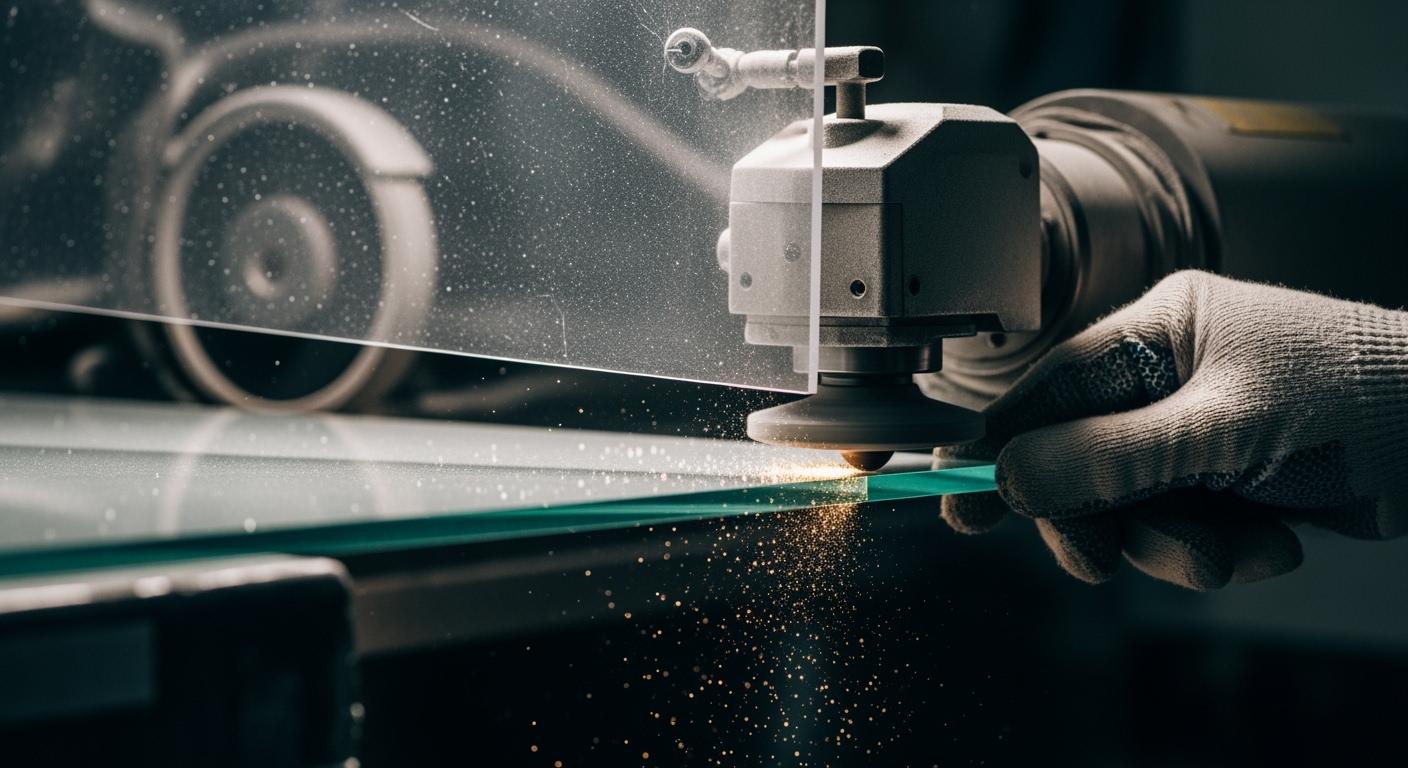

You can prevent cracks and chipping during glass grinding by choosing the right tools and using proven techniques. Quality matters. When you use Aimgrind’s diamond grinding wheels, you get a smooth finish and reduce the risk of breakage. Trust experience and advanced products to keep your glass edges strong and flawless.

