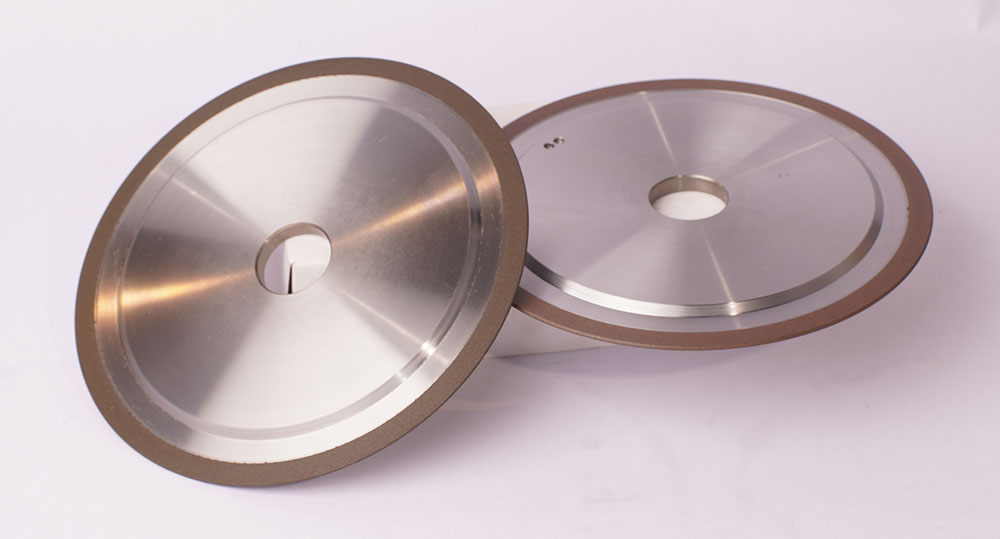

CBN grinding wheels deliver significant advantages for high-performance grinding operations. These tools are becoming essential for workshops aiming to stay competitive. The key benefits include:

- Superior durability

- Exceptional thermal conductivity

- Enhanced efficiency

- Consistent precision

- Long-term cost savings

This outstanding performance is a primary reason the global market for these wheels is projected to grow at a 5.8% compound annual growth rate.

Industry leaders like Aimgrind demonstrate how these advantages from cbn wheels grinding translate directly into better production quality, faster grinding, and greater cost-effectiveness for manufacturers using CBN.

Key Takeaways

- CBN grinding wheels last longer than regular wheels. They are very hard and strong.

- These wheels keep things cool during grinding. This stops parts from getting damaged by heat.

- CBN wheels help you work faster. They remove material quickly and reduce machine stops.

- They make parts very precise. This means every part is the same and meets exact sizes.

- Using CBN wheels saves money over time. They last longer and make fewer mistakes.

1. UNMATCHED DURABILITY AND LIFESPAN

The durability of CBN grinding wheels sets them apart from conventional abrasives. This exceptional resilience is a direct result of the material’s physical properties, leading to a longer operational life and more reliable performance. Manufacturers gain a significant competitive edge by investing in these robust tools.

THE HARDNESS OF CBN

Cubic Boron Nitride (CBN) is the second hardest material known, surpassed only by diamond. Its Knoop hardness value is approximately 4,500, which is more than double that of conventional abrasives like aluminum oxide (around 2,100). This enhanced hardness gives CBN wheels incredible strength for demanding grinding tasks. The material’s structure provides high abrasion resistance, allowing it to cut through hardened ferrous metals with ease.

EXTENDED WHEEL LIFE

The enhanced hardness of CBN directly translates to longer tool life. Unlike traditional wheels that dull quickly, CBN wheels maintain their sharp cutting edges for extended periods. This superior durability means fewer wheel changes, less machine downtime, and more consistent grinding operations.

