Selecting the right CNC grinding machine is a critical decision for your precision manufacturing operations. The global market for CNC grinding machines is growing, reflecting their importance in modern manufacturing.

| Metric | Value |

|---|---|

| Projected CAGR (2025 – 2035) | 3.89% |

| Market Size 2025 | 4.665 (USD Billion) |

| Market Size 2035 | 6.834 (USD Billion) |

Your choice of machine directly impacts grinding performance and precision. A methodical approach to evaluating key considerations and features ensures your investment pays off.

Note: The right machine boosts productivity. It also secures your long-term return on investment. This makes the selection process for CNC grinders vital for success.

Key Takeaways

- Choose a CNC grinding machine that fits your parts. It must handle their size and weight. This helps with future projects.

- Look for high accuracy and a strong machine frame. This ensures parts are made correctly. It also makes the machine last longer.

- The spindle and grinding wheel are very important. Match their power and type to your materials. This helps make good parts.

- A good control system makes the machine easy to use. Automation features like robots help make more parts faster. This saves time and effort.

- Think about coolant, lubrication, and support from the maker. These things keep the machine running well. They also help you make money over time.

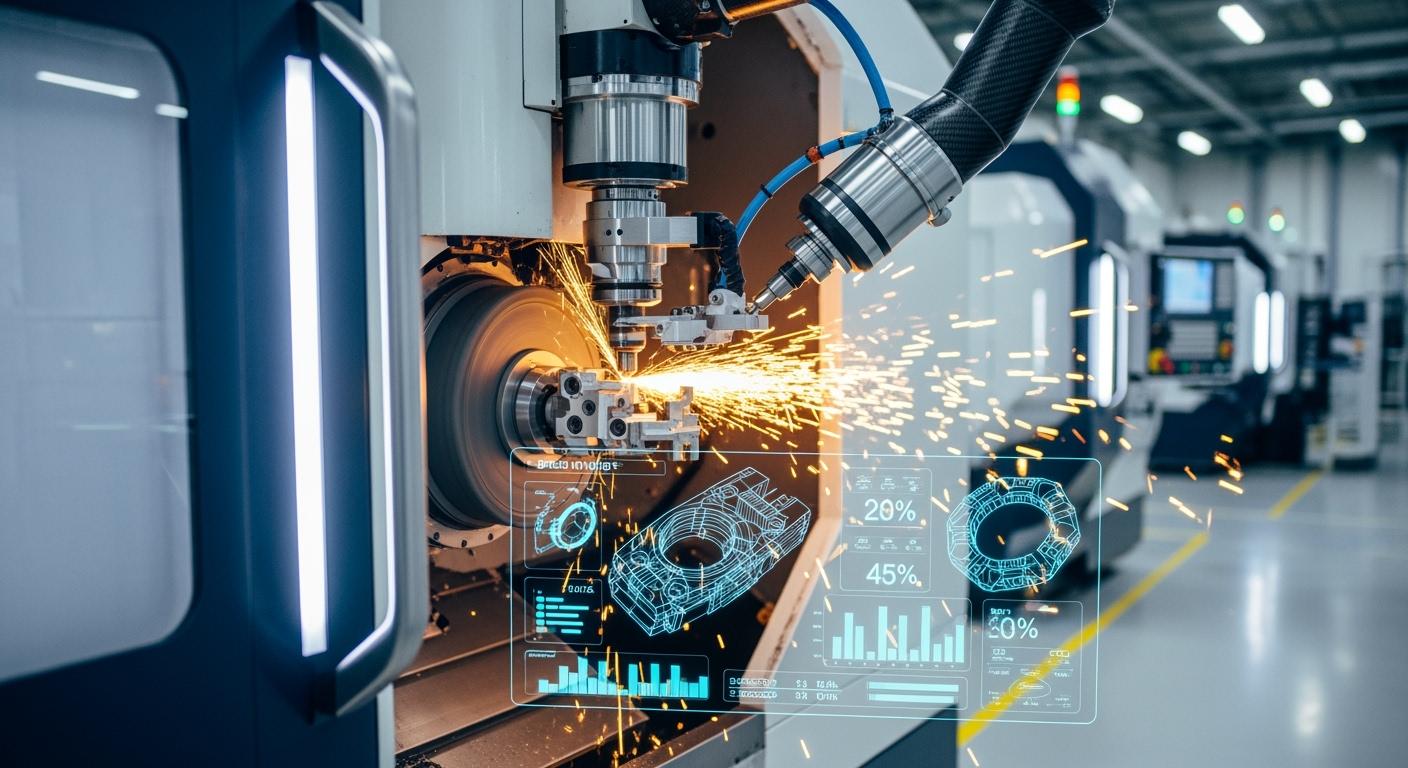

Core Specifications for New CNC Grinding Machines

When you evaluate new CNC grinding machines, you must start with the core specifications. These foundational features determine if a machine can handle your specific manufacturing tasks. Getting these right is the first step toward achieving your production goals.

