You use a grinding wheel to shape or smooth materials. The surface speed of grinding wheel tells you how fast the outer edge moves during grinding. This speed affects your safety, the grinding results, and how long your grinding wheel lasts.

If you set the surface speed of grinding wheel too high or too low, you risk poor grinding results and possible accidents.

Key Takeaways

-

Surface speed tells how fast the grinding wheel edge moves. It affects safety, grinding quality, and how long the wheel lasts. – Always use the grinding wheel at or under its top safe speed. This helps stop accidents and damage. – Higher surface speeds take off material faster. They also make smoother finishes. Low speeds give bad results and uneven wear. – Use the formula SFPM = RPM × 0.262 × Wheel Diameter to find surface speed. Change the RPM as the wheel gets smaller. – Check and take care of your grinder and wheel often. Use the right tools. Train workers to keep grinding safe and good.

Surface Speed of Grinding Wheel

What It Means

The surface speed of grinding wheel shows how fast the edge moves. This speed is also called peripheral speed. Imagine one grain of abrasive going around the wheel in one minute. The surface speed affects how well you grind. It also affects how smooth the finish looks. It can change how long your grinding wheel lasts.

Manufacturers set a top speed for every grinding wheel. This is the fastest speed you can use safely. If you go faster than this, you might break the wheel. The surface speed matters more than just counting RPM. It measures how far the abrasive travels. This helps you get better results and keeps you safe.

Units and Measurement

You measure the surface speed in surface feet per minute or meters per second. These units show how far the wheel’s edge moves in a certain time. Surface feet per minute is used most in factories. It helps you know the peripheral speed. This is important for grinding well and staying safe.

Here is a table with common surface speeds for different grinding wheels:

|

Grinding Wheel Type |

Typical Surface Speed Range (surface feet per minute, sfpm) |

|---|---|

|

Cutoff wheels |

Approximately 9,000 to 16,000 sfpm |

|

Cylindrical grinding |

Approximately 5,000 to 12,000 sfpm |

|

Disc grinding |

Approximately 4,000 to 5,500 sfpm |

|

Internal grinding |

Approximately 4,000 to 12,000 sfpm |

|

Portable grinding |

Approximately 6,500 to 12,500 sfpm |

|

Snagging |

Approximately 5,000 to 12,500 sfpm |

|

Surface grinding |

Approximately 4,000 to 6,500 sfpm |

|

Tool grinding |

Approximately 5,000 to 6,000 sfpm |

|

Weld grinding |

Approximately 9,500 to 14,200 sfpm |

Note: Always look at the maximum speed on your grinding wheel before you start. Never go over the speed the maker says is safe.

