Finding the right aluminum oxide grinding wheel is crucial for your project. This guide draws on Aimgrind‘s deep expertise in customized grinding solutions. The market for quality abrasives is growing, projected to expand from USD 41.05 billion in 2024 to USD 65.86 billion by 2035. Industries like metalworking and aerospace depend on these tools. This article details our top aluminum oxide grinding wheels and explains key grinding terms.

Top 10 Wheels by Use:

- Heavy Removal: Walter ST-X

- Precision Surface Grinding: Norton 3SG

- Tool Sharpening: TYROLIT Premium

- General Purpose: Aimgrind Conventional Bonded Abrasives

- Cutting: 3M Silver

- Weld Blending: Saint-Gobain Norzon

- Non-Ferrous Metals: Carborundum Premier Red

- DIY Projects: CUMI General Purpose Wheel

- High-Speed Grinding: Noitake Super Wheel

- Cool Grinding: Norton 57A

Key Takeaways

- Choose the right aluminum oxide grinding wheel for your specific job. This ensures the best results.

- Understand key factors like grit, bond, and hardness. These factors affect how the wheel works.

- Always match the grinding wheel to the material you are working on. This improves efficiency and finish quality.

- Prioritize safety when using grinding wheels. Always wear protective gear and follow proper operating steps.

Understanding the aluminum oxide grinding wheel

Before you select a tool, you should understand its core components. An aluminum oxide grinding wheel is a versatile tool for many projects. This section breaks down the essentials for you.

What is aluminum oxide?

Aluminum oxide (Al2O3) is a very hard and durable material. Manufacturers create it by treating bauxite ore in a special furnace. Its strong crystal structure, known as corundum, gives it superior abrasive properties. This material has a hardness of 9 on the Mohs scale, second only to diamond. This makes it excellent for grinding and finishing tough metals. Its high melting point and chemical resistance ensure it performs well under pressure. Different types, like white or blue fired aluminum oxide, are used for precision grinding on hard materials.

Key factors: grit, bond, and hardness

You must consider three main factors when choosing from various aluminum oxide grinding wheels. These factors determine how the wheel performs.

- Grit: This refers to the size of the abrasive particles. A lower number means coarser abrasives for fast material removal. A higher number indicates finer abrasives for smooth finishing.

- Bond: The bond holds the abrasives together. Bonds like rubber are flexible. They provide a smooth cutting action perfect for fine finishing.

- Hardness: This measures the bond’s strength on a scale from A (soft) to Z (hard). A harder wheel holds onto abrasives longer.

Matching the wheel to your material

The right wheel depends on your material. Your choice affects both efficiency and the quality of the finish.

Pro Tip: Always match your wheel to your workpiece. High-tensile materials like hardened steel require a friable aluminum oxide grinding wheel. These wheels have grains that break away to expose fresh, sharp edges for effective grinding.

For softer, non-ferrous metals, you might need a different approach. An aluminum grinding wheel can sometimes get clogged. For materials like aluminum or brass, many professionals prefer silicon carbide abrasives. They are sharper and work well with a coarser grit and a harder bond for clean, efficient work.

Top 10 aluminum oxide grinding wheels by use

Choosing the right wheel transforms your project from a chore into a craft. This list breaks down the top 10 aluminum oxide grinding wheels, helping you select the perfect tool for your specific application.

1. Walter ST-X – for heavy metal removal

When you need to remove a lot of material quickly, the Walter ST-X is a powerful choice. It is designed for aggressive grinding on tough metals like steel and iron.

- Key Features: A specially formulated grain mix provides a very high removal rate. Its reinforced construction ensures safety during demanding jobs.

- Ideal Materials: Carbon steel, structural steel, and iron.

- Pros: Excellent for rapid stock removal and heavy-duty grinding tasks.

- Cons: Its aggressive nature means it may wear faster than other wheels during prolonged use.

2. Norton 3SG – for precision surface grinding

For projects that demand exceptional accuracy and a flawless finishing, the Norton 3SG stands out. It is a top performer in precision surface grinding applications.

Unique Features:

- It has a very high concentration of SG ceramic grain for a fast cut and extended wheel life.

- The unique, microcrystalline structure is self-sharpening, which contributes to its long product life.

