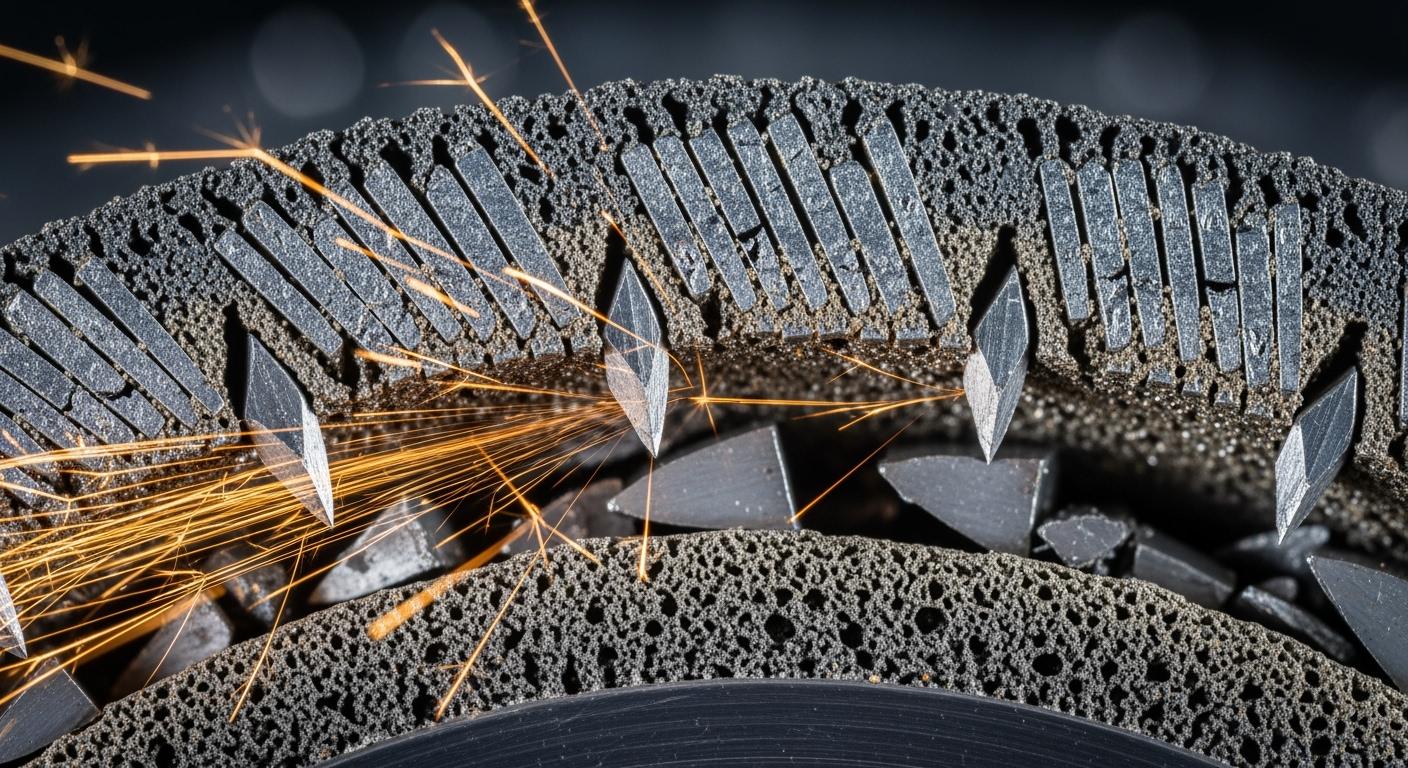

The bond in grinding wheels is often mistaken for simple glue. The true role of bonds is far more active. A bond acts like a manager for the abrasive grains, deciding when a dull grain is shed to expose a new, sharp grain. This bond controls the wheel’s erosion. The bond’s function dictates the cutting action and performance. The bond ensures the abrasives in the wheels perform their grinding job. The market for bonded abrasives is growing, showing the value of this bonded technology. The bond makes bonded abrasives work, and this active role of bonds is key to efficient grinding.

| Attribute | Value |

|---|---|

| Market Size in 2024 | USD 16.94 Billion |

| Market Size in 2025 | USD 17.76 Billion |

| Market Size by 2034 | USD 27.18 Billion |

Key Takeaways

- Bonds in grinding wheels are not just glue; they actively control how the wheel works by deciding when dull abrasive grains are released to show new, sharp ones.

- The strength of the bond, called wheel grade, affects how fast material is removed and how smooth the final surface becomes. A softer bond releases grains easily for a finer finish, while a harder bond holds grains longer for faster material removal.

