Many people notice their grinding wheels wear out fast, but achieving a lifetime grinding wheel doesn’t require drastic changes. Choosing the right wheel and properly maintaining it makes a big difference. Studies show some main reasons for a short wheel life:

1. Low quality wheels wear out quickly

2. Excessive or unnecessary dressing

3. Improper use of the wheel

4. Selecting the wrong grinding wheel for the job

5. Using incorrect grinding speeds

6. Applying the wrong grinding fluids

Other issues include applying too much force, choosing grit that’s too fine, insufficient coolant, and improper storage of wheels. Small adjustments in how you select and use grinding wheels can significantly extend their lifespan, helping you achieve a lifetime grinding wheel.

Key Takeaways

-

Pick grinding wheels that are made with good materials. This helps them last longer and work better. Match the grinding wheel and abrasive to what you are working on. This can help the wheel wear out less and give better results. Use the right speed, pressure, and feed rate when you grind. This stops the wheel from getting damaged early and keeps it working well. Use the right cooling and lubrication with clean coolant. This lowers heat and keeps the wheel and workpiece safe. Check, dress, clean, and store grinding wheels often and in the right way. This keeps them safe and helps them last longer.

Critical Factors for Lifetime Grinding Wheel Performance

How long a grinding wheel lasts depends on many things. Knowing these important things helps people get better results and make wheels last longer.

Wheel Quality

The quality and how the wheel is made matter a lot. Good grinding wheels use better abrasive grains and bonding materials. These wheels wear down less and more evenly. They also have smoother surfaces. When wheels are made carefully, they last longer.

-

Abrasive grain type, size, and amount affect how long wheels last.

-

The bonding material changes how strong the wheel is.

-

Buying good wheels means you do not need to replace them as often.

-

Bad wheels wear out fast and do not work as well.

|

Performance Parameter |

High-Quality Grinding Wheels |

Low-Quality Grinding Wheels |

|---|---|---|

|

Radial Wear Difference |

More wear difference |

|

|

Wear Distribution Uniformity |

More even wear |

Less even wear |

|

Grain Concentration Gradient |

Smaller changes |

Bigger changes |

|

Surface Topography |

Easier to cut |

Rougher surfaces |

|

Grinding Forces |

Lower and steady |

Higher and uneven |

|

Thermal Load Consideration |

Well managed |

Not managed well |

Tip: Pick grinding wheels that are made well and tested for quality. This helps them last longer and work better.

Material Compatibility

Matching the grinding wheel to the material is very important. How fast a wheel wears out depends on how well it fits the material’s hardness and heat needs.

-

CBN wheels are best for ferrous materials like steel and cast iron.

-

Harder materials need wheels that are also hard and tough.

-

Grinding ferrous materials makes a lot of heat, so thermal stability matters.

-

Using the right wheel keeps the edges sharp and stops clogging.

Some materials, like reaction-bonded silicon carbide and high-nickel superalloys, wear out wheels quickly. These materials are very hard and stick to the wheel, breaking the grit and bond. Grinding cemented carbides with lots of cobalt also makes wheels wear out faster.

Note: Always use a grinding wheel that matches the material. This stops too much wear and helps the wheel last longer.

Abrasive and Bond Type

The kind of abrasive and bond in a grinding wheel changes how it works and how long it lasts. Different abrasives have their own good and bad points.

-

Aluminum oxide wears down slowly and lasts a long time. It is cheap and works for many jobs.

-

Silicon carbide is harder and sharper but wears out faster.

-

Diamond and CBN abrasives are very hard and last a long time. They cost more but are best for hard materials.

-

Ceramic alumina grains sharpen themselves and last longer under pressure.

-

Zirconia alumina grains cut fast and last long, especially on steel.

The bond type also matters:

|

Bond Type |

Durability and Lifespan |

Key Properties and Effects on Durability |

Typical Applications |

|---|---|---|---|

|

Hardest, longest lasting |

Very strong, slower speed, lasts longer |

Glass, ceramics, carbide, aerospace |

|

|

Vitrified Bonds |

Medium to high durability |

Porous, faster speeds, can be dressed |

Automotive, high-production |

|

Electroplated Bonds |

Shorter life |

One abrasive layer, fast speeds, less strong |

Precision, low-medium production |

Tip: Pick the right abrasive and bond for your job. This helps balance how long the wheel lasts, how fast it grinds, and the cost.

Environmental Conditions

The place where you use grinding wheels affects how well they work and how long they last. Temperature, humidity, dust, and coolant all matter.

