Knowing the correct standard grinding wheel shape and size helps workers stay safe. It also helps them do a better job. Each standard grinding wheel has a special design for its task. The shape and size decide how the wheel works. They also help keep workers safe. If the wheel is too big, it can cause accidents. The right size fits well and works better.

Workers should check the standard grinding wheel for cracks. They should wear safety gear before starting any grinding job.

Key Takeaways

Pick the right grinding wheel shape and size for your job and machine. This helps you get better results and stay safe. – Look at the wheel markings closely. They tell you the type, size, abrasive material, grit, and top speed. – Use the right abrasive and grit size for the material you are grinding. This makes the job work better and stops damage. – Always check grinding wheels for cracks or chips. Wear the right safety gear to stop accidents. – Follow safety rules and use guards. Make sure the wheel speed matches the grinder. This keeps your work safe and helps you work well.

Standard Grinding Wheel Types and Sizes

Common Types of Grinding Wheels

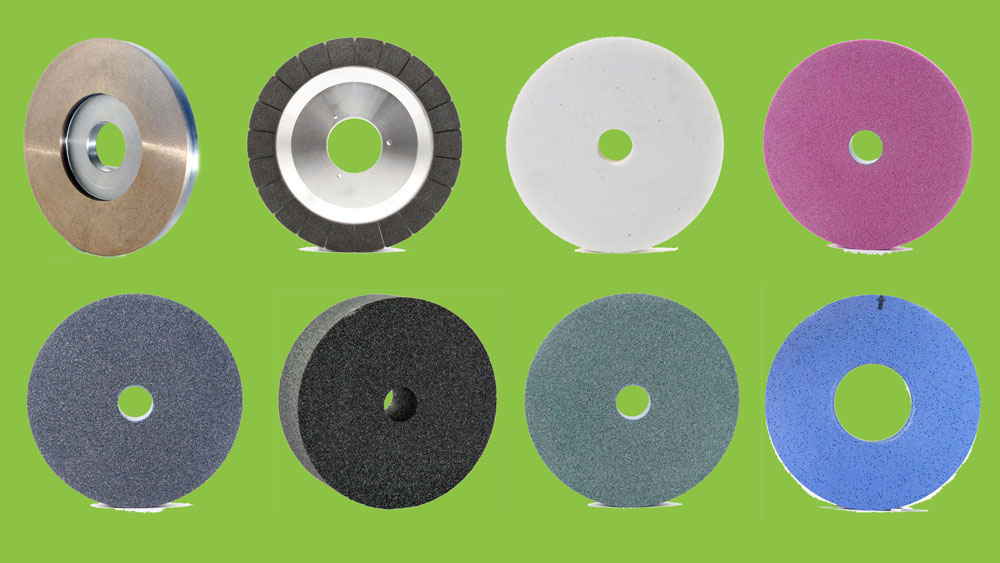

Grinding wheels have many shapes and sizes. Each one is made for a certain job. Here are some common types:

Straight grinding wheels: These sharpen tools like chisels and lawnmower blades.

Large diameter grinding wheels: People use these for round objects and outside edges.

Grinding cup wheels: The cup shape helps polish stone, concrete, and take off paint.

Grinding dish wheels: These are thinner and fit into small spaces.

Segmented grinding wheels: These have pieces that remove material fast with cooling fluids.

Cutting face grinding wheels: These thin wheels cut tile or shape saw teeth.

Cylinder wheels: These grind flat surfaces using the top.

Tapered wheels: The thick end grinds threads and gear teeth.

Saucer wheels: These work on milling cutters and twist drills.

Diamond wheels: These finish industrial diamonds.

Cut off wheels: These cut bars and remove metal fast.

Standard Dimensions Explained

Manufacturers list grinding wheel sizes by diameter, thickness, and arbor hole. The usual way is Diameter x Thickness x Arbor Hole. For example, 12x2x1-1/4 means 12 inches wide, 2 inches thick, and a 1.25 inch hole. The table below shows some common sizes for a grinding wheel:

Dimension | Size (inches) |

|---|---|

Diameter | 4.5 |

Thickness | 0.25 |

Arbor Hole Size | 0.875 (7/8) |

These numbers help people pick the right wheel for their machine.

Applications by Shape and Size

The shape and size of a grinding wheel matter for the machine and the job. Straight wheels are good for big surfaces or round things. Cup wheels work on heavy materials like granite and marble. Dish wheels polish flat places and reach curved spots. Cylinder wheels grind inside round shapes. Saucer wheels help with milling cutters and twist drills. The diameter and thickness must fit the grinder’s spindle and speed. Using the wrong size can make the surface rough, cause shaking, or break the machine. Workers should always check the wheel size before starting.

Tip: Always use the right grinding wheel type and size for your machine and job to stay safe and do good work.

Grinding Wheel Markings and Identification

How to Read Grinding Wheel Markings

Grinding wheel markings help users pick the right wheel for each grinding job. These markings follow industry standards, such as ISO and ANSI. Each part of the marking gives important information about the wheel’s shape, grinding wheel specifications, and safe use.