Key Takeaways

- Choose the right grinding wheel for your glass type. Aimgrind diamond wheels reduce defects and improve edge quality.

- Maintain consistent pressure during grinding. Uneven force can lead to cracks and weaken the glass.

- Keep the grinding surface wet. Adequate coolant prevents thermal shock and protects against cracks.

- Regularly inspect and maintain your equipment. This ensures optimal performance and reduces the risk of defects.

Causes of Cracks in Glass Grinding

Understanding why cracks develop during glass grinding helps you prevent costly defects and improve your processing results. Industry studies show that the most common causes of the glass cracking problem include:

- Mechanical stress from collisions or mishandling during processing

- Thermal stress from sudden temperature changes in the process

- Material defects or micro-scratches left from earlier manufacturing steps

Research shows that as the number and length of cracks increase, the bending strength of glass drops. This makes it important to control every step of the grinding process.

Excessive Pressure

Excessive pressure during glass grinding pushes abrasive grains deep into the surface. This causes severe subsurface defects. When you apply too much force, both radial and lateral cracks form under the grinding wheel. These cracks move downward and spread, making the glass cracking problem worse. You also see microcracks and irreversible damage in the contact area.

Incorrect Wheel Choice

Choosing the wrong grinding wheel for your glass processing leads to more defects. You must match the abrasive grains, grit size, and bond type to your application. For example, diamond wheels work best for carbide and glass, while CBN wheels suit ferrous metals. If you use the wrong wheel, you increase the risk of the glass cracking problem and other defects.

- The wrong wheel can cause:

- More frequent cracks in the glass

- Poor surface quality and more defects

- Higher chance of material failure during processing

Poor Coolant Use

Improper coolant use can cause thermal shock. This happens when the glass heats up and cools down too quickly during processing. The result is microscopic cracks along the edge, which grow over time. These defects weaken the glass and make the glass cracking problem harder to control.

Machine Issues

Machine condition plays a big role in glass processing quality. Worn or sharp wheels, incorrect grit types, and poor machine calibration all lead to different types of cracks and defects. The table below shows how wheel condition and grit type affect crack formation:

| Grinding Wheel Condition | Crack Type | Crack Characteristics |

|---|---|---|

| Sharp Wheels | Chevron Cracks | Larger depth and total length of cracks |

| Worn Wheels | Partial Cone Cracks | Preferred direction observed in crack formation |

| Sharp Grits | Chevron Cracks | More significant defects and damage |

| Blunt Grits | Partial Cone Cracks | Smaller cracks, preferred direction |

You must check your machines and wheels often to avoid the glass cracking problem and reduce defects during processing.

How to Prevent Cracks in Glass Edge Grinding

You can prevent cracks in glass edge grinding by following proven strategies and using the right tools. Aimgrind diamond grinding wheels help you achieve a smooth finish and reduce chipping. You need to focus on four main areas to protect your glass edges and improve the edge grinding process.

Use Finer Grits and Quality Wheels

You should select finer grit sizes and high-quality grinding wheels for glass edge grinding. Finer grits remove material gently and minimize the risk of cracks. Aimgrind diamond grinding wheels with resin bond provide a softer touch and act as a shock absorber. This prevents aggressive grinding and keeps the surface damage-free.

A resin bond holds the diamond particles in a polymer matrix, almost like stones set in a hard epoxy. This bond is softer and has a slight dampening effect, which prevents it from being too aggressive. It acts as a shock absorber at a microscopic level, allowing the fine diamond particles to shear away material cleanly without creating new cracks. This is the key to achieving a smooth, damage-free surface.

You should always match the wheel type to your application. Quality wheels from Aimgrind help you prevent cracks and keep your edges strong.

Maintain Consistent Pressure

You must apply steady and consistent pressure during the edge grinding process. Uneven force can cause cracks and weaken the glass. You need to avoid pushing too hard or too lightly. Aimgrind diamond grinding wheels allow you to control the grinding process and maintain uniform pressure. This helps you prevent cracks and keeps your edges smooth.

