You want to achieve clean, fast cutting results with maximum efficiency. A cut off wheel is a high-performance tool that demands respect. Angle grinders rank as the third most dangerous tool, causing over 5,400 injuries annually, often from wheel breakage. Mastering proper technique is the key to both safety and performance with cut off wheels. This guide provides the clear, actionable steps you need to handle these powerful cut off wheels correctly, preventing accidents and achieving perfect cut-off results every time.

Key Takeaways

- Always wear safety glasses and a face shield to protect your eyes and face from sparks and debris.

- Inspect your cut-off wheel and tool before each use to check for damage and ensure the speed limits match.

- Secure your workpiece tightly with clamps to prevent movement and keep your work area clear of flammable items.

- Use the correct cut-off wheel for your material and hold the tool at a 90-degree angle with light, steady pressure.

- Never remove the safety guard, force the cut, or use a damaged wheel, as these actions are very dangerous.

Essential cut off wheel safety tips

Following proper safety protocols is the most important part of any cutting job. These essential safety tips will protect you from injury and help you work with confidence. Your commitment to safety ensures a successful outcome for every project.

PPE for operator safety

You must always wear the correct personal protective equipment (PPE) before you start a cut-off operation. Your eyes are especially vulnerable to flying sparks and debris. OSHA regulations are very clear on this matter for operator safety.

For portable cutoff wheels, you need dedicated personal protective equipment. This includes both primary and secondary eye and face protection.

- Safety Glasses (Primary Protection): You should always wear impact-rated safety glasses. Look for a “Z87+” mark on the frame or lens. This code indicates the glasses meet ANSI standards for high-velocity impact resistance, which is critical for grinding and cutoff work.

- Face Shield (Secondary Protection): You must wear a face shield over your safety glasses. A face shield provides a higher level of protection for your entire face from sparks and larger debris. It is not a substitute for safety glasses, as gaps around the shield can still allow particles to reach your eyes.

This table breaks down the ANSI Z87.1 guidelines for eye and face protection.

| Hazard Category | Primary Protection | When to Add Face-Level Coverage | Key Marking or Code |

|---|---|---|---|

| Impact | Impact-rated spectacles or goggles | Face shield over glasses during grinding or rotary cutting | Z87+ |

| Coverage Zone | Close to the orbital area | Full-face frontage | Both devices are required for full protection |

Beyond eye protection, complete operator safety includes:

- Gloves: Wear sturdy, flame-resistant gloves.

- Hearing Protection: Use earplugs or earmuffs, as cutoff tools are loud.

- Respiratory Protection: A dust mask or respirator is vital, especially in enclosed spaces.

- Proper Attire: Avoid loose clothing and jewelry that could get caught in the tool.

Pre-use wheel and tool inspection

Before you mount any cut off wheel, you must inspect it for damage. A damaged wheel can shatter during usage, creating extreme hazards.

A simple and effective method is the “ring test.” This test helps you detect hidden cracks inside new wheels.

- Make sure the wheel is clean and dry.

- Suspend the wheel through its center hole using a pin or your finger.

- Gently tap the wheel with a non-metallic object, like a plastic screwdriver handle. Tap it about 1-2 inches from the edge.

- A good wheel will make a clear, metallic ringing sound. A damaged wheel will produce a dull thud.

- Never use wheels that fail the ring test. Dispose of them immediately.

After inspecting the wheel, check your tool. You must verify that the tool’s maximum RPM (Revolutions Per Minute) does not exceed the maximum RPM printed on the cut-off wheel. You can find the RPM rating on both the tool and the wheel itself. Operating a wheel at a speed higher than its rating is a primary cause of breakage and serious injury. Always follow the manufacturer’s instructions for mounting cut-off wheels correctly.

Secure the workpiece

An unstable workpiece is a major safety risk. Movement during a cut-off can cause the wheel to bind, kick back, or shatter. This can lead to loss of control and severe injury.

You must always secure workpiece materials firmly before starting your cutoff. Use clamps, vises, or other appropriate fixtures to hold the material in place. A stable setup allows you to focus on making a clean, controlled cut and is fundamental for operator safety. Never attempt to hold a small piece by hand while cutting.