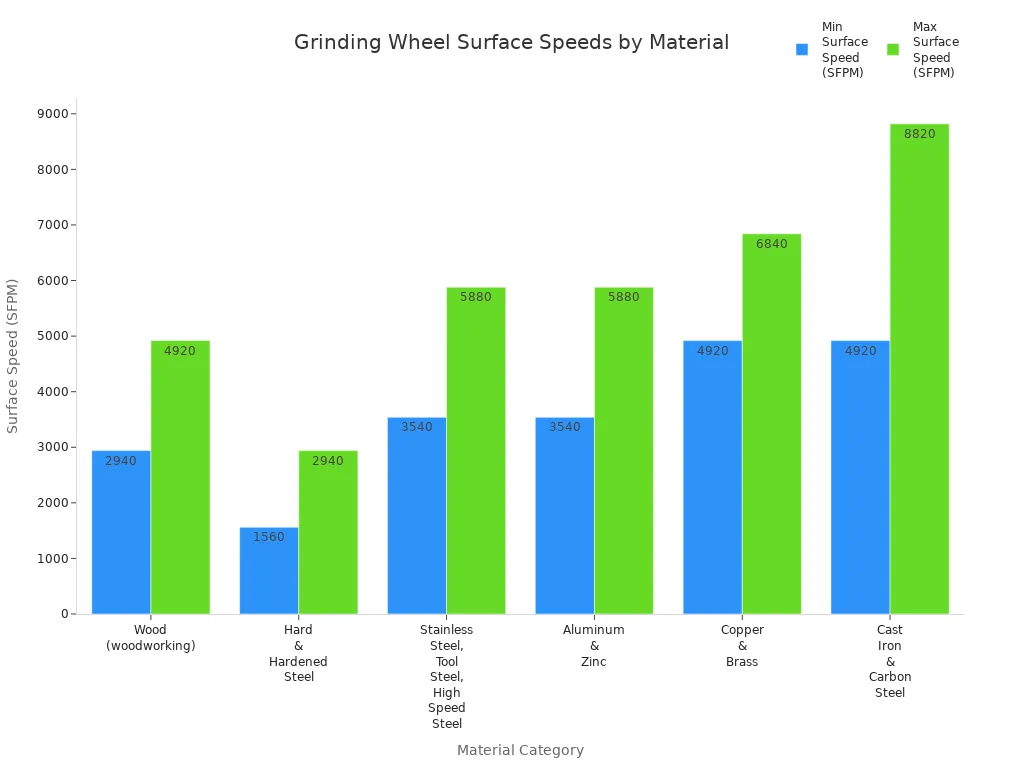

The surface speed changes with the material you grind. Woodworking wheels usually run slower than metal wheels. Here is a chart that shows typical speeds for wood and metal:

Grinding wheels for wood often run between 2,940 and 4,920 surface feet per minute. For metals like cast iron or carbon steel, the speed can reach 8,820 SFPM. The right speed helps you get good results. It also keeps your grinding wheel working well.

Peripheral speed is the main thing to watch. It shows how fast the abrasive grains move. It helps you avoid problems like overheating or breaking the wheel. Always use the right speed for your grinding job. This will help you stay safe and get the best results from your grinding wheel.

Grinding Wheel Performance

Material Removal

You control how much material you remove by adjusting the speed of your grinding wheel. When you increase the peripheral speed, you make the grinding process more efficient. At low speeds, the grinding wheel mostly pushes and smears the material. This method does not work well and slows you down. When you use higher speeds, the grinding wheel breaks the material apart more easily. You see faster removal and cleaner grooves. High peripheral speed also helps you cut through tough fibers. You get better results and save time.

-

Low speed: More ploughing and smearing, less material removed.

-

High speed: More brittle fracture, faster removal, better groove quality.

Surface Finish

The speed of your grinding wheel changes the look and feel of your finished work. If you use the right peripheral speed, you get a smoother surface. High speeds help you avoid rough marks and leftover fibers. You see a shiny, even finish. If you set the speed too low, you may notice scratches or uneven spots. The grinding wheel cannot cut cleanly, and the surface looks dull. You want to match the speed to your material for the best grinding performance.

Tip: Always check your grinding wheel speed before starting. A good surface finish depends on using the correct peripheral speed.

Wheel Wear

Grinding wheel performance also depends on how quickly your wheel wears out. If you use the wrong speed, you shorten the life of your grinding wheel. High speeds can cause overheating. The wheel may glaze or burn, which means the abrasive grains stop working. Low speeds can make the wheel wear unevenly. You may see grooves or flat spots. Both problems reduce grinding wheel performance and cost you money.

Here is a table showing what happens when you use improper speeds:

|

Speed Setting |

Common Problems |

Result |

|---|---|---|

|

Too High |

Burning, glazing |

Shorter wheel life |

|

Too Low |

Smearing, uneven wear |

Poor grinding results |

You improve grinding wheel performance by choosing the right speed. You get better material removal, a smoother finish, and longer wheel life.

Calculating Surface Speed

Formula

You can find the surface speed of a grinding wheel using a simple formula. This formula helps you know how fast the edge of your wheel moves. The standard formula is:

Surface Speed (SFPM) = RPM × 0.262 × Wheel Diameter (inches)

SFPM stands for surface feet per minute. RPM means revolutions per minute. The number 0.262 changes the units so you get the answer in feet per minute. This formula works for most grinding wheels and helps you set the right operating speed.

Tip: Always check your grinding wheel’s label for the maximum safe speed before you start.

Example

Let’s look at a real example. Suppose you have a 7-inch grinding wheel running at 3,000 RPM. You want to know the surface speed.

-

Write down the formula:

SFPM = RPM × 0.262 × Wheel Diameter -

Plug in the numbers:

SFPM = 3,000 × 0.262 × 7 -

Do the math:

3,000 × 0.262 = 786

786 × 7 = 5,502 SFPM

So, your grinding wheel moves at 5,502 surface feet per minute.

