You need to address brake defects fast to keep your system safe. When you spot brake issues early, you protect yourself and your passengers. Trust Aimgrind for expert support in Brake Rotor Grinding. Diamond grinding wheels help you fix brake problems with precision. Choose quality tools for every brake job.

Key Takeaways

- Regularly inspect brake rotors for issues like warping or scoring. Early detection prevents costly repairs and keeps your vehicle safe.

- Use Aimgrind’s diamond grinding wheels for precise results. Quality tools lead to better performance and longer-lasting brake components.

- Maintain a clean and dry work environment. This reduces the risk of corrosion and ensures effective brake repairs.

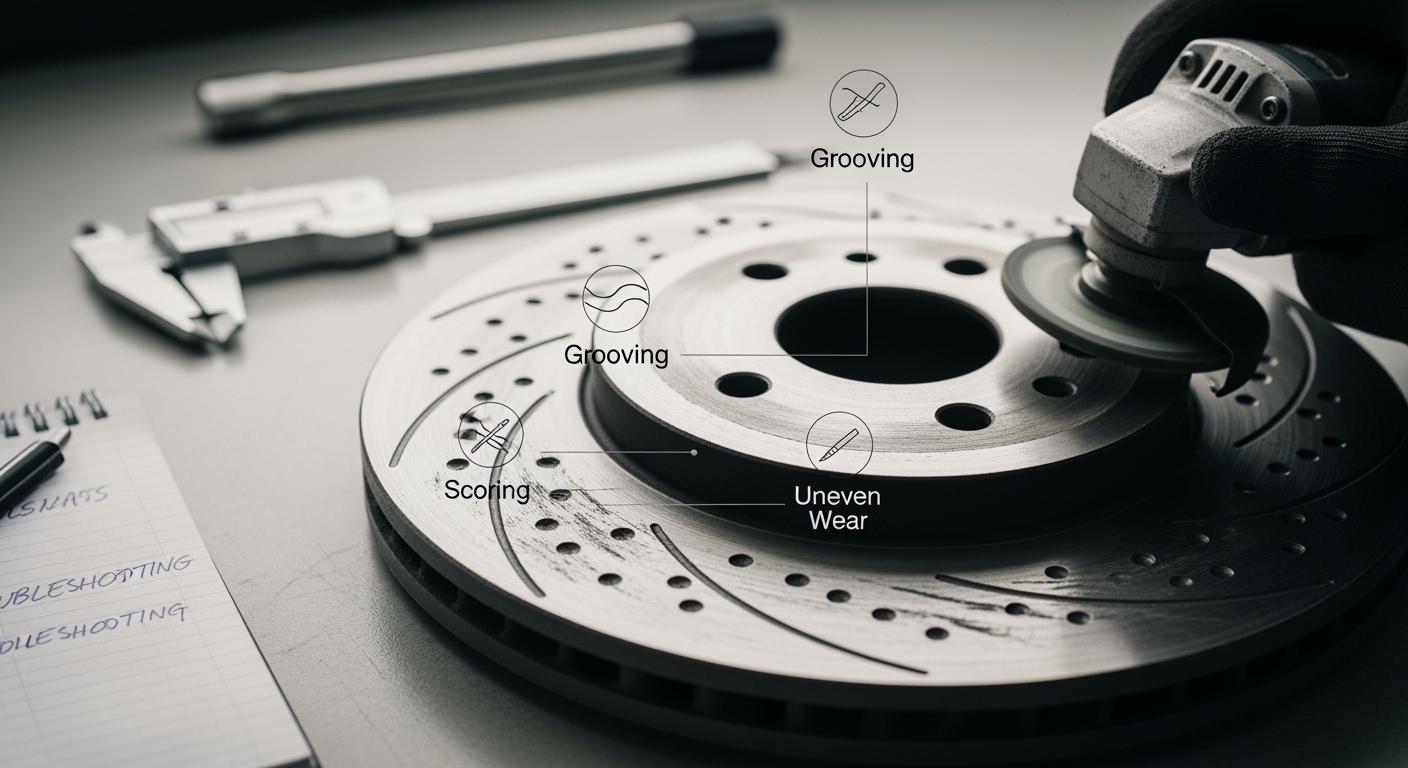

Identifying Brake Rotor Grinding Defects

When you work on brake rotor grinding, you may notice several common brake issues. Spotting these problems early helps you avoid brake failure issues and keeps your vehicle safe.

Uneven Surfaces

Uneven surfaces on the rotor can cause vibrations during braking. If the grooves cut into the rotor are too deep or too shallow, you may feel shuddering or notice poor braking performance. Uneven pad material can build up, making the problem worse. Regular brake maintenance and using Aimgrind’s diamond grinding wheels help you achieve a smooth, even finish.

Excessive Runout

Excessive runout means the rotor wobbles as it spins. This can lead to brake problems like pulsation or uneven wear. You can check runout with a dial indicator. Here are the maximum runout values:

| Brake Rotor Type | Maximum Total Runout |

|---|---|

| Base Brake Rotors | 0.050 mm |

| Performance Brake Rotors | 0.150 mm |

If you find runout above these limits, you should repair or replace the rotor.

