Vibration is the main challenge in deep hole internal grinding. This issue directly harms machining accuracy. A systematic solution is the only way to achieve a smooth finish and high accuracy. This process involves diagnosing the source of vibration and optimizing the entire grinding setup.

Note: Success in grinding depends on creating a stable process. This improves both part quality and machining accuracy.

Key Takeaways

- Vibration is a big problem in deep hole internal grinding. It makes parts less accurate. You must fix it to get good results.

- Find out what causes the vibration. It could be a weak quill, an unbalanced grinding wheel, or a loose workpiece. Look for rough surfaces or bad part shapes.

- Make your grinding setup strong. Use a thick quill and a balanced spindle. This helps stop vibration before it starts.

- Pick the right grinding wheel. A good wheel cuts easily and causes less vibration. Also, use the correct speeds and feeds for your machine.

- Use ‘spark-out’ at the end of grinding. This step helps make the part very accurate and gives it a smooth finish.

Diagnosing Vibration in Deep Hole Internal Grinding

Identifying the source of vibration is the first step toward a solution. The underlying cause of vibration is not always obvious, but its effects are clear. Ignoring this vibration problem leads to poor outcomes in any CNC machining process.

Common Signs of Excessive Vibration:

- Rough surface finishes and visible chatter marks.

- Dimensional inaccuracies, such as out-of-round holes.

- Shortened lifespan of spindles and grinding tools.

Quill Deflection and Spindle Balance

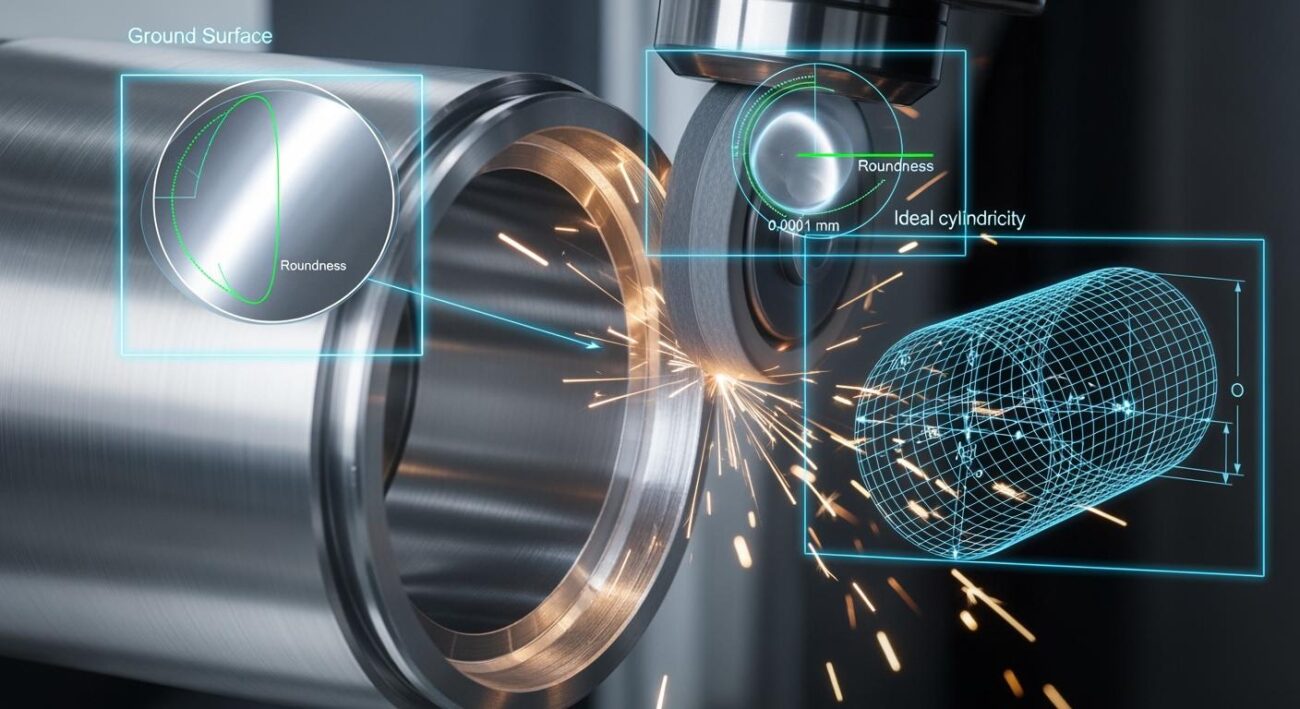

The quill is a primary suspect in deep hole internal grinding. Its length-to-diameter ratio is critical, a principle shared with deep hole drilling. A long, slender quill deflects easily under grinding forces, causing vibration and chatter that ruin machining accuracy. This concept is fundamental to deep hole drilling rigidity. High-speed spindles must also be precisely balanced. Industry standards like ISO 1940-1 provide G-values (e.g., G2.5 or G1.0) that define the required balance for high accuracy in CNC machining. An imbalanced spindle introduces a powerful vibration from the start. This is why deep hole drilling emphasizes a stable tool path for better accuracy. The same logic applies to deep hole drilling for maintaining accuracy in CNC machining.