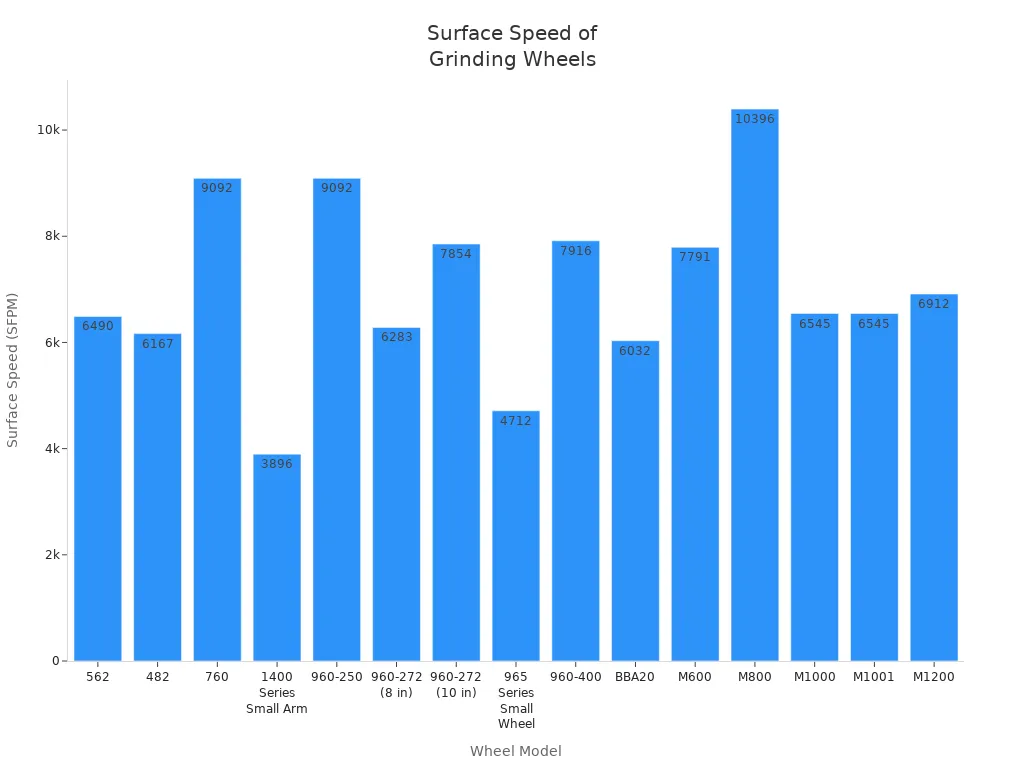

Here is a table with more examples using different wheel sizes and speeds:

|

Wheel Model |

RPM |

Wheel Diameter (inches) |

Surface Speed (SFPM) |

|---|---|---|---|

|

562 |

4140 |

5 |

5,433 |

|

960-272 |

3000 |

8 |

6,288 |

|

BBA20 |

1150 |

20 |

6,020 |

|

M1000 |

2500 |

10 |

6,550 |

You can see that both RPM and wheel size change the surface speed. If your wheel gets smaller as it wears down, the speed drops. To keep the same surface speed, you need to increase the RPM. This keeps your grinding results steady and safe.

Note: Always adjust your machine’s RPM as your grinding wheel wears down. This helps you keep the right speed for safe and effective grinding.

Over-Speed Condition

Dangers

An over-speed condition happens when you run a grinding wheel faster than its rated speed. This can be very dangerous. The wheel is designed to handle only a certain maximum speed. If you go above this limit, the wheel can break apart. Pieces of the wheel may fly off at high speed. You risk serious injury to yourself and others nearby. The safety of shop personnel depends on keeping the wheel within its safe range.

When you ignore the rated speed, you face several risks:

-

Wheel failure: The wheel can shatter without warning.

-

Serious injury: Flying debris can hit your face, hands, or body.

-

Equipment damage: Broken pieces can harm your grinder or other tools.

-

Serious injury: Even small fragments can cause cuts or eye injuries.

-

Serious injury: In some cases, accidents can be life-threatening.

You must always respect the rated speed to avoid these dangers. Never guess or assume the wheel can handle more.