A Quick Comparison: CBN vs. Aluminum Oxide The differences in performance and longevity are clear when comparing these two materials.

| Feature | Aluminum Oxide | CBN |

|---|---|---|

| Wear Resistance | Dulls over time, losing its bite. | Resists wear even in high-heat environments. |

| Wheel Life | Shorter due to rapid dulling. | Significantly longer wheel life. |

| Hardness | Durable but much softer than CBN. | Super hard, ideal for tight tolerances. |

CONSISTENT TOOL GEOMETRY

Maintaining consistent tool geometry is crucial in high-volume production. The superior wear resistance of CBN ensures that the wheel’s shape and profile remain intact over many cycles. This stability allows the wheels to produce parts with uniform precision from start to finish. CBN’s ability to hold consistent sharp edges minimizes material loss from the cutting surface, which is essential for achieving tight tolerances and reducing scrap rates during the grinding process.

2. KEY THERMAL BENEFITS

The thermal benefits of CBN grinding wheels are a game-changer for precision manufacturing. These wheels manage heat exceptionally well, protecting both the tool and the workpiece from damage during intense operations. This efficiency leads to higher quality parts and more reliable production.

COOLER GRINDING ACTION

CBN wheels provide a “cool grinding” action due to the material’s high thermal conductivity. Cubic Boron Nitride dissipates heat far more effectively than conventional abrasives. For instance, CBN has a thermal conductivity of around 240 W/mK, while alumina is only about 37 W/mK. This property allows heat to move quickly away from the grinding zone and into the wheel itself. The result is a cooler process that maintains the integrity of heat-sensitive materials.

PREVENTING WORKPIECE DAMAGE

Excessive heat during grinding can cause serious problems like burns, micro-cracks, and loss of hardness in the workpiece. The cool cutting action of CBN directly prevents this thermal damage. Studies show that workpieces ground with certain vitrified bond CBN wheels exhibit only minor cracks and burn marks compared to those ground under less optimal conditions.

This reduction in thermal stress is crucial. It lowers scrap rates and ensures every finished part meets strict quality standards, which can also reduce or eliminate the need for liquid coolants, lowering operational costs.

SUPERIOR HEAT RESISTANCE

The superior heat resistance of CBN ensures the wheels perform reliably under extreme conditions. In an oxygen atmosphere, CBN forms a protective layer that prevents oxidation up to approximately 1300 °C. This stability means the abrasive grains do not dull or break down easily when subjected to the high temperatures generated during aggressive grinding. This resilience allows for faster material removal rates without compromising the wheel’s structure or performance, making these wheels ideal for demanding applications.