Scoring and Grooves

Scoring and grooves appear when metal parts grind against the rotor. Worn brake pads or debris can cause deep marks. These marks weaken the rotor and may lead to brake warning light activation. Aimgrind’s diamond grinding wheels remove these grooves and restore the surface.

Brake Grinding Noise

You may hear brake grinding noise if the friction material wears away. Metal-to-metal contact creates harsh sounds and can damage the rotor. Ignoring this noise can lead to costly repairs. Quick troubleshooting and the right grinding tools prevent further damage.

Tip: Regular brake maintenance and using quality grinding wheels help you avoid common brake issues and keep your system safe.

Diagnosing Brake Defects

Machine Setup Issues

You need to check your machine setup before you start any brake repair. If the machine is not level or the mounting is loose, you may see problems like uneven cuts or a hard brake pedal. Always make sure the grinding machine is clean and the rotor is mounted tightly. If you skip this step, you risk poor brake performance and extra repair work. Use the right tools and follow the service manual for every brake job. This helps you avoid mistakes and keeps your brake maintenance on track.

Rotor Condition

You must inspect the rotor before you begin grinding. Look for signs of rust, corrosion, or warping. These issues can cause the brake warning light to turn on or make the brakes take too long to stop. If you see deep grooves or uneven wear, you may need to repair or replace the rotor.

Variation in rotor thickness will cause pedal pulsation. The variation might be the result of excess heat buildup that has warped the rotor, or the rotor may be contaminated by isolated thick spots caused by rust or corrosion buildup.

If you notice any of these problems, address them right away. This step is key for effective brake repair and maintenance.

Operator Technique

Your technique matters when you work on brakes. Poor habits can lead to more defects and extra repair costs. Here are some common mistakes:

- Hard braking can quickly wear out brake pads and cause rotor warping, reducing the lifespan of these parts and affecting braking performance.

- Heavy loads and frequent hard braking put extra strain on brake pads and rotors, causing more damage.

- Driving with worn pads can lead to deep grooves or scoring on rotors, creating a grinding sound even after new pads are installed.

- Warped rotors from excessive heat can cause vibrations and noise, making braking less smooth and effective.

- Small debris caught in brakes can cause metal-to-metal contact, leading to increased wear and reduced brake effectiveness.

- Hard braking can lead to uneven wear and make the vehicle pull to one side when braking.

You should always use smooth, steady pressure when braking. Avoid sudden stops unless needed for safety. Good habits help you avoid common brake problems and make troubleshooting easier.

Environmental Factors

The environment can affect your brake repair results. Temperature, humidity, and even salt in the air can change how your brakes work. Check the table below to see how different factors can impact brake rotor grinding quality:

| Environmental Factor | Effect on Brake Rotor Grinding Quality |

|---|---|

| High Humidity | Accelerates corrosion of brake components, affecting rotors and calipers. |

| High Temperature | Causes excessive heat buildup, leading to metal expansion and distortion. |

| Frequent Temperature Fluctuations | Introduces air into hydraulic systems, affecting braking efficiency. |

| Salt Air | Creates corrosive conditions that attack metal components more aggressively. |

| Heavy Rain | Floods brake components, temporarily reducing friction. |

You should store brake parts in a dry place and avoid working in wet or salty conditions when possible. This helps you keep your brake system in good shape and reduces the need for extra repair.

Tip: Regular brake maintenance and careful troubleshooting help you catch problems early. This keeps your brake system safe and reliable.

Brake Troubleshooting Guide

Inspecting Rotor Surfaces

You need to check the rotor surface before you start any brake repair. Use both your hands and inspection tools to find surface defects. Here are some ways you can inspect rotors:

- Run your fingers gently over the rotor to feel for grooves, scoring, or rough spots.

- Use a flashlight to look for cracks, rust, or discoloration.

- For early crack detection, use a STATOGRAPH test instrument with the right probe.

- Check for uneven wear or buildup that could trigger the brake warning light.

If you find any problems, you should address them right away. Aimgrind’s diamond grinding wheels help you remove surface defects and restore a smooth finish.

Tip: Always inspect both sides of the rotor for hidden damage.

Measuring Runout

You must measure runout to make sure the rotor spins straight. Lateral runout means the rotor wobbles side to side, which can cause uneven wear and brake pedal vibration. Here’s how you can measure runout:

- Use a micrometer to check rotor thickness at six spots around the face.

- Start measuring a quarter inch from the edge.

- Make sure the thickness difference does not go over .001 inch (0.025 mm).

- If you see a difference greater than .006 inch (0.15 mm), you may have Disc Thickness Variation and need to replace the rotor.

If you find too much runout, use Aimgrind’s diamond grinding wheels to correct the surface or replace the rotor if needed.

Fixing Scoring and Grooves

Scoring and grooves can weaken the rotor and cause brake grinding noise. Follow these steps to fix them:

- Measure rotor thickness at eight points with a micrometer to make sure it is not too thin.