Keep Grinding Surface Wet

You should keep the grinding surface wet throughout the edge grinding process. Water or coolant reduces heat and prevents thermal shock. Wet grinding protects the glass from sudden temperature changes and lowers the risk of cracks. You need to use enough coolant and make sure the grinding area stays moist. Aimgrind wheels work well with wet grinding and help you achieve a flawless finish.

Adjust Speed for Glass Thickness

You must adjust the speed based on the thickness of the glass. Grinding too fast or too slow can cause cracks and damage the edges. You need to follow recommended speed settings for different glass thicknesses. The table below shows the best speed for each thickness:

| Glass Thickness (mm) | Recommended Speed (m) |

|---|---|

| Less than 8 | Less than 2.5 |

| 10 to 19 | Less than 1.5 |

You should check your machine settings and make sure you use the right speed for your glass. Aimgrind diamond grinding wheels perform well at these speeds and help you prevent cracks during the edge grinding process.

Actionable Steps for Crack Prevention

You can follow these steps to prevent cracks in glass edge grinding:

- Choose the right grinding wheel for your application.

- Dress the grinding wheel properly.

- Use adequate coolant during grinding.

- Adjust the grinding parameters according to your requirements.

- Inspect your machine and accessories.

- Test and evaluate your grinding quality and efficiency.

You need to use Aimgrind diamond grinding wheels and follow these steps to protect your glass edges. You can prevent cracks and chipping, improve the edge grinding process, and achieve strong, flawless edges.

Best Practices for Coldworking Glass

Proper Glass Handling

You must handle glass with care during coldworking to prevent cracks and maintain quality. Sudden temperature changes can cause thermal shock, which leads to internal stress and breakage. You can avoid these issues by following a few simple steps:

- Always let glass reach room temperature before starting the grinding process.

- Never pour cold water on hot glass, as this can cause rapid contraction and cracks.

- Keep different types of glass separate during processing to avoid unexpected reactions.

These handling techniques help you protect the glass and ensure a high-quality finish. Careful handling supports quality processing and keeps your coldworking edges strong.

Edge Trimming Techniques

You need to use the right edge trimming techniques to achieve a smooth, polished finish and prevent chipping. The table below shows the most effective methods for coldworking edges:

| Technique | Description |

|---|---|

| Hand Tools | Use diamond hand pads, starting from 60 grit and moving up to 400 grit, for a smoother finish. |

| Wet Belt Sander | Choose larger models for ergonomic use and faster results. Always connect to water for best quality. |

| Grit Progression | Start with coarse grits (60-80) to shape the edge, then move to finer grits (120-400) for polishing. |

You should follow these steps for glass edge processing. Begin with shaping, then move to smoothing and polishing. This process gives you a cold polished edge and a professional finished piece. Consistent technique leads to a flawless bevel and a high-quality finish.

Regular Inspection and Maintenance

You must inspect your tools and machines often during coldworking. Check for wear on grinding wheels and make sure all equipment works properly. Clean your workspace to prevent debris from scratching the glass. Regular maintenance keeps your grinding process smooth and your edges free from defects. This routine helps you maintain the quality of every bevel and polish, ensuring each finish meets your standards.

By following these coldworking techniques, you can achieve strong, flawless edges and a high-quality finish on every piece. You will see better results in every process, from grinding to bevel and polish.

Choosing the Right Grinding Tools

Selecting the right grinding tools is essential for achieving flawless glass edges and reliable coldworking results. You need to consider several factors to ensure your grinding process delivers consistent quality and efficiency. Aimgrind offers a wide range of diamond grinding wheels and custom solutions designed for glass processing. These tools help you reduce defects, improve productivity, and maintain the highest standards in every stage of your operation.

Aimgrind Diamond Grinding Wheels

Aimgrind diamond grinding wheels set the standard for precision and durability in glass processing. You can rely on these wheels for both edge grinding and coldworking tasks. The diamond abrasive layer provides high cutting efficiency and a long service life. This means you spend less time changing wheels and more time producing quality glass.