Grinding Wheel Imbalance and Wear

The grinding wheel itself is a frequent source of vibration. Vibration due to wheel unbalance can arise from many factors, including uneven particle distribution, eccentric installation, or even coolant absorption. As the wheel wears unevenly during grinding, this imbalance worsens. The resulting vibration transfers directly to the workpiece, creating chatter and compromising machining accuracy. This is a common challenge in CNC machining that requires constant monitoring for optimal accuracy.

Workpiece and Fixture Rigidity

A stable workpiece is essential for successful grinding. Insufficient clamping force or a poorly designed fixture can allow the part to shift during the CNC machining operation. This movement introduces severe vibration, making it impossible to achieve the desired machining accuracy. The fixture must be rigid enough to withstand grinding forces without flexing. This is a core principle of all CNC machining, where stability equals accuracy. A secure setup prevents chatter and ensures consistent results in any CNC machining task.

Incorrect Grinding Parameters

Even with a perfect mechanical setup, incorrect parameters can induce vibration. Excessive feed rates increase the grinding force, which raises the vibration amplitude. There is also a direct relationship between the grinding wheel speed and the machine’s natural frequency. If the operating speed excites a resonant frequency, severe vibration will occur.

Modern diagnostic tools offer a powerful technique for analysis. An accelerometer can measure the vibration frequency and amplitude, providing data to pinpoint the source of the vibration. This technique helps operators distinguish between issues like spindle imbalance and chatter from the cutting process, leading to faster and more effective solutions for any CNC machining challenge. This data-driven approach is key to optimizing deep hole internal grinding and achieving superior accuracy.

Strategies to Reduce the Effect of Vibration

Diagnosing vibration is only the first step. The next phase involves implementing targeted strategies to reduce the effect of vibration. A stable system is the foundation for any successful production grinding operation. This requires a holistic approach that addresses the machine’s mechanical stiffness, the cutting tool, and the operating parameters. By systematically improving each area, operators can significantly reduce chatter and improve overall machining accuracy.

Maximize Quill and Spindle Stiffness

The quill and spindle assembly is the backbone of the grinding process. Its stiffness directly impacts the system’s ability to resist cutting forces without deflecting. A lack of stiffness is a primary cause of vibration.

💡 Pro Tip: Increasing the quill’s diameter is the most effective way to boost its stiffness. A small increase in diameter provides a large increase in rigidity.

When a larger diameter is not possible, material choice becomes critical. Different materials offer unique advantages for managing vibration.

- Tungsten Carbide Quills: These are the gold standard for precision internal grinding. Their high stiffness minimizes deflection, which is essential for tight tolerances. They are the most expensive option but offer exceptional longevity.

- Heavy Metal Quills: These materials provide excellent vibration absorption. Their damping characteristics are ideal for controlling chatter. They offer a balance of cost and stiffness between steel and carbide.

The spindle itself must also contribute to a stable system. High-frequency grinding spindles are engineered for extreme accuracy and stiffness. Modern spindles often use advanced bearing technology, such as hydrostatic or hybrid hydrostatic systems. These bearings support the spindle on a thin film of pressurized fluid. This design provides exceptional damping and stiffness, absorbing vibration before it can affect the workpiece. This technique is crucial for achieving the highest levels of accuracy in CNC machining.

| Specification | High Frequency Internal Grinding Spindles | High Frequency Deep Hole Grinding Spindles |

|---|---|---|

| Accuracy (mm) | 0.002 (2 microns) | 0.002 (2 microns) |

| Application | Internal grinding for small to large diameter bores | Grinding long diameter bores, deep bores up to 2 meters |

| Features | Very high axial and radial stiffness, high torque | Can be mounted on VTLs, easy to handle and maintain |

| Cooling | Continuous water cooling circuit | N/A |

Optimize Grinding Wheel Selection and Preparation

The grinding wheel is where the action happens. An improperly selected or prepared wheel will generate excessive vibration regardless of machine stiffness. The goal is to choose a wheel that cuts freely with minimal force. This reduces the load on the quill and minimizes the chance of chatter.

For grinding hard alloys, ceramics, and composites, a custom diamond grinding wheel is a premium solution. A specialized provider like Aimgrind offers personalized selection and formula design to create a wheel perfectly matched to your material and machine. This custom approach ensures optimal cutting performance, which minimizes cutting forces and the resulting vibration. Aimgrind’s ability to engineer wheels with specific resin, metal, or vitrified bonds provides a tailored solution for any production grinding challenge.