-

High temperatures make wheels get bigger, which can cause problems.

-

Humidity changes how well coolant works and can hurt the wheel.

-

Dust and dirt block the wheel’s holes and make it cut worse.

-

Bad air flow and poor dust control make things dirty and lower performance.

People often forget to use coolant or store wheels right. Oil or metal bits can also get on the wheel and cause damage. These mistakes make wheels wear out faster.

Block Quote: Keep your workshop stable, use coolant the right way, and store wheels carefully. This will help your grinding wheels last longer and work better.

Usage Practices and Wheel Life

Speed and RPM

How long a grinding wheel lasts depends on using the right speed. Operators need to keep the surface feet per minute (sfpm) steady as the wheel gets smaller. When a diamond grinding wheel’s diameter shrinks, you should raise the RPM. This keeps the sfpm the same. Doing this stops too much stress on the abrasive grains. It also helps prevent the wheel from breaking early. Never use a wheel faster than its top RPM. This can be unsafe and make the wheel wear out faster. The table below shows the best speeds for different grinding jobs:

|

Grinding Type |

Recommended Speed Range (sfpm) |

|---|---|

|

Cylindrical Grinding |

5000 to 6500 sfpm (typical) |

|

Surface Grinding |

4000 to 6500 sfpm |

|

Tool Grinding |

5000 to 6000 sfpm |

Using the right pressure and speed helps you get good results. It also makes your diamond grinding wheel last longer.

Pressure and Feed Rate

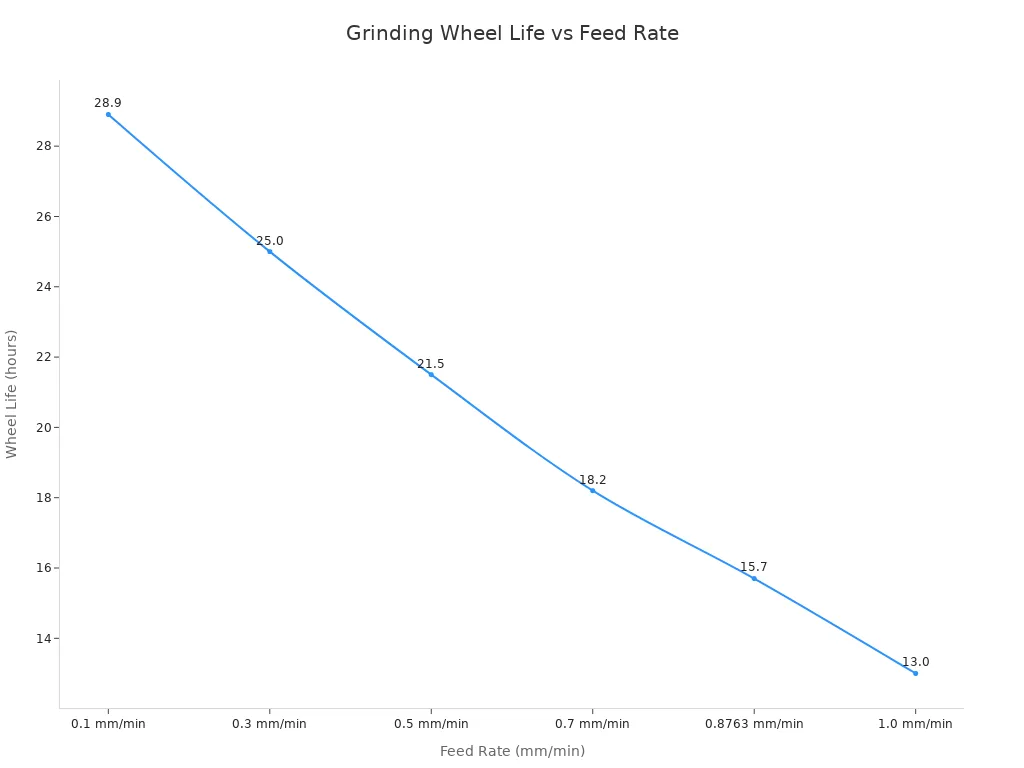

Too much pressure during grinding wears out the diamond grinding wheel fast. Operators should use steady, gentle pressure to protect the wheel. Pushing too hard can make the abrasive grains dull. It can also glaze the wheel or even cause cracks. The feed rate matters too. Lower feed rates help the wheel last longer. Higher feed rates make it wear out faster. The chart below shows that wheel life drops when feed rate goes up:

Keeping pressure and speed in the right range helps grinding work better and faster.

