Successfully machining thin-walled parts to prevent deformation hinges on a few key strategies. This precision machining is vital, as demand for these parts grows in aerospace and medical sectors. The primary goal is to minimize forces that cause deformation. This requires careful clamping and controlled machining, as improper clamping can distort thin-walled components.

Key Takeaways

- Use special workholding like collet or vacuum chucks. These hold thin parts gently and evenly. This stops the parts from bending.

- Set machine speeds and cut depths carefully. Slow down the grinding process. This reduces heat and pressure on the thin parts.

- Pick the right grinding wheel. Use wheels that cut easily. This lowers the force needed and keeps the part from getting too hot.

- Use high-pressure coolant. This removes heat and chips. It keeps the part cool and clean during grinding.

- Monitor the grinding process. Sensors can find problems early. This helps fix issues before parts get ruined.

Workholding Strategies to Prevent Deformation

Proper workholding is the first line of defense against the deformation of thin-walled workpieces. The goal is to secure the component firmly without introducing stress that causes distortion. Low-force clamping systems are essential for successful CNC machining of delicate parts.

Diaphragm and Collet Chucks

Standard three-jaw chucks often create uneven pressure, leading to part deformation. Collet and diaphragm chucks offer a superior solution for thin-walled components.

A collet chuck provides a 360-degree grip around the workpiece. This design distributes clamping force uniformly across the entire circumference. The even pressure minimizes stress and is crucial for preventing deformation in delicate or thin-walled parts during machining. Diaphragm chucks operate on a similar principle, using a flexible plate for gentle, consistent clamping.

Magnetic and Vacuum Chucking

For some applications, eliminating mechanical clamping altogether is the best approach. Magnetic and vacuum chucks provide secure holding without physical clamps.

- Magnetic Chucks: These are ideal for ferrous materials. They use magnetic force to hold thin-walled parts, distributing the holding force evenly and avoiding the pressure points associated with mechanical clamping.

- Vacuum Chucks: These systems use suction to secure a component. This method is excellent for non-ferrous materials and parts with large, flat surfaces. However, vacuum clamping for non-rigid thin-walled parts can be complex and requires careful engineering to avoid deformation.

Custom Fixturing and Support Rings

Complex geometries often require specialized solutions. Custom fixtures are designed to match the exact shape of a component, maximizing surface contact and distributing clamping pressure. This is a key strategy to prevent deformation. For cylindrical thin-walled parts, external support rings are effective. These rings provide the necessary rigidity to the part during the CNC machining process, counteracting grinding forces and ensuring the component maintains its roundness. This level of custom support is vital for high-precision machining.

Optimize Parameters for Machining Thin-Walled Parts

Beyond workholding, your CNC machining parameters are critical. Aggressive machining generates excessive heat and pressure, the primary causes of deformation of thin-walled workpieces. Optimizing these settings is essential for successful machining of thin-walled parts.

Control Infeed and Cut Depth

The infeed rate and depth of cut directly control the force exerted on the component. For thin-walled parts, a conservative approach is best.

Use a shallow depth of cut to remove material gradually. This minimizes grinding pressure and heat buildup. A slower infeed rate gives the material time to cool between passes, which helps prevent deformation. This controlled machining approach is fundamental when working with delicate, thin-walled geometries.

Manage Wheel and Workpiece Speeds

Balancing wheel and workpiece speeds is a key factor in stable machining. An improper speed relationship can introduce vibration, or chatter, leading to poor surface finish and dimensional inaccuracies. When machining thin-walled parts, stability is paramount.

- Workpiece Speed: A workpiece rotating too quickly can cause instability and chatter. Reducing the rotational speed allows the grinding wheel to cut more effectively and stabilizes the CNC process.

- Speed Differential: The difference in speed between the grinding wheel and the workpiece affects the material removal rate. A greater differential removes material faster but also increases force. Finding the right balance is crucial for these parts.

- Part Positioning: Incorrect center height can also cause the part to bounce, resulting in chatter. Proper alignment ensures the thin-walled component maintains stable contact with the wheel.