Workpiece Size and Weight Capacity

First, you need to confirm the machine can physically accommodate your parts. Your workpiece dimensions—including its length, diameter, and weight—define the minimum capacity your CNC grinders must have. You should check the machine’s work envelope to ensure it fits your largest and smallest components.

Note: Always select a machine with a capacity slightly larger than your current needs. This provides flexibility for future projects.

The table below shows examples of specifications for different machine models.

| Machine Model | Workpiece Length (mm/inch) | Workpiece Diameter (mm/inch) | Max. Workpiece Weight (kg/lbs) |

|---|---|---|---|

| S30 | 1000 / 39.4 | 449 / 17.6 | 130 / 286 |

| S20 | 650 / 25.6 | N/A | 20 / 44 |

| favorite | 1600 / 63 | N/A | 150 / 330 |

Grinding Accuracy and Repeatability

Accuracy is paramount in precision manufacturing. You must look for a CNC grinding machine that delivers tight tolerances consistently. High precision grinding often requires tolerances below ±25 micrometers (±0.001 inches). Repeatability ensures that the first part and the last part of a production run have the same high-quality surface finish. This consistency is vital for modern quality control and is a key indicator of a machine’s performance. A CNC tool grinder with excellent accuracy guarantees a superior final finish.

Machine Rigidity and Construction

The structural integrity of a CNC machine directly impacts its ability to absorb vibrations during the grinding process. A rigid frame minimizes chatter, leading to a better surface finish and greater precision. Manufacturers often use materials like cast iron or epoxy granite for the machine base due to their excellent damping properties.

| Material | Vibration Damping Properties |

|---|---|

| Cast Iron | Good damping from its material structure. |

| Epoxy Granite | Excellent damping, up to 10 times better than cast iron. |

Modern manufacturers use advanced tools like Finite Element Analysis (FEA) to optimize structural design. FEA helps identify and strengthen weak points, reduce deformation under load, and improve the machine’s overall performance. This analysis ensures the final design provides maximum stability for high precision operations.

Spindle Power and Wheel System

The spindle and wheel system is the heart of all CNC grinding machines. Its performance directly determines your manufacturing capabilities. You must remember the grinding wheel is as critical as the machine itself. For hard materials like ceramics or alloys, you need high-performance options like diamond grinding wheels. Specialized suppliers, such as Aimgrind, offer customized wheel solutions. They match the bond and abrasive to your specific application, which maximizes your CNC machine’s performance and helps you create high-performance parts.

Spindle Power and Speed Range (RPM)

You need to match the spindle’s power and speed to your materials and grinding operations. A high-torque spindle at lower RPMs is essential for achieving a high-quality surface finish on certain materials.

- It maintains cutting force for dense materials like carbon composites.

- It allows for steady, powerful cuts that prevent tool chatter.

- This setup reduces overheating, which protects the workpiece surface.

Selecting the right spindle features ensures you achieve the desired surface finish and dimensional precision.

Spindle Design and Bearing Quality

The spindle’s internal design is crucial for long-term reliability. High-quality bearings protect the spindle from contamination and wear. Many modern CNC grinders use sealed-for-life bearing systems.

- These bearings are maintenance-free, as the lubricant lasts the bearing’s entire service life.

- The sealed design prevents contaminants from entering, reducing wear and tear.

- This protection extends bearing life and leads to fewer failures, ensuring consistent machine performance.

Automated Wheel Dressing Systems

An automated wheel dressing system keeps your grinding wheel in optimal condition. This process sharpens the wheel’s surface and ensures its profile is accurate for high precision work. Different dressing tools offer unique benefits.

| Feature | Rotary Dressers | Fixed Dressers |

|---|---|---|

| Production Capacity | High production capacities | Smaller, specialized setups |

| Precision | Accurate and repeatable results | Good for specific geometries |

| Application | Complex profiles, longer usage periods | Sharp edges, specific geometries |

Modern CNC systems often use acoustic emission sensors to improve dressing precision. These sensors “listen” to the contact between the dresser and the wheel. This feedback allows the CNC to make micro-adjustments, ensuring a perfect wheel surface for every grinding cycle. This technology is vital for a CNC tool grinder used in precision manufacturing.

The CNC Grinding Machine Control System

The CNC control system is the brain of your grinding machine. It translates your design into precise movements. A powerful and intuitive control system is essential for efficient manufacturing and achieving high precision. You should evaluate its usability, automation features, and software integration capabilities.

CNC Control Usability and Interface

You need a control system that your operators can use with confidence. A user-friendly interface simplifies complex grinding tasks and reduces the learning curve. Look for features that replace intricate code with straightforward prompts and menus. These modern interfaces allow operators to quickly adjust settings and monitor performance, which minimizes human error. When selecting CNC grinders, you will encounter several popular control systems.

| Control System | Strengths | Best Use Cases |

|---|---|---|

| Fanuc | Global support, reliability | High-volume machining |

| Siemens | Advanced 5-axis, automation | Aerospace, mold making |

| Heidenhain | Precision, finish quality | Mold/die, precision 5-axis |

Choosing the right CNC control helps your team work more efficiently and reduces setup times.