Coolant and Lubrication

Cooling and lubrication are important for making a diamond grinding wheel last longer. Coolant lowers friction and heat. This protects both the wheel and the workpiece. Lubrication helps wash away debris and stops build-up that can hurt the wheel. Operators should pick the right coolant, keep it clean, and aim it where the wheel touches the material. Regular checks, like filtering and checking coolant levels, help the system work well. Good cooling and lubrication make grinding better and help machines work well.

Tip: Always use clean coolant and the right lubrication. This stops overheating and helps your diamond grinding wheel last longer.

Vibration and Balance

Vibration can hurt a diamond grinding wheel and make it wear out faster. Moisture or mounting the wheel wrong often causes vibration. Operators should take wheels off after use and store them flat. This helps stop moisture problems. Balancing the wheel is important too. Mount the wheel right, balance it by hand or with a machine, and check it after dressing. Balanced wheels wear down less, grind better, and give good results.

Note: Check and balance your diamond grinding wheel often. This keeps you safe, gives better grinding, and helps the wheel last longer.

Maintenance for Longer Wheel Life

Inspection and Safety

Checking grinding wheels often keeps them safe and helps them last longer. Operators must turn off and unplug machines before checking wheels. They take off the wheel and look for cracks or chips. If they see any damage, they change the wheel right away. They check if the wheel is straight by putting it on a flat surface. This helps them see if it wobbles. They also look at mounting flanges for wear to keep the wheel attached well. Balance checks with a stand or arbor stop vibration. Operators watch the expiry date because most wheels last about three years. Storing wheels in dry, clean places keeps them strong. The ring test uses a tap with a non-metal tool to find hidden cracks. If the wheel makes a clear ring, it is safe to use. These steps help stop accidents and make wheels last longer.

Safety tip: Operators should check safety guards, work rests, and cords before using the grinder. Tag and remove any grinder with problems to keep everyone safe.

Dressing and Truing

Dressing and truing are important for keeping grinding wheels working well and lasting longer. Dressing cleans and sharpens the wheel by taking off old debris and worn grains. This brings out new grains and helps the wheel cut better. Truing fixes the wheel’s shape and makes it balanced again. Both steps keep the wheel sharp and shaped right for good grinding. Dressing the wheel the right way stops overheating and burn marks on the workpiece. Operators use the correct tools and follow the maker’s rules for how often and how to do it. Doing dressing and truing often helps the wheel last longer and makes grinding work better.

|

Maintenance Step |

Purpose |

Benefit for Lifespan |

|---|---|---|

|

Dressing |

Cleans and sharpens |

Restores cutting ability, reduces wear |

|

Truing |

Reshapes and balances |

Prevents vibration, ensures precision |

Cleaning and Storage

Cleaning and storing grinding wheels the right way helps them last longer. Operators keep wheels in dry, airy places with steady temperatures. They keep wheels away from water, oil, and chemicals that can hurt them. Using racks or cabinets stops wheels from getting stacked and damaged. Thin slice wheels need spacers between each one so they do not crack. Before using, operators clean wheels with brushes or air and check for chips or dirt. Carrying wheels carefully stops them from breaking by accident. Sorting and labeling wheels by type helps avoid mix-ups. Checking and turning stored wheels often stops flat spots and helps them wear evenly. Following the maker’s advice for care and storage keeps wheels in good shape and makes them last longer.

Note: Storing wheels the wrong way lets in water and big temperature changes, which makes them weak and shortens their life. Always keep wheels in their original box or a safe cover.

Monitoring and Replacement Factors

Signs of Wear

Operators can spot wheel wear by looking for several clear signs.

-

Uneven wear, cracks, chips, or glazing often appear on the wheel’s surface.

-

The wheel may lose its original shape or profile.

-

Grinding may take longer, and the machine may remove less material.

-

The workpiece may show a rough finish or poor quality.

-

Increased vibration or strange noises, such as squealing or rattling, can happen during use.

-

Heat may build up on the workpiece, and coolant may not flow well.

-

Some wheels have lines or color changes that show wear.

-

If the wheel gets close to its recommended lifespan, it should be checked.

Operators should always inspect wheels before use. These signs help prevent accidents and keep grinding safe.

When to Replace

Grinding wheels need replacement when they show too much wheel wear or damage.

-

If the wheel cannot grind well, or if it creates too much heat, it should be replaced.

-

A rough or uneven finish on the workpiece means the wheel is no longer effective.

-

Cracks found by the ring test signal a safety risk and require immediate replacement.

-

If maintenance or dressing does not fix the problem, the wheel has reached the end of its life.