Workspace safety and awareness

Your immediate work area must be safe and clear of potential hazards. The sparks generated by portable cutoff wheels can travel a significant distance and ignite flammable materials.

Follow these fire safety guidelines:

- Move all combustible materials at least 35 feet away from your cutting area.

- Sweep the floor clean of debris like paper, sawdust, or oily rags within a 35-foot radius.

- If you cannot move flammable items, use a fire watcher to monitor the area for sparks.

Proper ventilation is also crucial, especially when working indoors or in hazardous environments. Cutting can create harmful dust and fumes. Ensure your workspace has adequate local or general exhaust ventilation to capture contaminants at the source. This prevents you from inhaling harmful particles. Working in well-ventilated or open spaces is always the best practice for your long-term health and safety. Following these instructions for your workspace creates a much safer environment for your cutoff tasks.

Choosing the right cut-off wheels

Selecting the correct cut off wheel is a science. Your choice affects safety, cutting speed, and the quality of your finish. Using the wrong wheel leads to poor results and potential danger. Brands like Aimgrind specialize in matching the perfect abrasive tool to your specific job. Following the manufacturer’s instructions ensures optimal performance and safe usage.

Match the wheel to the material

You must match your wheel’s abrasive material to the workpiece. Different materials require different abrasive grains for efficient cutting. Using the right grain gives you a faster cut and a longer wheel life.

- Aluminum Oxide: A good, all-purpose choice for general metal cutting.

- Zirconia Alumina: An excellent option for stainless steel and other hard ferrous metals. It works best under pressure.

- Silicon Carbide: Ideal for cutting non-metals like plastic, rubber, and masonry.

- Superabrasives (Diamond & CBN): For the toughest jobs, you need superabrasive wheels. Diamond wheels excel at cutting hard, non-ferrous materials like ceramics and composites. CBN (Cubic Boron Nitride) wheels are best for hardened ferrous metals and alloys.