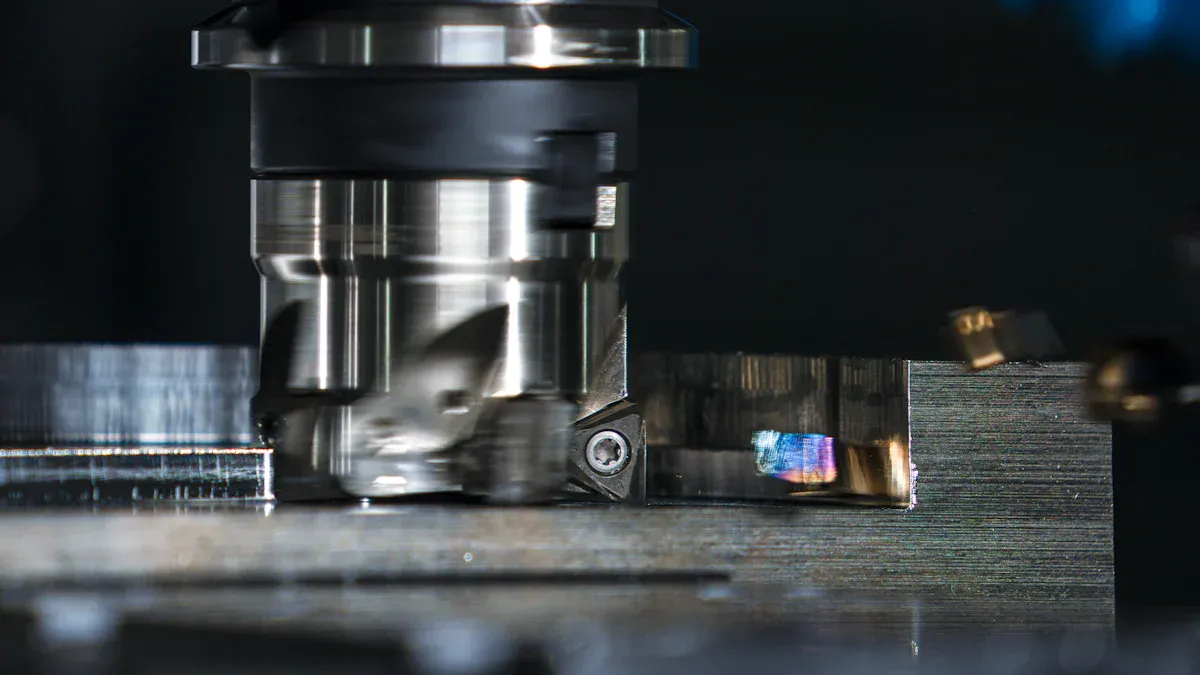

3. ENHANCED GRINDING EFFICIENCY

In 2025, manufacturing success depends on speed and efficiency. CBN grinding wheels deliver a major boost in productivity. They allow workshops to complete jobs faster, reduce interruptions, and improve overall workflow. This high grinding efficiency is a key reason for their growing adoption.

FASTER MATERIAL REMOVAL

CBN wheels remove material much faster than traditional abrasives. The extreme hardness of CBN allows for aggressive grinding without losing sharpness. This means operators can achieve desired results in less time. The performance difference is clear when comparing material removal rates (MRR) across different abrasives.

| Abrasive Material | Typical Application / Material | Material Removal Rate (MRR) Characteristics |

|---|---|---|

| Cubic Boron Nitride (CBN) | Hardened steel gears (hard-to-grind ferrous metals) | High MRR, maintained even under high-pressure and high-temperature conditions |

| Aluminum Oxide | General-purpose grinding, various gear materials | Decent rate of material removal |

| Silicon Carbide | Cast iron, non-ferrous metals | Higher MRR than aluminum oxide, due to sharper grains |

REDUCED MACHINE DOWNTIME

Downtime for wheel changes and maintenance slows down production. CBN wheels last significantly longer, which directly reduces these costly interruptions. With adaptive control systems, CBN wheels can last up to five times longer than conventional wheels. This extended life means machines spend more time grinding and less time idle.

The financial impact is substantial. Manufacturers using CBN often see savings in grinding costs from 20 to 50 percent. This improvement comes from reduced wheel maintenance and fewer machine stops.

FASTER CBN WHEELS GRINDING

The benefits of cbn wheels grinding combine to shorten the entire production cycle. For tasks like inner hole grinding, these wheels allow for faster speeds and feeds, effectively doubling processing efficiency. The long life of the wheels also eliminates time spent on dressing and replacement. For gear grinding, cbn wheels grinding enables high-speed work while preventing burns and maintaining accuracy. This consistent performance ensures a faster, more reliable process from start to finish.

4. PRECISION AND CONSISTENCY

Precision manufacturing demands that every part is identical. CBN grinding wheels provide the stability needed to produce high-quality components consistently. Unlike traditional abrasives that wear down quickly, CBN wheels hold their shape, ensuring every grinding pass delivers the same result. This reliability is essential for automated and high-volume production lines.

REPEATABLE FORM HOLDING

The ability of a wheel to maintain its profile is crucial for part-to-part uniformity. The superior hardness of CBN ensures these wheels resist wear and hold their form for thousands of cycles. This improved consistency is a major advantage.

For complex jobs like gear grinding, dressable vitrified CBN wheels allow operators to make precise profile corrections. This capability ensures the final part meets exact specifications. Strong bond systems also lock the CBN particles in place, resulting in a durable wheel that maintains its cutting performance over time.

ACHIEVING TIGHT TOLERANCES

Modern industries like aerospace and automotive require parts with extremely tight tolerances. The grinding process with CBN is ideal for this work because it removes material with exceptional control, creating smooth surfaces and precise dimensions.

- Aerospace components often need very low surface roughness (Ra) and strict dimensional accuracy.

- Using modern CNC machines, operators can grind parts like aircraft control pistons to an accuracy of one or two microns.

This level of precision is difficult to achieve with other methods, making CBN essential for high-quality manufacturing.