A typical marking looks like this: 230 x 3 x 22.2 mm WA 60 K 7 V 80 m/s.

Here is what each part means:

Type: The ISO number shows the wheel’s shape. For example, Type 27 means a depressed center wheel.

Size: The numbers show diameter x thickness x hole size, all in millimeters. For example, 230 x 3 x 22.2 mm means the wheel is 230 mm across, 3 mm thick, and has a 22.2 mm hole.

Specification: This code tells about the abrasive material (like WA for white aluminum oxide), grit size (such as 60), grade (K for hardness), structure (7 for density), and bond type (V for vitrified).

Maximum Operating Speed: The marking shows the maximum speed in meters per second (like 80 m/s) and sometimes in revolutions per minute.

Restrictions for Use: Codes such as RE1 or RE2 tell if the wheel is not for hand-held grinding or cutting.

Other Information: The label may show the manufacturer, test record, expiry date, and a mounting arrow.

Tip: Always check the maximum operating speed before using any grinding wheel.

Identifying Shape, Size, and Type

Users can find the grinding wheel’s type and size by reading the label. The ISO type number tells the shape, such as Type 1 for straight wheels or Type 27 for depressed center wheels. The size appears as diameter x thickness x hole size, making it easy to match the wheel to the grinder.

The specification code gives more details. For example, “A60V” means the wheel uses aluminum oxide, has a grit size of 60, and a vitrified bond. The label also lists the maximum speed and any safety limits. These markings help users choose the right grinding wheel for each grinding task and keep the work safe.

Marking Example | Meaning |

|---|---|

230 x 3 x 22.2 mm | Size: diameter x thickness x hole size |

Type 27 | Shape: depressed center wheel |

WA 60 K 7 V | Specification: abrasive, grit, grade, structure, bond |

80 m/s | Maximum operating speed |

Reading these markings ensures the grinding wheel fits the machine and meets the job’s needs.

Types of Grinding Wheels and Their Uses

Type 1: Straight Wheels

Type 1 grinding wheels are also called straight wheels. They have a flat, straight shape. Their size is given by diameter, thickness, and arbor hole. A common size is 12 inches wide, 2 inches thick, and a 1-1/4 inch hole. Workers can use a bushing for smaller arbors. This shape lets the wheel cover more area when grinding.

Type 1 wheels are used in many factories. They work for rough and smooth grinding jobs. People use them on steel, aluminum, ceramics, cast iron, bronze, brass, concrete, stone, terrazzo, and stainless steel. These wheels fit angle grinders, die grinders, and bench grinders. They sharpen tools, remove sharp edges, grind metal, and prepare surfaces. Most Type 1 wheels use aluminum oxide as the abrasive grain.

The flat shape of Type 1 wheels helps make smooth finishes and sharp edges. This shape also lowers the chance of uneven grinding and makes it safer when mounted right.

Type 2: Cylindrical Wheels

Type 2 grinding wheels are called cylinder wheels. They have a ring shape with the grinding part on the rim. These wheels are wide and have no center support. Some are up to 12 inches wide. Workers use them only in vertical or horizontal spindle grinders.

Cylinder wheels are good for making flat surfaces. Grinding happens on the end face of the wheel. The wide area helps remove material fast and leaves a smooth finish.

Large, hollow shape fits special machines.

Used for flat grinding in toolrooms and factories.

Good for jobs that need even contact with the workpiece.

The cylinder shape keeps the wheel steady while grinding and stops shaking. This design helps the wheel stay in place, which makes it safer and more accurate.

Type 5: Raised Hub Wheels

Type 5 grinding wheels are called raised hub wheels. They have a flat face and a small raised center or hub. The hub lets the wheel sit higher on the spindle. This helps with space and mounting. Their size is given by diameter, thickness, and hub height.

Workers use raised hub wheels for grinding flat surfaces and sharpening tools. The hub makes it easier to reach tight spots and edges. These wheels are common in toolrooms and machine shops.

Raised hub gives extra space for mounting.

Good for grinding flat surfaces and edges.

Used for careful grinding jobs.

The raised hub shape keeps the wheel steady and stops it from wobbling. This helps workers keep control and stay safe while grinding.

Type 6: Cup Wheels

Type 6 grinding wheels are called straight cup wheels. They have a cup or bowl shape with a round side. Workers use these wheels for grinding flat surfaces and sharpening tools. The cup shape lets you grind on the side wall, not just the flat face.

Wheel Type | Shape Description | Examples |

|---|---|---|

Type 6 | 6A2, 6A9, 6A2C, 6A2H |

The cup shape is good for grinding flat surfaces and sharpening. Grinding happens on the rim face, which helps make smooth finishes. Things like back thickness and flange size help mount the wheel right and keep it steady.

Safety guards must cover cup wheels when used. The cup shape lets you grind with control, but the wheel must be mounted right for safety.

Type 27: Depressed Center Wheels

Type 27 grinding wheels are called depressed center wheels. They have a center that is lower than the edge. This shape helps reach the workpiece better and stops the wheel from getting stuck. These wheels are made from aluminum oxide, silicon carbide, or ceramic. They come in sizes from 4 to 16 inches wide, with different thicknesses for each job.