- Its high-performance bond provides versatility and exceptional form holding for consistent finishing.

Performance Notes:

- You may need to “push” this wheel with a more aggressive depth of cut to make it work properly.

- Using it aggressively can reduce your grinding time significantly without causing surface burn.

- It is considered one of the best wheels available for grinding tough CPM materials.

3. TYROLIT Premium – for tool and cutter sharpening

You need precision and a cool cut when sharpening tools. The TYROLIT Premium wheel delivers both. It helps you restore a sharp edge to cutters, drills, and other tools without damaging the metal.

- Key Features: This wheel uses a high-quality aluminum oxide grain with a vitrified bond. This combination allows for cool grinding and excellent shape retention.

- Ideal Materials: High-speed steel (HSS), tool steels, and other hardened metals.

- Pros: Provides a sharp, clean edge with minimal heat buildup, protecting the tool’s temper. Its quality ensures a great finishing.

- Cons: It is a specialized wheel and may be more expensive than general-purpose options.

4. Aimgrind Conventional Bonded Abrasive – for general purpose bench grinding

For everyday tasks in your workshop, you need a reliable and versatile tool. The Aimgrind Conventional Bonded Abrasive is an excellent choice for general-purpose bench grinding. These abrasives offer a fantastic balance of performance and affordability.

- Key Features: These wheels use high-quality aluminum oxide and silicon carbide grains. This makes them durable and efficient for a wide range of grinding jobs. Their robust construction ensures consistent performance and a smooth finishing.

- Ideal Materials: A variety of metals, including steel, iron, and other alloys. They are some of the best abrasives for aluminum.

- Pros: These high-performing grinding tools are extremely cost-effective and versatile. They provide reliable quality and durability for sharpening tools, shaping parts, and general cleanup tasks. Their performance makes them a valuable addition to any workshop.

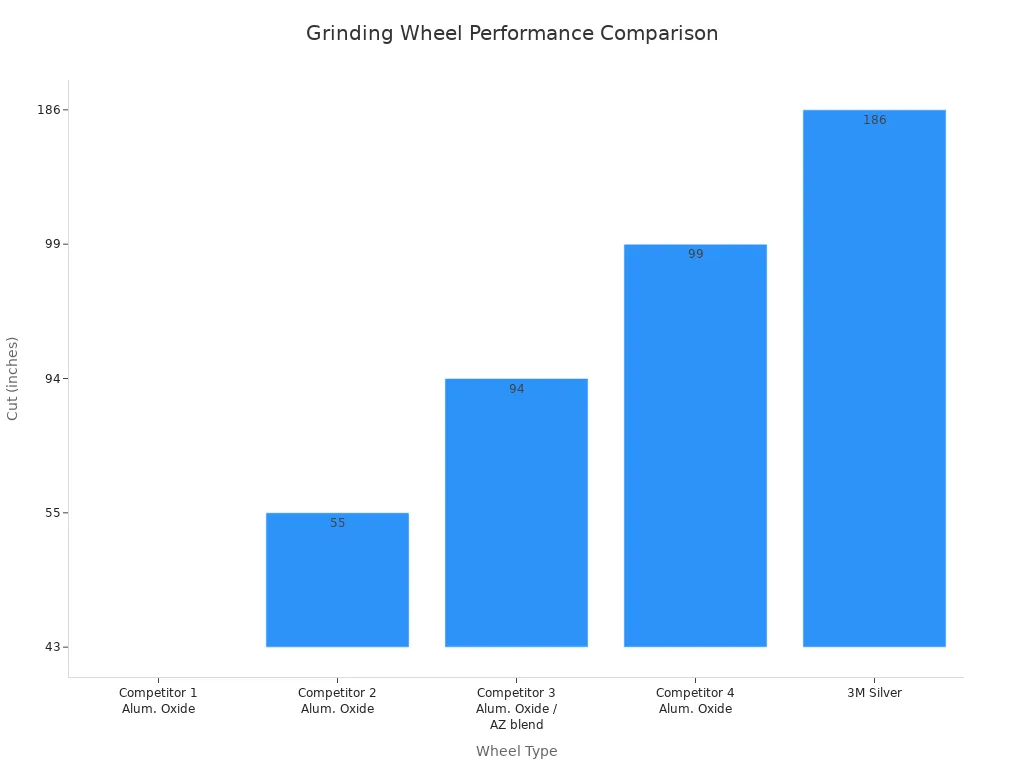

5. 3M Silver – for cutting and slotting

When your job involves cutting metal, you want speed and longevity. The 3M Silver cut-off wheel uses advanced technology to deliver both. It is designed for fast, smooth cutting on many types of metal.

