The maximum operating speed on a grinding wheel is a critical safety limit set by its manufacturer. This value represents the fastest speed at which the wheel can be safely used.

Safety Alert ⚠️

A grinder’s Revolutions Per Minute (RPM) must always be less than or equal to the maximum speed marked on the wheel.

This maximum safe speed is determined through rigorous testing. The tests establish the maximum safe operating speed to prevent wheel failure from powerful centrifugal forces. Following the maximum operating speed is essential for any safe grinding operation.

Key Takeaways

- Always check the maximum speed on a grinding wheel. This speed is a safety limit. Never use a wheel if your grinder’s speed is higher than this limit.

- Manufacturers test grinding wheels to find their safe speed. They spin wheels until they break. This helps them set a safe limit for you to use.

- Using a grinding wheel too fast is very dangerous. The wheel can explode into pieces. These pieces fly out and can cause serious injury or death.

- Do not use a large wheel on a small, fast grinder. This makes the wheel spin too fast. It can cause the wheel to break apart.

- Always wear safety gear like goggles and a face shield. This protects you from flying pieces if a wheel breaks.

Understanding the Maximum Operating Speed

The maximum operating speed is not an arbitrary number. It is a carefully calculated limit based on a wheel’s physical properties and rigorous safety testing. Understanding how this rating is established and where to find it is essential for every operator.

How Speed Ratings Are Determined

Manufacturers determine a wheel’s permissible operating speed through destructive testing. They place a wheel in a secure test chamber and increase its rotational speed until it shatters from centrifugal force. This breaking point is called the “burst speed.”

Safety standards, such as EN 12413, require the burst speed to be significantly higher than the listed grinding wheel speed. The difference between these two speeds creates a crucial safety factor. This factor ensures the wheel can safely handle the stresses of normal operation. The specific grinding wheel characteristics and grinding wheel dimensions influence this calculation. These testing procedures adhere to strict industry regulations.

The U.S. Occupational Safety and Health Administration (OSHA) requires that abrasive wheel machinery guards comply with the American National Standard ANSI B7.1. This standard outlines the safe use, care, and protection of abrasive wheels.

Finding the RPM on Your Wheel

Operators can easily find the speed rating on the wheel itself. The rated maximum speed is always printed on the wheel’s label or blotter (the paper ring around the center hole). This information includes the grinding wheel specifications, typically listing the speed in both Revolutions Per Minute (RPM) and surface speed in meters per second (m/s).