Tip: Diamond grinding wheels from Aimgrind work well for both wet and dry grinding. You can use them on a wide range of glass types, from architectural panels to delicate optical pieces.

You benefit from Aimgrind’s expertise in matching the right wheel to your application. The company offers wheels in various sizes, shapes, and bond types. This flexibility ensures you always have the right tool for your specific glass processing needs. When you use Aimgrind diamond wheels, you achieve smooth, chip-free edges and reduce the risk of cracks during grinding and coldworking.

Selecting Bond Types and Grit Sizes

Choosing the correct bond type and grit size is crucial for quality glass edge processing. You should follow these criteria when selecting grinding tools:

- Understand the core construction of the wheel. Focus on bond type, grit, and geometry for optimal performance.

- Verify dimensional accuracy and shank compatibility. Proper fit prevents vibration and damage during grinding.

- Evaluate real-world durability. Look for wheels that maintain consistent material removal rates over time.

- Check for safety certifications and compliance. Safe operation is essential in every glass processing environment.

Different bond types and grit sizes affect the quality and durability of glass edges. Coarser grits remove material quickly but can leave rougher edges. Finer grits create smooth finishes, which are important for high-quality glass products. Metal bonds provide strength for aggressive grinding, while resin bonds offer elasticity for stress-prone operations. Vitrified bonds deliver rigidity, making them ideal for precision work. Resinoid bonds handle higher stress, which helps maintain edge durability during coldworking.

Note: The physical and chemical properties of each bond type, such as hardness and elasticity, directly impact grinding performance. You should match the bond and grit to your specific glass processing stage for the best results.

Custom Solutions for Glass Applications

Every glass processing operation has unique requirements. Aimgrind provides custom solutions to help you meet these challenges. You can request wheels tailored to your machine, glass type, and production goals. This customization ensures you get the best possible performance and finish.