Customers report that 3M™ Silver Cut-off Wheels last longer than other wheels. This means you change wheels less often and finish more parts, improving productivity.

The wheel features 3M Precision-Shaped Grain, which continually fractures to create sharp points. This allows it to slice cleanly through metal instead of plowing, which contributes to its high cut-rate and durability. It is one of the best abrasives for aluminum and steel.

| Wheel Type | Cut (inches) |

|---|---|

| Competitor 1 Alum. Oxide | 43 |

| Competitor 2 Alum. Oxide | 55 |

| Competitor 3 Alum. Oxide / AZ blend | 94 |

| Competitor 4 Alum. Oxide | 99 |

| 3M Silver | 186 |

6. Saint-Gobain Norzon – for weld blending

After welding, you need to smooth the joint for a clean finishing. The Saint-Gobain Norzon wheel is engineered for this task. It excels at blending welds and finishing surfaces.

Key Features:

- It uses a self-sharpening Zirconia Alumina grain for an aggressive cutting action.

- The wheel resists loading, which helps you maintain a regular cut rate for a good linear finishing.

- It is ideal for grinding, shaping, blending, and weld removal.

Ideal Materials: Stainless steel, carbon steel, and other resistant alloys.

Pros: Its aggressive cut helps you achieve a faster finishing per part, maximizing your throughput.

7. Carborundum Premier Red – for non-ferrous metals

Grinding soft, non-ferrous metals like aluminum can be tricky. These materials can clog, or “load,” the wheel. The Carborundum Premier Red aluminum grinding wheel is designed to resist this issue. You can also find similar anti-clogging properties in quality flap discs for aluminum.

- Key Features: This wheel features a treated aluminum oxide grain and a specialized bond. This combination reduces loading and provides a smooth finishing on soft metals. Many professionals also use flap discs for aluminum for similar finishing tasks.

- Ideal Materials: Aluminum, brass, copper, and bronze.

- Pros: Prevents wheel clogging, leading to a longer life and better finishing. It is one of the best abrasives for aluminum.

- Cons: It is not ideal for grinding hard ferrous metals.

8. CUMI General Purpose Wheel – for budget-friendly DIY projects

If you are a DIY enthusiast or need a wheel for occasional use, you do not need to spend a lot. The CUMI General Purpose Wheel offers good quality at an affordable price. It is a solid choice for various home projects. You can also use flap discs for aluminum for many DIY finishing jobs.

- Key Features: This aluminum oxide grinding wheel provides reliable performance for light-duty grinding and sharpening. It is a great entry-level option.

- Ideal Materials: Mild steel and other common metals.

- Pros: Very budget-friendly and suitable for a wide range of non-critical applications.

- Cons: May not offer the same durability or performance as premium wheels for heavy use.

9. Noitake Super Wheel – for high-speed angle grinders

Angle grinders operate at very high speeds. You need a wheel built to handle the stress. The Noitake Super Wheel is designed for safety and performance on high-speed tools. Like other high-quality abrasives, it provides a great finishing.

- Key Features: This wheel is specially bonded and reinforced for high-speed grinding. It offers excellent balance to reduce vibration and improve control. Many flap discs for aluminum are also rated for high speeds.

- Ideal Materials: Steel, cast iron, and other ferrous metals.

- Pros: Engineered for high-speed safety and a long service life. It provides a fast, efficient cut.

- Cons: It is specifically for high-speed grinders and should not be used on bench grinders.

10. Norton 57A – for cool grinding on sensitive materials

Some materials are sensitive to heat. Too much heat from grinding can cause warping or discoloration. The Norton 57A is one of the aluminum oxide grinding wheels designed for cool grinding, protecting your workpiece.

- Key Features: This wheel uses a friable, sharp aluminum oxide grain. The grains fracture easily to expose new cutting edges, which reduces heat buildup. Its vitrified bond also promotes a cooler cut.