THE AIMGRIND CBN ADVANTAGE

Achieving a consistent surface finish and exact dimensions depends on using the right tool. Aimgrind specializes in customized cbn grinding wheels to meet specific application needs. By offering wheels with vitrified, resin, and electroplated bonds, Aimgrind helps customers optimize their cbn wheels grinding process. This tailored approach ensures manufacturers can achieve their desired quality and a consistent surface finish, turning precision goals into reality.

5. LONG-TERM COST SAVINGS

While CBN grinding wheels may have a higher initial price, they deliver significant long-term cost savings. Manufacturers see a strong return on investment by looking beyond the purchase price to the total cost of ownership. These advanced wheels reduce operational expenses and boost overall profitability.

TOTAL COST OF OWNERSHIP

Evaluating the total cost of ownership (TCO) reveals the true value of CBN. A complete cost analysis considers more than just the price tag. Key factors include:

- Tool Life: The exceptional durability of CBN leads to reduced tool replacement.

- Operational Costs: This covers energy use, coolant, and maintenance expenses.

- Labor Hours: Faster grinding cycles and fewer wheel changes save valuable time.

- Downtime: Extended maintenance intervals keep machines running longer.

By analyzing the cost-per-part, companies can directly compare the efficiency of CBN wheels against conventional abrasives and justify the investment.

REDUCING SCRAP RATES

Precision and consistency directly impact a company’s bottom line. The cool grinding action of CBN prevents thermal damage, and its form-holding ability ensures every part meets tight tolerances. This reliability minimizes errors and dramatically lowers the scrap rate. Fewer rejected parts mean less wasted material, labor, and machine time, contributing to substantial savings.

The superior performance of these wheels also means reduced tool dressing requirements. This not only saves time but also extends the life of the grinding wheel, further lowering overall costs.

WHEEL RE-PLATING AND RE-TRUING

The savings continue even after a wheel wears down. Many CBN wheels, especially those with an electroplated bond, are not single-use tools. The sturdy steel core can be stripped and re-plated with new CBN abrasive. A typical core can be re-plated 2 to 5 times, depending on its condition. This re-plating process costs significantly less than buying entirely new wheels, making it an economical and sustainable choice for long-term grinding operations.

In summary, the benefits of CBN grinding wheels are clear: superior durability, cool grinding action, enhanced efficiency, reliable precision, and long-term savings. The total value from less downtime and fewer scrapped parts makes these advanced CBN wheels a strategic investment for any modern workshop.

As industries demand higher precision, the performance of your grinding process becomes critical.

To optimize your cbn wheels grinding and achieve a consistent surface finish, explore customized solutions. Aimgrind provides tailored wheels to boost your quality and keep you competitive.

FAQ

What materials can CBN grinding wheels grind?

CBN grinding wheels perform best on hard ferrous materials. They are ideal for grinding hardened steels, tool steels, and superalloys. Their exceptional hardness allows them to cut these tough materials with high efficiency and precision.

How do CBN wheels compare to conventional abrasives?

CBN wheels offer superior performance over traditional abrasives. They provide faster cutting action and cooler operation, which prevents workpiece damage. Their extended lifespan also means fewer wheel changes and less machine downtime, making them a more efficient choice.

Are CBN wheels suitable for high-speed grinding?

Yes, CBN wheels are designed for high-speed grinding. The material has exceptional hardness and thermal stability. This allows the wheels to maintain their sharpness and structural integrity even under the extreme heat and pressure of high-speed applications.

What are the different bond types for CBN wheels?

CBN wheels come in several bond types to suit different jobs. The most common options include vitrified, resin, and electroplated bonds. Each bond type offers unique characteristics for specific finish requirements, material removal rates, and tool life.

See Also

Understanding CBN Grinding Wheels: Their Function and Operational Principles

Selecting the Optimal Grinding Wheel for Your Carbide Tooling Needs

Exploring Diverse Grinding Wheel Varieties and Their Real-World Uses

Finding the Ideal Crankshaft Grinding Wheel Within Your Budget

Selecting the Perfect Bench Grinding Wheel Material for Specific Tasks

Contact Us

For More Grinding Solution or Customized Abrasive Tools