Selecting the right diamond CBN superabrasive wheels is crucial. You can make a costly error by choosing the wrong grinding wheel for your material. This mistake can ruin both your workpiece and your grinding wheel.

Critical Error: Never use a diamond grinding wheel on steel. The carbon in diamond reacts with the iron in steel at high temperatures. This reaction quickly wears down your grinding wheel. Similarly, CBN superabrasive wheels are not hard enough for tungsten carbide.

This single material mismatch highlights just one of several common pitfalls. Understanding these issues helps you select the perfect grinding wheel.

Key Takeaways

- Match the abrasive to your material. Use diamond wheels for hard, non-metal materials. Use CBN wheels for hardened steel.

- Choose the correct grit size. Coarse grit removes material fast but leaves a rough finish. Fine grit gives a smooth finish but removes material slowly.

- Select the right bond type. The bond holds the abrasive grains. A wrong bond can make the wheel wear out too fast or glaze.

- Pick the right abrasive concentration. Too little abrasive makes the wheel wear fast. Too much abrasive can cause glazing and cost more.

- Ensure your machine is rigid and use the correct coolant. A good machine and proper coolant prevent damage and improve grinding results.

The Core of Choosing the Right Grinding Wheel: Material Mismatch

Choosing the right grinding wheel starts with one simple rule: match the abrasive to the material. Getting this wrong is the most common and costly error you can make. It leads to poor performance, damaged parts, and wasted money. Let’s break down this fundamental mistake.

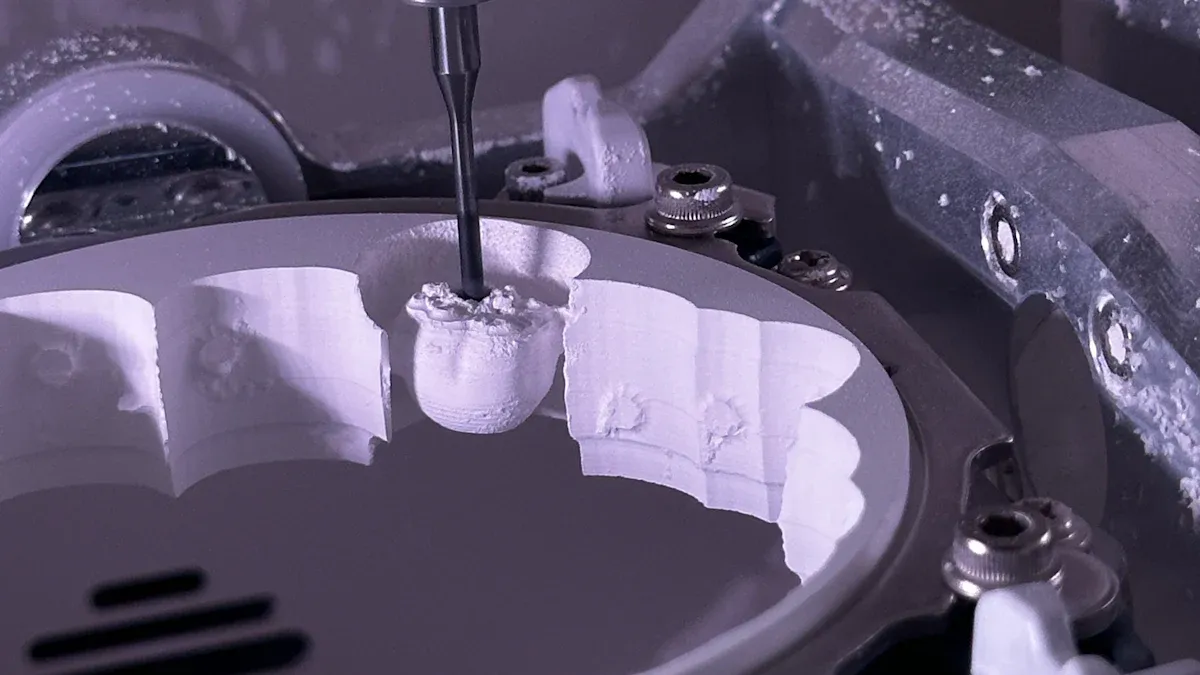

Using Diamond Wheels on Ferrous Metals

You should never use diamond wheels to grind ferrous metals like steel or cast iron. The reason is a chemical reaction. At grinding temperatures above 700°C, the carbon in the diamond grinding wheel reacts with the iron in your workpiece. This process, called catalytic graphitization, essentially turns the superhard diamond abrasive into soft graphite. This causes your grinding wheel to wear down incredibly fast.

“We used to change our grinding wheels every 3–4 days for stainless steel workpieces. Now, with UD’s brazed segments, we go 12+ days without replacement.”

— Maria Lopez, Production Manager, MetalCraft Solutions (Spain)

This rapid wear makes the grinding wheel ineffective and forces you to replace it constantly, driving up your operational costs.