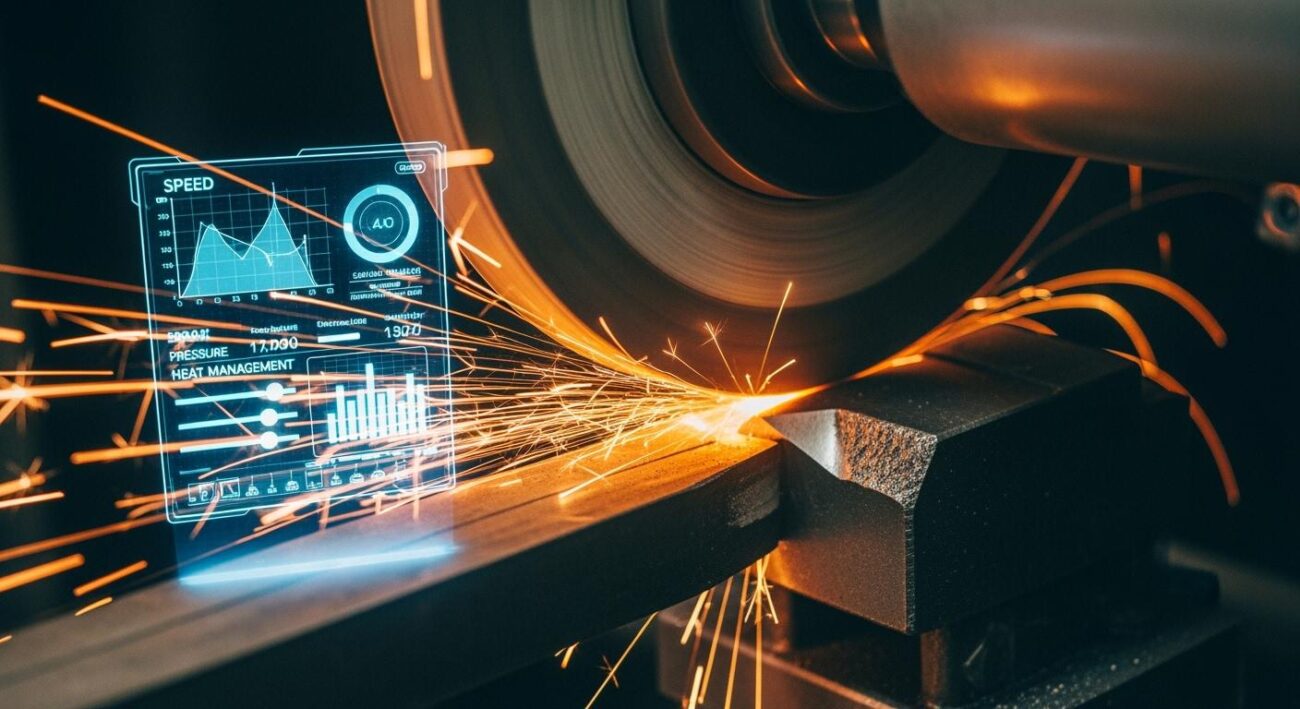

Modern advancements in glass grinding technology, such as automated edge grinding machines and robotics, have transformed the industry. These systems process a wide range of glass thicknesses and specifications, improving flexibility and efficiency. Automated machines can polish glass edges from 4mm to 60mm thick, allowing you to handle more projects with fewer limitations. You can also customize edge bevels, which improves product quality and reduces scrap rates.

Automation and sensor integration allow you to monitor grinding parameters in real time. This helps you optimize performance, reduce labor costs, and enhance safety by minimizing human exposure to hazards.

Aimgrind’s commitment to innovation means you always have access to the latest grinding solutions. Whether you need a standard diamond wheel or a fully customized tool, Aimgrind supports your glass processing goals with expert advice and reliable products.

Equipment Care and Maintenance

Proper equipment care and maintenance help you prevent cracks and chipping during grinding and coldworking. You protect your glass and achieve a flawless edge when you follow a consistent maintenance routine.

Spindle Bearing Checks

You should check spindle bearings often to keep your grinding machines running smoothly. Bearings support the spindle and help you maintain a stable edge during coldworking and grinding. If you ignore these checks, you risk vibration and uneven pressure, which can damage the glass. Use the following schedule to guide your checks:

| Frequency | Checks |

|---|---|

| Daily | Visual inspection, listen for unusual noises, monitor vibration levels, temperature check. |

| Weekly | Check lubrication system, inspect tool holder and retention knobs. |

| Monthly | Spindle runout testing, alignment checks, cooling system verification. |

| Quarterly | In-depth bearing condition assessment, vibration analysis, lubricant replacement. |

| Annual | Professional maintenance service, spindle balancing, bearing replacement if necessary. |

You can prevent costly repairs and keep your edge grinding process reliable by following this routine.

Wheel Dressing and Balancing

Grinding wheels need regular dressing and balancing to deliver the best results. Dressing cleans and sharpens the wheel, so you always have fresh abrasive surfaces for coldworking and edge finishing. This process removes debris and wear, restoring the wheel’s cutting ability. When you dress and balance your wheels, you reduce vibration and avoid uneven wear. This helps you prevent cracks and defects in the glass edge.

- Dressing restores the wheel’s shape and exposes new abrasive grains.

- Balancing ensures the wheel spins evenly, which protects the edge from chipping.

- Regular maintenance keeps your grinding process smooth and efficient.

Machine Calibration

You must calibrate your grinding machines regularly. Calibration ensures that every edge is polished correctly and that the coldworking process stays consistent. If your machines are not calibrated, you may see poor results and more cracks in the glass. Regular calibration and alignment help you maintain high standards and reduce the risk of defects.

Tip: Train your team to spot early signs of machine misalignment or wear. Early action prevents bigger problems and keeps your grinding and coldworking operations running smoothly.