- Check that both friction surfaces are parallel to avoid pedal pulsation.

- Look for wobbling during rotation and fix any lateral runout.

- Use the right lathe settings to avoid leaving new grooves.

- Clean the rotor with soap and water after machining to remove metal dust.

- When installing new rotors, clean the hub-to-rotor surface to prevent runout.

- After installation, recheck total runout and adjust if needed.

Aimgrind’s diamond grinding wheels give you a smooth finish and help you remove deep grooves quickly.

Resolving Brake Grinding Noise

Brake grinding noise often means you have serious wear. Here’s how you can solve this problem:

- Inspect brake pads and rotors for wear, grooves, or warping.

- Listen for grinding or squealing sounds when you press the brake pedal.

- If you hear grinding, stop driving and fix the problem right away to avoid more damage.

Replace worn parts and use Aimgrind’s diamond grinding wheels to restore the rotor surface. This keeps your brake system quiet and safe.

Note: Ignoring brake grinding noise can lead to costly repairs and unsafe driving.

Adjusting Machine Settings

Proper machine settings help you avoid defects during brake rotor grinding. You should:

- Adjust the spindle in-feed assembly if you notice wear or misalignment.

- Realign the dresser assembly to fix setup issues.

- Check that spindle heads are not worn out or misaligned.

- Align guides with each other and with the grinding wheels.

- Make sure the tooling and feed mechanism match the guides and grinding wheels.

These steps help you get a precise finish and reduce the risk of problems during brake repair and maintenance.

Correcting Operator Errors

Operator mistakes can lead to brake defects. Here’s how you can correct them:

- Review your technique and follow the service manual for every brake job.

- Use steady, even pressure when grinding or braking.

- Avoid rushing the process or skipping steps.

- Double-check your work before finishing the repair.

Aimgrind’s diamond grinding wheels make it easier to achieve a quality finish, even if you are new to brake maintenance.

Callout: Good habits and the right tools help you avoid common brake problems and keep your brake system in top shape.

Preventing Brake Grinding Issues

Machine Maintenance

You can prevent many brake problems by following a regular maintenance routine. Start each day by cleaning surfaces and tools to remove dust and metal shavings. Tighten all fasteners to keep the machine aligned. Listen for unusual noises or vibrations during brake repair and maintenance. Each week, check the hydraulic system for leaks and make sure fluid levels are correct. Inspect the backgauge for proper alignment. Test all safety features to keep your brake system safe. Preventive brake maintenance helps you avoid costly repairs and keeps the brake warning light off.

Proper Rotor Handling

Handle rotors with care during every brake repair. Always use clean gloves to avoid leaving oil or dirt on the surface. Store rotors in a dry place to prevent rust. Lift rotors carefully to avoid dropping or bending them. Proper handling keeps the rotor surface smooth and helps you avoid new problems during brake inspection.

Training and Best Practices

You need the right training to perform quality brake work. Many programs teach you about brakes, brake parts, and how to measure and replace rotors. The table below shows some helpful training modules:

| Module | Description |

|---|---|

| 1 | Braking Basics Presentation |

| 2 | Brake Parts ID Exercise |

| 3 | Brake Fluid Testing Demonstration |

| 4 | Brake Pad and Rotor Measurements Exercise |

| 5 | Brake Pad and Rotor Removal & Replacement |

| 6 | Electronic Parking Brake Resetting |

These programs often offer certification and hands-on practice. Good training helps you spot problems early and improves your troubleshooting skills.

Environmental Controls

Control your work environment to protect the brake system. Keep the area dry and free from dust. Avoid working in places with high humidity or salt in the air. Store brake parts away from water and chemicals. Good environmental controls help you avoid corrosion and keep your brake system in top shape.

Aimgrind supports you with high-quality, customized grinding solutions. You can trust Aimgrind’s diamond grinding wheels to deliver precise results for every brake job.

You can keep your brake system safe by following these steps:

- Inspect rotors for warping or scoring.

- Clean all brake parts and remove debris.

- Replace or resurface rotors if needed.

- Check for a brake warning light.

Regular brake maintenance helps you avoid costly repairs and keeps your vehicle safe.

| Advantage | Description |

|---|---|

| Efficiency | 25% better operational efficiency |

| Extended Life | Longer brake and machine component lifespan |

Choose Aimgrind’s diamond grinding wheels for the best brake results.

FAQ

What causes the brake warning light to turn on during grinding?

You may see the brake warning light if the rotor has deep grooves, uneven wear, or if the brake system detects a serious issue.

How often should you inspect your brake rotors?

You should check your brake rotors every 10,000 miles. Regular inspection helps you catch problems early and keeps your brake system safe.

Can you fix brake noise without replacing the rotor?

You can often fix brake noise by resurfacing the rotor with a diamond grinding wheel. This restores a smooth surface and improves brake performance.

Contact Us

For More Grinding Solution or Customized Abrasive Tools