Using CBN Wheels on Carbides or Ceramics

The correct abrasive for hardened steels and superalloys is Cubic Boron Nitride (CBN). A CBN grinding wheel does not react with iron, allowing for cooler, faster, and more efficient grinding. Aimgrind‘s high-performance CBN grinding wheels are specifically engineered for these tough materials. They deliver superior performance and a longer lifespan for your grinding wheel.

However, you also make a mistake when you use a CBN grinding wheel on tungsten carbide or hard ceramics. While CBN is very hard, diamond is the superior choice for these materials. The hardness difference is key.

| Hardness Scale | Tungsten Carbide | CBN (Cubic Boron Nitride) |

|---|---|---|

| Mohs Scale | ~9 | ~9.5 |

| Knoop Hardness (KHN) | 1000-2000 KHN | 4000-5000 KHN |

For the best results on hardened steels, a quality CBN grinding wheel is essential. If you need a custom superabrasive grinding wheel for your specific application, exploring specialized options is your best path forward. You can find excellent solutions for steel grinding among our CBN Grinding Wheels. Proper selection of diamond cbn superabrasive wheels ensures you get the job done right.

Mistake 1: Incorrect Grit Size Selection

After matching the abrasive to your material, you must select the correct grit size. The grit size of a grinding wheel determines the final surface finish and the speed of material removal. Choosing the wrong size can seriously affect your grinding wheel performance and the quality of your workpiece. A poor choice here can ruin an otherwise perfect setup.

Choosing a Grit That’s Too Coarse

You might choose a coarse grit grinding wheel for fast material removal. This approach, however, comes with significant downsides. A coarse grinding wheel creates a rougher surface finish. It can also cause hidden damage to your part.

Risks of Using a Coarse Grit Grinding Wheel:

- It leaves large, deep scratches on the surface.

- It can cause plastic deformation below the surface.

- It may create subsurface damage that finer grinding steps cannot remove.

The roughness of the finish is measured in Ra or RMS. A lower number means a smoother surface. You can see how a coarse grit grinding wheel affects the finish in the table below.

| Grit Size | Expected RMS Finish (Resin Bond) | Expected RMS Finish (Plated Bond) |

|---|---|---|

| 60 | 35-50 | – |

| 80 | 20-30 | 90-125 |

| 100 | 16-24 | 64-90 |

Choosing a Grit That’s Too Fine

You might select a fine grit grinding wheel to achieve a very smooth finish. This choice also has trade-offs. A fine grit grinding wheel removes material much more slowly. This slower rate increases your grinding cycle times and reduces overall productivity. The performance of your grinding wheel depends on this balance.

Using a grit that is too fine also increases the risk of the grinding wheel “glazing.” Glazing happens when the abrasive particles become dull and clogged with material. The grinding wheel stops cutting and starts rubbing, which generates excess heat and can damage your workpiece. A glazed grinding wheel requires frequent dressing to restore its cutting ability. This adds extra steps and downtime to your process. Choosing the right grinding wheel grit is essential for efficient operation.

Mistake 2: Ignoring the Grinding Wheel Bond

The bond is the glue that holds the abrasive grains in your grinding wheel. Choosing the right bond is just as important as choosing the right abrasive. The bond system controls how the grinding wheel wears, how it holds its shape, and its overall performance. Ignoring this detail leads to poor results and wasted resources.

Using the Wrong Bond Type

You must match the bond to your specific job. The main grinding wheel types use different bonds, and each has a distinct purpose. Using the wrong one guarantees poor performance from your grinding wheel.

- Resin Bond: You can use this versatile bond for many general-purpose applications.

- Vitrified Bond: You should choose this for grinding superhard tools like PCD and PCBN.

- Metal Bond: This is the toughest bond, ideal for jobs that need a hard matrix and coolant.

- Electroplated Bond: You use this for form grinding because it has an aggressive, open structure.

Selecting a bond that is too soft for a high-pressure job will cause your grinding wheel to wear out quickly. The table below shows how different bonds affect the performance of a grinding wheel.

| Bond Feature | Resin Bond | Vitrified Bond | Electroplated Bond |

|---|---|---|---|

| Cutting Speed | Generally fast | Slower | Fastest |

| Flexibility | More flexible | Rigid and brittle | Very rigid |

| Heat Resistance | Less resistant | Very resistant | Moderately resistant |

Mismatching the Bond Hardness

Bond hardness determines how securely the bond holds onto the abrasive grains. A common error is using a bond that is too hard for your material. This prevents the grinding wheel from self-sharpening. Dull abrasive grains are not released, causing the grinding wheel to “glaze over.”

What is Glazing? 🧊

Glazing happens when the surface of the grinding wheel becomes smooth and glossy. The grinding wheel stops cutting and starts rubbing the workpiece. This generates excess heat, damages your part, and ruins the grinding wheel.

A softer bond allows dull grains to fall away, exposing new, sharp grains. This self-sharpening action is perfect for grinding hard materials. A harder bond holds grains longer, which helps the grinding wheel maintain its shape when working on softer materials. The right balance ensures optimal cutting action and a long life for your grinding wheel.

