Selecting the correct grinding wheel is essential for achieving high-quality results in precision grinding. The market for these tools shows significant growth, reflecting their importance in modern manufacturing.

| Market Segment | 2024 Market Size (USD Billion) | 2035 Market Size (USD Billion) |

|---|---|---|

| Precision Grinding Wheels | 4.36 | 5.59 |

This guide clarifies different types of grinding wheels for specific grinding applications. It explores the uses of Vitrified, Resinoid, Electroplated, and specialized diamond wheels to help users choose the right precision grinding wheel for their tasks.

Key Takeaways

- Different grinding wheels work best for different jobs. Vitrified, Resinoid, Electroplated, and Diamond wheels each have special uses.

- Vitrified wheels are good for hard metals like steel. Resinoid wheels are flexible and work well for fast grinding.

- Electroplated wheels cut aggressively and do not need sharpening. Diamond wheels are best for very hard materials like ceramics.

- Always match the grinding wheel to the material you are working on. This helps you get the best results and finish your work well.

- Sometimes, a custom grinding wheel is needed for special materials or shapes. Experts can help you find the perfect wheel for tough jobs.

Exploring the Main Types of Grinding Wheels

Understanding the main types of grinding wheels is the first step toward optimizing your grinding process. Each type has a unique composition and set of characteristics designed for specific materials and outcomes.

Vitrified (Conventional) Wheels

Vitrified wheels are one of the most common types of grinding wheels. Manufacturers create their bond from synthetic, technical glasses. This process results in a strong, rigid, and porous wheel structure.

The porosity of a vitrified wheel is a key design feature. These tiny, interconnected air pockets act as channels for coolant.

- They allow grinding fluids to reach the cutting zone effectively.

- This improved cooling prevents thermal damage like burn marks on the workpiece.

- Efficient heat removal allows for faster grinding cycle times.

The level of porosity can be customized. A higher porosity is great for rapid stock removal. A lower porosity helps achieve very fine surface finishes.

Primary Applications:

Vitrified wheels are versatile tools used for many precision grinding tasks. They excel at grinding hard materials like steel, ferrous alloys, ceramics, and carbide. Common applications include surface grinding, cylindrical grinding, and toolroom grinding for sharpening cutting tools.

Resinoid (Resin Bond) Wheels

Resinoid wheels use an organic resin to bond the abrasive particles together. This bond is a mix of resin and abrasives, creating a strong yet flexible adhesive. The resins can range from softer plastics to high-strength polyimides, which offer superior toughness and heat resistance.

Compared to vitrified bonds, resinoid bonds have higher elasticity. This quality makes them less likely to fail under uneven loads. They are an excellent choice for high-speed grinding operations. Their resistance to heat allows them to operate at high speeds without losing their shape.

| Bond Type | Strength | Firmness |

|---|---|---|

| Vitrified Bond | High | High |

| Resinoid Bond | Moderate | Poor |

These wheels are ideal for use on hand tools and machines like chop saws. Their versatility extends to precision grinding, surface grinding, and cutting applications.

Electroplated Wheels

Electroplated wheels feature a single layer of superabrasive particles, like diamond or CBN. The manufacturing process bonds these particles directly to the wheel’s core.

- Abrasive grains are attached to the wheel core using a strong nickel coating.

- This nickel layer chemically and physically bonds the abrasive to the wheel body.

- A secondary nickel layer is often applied to create an even tighter bond.

This single-layer design provides an aggressive cutting action and excellent form-holding capabilities.

Key Advantage: No Dressing Needed

A major benefit of electroplated wheels is that they do not require dressing. This eliminates production downtime and ensures consistent performance, boosting operational efficiency. They are perfect for grinding complex forms and profiles with tight tolerances.

These wheels are the preferred choice for grinding composites like carbon fiber and fiberglass. They also work well on nickel-based superalloys, engineered ceramics, and materials for the medical and electronics industries.

Aimgrind’s Diamond Grinding Wheels

For the hardest and most brittle materials, diamond wheels are the ultimate solution. Diamond is the hardest known material. This property makes it exceptionally effective for grinding tough substances like tungsten carbide, ceramics, and composites. A high-quality precision grinding wheel using diamond abrasives ensures superior performance.