-

Wheels that cause safety risks or lower grinding quality must be removed.

OSHA standards require a ring test before mounting. The wheel must make a clear sound. If not, it should not be used. Operators must also check that the spindle speed does not go over the wheel’s limit.

Documentation

Keeping records of grinding wheel use helps extend wheel life.

-

Operators should track grinding strategies, dressing times, cutting volumes, and cycle times.

-

By recording this data, they can spot problems like vibration or too much heat.

-

Adjusting grinding and dressing based on records can reduce cycle times and make the wheel last longer.

-

Working with manufacturers and sharing usage data can help create better wheels.

Good documentation lets teams find and fix problems early. This saves money and keeps grinding safe and efficient.

Diamond Grinding Wheel Considerations

Application Factors

Picking the right diamond grinding wheel for each job is important. This helps workers get good results and makes the wheel last longer. Many things affect how long a diamond grinding wheel will work:

-

Material Compatibility: Workers must pick a wheel bond type, like metal, vitrified, or resin, that matches how hard the material is. This stops the diamond grinding wheel from wearing out too fast.

-

Desired Finish and Precision: If a job needs a smooth finish or high accuracy, use a finer grit and a harder bond. These choices change how fast the diamond grinding wheel wears down.

-

Wheel Speed and Durability: Each bond type works best at certain speeds. Using the right speed helps the diamond grinding wheel last longer.

-

Machine Specifications: Workers should match the diamond grinding wheel to the machine’s power and speed. This step helps the wheel work better and last longer.

-

Economic Factors: Balancing cost and durability means fewer wheel changes and more work done.

-

Suitable Materials: Different materials, like concrete, stone, metal, and ceramics, need the right diamond grinding wheel for each job.

-

Recommended RPM: Staying within the recommended RPM for the wheel size stops damage and early wear.

-

Dry vs. Wet Grinding: Wet grinding with a diamond grinding wheel lowers heat and dust. This helps the wheel last longer. Dry grinding is faster but wears the wheel out more quickly.

-

Grinding Pressure and Speed: Too much pressure or speed can make the diamond grinding wheel wear out fast. Workers should always follow the maker’s rules.

-

Maintenance and Storage: Cleaning, checking, and storing the diamond grinding wheel the right way keeps it in good shape.

Tip: Workers should always check the material and machine before picking a diamond grinding wheel. This easy step can stop the wheel from failing early.

Cooling and Pressure

The diamond grinding wheel needs special care with cooling and pressure. Oil-based coolants work better than water-based ones for these wheels. Oil lubricants help the diamond grinding wheel last longer, even if they do not cool as well as water. The thickness of the grinding coolant matters. If the coolant is too thick, it can cause hydroplaning. If it is too thin, it does not give enough lubrication. This is more important than for milling coolants.

Regular wheels often use water-based coolants to remove heat. But the diamond grinding wheel works better with oil coolants that balance lubrication and wheel life. Additives in grinding coolants help them handle higher heat and give lubrication under pressure.

New designs have pressurized cooling channels inside the diamond grinding wheel. These channels help coolant reach the grinding area and lower the temperature by over 50%. This is important when grinding superalloys and hard materials. Higher coolant pressure and better flow lower the grinding temperature and make the surface smoother. Workers should use the right coolant and pressure for each diamond grinding wheel to get the best results.

Note: Using the right cooling method and pressure keeps the diamond grinding wheel from getting too hot and wearing out too soon.

Operators can make a grinding wheel last longer by picking the right one. They should use the correct speed and do regular maintenance. It is important to check wheels often and store them safely. Good habits help every grinding wheel work better and last longer. Readers can start with one new habit today. Small changes make grinding safer and more efficient.

FAQ

How often should operators inspect grinding wheels?

Operators need to check grinding wheels every time before use. They look for cracks, chips, or if the wheel is worn unevenly. Checking often helps stop accidents and keeps grinding safe.

What is the safest way to store grinding wheels?

Operators keep grinding wheels in dry and clean places. They use racks or cabinets so wheels stand up straight. Wheels should stay away from water, oil, and chemicals.

Can using the wrong coolant damage the grinding wheel?

Yes. The wrong coolant can make the wheel get too hot and wear out faster. Operators should use the coolant the wheel maker says is best.

Why does wheel balance matter during grinding?

Wheel balance helps stop vibration and makes grinding better. Balanced wheels last longer and help machines run well. Operators check balance after putting on and fixing the wheel.

Contact Us

For More Grinding Solution or Customized Abrasive Tools