Mistake 3: Improper Abrasive Concentration

Abrasive concentration is a critical factor for your grinding wheel. It tells you the amount of diamond or CBN abrasive in the wheel’s cutting section. You will see this shown as a ‘C’ number. For example, a C100 concentration means the grinding wheel has 72 carats of abrasive per cubic inch. The typical range for a superabrasive grinding wheel is between C25 and C125. Choosing the wrong concentration for your grinding wheel directly impacts its performance and cost.

Selecting a Concentration That’s Too Low

You might choose a low concentration to save money upfront. However, this choice often leads to poor results. A grinding wheel with too little abrasive wears down very quickly. This shortens the life of the grinding wheel and forces you to buy replacements more often. The low concentration also reduces the material removal rate. Your jobs will take longer, hurting your overall productivity. While a lower concentration grinding wheel can be useful for fine-grit applications or small contact areas, it is a mistake for most heavy-duty tasks. The wrong grinding wheel concentration compromises your entire operation.

Selecting a Concentration That’s Too High

On the other hand, you can also choose a concentration that is too high. A high-concentration grinding wheel costs more. This choice is only worth it if the application demands it. Using a grinding wheel with too much abrasive can increase grinding forces and heat. This can lead to glazing, where the grinding wheel stops cutting effectively.

Pro Tip 💡

A higher concentration grinding wheel (like C100 or C125) generally offers longer life and faster cutting. You should pair it with coarse grit sizes for demanding jobs. This combination delivers excellent performance.

The key is balance. You need enough abrasive for efficient cutting without overspending or creating other problems. The right concentration ensures your grinding wheel works perfectly for your specific material and task.

Key Factors for Diamond CBN Superabrasive Wheels: Machine & Coolant

You can select the perfect grinding wheel and still get poor results. Your machine and coolant system are just as important as the wheel itself. Ignoring these factors is a mistake that undermines the performance of even the best diamond cbn superabrasive wheels.

Ignoring Machine Rigidity and RPM

Your grinding machine’s condition directly impacts your grinding performance. A superabrasive grinding wheel needs a rigid, stable machine to work correctly.

- Older, less stiff machines cannot handle aggressive cutting. You will need more passes to complete a job.

- Modern, rigid machines allow you to run your grinding wheel at higher speeds. This reduces the number of passes and boosts production.

You must also manage the rotational speed (RPM). The surface speed of your grinding wheel is critical. As a grinding wheel wears down, its diameter decreases, and its surface speed drops. You need to increase the RPM to maintain efficiency. Running a grinding wheel too slow wastes the abrasive, while running it too fast can cause it to glaze. Finding the right RPM for your grinding wheel diameter ensures optimal cutting action and a longer life for the grinding wheel.

Using Inadequate or Incorrect Coolant

Coolant is not just optional; it is essential for high-quality results. Using the wrong type or an inadequate flow of coolant can ruin your workpiece and your grinding wheel.

Coolant Rule of Thumb 💧

You should use a water-based coolant for a diamond grinding wheel on carbides. For a CBN grinding wheel on ferrous metals, you must use an oil-based coolant. Water can react with CBN at high temperatures, damaging the abrasive.

Poor coolant flow is another common problem. If your coolant foams or the pump is faulty, heat will build up. This leads to thermal damage, increased wear on the grinding wheel, and a poor surface finish. Proper coolant delivery washes away chips, reduces friction, and is vital for the overall performance of your diamond cbn superabrasive wheels. A good coolant system protects your investment in a quality grinding wheel.

You now know the top five mistakes. You avoid material mismatch, pick the right grit for your grinding wheel, and choose the correct bond for your grinding wheel. You also select the proper concentration for your grinding wheel and consider your machine and coolant. Avoiding these errors with your grinding wheel ensures your grinding wheel performs well. For the perfect custom superabrasive grinding wheel, talk to our experts. We help you find the right grinding wheel for your diamond cbn superabrasive wheels needs, making sure every grinding wheel is the best grinding wheel for the job.

Grind with Passion, Achieve with Aim.

FAQ

What is the main difference between a diamond and a CBN grinding wheel?

You use a diamond grinding wheel for hard, non-ferrous materials like carbide, ceramics, and glass. You should use a CBN wheel for ferrous metals like hardened steel and tool steel. Using the wrong type will damage your wheel and workpiece.

Why is my grinding wheel glazing?

Your grinding wheel glazes when its abrasive grains become dull and clogged. This often happens if the bond is too hard for the material or the grit is too fine. The wheel stops cutting and starts rubbing, creating excess heat.

How do I choose the right grit size for my grinding wheel?

You select grit size based on your desired finish and cutting speed. For a rough cut and fast material removal, use a coarse grit grinding wheel. For a smooth, fine finish, you should choose a fine grit.

Does coolant matter for my grinding wheel?

Yes, coolant is essential. It prevents overheating, washes away debris, and reduces friction. Proper coolant protects your grinding wheel from premature wear. Using the right coolant also extends the life of the grinding wheel and ensures a better surface finish.

Contact Us

For More Grinding Solution or Customized Abrasive Tools