surface. It measures the tiny peaks and valleys to calculate the Ra value. A lower Ra means a smoother surface.

Contact Us

For More Grinding Solution or Customized Abrasive Tools