- Different types of bonds, like vitrified, resinoid, rubber, and metal, offer unique features. These features include rigidity, flexibility, and durability, which make them suitable for different grinding tasks and materials.

- Choosing the right bond is very important for successful grinding. The bond must match the material being ground and the specific grinding job to get the best results.

How Bonded Abrasives Define Wheel Performance

The performance of bonded abrasives depends heavily on the bond. The bond controls how the wheel interacts with a workpiece. This interaction determines the final outcome of any grinding operation. Understanding the properties of the bond is key to optimizing the performance of bonded abrasives.

Defining Wheel Grade and Bond Strength

Wheel grade measures the bond strength of a grinding wheel. It is not a measure of the abrasive grain’s hardness. Instead, bond strength refers to how strongly the bond holds the abrasives. This characteristic is crucial for the performance of bonded abrasives.

- Soft Grade: A soft bond releases dull abrasives easily. This action exposes fresh, sharp cutting points.

- Hard Grade: A hard bond holds onto abrasives for a longer time. This increases the life of the wheel.

The correct bond strength ensures the bonded abrasives work efficiently. A bond that is too hard will not expose new abrasives, causing the wheel to become dull. A bond that is too soft will wear down too quickly. The role of bonds is to manage this delicate balance for peak grinding performance.

Impact on Removal Rate and Surface Finish

The bond strength directly affects material removal rates and the final surface finish. The choice of bond dictates the overall performance of bonded abrasives. A softer bonded wheel often produces a finer finish. However, it also changes the efficiency of the grinding process.

Softer bond grades can lead to lower material removal rates. The abrasive grains in a softer bond get pushed into the tool under pressure. This action creates smaller chips and reduces the cutting depth. More energy is required to remove material, making the grinding less efficient for roughing tasks.

Harder bonded wheels, on the other hand, allow abrasives to withstand more force. This produces larger chips and faster material removal. The selection of the right bond is a trade-off. Operators must balance the need for rapid grinding with the desired surface quality. This decision highlights how the bond manages the performance of the entire system.

The Functional Role of Bonds in Different Abrasives

The type of bond in a grinding wheel fundamentally changes its behavior and application. Each bond type offers a unique set of properties, from extreme rigidity to flexible shock absorption. Understanding these differences is key to selecting the right tool for the job. The role of bonds is to optimize the cutting action of the abrasives for specific tasks and materials.

Vitrified Bonds: Rigidity and Porosity

Vitrified bonds are the most common type used in bonded abrasives. This bond is essentially a glass-like material. Manufacturers create this bond by firing the wheel at very high temperatures, often between 1250 and 1300 °C. This process melts glassy materials that flow to form strong, rigid bridges between the abrasive grains.

A key feature of the vitrified bond is its porosity. The firing process creates a network of open pores throughout the wheel structure. These pores are not just empty space; they serve two critical functions for effective grinding.

- They act as channels for coolant to reach the grinding zone, reducing heat and preventing damage to the workpiece.

- They provide space for grinding debris, or chips, to be cleared away, which stops the wheel from clogging.

This combination of strength and porosity makes vitrified bonded wheels excellent for precision grinding operations where form holding and cool cutting are necessary.

Resinoid Bond: Shock Absorption and Flexibility

Resinoid bonds use synthetic organic compounds, such as phenolic resin, to hold abrasives together. Unlike the rigid vitrified bond, a resinoid bond offers a degree of elasticity and resilience. This quality allows the bond to absorb vibrations and impacts during heavy-duty grinding. This shock absorption makes these bonded abrasives suitable for high-speed operations where wheels face significant mechanical stress.

The flexibility of a resinoid bond allows it to operate at much higher speeds than vitrified wheels. This performance difference is crucial for certain applications.

| Wheel Type | Typical Max Operating Speed (SFPM) |

|---|---|

| Vitrified | Up to 6,500 |

| Resinoid | Up to 16,500 |

This capability makes resinoid bonded wheels the top choice for cut-off, portable, and snagging grinding jobs. The bond can flex slightly under pressure without shattering, ensuring both safety and performance.

Rubber Bonds: Fine Finishes and Flexibility

Rubber bonds provide the greatest flexibility and resilience among common bond types. Manufacturers create this bond using natural or synthetic rubber mixed with sulfur and other agents. The mixture then undergoes a heating process called vulcanization at temperatures between 150°C and 200°C. This process creates a strong, elastic bond that holds the abrasives securely.

The main advantage of a rubber bond is its ability to produce exceptionally smooth and fine surface finishes. The bond’s flexibility allows the wheel to conform slightly to the workpiece, creating a polishing effect.

Application Highlight: Rubber bonded wheels are widely used for delicate finishing tasks. For example, the bearing industry relies on them for fine grinding to achieve precise and smooth surfaces. Their ability to deliver mirror-like finishes makes them essential in producing high-quality components.