A high-quality, well-balanced wheel is a foundational step in creating a stable grinding process. Advanced core materials and precision manufacturing ensure the wheel runs true, which is critical for achieving smooth finishes and micron-level accuracy in CNC machining. This is a key technique for any production grinding setup.

Fine-Tune Speeds, Feeds, and Coolant

With a rigid machine and an optimized wheel, the final step is to fine-tune the grinding parameters. Incorrect cutting conditions can introduce vibration into an otherwise stable system. The goal is to find a “sweet spot” where the material removal rate is high, but the vibration amplitude is low.

A critical technique for achieving final accuracy and a smooth surface finish is the “spark-out” phase.

- Spark-out is the final stage of a precision grinding cycle.

- The in-feed is stopped. The wheel is no longer actively pushed into the workpiece.

- During grinding, the machine, spindle, and part deflect slightly under pressure.

- With the in-feed stopped, the wheel makes several final passes. It removes tiny amounts of material with each pass.

- This process relieves the stored pressure and allows the entire system to relax.

- Sparks will diminish and finally disappear. This indicates the wheel is no longer cutting.

- The part now reaches its true, final dimension with the best possible surface finish.

Coolant application is also vital. A consistent flow of clean coolant not only prevents thermal damage but also helps flush chips from the grinding zone. This prevents the wheel from “loading,” a condition that increases grinding forces and can cause severe vibration. Proper cutting conditions are essential for good cutting performance in CNC machining.

Lessons from Deep Hole Drilling Rigidity

The field of deep hole drilling offers valuable lessons for deep hole internal grinding. Both processes face the same fundamental vibration problem: managing a long, slender tool. The characteristics of deep hole drilling provide powerful insights. BTA deep hole drilling tools, for example, are engineered with guide pads that balance cutting forces.

As the BTA tool cuts, the forces press the tool’s guide pads against the hole wall. This action burnishes the surface and forces the tool to follow an exceptionally straight path. The pads create a self-guiding effect, which is a core principle of deep hole drilling rigidity. This system actively counteracts the tendency for vibration of the drill bit.

While grinding quills do not have guide pads, the principle remains the same. The goal is to create a balanced, self-stabilizing system. This reinforces the importance of a stiff quill, a perfectly balanced spindle, and a free-cutting wheel. Every component must work together to maintain a straight, smooth path. Applying the lessons from deep hole drilling helps operators think about the entire grinding system, not just one component. This mindset is key to solving the vibration problem in CNC machining and achieving consistent machining accuracy and cutting performance. Success in deep hole drilling depends on stability, a lesson that directly improves CNC machining accuracy. The principles of deep hole drilling are directly applicable to improving CNC machining accuracy. The stability in deep hole drilling is a model for all CNC machining. The focus on rigidity in deep hole drilling is essential for accuracy. The methods used in deep hole drilling can prevent chatter and improve cutting performance. This approach leads to better machining accuracy. This focus on chatter amplitude reduction is a lesson from deep hole drilling. The low vibration frequency in stable deep hole drilling is a goal for grinding. The low vibration amplitude in deep hole drilling is also a goal.

Overcoming vibration in deep hole internal grinding is a methodical process. It requires a holistic approach to achieve high accuracy. Success in grinding depends on building a stable system from the ground up.

Follow these key steps for better grinding accuracy:

- Build a rigid foundation with your quill and workholding.

- Select an optimal cutting tool, like a specialized Aimgrind wheel.

- Fine-tune your operating parameters for the best accuracy.

Active damping in robotic grinding proves that systematic vibration control improves surface accuracy. Document your successful grinding setups. This creates a repeatable, high-performance process for future jobs.

FAQ

What is the most common cause of vibration in deep hole grinding?

Vibration often starts with the grinding quill. A long, slender quill can bend under pressure, causing chatter. An unbalanced or worn grinding wheel is another frequent source. Both issues directly harm surface finish and dimensional accuracy.

How can I make my grinding setup more rigid?

The best method is to use a quill with the largest possible diameter. A larger diameter dramatically increases stiffness. If size is limited, choose a stiffer material like tungsten carbide for your quill to minimize deflection and vibration.

Why is the grinding wheel so important for vibration control?

A well-chosen wheel cuts with less force. This reduces stress on the entire system. A custom wheel from a specialist like Aimgrind is matched to your material and machine. This ensures a stable process with minimal vibration from the start.

What does “spark-out” do in a grinding cycle?

Spark-out is a finishing technique. The feed stops, and the wheel makes final passes without pressure. This process removes tiny amounts of material, relieves system deflection, and allows the part to reach its true final dimension with a superior surface finish.

Contact Us

For More Grinding Solution or Customized Abrasive Tools