Advanced Automation and Software

Advanced software and automation features transform a good machine into a great one. Conversational programming, for example, allows operators to program parts directly at the machine by answering simple questions. This can reduce setup times by over 75%. Other automated benefits come from hardware additions.

- Robotic Loaders: These systems automate part loading and unloading, allowing the machine to run unattended for longer periods.

- In-Process Probes: These tools automatically measure the workpiece during the grinding cycle. They can also detect improperly clamped tools, ensuring process control.

- Adaptive Control: This software dynamically adjusts grinding parameters to compensate for wheel wear, ensuring consistent quality without manual intervention.

These automation tools significantly boost productivity for all types of CNC grinding machines.

CAD/CAM Software Integration

Seamless integration between your CAD/CAM software and the CNC is vital for complex jobs. This direct link allows you to move from a digital design to a finished part quickly and accurately. For a CNC tool grinder tasked with creating complex profiles, this integration is non-negotiable. It accelerates the production cycle and ensures design modifications are followed exactly. This systematic workflow eliminates human error, increases efficiency, and delivers the high-quality, reproducible results required in modern precision manufacturing.

Key Factors for Choosing a CNC Grinding Machine

Beyond core specifications, several operational factors are vital when choosing a CNC grinding machine. These features directly influence your machine’s daily performance, longevity, and overall profitability. A careful review of these elements ensures your investment supports efficient and reliable manufacturing.

Coolant and Filtration Efficiency

The grinding process generates significant heat. An effective coolant system is crucial to prevent thermal damage to the workpiece surface. The system’s filtration efficiency determines the quality of your finish. Clean coolant prevents debris from causing micro-scratches on the final surface. For a high-quality surface finish, you need a system that removes tiny particles.

| Desired Finish Quality | Recommended Filtration Size |

|---|---|

| Standard Roughing | 50 – 100 Microns |

| Fine Finish (Ground) | 10 – 20 Microns |

| Mirror Finish (Polished) | < 5 Microns |

Advanced filtration, like a magnetic separator combined with a paper filter, extends coolant life and improves the machine’s grinding performance. This ensures a consistent, high-quality finish on every part.

Automatic Lubrication and Safety

Proper lubrication is the lifeblood of all CNC grinders. Inadequate lubrication is a primary cause of expensive repairs and unplanned downtime. An automatic lubrication system protects critical components from premature wear. It prevents metal-on-metal contact, which reduces friction and heat buildup.

Note: Properly lubricated CNC grinding machines can achieve a 300% longer component life and experience 90% fewer unplanned shutdowns.

This system is one of the most important features for maintaining machine health and ensuring consistent high precision operations. It safeguards your investment and keeps your production running smoothly.

Other factors to consider when choosing a CNC machine

Your evaluation should also include long-term operational needs and support. Consider these additional factors to ensure the machine aligns with your business goals:

- Manufacturer Support: Look for suppliers who offer comprehensive training, after-sales service, and preventive maintenance programs. This support is invaluable for maximizing machine uptime.

- Automation Potential: For high-volume manufacturing, you need features like robotic loaders and in-process measurement. Automation boosts productivity and allows for “lights-out” operation.

- Machine Flexibility: Your machine should handle a diverse range of materials and part geometries. This flexibility prepares you for future projects and changing production demands.

Your success in precision grinding depends on several key features. You must evaluate machine accuracy, the spindle, and a quality diamond grinding wheel. Intuitive controls and strong manufacturer support are also vital. A thorough review transforms this purchase into a strategic investment for your machine.

The right machine and consumables are fundamental to achieving long-term manufacturing excellence and successful grinding operations.

FAQ

What is the most critical feature to evaluate in a new CNC grinding machine?

You should prioritize grinding accuracy and repeatability. These specifications directly impact part quality. A machine with high precision ensures every component meets tight tolerances. This capability is fundamental to modern manufacturing and guarantees consistent, high-quality results.

How important is the grinding wheel choice for my machine?

The grinding wheel is as vital as the machine itself. High-performance wheels, like diamond grinding wheels, unlock your machine’s full potential. Specialized suppliers like Aimgrind match the wheel to your material, maximizing efficiency and achieving a superior surface finish.

Why is machine rigidity important for long-term performance?

A rigid machine frame absorbs vibrations during grinding. This stability prevents chatter, leading to better surface finishes and greater accuracy. It also reduces wear on machine components, ensuring long-term reliability and protecting your investment.

Should I invest in automation features for my new machine?

Yes, if you need to boost productivity. Automation features like robotic loaders and in-process probes allow for “lights-out” operation. They reduce manual labor, minimize errors, and increase throughput, providing a significant return on your investment in high-volume settings.

Contact Us

For More Grinding Solution or Customized Abrasive Tools