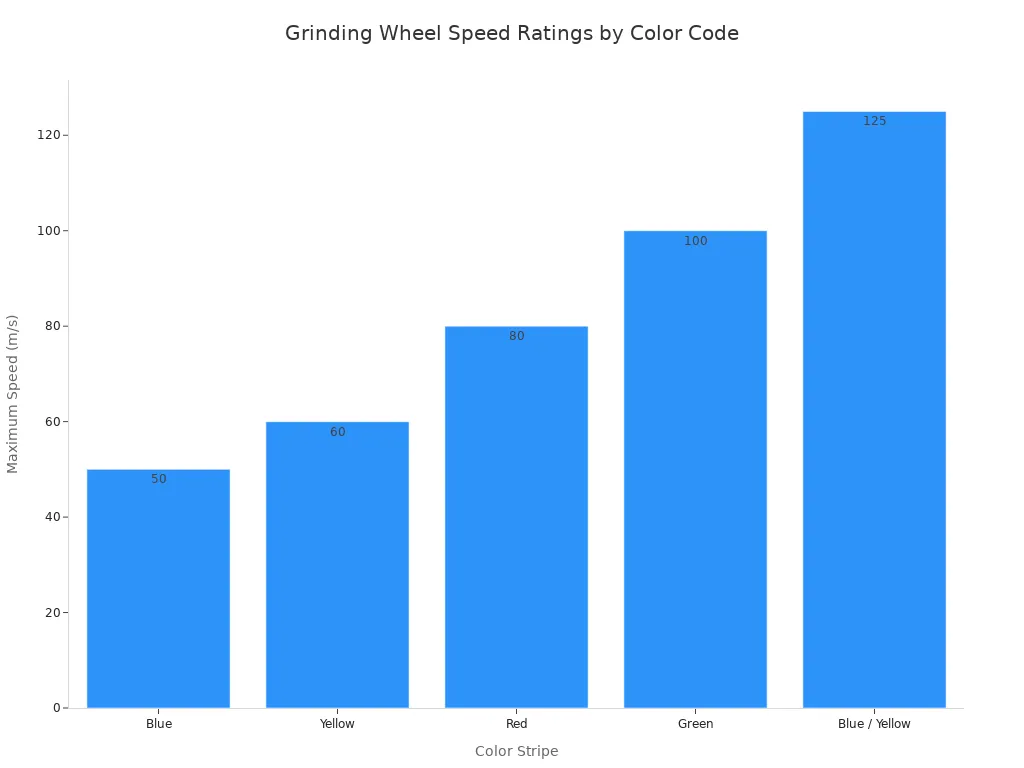

For some high-speed wheels, manufacturers also use a color-coded stripe system to provide a quick visual reference for the grinding wheel speed.

- Blue: 50 m/s

- Yellow: 60 m/s

- Red: 80 m/s

- Green: 100 m/s

- Blue/Yellow: 125 m/s

Always check the printed rating before mounting any wheel. This simple check is a fundamental step in preventing accidents.

RPM vs. SFM: What’s the Difference?

Operators often see two different speed measurements related to grinding: RPM and SFM. While both describe speed, they measure different things. Understanding the distinction is key to achieving both safety and optimal performance in any grinding task.

Defining Spindle Speed (RPM)

Spindle speed, measured in Revolutions Per Minute (RPM), describes how many full rotations a grinder’s spindle makes in one minute. It is a fixed characteristic of the machine itself. Different tools operate at different spindle speeds.

- Bench Grinders: Typically run at 3,750 RPM or less.

- Angle Grinders: Can operate at much higher speeds, sometimes exceeding 11,000 RPM.

The RPM of the grinder directly influences the grinding process. Higher spindle speeds can increase the material removal rate but may also cause more vibration. Operators must find a balance to remove material efficiently while maintaining a good surface finish.

| Aspect | Impact of Spindle Speed (RPM) |

|---|---|

| Material Removal Rate | Higher speeds generally increase the rate of material removal. |

| Surface Finish | Excessive speed can cause vibration, which negatively affects the surface finish. |

| Heat Generation | Faster speeds generate more heat, potentially damaging the workpiece or wheel. |

Understanding Peripheral Speed (SFM/m/s)

Peripheral speed measures how fast a point on the outer edge of the grinding wheel is traveling. This is a more accurate indicator of cutting performance than RPM. It is usually expressed in Surface Feet per Minute (SFM) or meters per second (m/s).

The cutting action happens at the wheel’s edge. Therefore, the peripheral speed is the true measure of the grinding wheel speed. Two wheels of different sizes running at the same RPM will have very different peripheral speeds. A larger wheel has a faster peripheral speed because its outer edge travels a greater distance with each rotation. This is why SFM provides a more consistent and reliable measure of a wheel’s cutting ability. The peripheral wheel speed is what truly matters for performance.

Converting Between Speed Units

An operator must sometimes convert between speed units to ensure a wheel is compatible with a grinder. This is especially true if a wheel is rated in SFM or m/s and the grinder is rated in RPM.

The formula to calculate SFM uses the grinder’s RPM and the grinding wheel diameter.

Formula to Calculate SFM from RPM:

SFM = (π × Diameter in inches × RPM) / 12An easier approximation is:

SFM = (Diameter in inches × RPM) / 4

These formulas show how a larger diameter increases the peripheral speed even when the RPM stays the same.

Many international wheels list their speed in meters per second (m/s). Operators can use a simple conversion factor to find the equivalent SFM.

Conversion from m/s to SFM:

1 m/s ≈ 197 SFM

Knowing how to calculate and convert between these units allows an operator to confidently match any wheel to the correct machine, ensuring both safety and high-quality results.