Aimgrind specializes in creating customized diamond grinding wheels for demanding industries. We understand that the bond is just as important as the abrasive. That is why we offer various bond types to match any challenge.

- Resin Bond: Offers a smoother finish and generates less heat. It is ideal for fine finishing and grinding heat-sensitive materials.

- Metal Bond: Provides a more aggressive cut and longer tool life. It is suited for heavy grinding and rapid stock removal on hard materials.

- Vitrified Bond: Combines the hardness of diamond with the rigidity and porosity of a vitrified structure. This bond is excellent for the precision grinding of ceramic and carbide materials.

Choosing the right bond ensures optimal performance for your specific applications. Aimgrind’s expertise helps you find the perfect match, enhancing productivity and achieving unparalleled precision.

Choosing Your Precision Grinding Wheel: A Comparison

Selecting the right tool from the various types of grinding wheels is critical for success. This choice directly impacts efficiency, cost, and the final quality of the workpiece. A systematic approach helps operators make the best decision for their specific grinding needs.

Material and Application Matching

The first step in choosing a grinding wheel is to match the abrasive material to the workpiece material. An abrasive must be significantly harder than the material it is grinding to cut effectively.

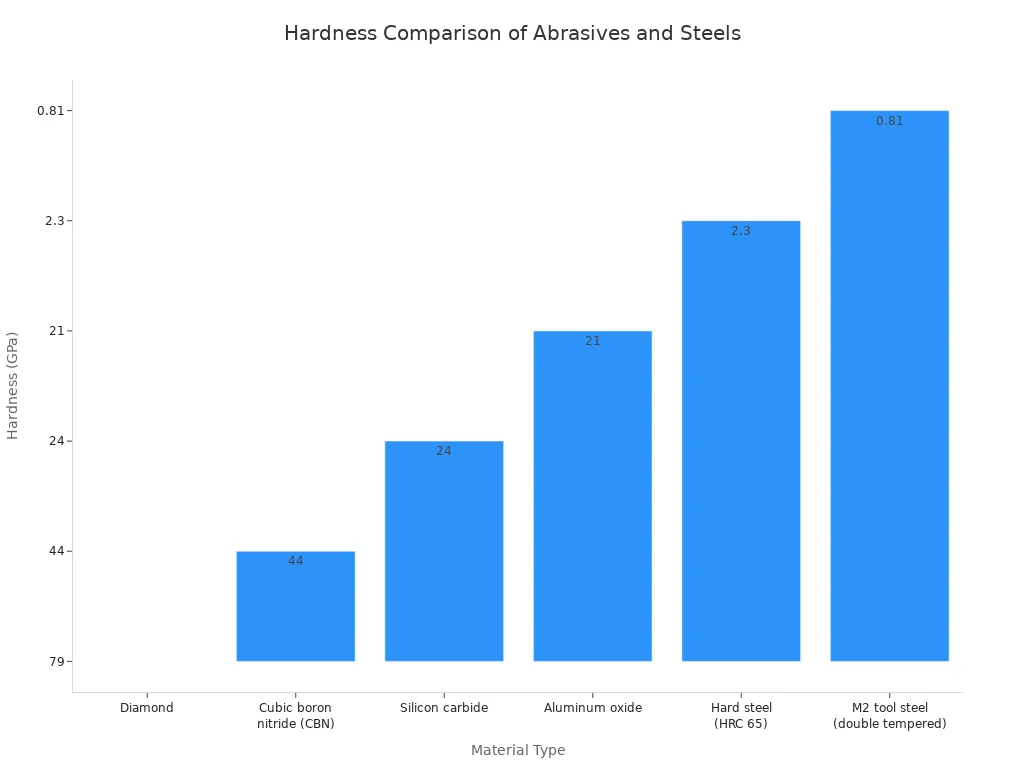

As the chart shows, abrasives like diamond and CBN are much harder than even hardened steels. This hardness difference is crucial for efficient material removal.

Here is a simple guide for matching materials:

- Aluminum Oxide: This conventional abrasive works well for grinding ferrous metals and alloys that react with carbon. It is a cost-effective choice for soft to moderately hard workpieces.

- Silicon Carbide: Harder than aluminum oxide, this abrasive is effective for grinding hard, non-metallic materials like ceramics, glass, and composites.