Prevention

You can prevent an over-speed condition by following a few simple steps. Always check your grinding wheel before use. Look for cracks or chips on the surface. Make sure the abrasive grains look even and the thickness is the same all around. Inspect the label and markings on the wheel. Confirm that the diameter, grit size, and maximum speed match what you need.

Follow these best practices to stay safe:

-

Check the grinding wheel for defects before mounting.

-

Inspect the wheel’s markings for the correct diameter, grit, and maximum speed.

-

Make sure the grinder’s RPM does not exceed the wheel’s maximum speed.

Tip: Place the grinder’s RPM rating in a spot where you can see it easily. This helps you compare it with the wheel’s rating every time you use the machine.

-

Always use a wheel with a maximum speed equal to or higher than your grinder’s RPM.

-

Never operate a wheel above its rated speed. This can cause an over-speed condition and lead to serious injury.

-

Make the RPM rating easy to find. This encourages you and others to check before starting work.

By following these steps, you protect yourself and everyone in the shop. You keep your equipment in good shape and avoid costly accidents.

Monitoring and Control

Tips

You can keep your grinding wheel running at the right speed by following a few simple steps. These tips help you get better results and keep your work safe.

-

Clean the grinding bed, wheel, and nearby surfaces often. Dust and debris can slow down your machine and change the speed.

-

Lubricate moving parts. This reduces friction and helps the wheel keep a steady speed.

-

Check belts, bearings, and electrical parts every day. Replace anything worn out. This keeps your machine running at the correct speed.

-

Adjust the wheel speed for the material you are grinding. Use lower speed for soft materials and higher speed for hard ones.

-

Set the right feed rate and depth of cut. This helps you avoid overheating and keeps the wheel from wearing out too fast.

-

Pick the right abrasive wheel. Use a finer grit for finishing and a coarser one for removing metal. Choose the right bond and wheel hardness for your job.

-

Dress the grinding wheel often with a diamond tool. This keeps the wheel sharp and helps it run at the right speed.

-

Train all operators well. Make sure everyone knows how to set and check the speed, and understands safety rules.

Tip: Good habits and regular checks help you keep the grinding wheel at the best speed for every job.

Tools

You have many tools to help you monitor and control the speed of your grinding wheel. These tools make it easier to keep your machine safe and efficient.

-

Tachometers: Use a digital or analog tachometer to measure the wheel’s speed directly. Place the sensor near the wheel to get a quick reading.

-

Variable speed drives: These let you adjust the speed of your grinder with a simple dial or button. You can match the speed to the material and the wheel size.

-

Speed charts and calculators: Keep a chart or calculator nearby. These help you set the right speed for different wheels and materials.

-

Wheel dressing tools: Use diamond dressers to keep the wheel sharp. A sharp wheel runs at a more stable speed and gives better results.

-

Maintenance logs: Write down speed checks and adjustments in a logbook. This helps you spot problems early and keep your grinder in top shape.

Note: Always check the speed before you start grinding. Using the right tools and following best practices keeps your work safe and your grinding wheel working longer.

You now know why surface speed matters for grinding wheels. Using the right speed keeps you safe, improves your work, and helps your tools last longer.

-

Always check your wheel’s speed before you start.

-

Follow the best practices for every job.

Stay alert and make safe grinding a habit. Check your speeds, use the right tools, and get the best results every time.

FAQ

What happens if you use a grinding wheel at the wrong speed?

If you use the wrong speed, you risk poor grinding results. The wheel can wear out faster or even break. You may also see burns or rough finishes on your workpiece.

How do you find the maximum safe speed for your grinding wheel?

Check the label or markings on your grinding wheel. The manufacturer lists the maximum safe speed. Never use a wheel above this speed.

Why does wheel size affect surface speed?

A larger wheel covers more distance in one turn. This means the edge moves faster at the same RPM. Always adjust RPM when you change wheel size to keep the right surface speed.

Can you use the same speed for all materials?

No. Harder materials need higher speeds for good results. Softer materials work better at lower speeds. Always match the speed to your material for safety and best performance.

What tool helps you check your grinding wheel speed?

You can use a tachometer. This tool measures the RPM of your wheel. It helps you make sure you stay within safe limits.

Contact Us

For More Grinding Solution or Customized Abrasive Tools