- Ideal Materials: Heat-sensitive tool steels and other high-alloy steels.

- Pros: Minimizes the risk of burning or damaging the workpiece. It is excellent for precision finishing on delicate parts. You can find similar cool-grinding abrasives in flap discs for aluminum.

Safety and best practices

Using a grinding wheel safely is just as important as choosing the right one. You can ensure a secure and effective grinding experience by following established safety protocols in your workshop.

Proper wheel mounting and inspection

Before you mount any new wheel, you must inspect it for damage. The ANSI B7.1 standard provides the rules for safe wheel use. A simple and effective method is the “ring test.”

How to Perform the Ring Test

- Suspend the wheel on your finger or a small pin through its center hole.

- Gently tap the side of the wheel with a nonmetallic object, like a plastic screwdriver handle.

- A clear, metallic ring means the wheel is intact. A dull thud suggests a crack, and you should not use the wheel.

When mounting, always use the doughnut-shaped blotters that come with the wheel. These go between the wheel and the metal flanges. Ensure the flanges are clean, flat, and tightened correctly to apply even pressure. The wheel should fit freely on the spindle without being too loose.

Essential personal protective equipment (PPE)

Protecting yourself from flying debris and dust is critical. Your safety gear should always include:

- Eye and Face Protection: You must wear safety glasses or a face shield that meets ANSI Z87.1 standards. This protects your eyes from flying particles generated during grinding.

- Respiratory Protection: Abrasive dust can be harmful to inhale. Use a NIOSH-certified respirator to protect your lungs. For heavy grinding, a respirator that covers your head, neck, and shoulders offers the best protection.

- Hand and Body Protection: Wear sturdy gloves and avoid loose clothing that could get caught in the grinder.

Safe grinder operation

Proper machine setup and operation prevent accidents. You should always check your grinder’s settings before you start working.

First, adjust the tool rest. It must be positioned no more than 1/8 inch away from the grinding wheel. Next, check the spark guard. The opening between the guard and the wheel should not exceed 1/4 inch.

Avoid common mistakes that can lead to wheel failure. Do not apply too much pressure or feed the workpiece into the wheel too quickly. Using a wheel past its shelf life or at a speed higher than its rating is also dangerous. A delicate touch and proper technique are key to safe grinding.

Choosing the right aluminum oxide grinding wheel means matching it to your job for the best finishing. For versatile quality, use Aimgrind’s conventional bonded abrasives for daily grinding. For high-precision finishing, specialized aluminum oxide grinding wheels like the Norton 3SG offer superior quality finishing.

Ready for the perfect finishing? 🎯

Explore Aimgrind’s custom abrasives for your unique finishing challenges. Our quality abrasives are the best abrasives for a perfect finishing, from rough grinding to fine finishing. Visit our website to achieve your goals.

FAQ

What is the difference between aluminum oxide and silicon carbide?

You use aluminum oxide for high-tensile materials like steel. It is very tough and durable. Silicon carbide is harder and sharper. You use it for grinding hard, brittle materials like cast iron, ceramics, or soft non-ferrous metals like aluminum.

How do you “dress” a grinding wheel?

Dressing a wheel cleans its surface. You use a dressing tool to remove clogged material and dull abrasive grains. This action exposes fresh, sharp cutting edges. It helps you maintain the wheel’s shape and cutting efficiency for a better finishing.

Why is the “ring test” so important? 🧐

The ring test helps you check for hidden cracks in a wheel. A cracked wheel can shatter at high speed, causing serious injury. You should always perform this simple test before mounting any new wheel to ensure it is safe to use.

How do you choose the right grit size?

You select grit size based on your goal.

Use a low grit number (e.g., 24-60) for fast material removal. For a smooth, fine finishing, you should choose a high grit number (e.g., 80-220). Your choice directly affects the surface quality.

See Also

Selecting Optimal Bench Grinding Wheel Materials for Specific Applications

Picking the Perfect Metal Grinding Wheel for Every Project

Finding the Ideal Grinding Wheel for Your Carbide Tooling

Exploring Various Grinding Wheel Types and Their Practical Uses

Choosing the Appropriate Grinding Wheel for Stainless Steel Fabrication

Contact Us

For More Grinding Solution or Customized Abrasive Tools