Risks of Exceeding the Maximum Speed

Ignoring a grinding wheel’s speed rating introduces severe and often life-threatening risks. The maximum operating speed is a strict limit for a reason. Understanding the physics behind these dangers helps operators appreciate the importance of this safety rule.

The Danger of Centrifugal Force

Every rotating object generates an outward-pulling force called centrifugal force. This force increases dramatically as the rotation speed increases. In fact, the centrifugal force grows with the square of the rotational speed. This means doubling the speed of a grinding wheel quadruples the force trying to tear it apart.

This immense force creates powerful stresses inside the wheel.

- Tangential Stress: This is a pulling stress that is strongest at the inner wall of the abrasive layer, right where it bonds to the wheel’s substrate.

- Radial Stress: This is an outward stress that occurs within the abrasive layer itself.

A grinding wheel fails when these stresses become greater than the strength of the wheel’s material. The adhesive bonding the abrasives can no longer hold everything together. This causes cracks to form, leading to a complete and violent failure of the wheel.

Catastrophic Wheel Explosions

When a grinding wheel fails at high speed, it does not simply crack or break. It explodes. The wheel shatters into multiple pieces that fly outward like shrapnel at extremely high velocities. These projectiles can cause devastating injuries or death to the operator and anyone nearby. They can easily penetrate safety glasses, clothing, and skin.

Safety First 🛡️

Machine guards are the first line of defense against a wheel explosion. An operator must never operate a grinder without a properly installed guard.

In addition to machine guards, operators must wear appropriate Personal Protective Equipment (PPE) to protect themselves from flying debris and sparks. Essential PPE includes:

- Proper eye protection, such as safety goggles

- A full-face shield for added protection

- Head protection

- Hearing protection

- Durable gloves and aprons, especially when hot sparks are generated

Common Over-Speeding Mistakes

Most over-speeding incidents happen due to simple, preventable mistakes. Awareness of these common errors is key to avoiding a dangerous situation.

One of the most frequent and dangerous mistakes is mounting a large wheel on a small, high-RPM grinder. A larger wheel has a lower maximum safe speed to keep its outer edge from traveling too fast. Small grinders, however, spin at very high RPMs. This mismatch forces the large wheel to spin far beyond its limits.

| Disc Diameter | Typical Max RPM Rating | Common Grinder Size | Grinder RPM Range | Safety Outcome |

|---|---|---|---|---|

| 4.5″ (115mm) | 13,300 RPM | 4.5″ Grinder | 11,000 – 13,000 RPM | ✅ Safe Match |

| 5″ (125mm) | 12,250 RPM | 4.5″ Grinder | 11,000 – 13,000 RPM | ⚠️ High Risk |

| 7″ (180mm) | 8,500 RPM | 4.5″ Grinder | 11,000 – 13,000 RPM | ⛔ Extreme Danger |

This practice is hazardous for two main reasons. First, the wheel is spinning dangerously fast, creating immense centrifugal force. Second, a larger wheel does not fit with the grinder’s safety guard, tempting operators to remove it and eliminating their primary protection.

Another critical error is using a wheel with a missing or unreadable label. Without a clear speed rating, an operator cannot confirm if the wheel is safe for their grinder. Using a wheel from an unknown source or with no visible maximum speed rating creates multiple risks:

- Bursting Wheel: The wheel could be rated for a much lower speed, leading to an explosion.

- Kickback: An incorrect speed can cause the tool to kick back violently, leading to loss of control.

- Overheating: Excessive speed generates too much heat, which can damage the wheel and the workpiece.

An operator must never use a wheel without knowing its rating or a grinder without knowing its RPM.

Typical Grinding Wheel Speed Ranges

Different grinding applications require different speeds to achieve optimal grinding performance. While the maximum speed on the wheel is the ultimate safety limit, understanding typical speed ranges for each grinding operation helps operators select the right tool for the job.

| Grinding Application | Typical Speed Range |

|---|---|

| Surface Grinding | 4,000 – 5,000 SFM |

| Cylindrical Grinding | 5,500 – 6,500 SFM |

| Off-Hand Grinding | 80 m/s (approx. 15,700 SFM) |

| Cup Grinding | 50 m/s (approx. 9,850 SFM) |

Important Note 📝

These values are general guidelines. The maximum operating speed printed on the wheel itself is always the final authority and must never be exceeded.