Common details include:

Thickness: 1/4 inch

Arbor Hole Size: 7/8 inch

Abrasive Material: Aluminum Oxide

Grit Size: 24 (Coarse)

Maximum Operating Speed: 13,300 RPM

Workers use Type 27 wheels in building, metal work, casting, electrical, medicine, and heavy machines. These wheels are great for rough grinding and removing lots of metal from ferrous metals, stainless steel, alloy steels, and cast iron. They are used for beveling, removing slag, grinding welds, and working on edges.

The depressed center lets users work at angles from 0º to 15º. This shape gives better control and safety, especially for tough grinding jobs.

Selecting the Right Standard Grinding Wheel

Material, Grit, and Bond

When picking a grinding wheel, start by knowing the material. Workers need to check if it is hard or soft. They also look at what it is made of. Harder things need wheels with strong abrasives like aluminum oxide for steel. Silicon carbide works well for cast iron and metals that are not iron. Diamond wheels are best for cutting ceramics and very hard things. If the material gets hot easily, use a wheel with a soft bond and open spaces. This helps keep it cool. The finish you want also changes the grit size and how hard the wheel should be.

Grit size and bond type are important for how the wheel works. Big grit sizes take off more material but make rough surfaces. Small grits make things smoother. Softer bonds wear out faster but show new abrasive grains. This helps cut better. Harder bonds last longer but may slow down cutting. Workers need to pick the right grit size and bond for each job.

Tip: Always look at the grinding wheel’s details and top speed before using it.

Matching Wheel to Application

Picking the right grinding wheel for the job makes work better and safer. Workers should match the wheel’s type and size to what they are grinding. For rough jobs, use coarse grits and strong bonds. Fine grits are good for finishing and making things smooth. Medium grits work for grinding round shapes. The wheel must fit the grinder’s arbor size so it stays on tight.

Application | Wheel Type & Grit | Notes |

|---|---|---|

Stock Removal | Fast cutting, up to 45° angle | |

Fine Surface Finish | Fine grit, resin bond | Smooth finish, slower removal |

Tight Spaces | Type 28, concave design | Aggressive at low angles |

Aluminum Grinding | Silicon carbide blend | Prevents loading, high cut rate |

Stainless Steel | INOX wheels, fine grit | Avoids contamination and rust |

Workers should use coolant when grinding wet. This keeps things cool and helps the wheel last longer. Dressing tools help keep the wheel in good shape. Do not pick wheels just because they are cheap. The best way is to match the wheel’s details to the job and material.

Safety Considerations

Safety is very important when using grinding wheels. Workers must check wheels for cracks, chips, or wear before putting them on. The wheel’s top speed must match the grinder’s speed. Guards and work rests should be tight and set right. Workers need to wear safety glasses, gloves, and helmets to stay safe from grinding dangers.

Checking and fixing wheels often stops accidents. Workers should follow OSHA and ANSI rules. Never use wheels that are broken or too fast for the grinder. Make sure the workpiece does not move. Use special abrasive grains for hard things to work better and stop overheating. Picking the right wheel and taking care of it lowers risks and helps work go well.

Note: Do not make mistakes like picking the wrong wheel, not taking care of it, or using the wrong speed. These mistakes can break the wheel, cause burns, or other dangers.

Knowing about standard grinding wheel shapes, sizes, and markings helps people pick the right tool and stay safe.

Specification codes tell what abrasive is used, the grit size, the bond, and how fast the wheel can go safely.

Markings show the wheel’s size and if there are any limits on how it can be used.

Checking the wheel often and putting it on the machine the right way helps stop injuries.

Choosing the right grinding wheel makes work better and keeps people safe. Workers should always read the markings, follow safety rules, and use the right wheel for the job.

FAQ

What does the arbor hole size mean on a grinding wheel?

The arbor hole size shows the diameter of the hole in the center of the wheel. This hole fits onto the grinder’s spindle. The right size keeps the wheel steady and safe during use.

How can someone tell if a grinding wheel is safe to use?

Workers should tap the wheel gently with a non-metal tool. A clear ring means the wheel is safe. A dull sound may show cracks. Always check for chips or damage before mounting.

Why do grinding wheels have different shapes?

Each shape fits a special job. Straight wheels work for flat surfaces. Cup wheels help with heavy grinding. Depressed center wheels reach tight spots. The right shape improves results and safety.

Can one grinding wheel work for all materials?

No, each material needs a special abrasive. Aluminum oxide works for steel. Silicon carbide fits softer metals. Diamond wheels cut hard materials. Using the wrong wheel can damage both the tool and the workpiece.

What does the grit number on a grinding wheel mean?

The grit number shows the size of the abrasive grains. Lower numbers mean coarse grains for fast removal. Higher numbers mean fine grains for smooth finishes. Workers pick the grit based on the job’s needs.

Contact Us

For More Grinding Solution or Customized Abrasive Tools