By following these care and maintenance steps, you protect your equipment, improve your edge quality, and extend the life of your glass grinding tools.

Safety and Training in Glass Grinding

Operator Training

You play a key role in preventing cracks and chipping during grinding. Proper training gives you the skills to operate machines safely and handle glass with care. When you understand the properties of glass and the correct use of grinding equipment, you reduce the risk of defects. Training also teaches you how to inspect each edge for damage before and after grinding. Many defects happen when operators lack training, so investing in skill development leads to fewer mistakes and better edge quality.

- Training should cover:

- Safe machine operation

- Glass inspection before grinding

- Correct edge handling techniques

- Emergency procedures

Well-trained operators help maintain a safe workspace and produce high-quality edges every time.

Personal Protective Equipment

You must wear the right personal protective equipment when working with glass and grinding machines. This protects you from injuries and keeps your focus on producing smooth edges. Always use heavy-duty gloves to protect your hands from sharp edges. Safety goggles shield your eyes from flying particles during grinding. Steel-toed boots keep your feet safe from falling glass. Dust masks prevent you from breathing in harmful particles created during grinding.

- Essential PPE includes:

- Safety goggles

- Heavy-duty gloves

- Steel-toed boots

- Dust masks

A well-equipped operator stays safe and works more confidently at the grinding station.

Safe Glass Handling

Safe handling keeps your glass intact and your edges flawless. You should always inspect glass for defects before starting any grinding work. Use teamwork and proper lifting methods to avoid dropping or stressing the glass. Store glass securely and keep your workspace organized to prevent accidents.

| Best Practice | Description |

|---|---|

| Adjustable Speed Equipment | Use machines with adjustable speed for better edge control. |

| Regular Maintenance | Clean and check tools often to ensure safe grinding and edge quality. |

| Specialized Tools | Use sharp tools to minimize pressure and avoid edge chipping. |

| Proper Material Support | Support glass well to prevent vibration and edge damage. |

| Cooling Systems | Use water or coolant to protect the edge from heat during grinding. |

| Tool Inspections | Check tools for wear to prevent chipping and maintain edge integrity. |

Tip: Always keep a steady water flow during grinding. This cools the edge and reduces the risk of cracks or chips.

By following these safety and training practices, you protect yourself and ensure every edge meets the highest standards in glass grinding.

You can prevent cracks and chipping by using the right grinding tools, steady pressure, and proper cooling. Aimgrind diamond grinding wheels help you achieve smooth glass edges and reduce defects. Studies show that most cracks start at the edge surface or transition areas, depending on the process:

- As cut: Fractures start at the edge and pane surface.

- Smooth ground: 90% of cracks begin at the edge surface.

| Factor | Impact on Results |

|---|---|

| Tool wear | Affects surface roughness and crack risk |

| Cutting speed | Higher speeds improve surface quality |

Use these proven methods and reach out to Aimgrind for custom solutions that fit your needs.

FAQ

What causes chipping during glass grinding?

You often see chipping when you use too much pressure or select the wrong wheel. Poor coolant flow and machine vibration also increase the risk. Always check your process and tools to reduce chipping.

How do you choose the right grit size for edge grinding?

You should start with a coarser grit for shaping. Move to a finer grit for polishing. Finer grits help you achieve a smooth finish and reduce the chance of cracks.

Why is coolant important in glass grinding?

Coolant keeps the grinding area cool. It prevents thermal shock and reduces the risk of cracks. You should always use enough coolant for safe and effective grinding.

How often should you inspect your grinding equipment?

You need to inspect your equipment daily. Look for signs of wear, vibration, or noise. Regular checks help you catch problems early and keep your grinding process safe.

Can Aimgrind diamond grinding wheels be customized for my application?

Yes. You can request custom sizes, shapes, and bond types. Aimgrind works with you to match the wheel to your specific glass processing needs.

Contact Us

For More Grinding Solution or Customized Abrasive Tools