- Diamond: As the hardest material, diamond is the top choice for grinding extremely hard materials that do not react with carbon. This includes ceramics like zirconia, hard alloys, and composites.

- Cubic Boron Nitride (CBN): CBN is the second-hardest material and is ideal for grinding hardened ferrous metals like high-speed steel and tool steels. It maintains its hardness at high temperatures.

Note: Superabrasives like diamond and CBN are generally not recommended for soft non-ferrous metals (e.g., aluminum, brass) because the wheel can clog quickly.

Comparing Wheel Characteristics

Beyond the abrasive material, the wheel’s bond and overall structure determine its performance. Each precision grinding wheel type offers a unique combination of characteristics suited for different applications.

This table provides a quick reference for comparing the main wheel types.

| Wheel Type | Best For (Materials) | Common Applications |

|---|---|---|

| Vitrified | Ferrous alloys, steel, carbide, ceramics | Surface grinding, cylindrical grinding, tool sharpening |

| Resinoid | Stainless steel, titanium, tough alloys | High-speed grinding, cutting, finishing of metal components |

| Electroplated | Composites, superalloys, ceramics, glass | Grinding complex profiles, cutting hard materials, shaping molds |

| Diamond | Tungsten carbide, ceramics, glass, composites | Precision grinding of hard tools, polishing glass, finishing aerospace parts |

Vitrified wheels offer high stock removal rates but can be brittle. Resinoid wheels provide flexibility and are great for rapid material removal in rough grinding. Electroplated wheels give an aggressive initial cut but have a shorter lifespan because they have only a single abrasive layer. Diamond wheels offer exceptional durability and are the best for the precision grinding of the hardest materials.

When to Choose a Custom Solution

Standard, off-the-shelf wheels work for many jobs. However, some manufacturing challenges require a specialized approach. A custom solution becomes necessary when standard options fail to deliver the desired results.

Consider a custom solution if you face these issues:

- Unique Materials: Grinding advanced materials like superalloys or technical ceramics often requires a special formula.

- Tight Tolerances: Industries like aerospace, medical, and precision engineering demand extremely high precision that standard wheels may not achieve.

- Complex Geometries: Grinding non-standard shapes or intricate profiles can be impossible without a custom-designed wheel.

- Poor Performance: If your current wheels wear out too quickly, cause thermal damage, or fail to produce the required surface finish, it is time to seek an expert.

For these complex grinding challenges, consulting a specialist ensures a perfect match. Aimgrind excels at diagnosing problems and providing custom formula designs. Our process ensures your grinding wheel is perfectly optimized for your equipment and material, enhancing productivity and achieving superior results.

Choosing the right precision grinding wheel is vital for success. The best choice among Vitrified, Resinoid, Electroplated, and Diamond wheels depends on the material and the desired outcome. A proper selection enhances productivity, as optimized grinding processes can improve output significantly. Making the correct choice is key to achieving precision in various applications.

For unique challenges, expert guidance ensures the perfect grinding wheel is matched to your equipment. Leverage Aimgrind’s expertise to solve complex grinding problems and boost your performance. Grind with Passion, Achieve with Aim.

FAQ

What is the most important factor when choosing a grinding wheel?

The workpiece material is the most critical factor. An abrasive must be harder than the material it grinds for effective cutting. This match ensures good performance and a quality finish. It directly impacts the efficiency of the entire grinding operation.

How do you know when to replace a grinding wheel?

Operators should replace a wheel when it shows signs of damage, like cracks or chips. A wheel that no longer cuts effectively or has lost its original shape also needs replacement. This practice ensures both safety and consistent grinding quality.

What is the difference between a diamond wheel and a CBN wheel?

Diamond wheels excel at grinding extremely hard, non-ferrous materials like carbide, ceramics, and glass. CBN (Cubic Boron Nitride) wheels are the top choice for grinding hard ferrous metals, such as tool steels and superalloys. Each superabrasive has specific material strengths.

Why is the bond type so important in a grinding wheel?

The bond holds the abrasive grains together and controls how the wheel wears. A hard bond provides a long life for heavy stock removal. A soft bond releases dull grains faster, exposing sharp abrasives for a fine finish. The correct bond optimizes performance.

Contact Us

For More Grinding Solution or Customized Abrasive Tools