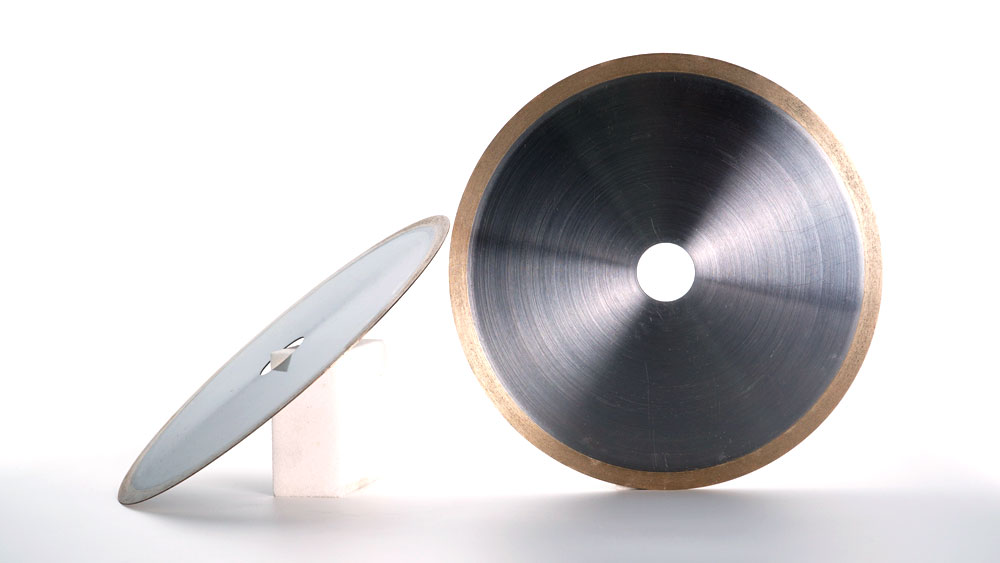

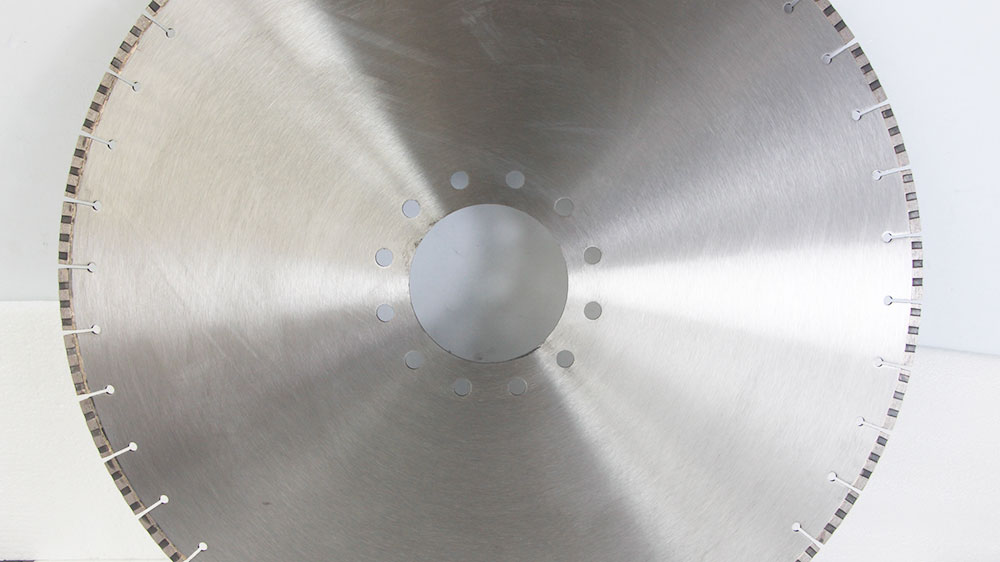

Flat (Type 1) vs. depressed center (Type 27) wheels

You will see two common shapes for portable cutoff wheels: Type 1 and Type 27.

- Type 1 (Flat) Wheels: These wheels are completely flat. They are the standard for general-purpose, straight-line cutoff tasks.

- Type 27 (Depressed Center) Wheels: These wheels have a sunken center. This design provides extra clearance, which helps you work at tight angles. The raised hub lets the tool’s locking nut sit recessed, making these wheels perfect for flush cutting.

Aimgrind’s customized cutting solutions

Sometimes, a standard wheel isn’t enough, especially for specialized materials like advanced ceramics or composites. This is where customized cutting solutions become essential. With nearly two decades of experience, Aimgrind provides personalized cut-off wheels designed for your exact needs. We analyze your material, machine type, and desired finish to create the perfect wheel. Our range includes high-performance diamond, CBN, and conventional cutoff wheels for any application.

Pro Tip: For maximum efficiency and superior results on unique materials, a custom solution is your best bet. Explore Aimgrind’s customized cutting wheels to find the perfect match for your project.

Decode the wheel label

The letters and numbers on a cut-off wheel’s label are not random. They provide vital information about the wheel’s composition. Understanding these instructions helps you confirm you have the right wheel for the job.

Here is a simple breakdown of a common label code:

| Code Part | What It Means | Example: A60-T |

|---|---|---|

| Abrasive | The type of cutting grain. | A = Aluminum Oxide |

| Grit Size | The coarseness of the grain. | 60 = Medium Grit |

| Hardness | How tightly the bond holds the grain. | T = Hard Bond |

Always check the expiration date on organic-bonded portable cutoff wheels. For safety, you should not use these wheels more than three years after their manufacture date. This ensures the bond integrity is not compromised during usage.

Proper cutting techniques

Your technique is just as important as your tool. Proper cutting form ensures safety, improves the quality of your cut-off, and extends the life of your wheels. Following these guidelines will boost your efficiency and help you master the art of the perfect cut.

Maintain a 90-degree angle

You must hold the tool so the wheel meets the workpiece at a 90-degree angle. This straight-on approach is critical for a clean, straight cut. A tilted angle puts sideways pressure on the wheel, which can cause it to bend, bind, or even shatter. This is a dangerous situation you must avoid. Always position your body to support a straight cutting motion. Adopting a stable and comfortable stance will help you maintain control throughout the cut-off operation.