Aimgrind’s Metal Bonds: Durability and Form Holding

For the most demanding applications, a metal bond offers unmatched strength and wheel durability. This bond type uses metal powders, such as bronze, cobalt, or tungsten, which are sintered under heat and pressure to lock superabrasive grains in place. The result is a superabrasive grinding wheel with extreme wear resistance and thermal stability. This makes the metal bond ideal for grinding very hard materials like ceramics, carbides, and hardened tool steels.

One of the greatest strengths of a metal bond is its form-holding capability. The rigid metal matrix resists wear and maintains its precise shape, even when grinding complex profiles on carbide tools. This ensures consistent part quality and reduces the need for frequent wheel dressing.

Aimgrind specializes in high-performance Metal bond grinding wheels that leverage this technology. These wheels pair a robust metal bond with superabrasive materials like diamond or Cubic Boron Nitride (CBN). The chemical stability of CBN combined with the toughness of the metal bond provides long-lasting durability and consistent cutting performance. This synergy makes Aimgrind’s wheels a premier choice for precision grinding in demanding industries like aerospace and tool manufacturing, where both accuracy and long wheel life are critical.

Matching the Bond to Your Application

Selecting the correct bond is as important as choosing the right abrasives. The bond type dictates how the wheel performs with different materials and in various operations. A successful grinding application depends on this crucial match. The bond manages the cutting action for optimal results.

Matching Bond to Material

Different materials require a specific bond to achieve efficient grinding. The bond must withstand the forces and temperatures generated when interacting with the workpiece. A proper bond type ensures the bonded abrasives perform correctly.

- General Steels: A vitrified bond is the standard choice for grinding hardened steels and high-speed tool steels. Its rigidity and porosity provide excellent dimensional stability for precision grinding.

- High-Tensile Materials: A ceramic or vitrified bond works well for grinding tough superalloys like Inconel and titanium. This bond offers great thermal stability and holds the abrasives firmly for a consistent cutting action.

- Carbides and Ceramics: A metal bond is necessary for grinding extremely hard materials. Aimgrind’s metal bonded wheels use this strong bond to hold diamond or CBN abrasives, providing superior durability for these demanding applications.

- Polishing and Finishing: A rubber bond is ideal for creating smooth surfaces. Its flexibility allows for a gentle polishing effect on various materials.

Matching Bond to Operation

The grinding operation itself places unique demands on the wheel. The bond provides the functional properties needed for specific tasks, from rapid material removal to creating a mirror-like finish. This makes the bond a key factor in performance.

Resinoid bonded abrasives are perfect for rough grinding and snagging. The resinoid bond has excellent shock resistance. This property allows the wheel to handle the high-impact forces of rapid stock removal in foundries and steel mills. This bond makes resinoid cutting wheels highly effective.

For high-precision surface grinding applications, a vitrified bond is superior. Its rigid structure ensures the wheel maintains its shape, which is critical for achieving tight tolerances. In contrast, centerless grinding operations often use rubber bonded wheels to produce exceptionally fine finishes. The flexibility of the rubber bond allows the abrasives to create a smooth, high-quality surface.

The bond acts as the control system for grinding wheels. It is not just a simple skeleton holding the abrasive grains. The bond’s main job is managing when to expose new abrasive grains. This bond function determines the wheel’s overall performance. A bond provides rigidity or flexibility for different grinding tasks. The role of bonds is critical for success. Choosing the right bonded abrasives, like the expertly designed wheels from Aimgrind, is just as important as the abrasive grain selection for optimizing any grinding process.

FAQ

What is grinding wheel grade?

Wheel grade measures the strength of the bond. It does not measure the hardness of the abrasive grain. A “soft” grade means the bond releases grains easily. A “hard” grade means the bond holds grains very tightly, increasing the wheel’s life.

Why do different bonds have different operating speeds?

Each bond type has unique physical properties. Resinoid bonds offer flexibility, allowing them to run safely at very high speeds. Vitrified bonds are more rigid and brittle. They operate at lower speeds to prevent shattering under stress. This makes each bond suitable for different tasks.

When should an operator choose a metal bond?

An operator chooses a metal bond for grinding extremely hard materials like ceramics and carbides. Metal bonds provide superior durability and hold their shape well. Aimgrind’s metal bond wheels use this strength for precision grinding in aerospace and tool manufacturing.

How does bond choice affect surface finish?

The bond type directly influences the final surface finish. A flexible bond, like rubber, can conform to the workpiece to create a very smooth, polished surface. A rigid bond, like vitrified, provides excellent form holding for achieving precise dimensions rather than a mirror finish.

Contact Us

For More Grinding Solution or Customized Abrasive Tools