For specialized tasks, like grinding hard alloys or ceramics, using a precisely engineered wheel is crucial. Aimgrind provides customized diamond grinding wheels designed to operate optimally and safely within the required speed parameters for specific materials, ensuring both safety and efficiency.

Surface Grinding

Surface grinding creates flat surfaces. The ideal speed often depends on the material.

- A general range of 4,500 to 6,500 SFPM is common.

- Harder steels often see good results around 6,000 SFPM with aluminum oxide wheels.

- Hardened tool steel may require a speed of approximately 4,600 SFPM with ceramic wheels.

Cylindrical Grinding

Cylindrical grinding shapes the outside of a workpiece. The grinding wheel speed directly impacts the final quality.

- An increase in speed can slightly reduce the part’s roundness due to deformation.

- However, a higher speed also improves the surface finish by increasing the number of abrasive particles cutting the material.

Off-Hand and Portable Grinding

This category includes bench grinders and portable angle grinders. Operators must always match the wheel’s RPM rating to the tool’s speed. Using a wheel with a lower RPM rating than the grinder is extremely dangerous.

| Grinder/Wheel Size | Typical Maximum RPM |

|---|---|

| 4.5″ Angle Grinders | 10,000 – 11,000 RPM |

| 6″ Wheels | 8,500 – 9,000 RPM |

| Grinders for Stainless Steel | 2,000 – 7,600 RPM |

Cutting-Off Wheels

Cutting-off wheels are thin wheels used for slicing material. They often have fiberglass reinforcement to improve structural integrity and contain fragments if a break occurs. However, this reinforcement does not change the maximum safe speed. An operator must always ensure the machine’s RPM is at or below the wheel’s rating to prevent a catastrophic failure during the grinding operation.

Before starting any grinding operation, an operator must perform one non-negotiable safety check. Always verify the grinder’s RPM is less than or equal to the maximum speed printed on the wheel. If the machine’s speed is higher, that wheel must not be used under any circumstances. Following the maximum operating speed is the most critical step to prevent wheel failure and ensure personal safety.

Safety Reminder ⚠️

- Check: Grinder RPM ≤ Wheel Max RPM.

- Confirm: If grinder RPM is higher, DO NOT USE the wheel.

FAQ

What happens if a wheel has a missing speed rating?

An operator must never use a wheel with a missing or unreadable speed rating. There is no way to confirm its safety. Using an unknown wheel creates a severe risk of a catastrophic explosion if its maximum speed is lower than the grinder’s RPM.

Can an operator use a larger wheel on a small grinder?

No. This is extremely dangerous. Small grinders have high RPMs. A larger wheel has a lower RPM rating. This mismatch forces the wheel to spin far beyond its safety limit, which can cause it to shatter. Operators must always match the wheel to the grinder.

Does wheel wear affect the grinding speed?

Yes. As a wheel wears down, its diameter decreases. This reduces its peripheral speed (SFM) even if the grinder’s RPM remains constant. The grinding wheel speed at the edge becomes slower, which can affect performance. The wheel remains safe as long as the initial match was correct.

Why do some wheels have color stripes?

Color stripes offer a quick visual guide to a wheel’s maximum speed rating in meters per second (m/s).

- Red: 80 m/s

- Green: 100 m/s

An operator should always confirm the speed by reading the RPM value printed on the label.

See Also

Selecting the Optimal Grinding Wheel Dresser for Your Specific Needs

Finding the Perfect Grinding Wheel for Your Carbide Tool Applications

Guide to Choosing the Ideal Grinding Wheel for Stainless Steel Projects

Exploring Various Grinding Wheel Types and Their Real-World Uses

Picking the Best Bench Grinding Wheel Material for Your Workshop

Contact Us

For More Grinding Solution or Customized Abrasive Tools