Apply light, steady pressure

You should let the tool do the work. Forcing the cut-off wheel into the material is a common mistake that compromises both safety and performance. Pushing too hard does not speed up the cutting process. Instead, it creates problems.

- Excessive pressure generates extreme heat, which can damage the workpiece and cause the wheel to wear down quickly.

- It makes the cutting disc more prone to damage or breakage, reducing its lifespan.

- You will prematurely wear down the disc, forcing you to replace it more often.

A great way to gauge your pressure is to listen to the tool’s motor. A steady hum means you are applying the right amount of force. If the motor strains or slows down, you are pushing too hard. Back off and let the speed of the wheel perform the cutting.

Use a consistent cutting motion

Your cutting motion should be smooth and deliberate. Avoid jerky or rocking movements. For most materials, a gentle back-and-forth motion within the cut can help clear debris and reduce heat buildup. This technique improves cutting efficiency. When making a deep cut, do not plunge the wheel all at once. Instead, make several shallow passes. This method gives you more control and helps you achieve the proper depth of cut safely. Consistent motion is key to a professional-looking result.

Correct startup and shutdown

Proper tool usage begins before the wheel even touches the material. Always allow the tool to reach its full operating speed before you start cutting. Beginning a cut with the tool at a low RPM can cause it to grab or kick back.

Equally important are the shut down procedures.

- Remove the wheel from the cut completely.

- Turn off the tool’s power switch.

- Wait for the wheel to come to a complete stop on its own.

- Never use the workpiece to slow down or stop the spinning wheel.

- Set the tool down on a stable surface only after the wheel has stopped.

Following these instructions for startup and shutdown is a fundamental part of safe tool usage.

Control sparks and debris

Portable cutoff wheels create a shower of sparks and debris. You must direct this stream away from yourself and others. Position your body and the tool’s guard to guide the sparks downward or to an open area. Be aware of your surroundings. Ensure the spark stream is not aimed at flammable materials, electrical cords, or other people. These simple guidelines for managing the cutoff debris are essential for preventing fires and injuries in your workspace. This awareness protects you and your environment during every cutting task.

Common mistakes to avoid

Knowing what not to do is just as important as knowing the right techniques. You can improve your results and prevent accidents by steering clear of these common mistakes to avoid. Following these simple guidelines ensures proper tool usage.

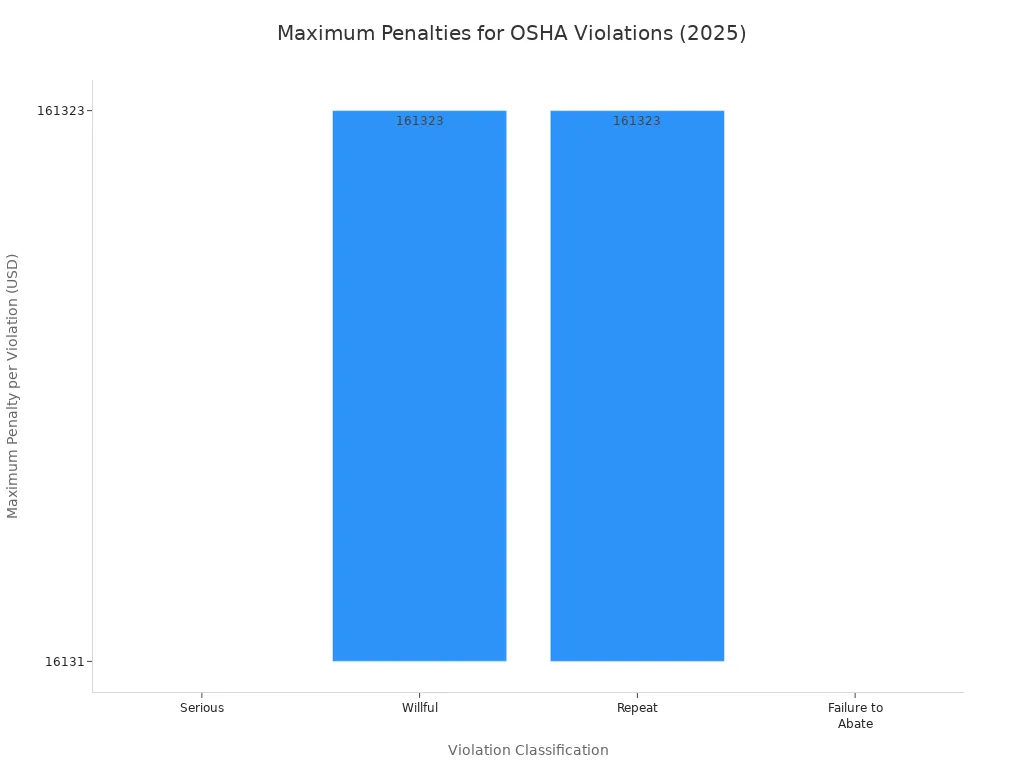

Never remove the safety guard

You must never operate a tool without its safety guards in place. The guard protects you from flying debris and dangerous kickback accidents. Removing safety guards is not only unsafe, but it can also lead to severe legal and financial penalties for employers.

Don’t use a damaged wheel

You should always inspect your cutoff wheels before each use. A damaged wheel can shatter during operation, causing a serious injury. Dispose of a wheel immediately if you see any of these issues:

- Cracks and Chips: Any visible cracks on the surface or edges.

- Glazing: A smooth, shiny surface that has lost its cutting ability.

- Worn Edges: Rounded or uneven edges that reduce cutting efficiency.

- Excessive Thinning: The wheel is noticeably thinner than a new one.

Avoid side pressure and grinding

You must remember that cut-off wheels are designed for one job: straight-line cutting. Applying side pressure to the wheel is extremely dangerous. This action can cause the wheel to bend, break, or shatter. Never use a cutoff wheel for grinding or deburring surfaces.

Don’t force the cut

You should always let the speed of the tool do the work. Forcing a cut-off wheel into the material is a critical error. Applying too much pressure can cause the wheel to bind in the cut, which reduces the lifespan of the product. A gentle, steady approach is the correct way to perform a cutoff.

Avoid using the wrong wheel

Your choice of wheel directly impacts your safety and the quality of your cut. Using a wheel that is not designed for your specific material leads to poor performance and potential hazards. Always match your wheel to the material you are cutting.

You now have the knowledge to boost your cutting efficiency and safety. True mastery of the cut-off process comes from combining the right cut off wheel with proper technique. Following these steps—from selecting a quality wheel to adjusting your cutting methods for the job—prevents accidents and produces superior results. Work confidently, knowing you have the right approach.

Grind with Passion, Achieve with Aim.

FAQ

What is the most important safety rule?

You must always wear proper personal protective equipment (PPE). This includes safety glasses and a face shield. You should also never operate the tool without its safety guard. These rules protect you from serious injury.

Can I use a cut-off wheel for grinding?

You should never use a cut-off wheel for grinding. These wheels are thin and designed only for straight cutting. Applying side pressure can cause the wheel to shatter, creating a dangerous situation.

How do I know if my wheel is damaged?

You can inspect the wheel for any visible cracks or chips. You can also perform the “ring test.” Tap the wheel gently with a plastic handle. A good wheel makes a clear ring, while a damaged one sounds dull.

What wheel should I use for hard metals?

You need a specialized wheel for hard metals. Zirconia alumina is a great choice for stainless steel. For hardened alloys, you should use a superabrasive wheel like CBN to get the best performance and efficiency.

See Also

Mastering Your Dremel Grinding Wheel: Safe and Effective Usage Guide

Selecting the Perfect Grinding Wheel for Your Circular Saw Blade

Optimal Grinding Wheels: Essential Choices for Sharpening Carbide Tools

Finding Your Ideal Grinding Wheel Dresser for Peak Performance

Selecting the Appropriate Metal Grinding Wheel for Your Specific Project

Contact Us

For More Grinding Solution or Customized Abrasive Tools