Implement Spark-Out Passes

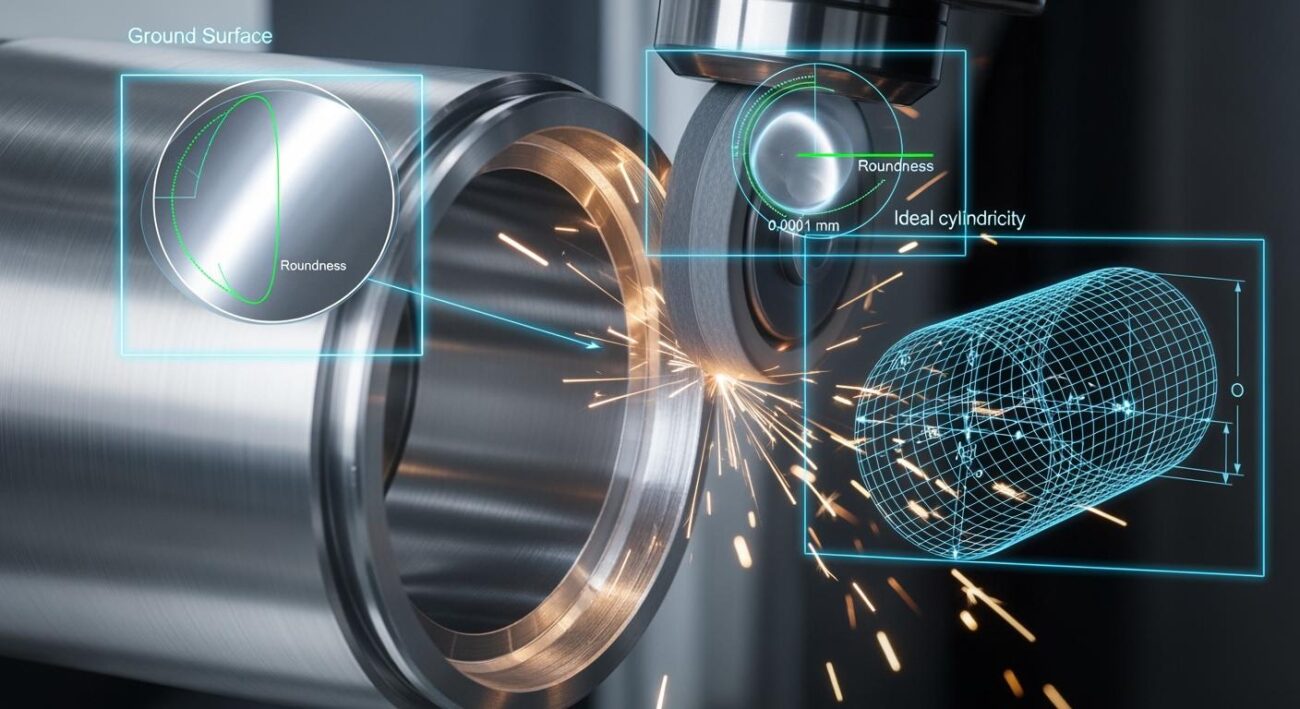

A spark-out pass is a finishing move in a precision grinding cycle. After the main material removal, the infeed is stopped, but the wheel continues to pass over the workpiece. This step is not optional for high-precision machining. It allows accumulated forces from the CNC machining cycle to relax. Any deflection in the system is corrected as the wheel removes the last microscopic bits of material. This process eliminates taper, ensures the part reaches its final dimension, and creates an optimal surface finish. Increasing the spark-out duration is an effective way to guarantee the geometry of thin-walled parts.

Grinding Wheel Selection and Conditioning

The grinding wheel is where the machining process meets the material. Its selection and condition directly influence the forces exerted on thin-walled parts. A poor choice can instantly negate even the best workholding and parameter settings.

Choose the Right Abrasive and Bond

A free-cutting grinding wheel is critical for the successful machining of thin-walled components. These wheels are designed to break down at a controlled rate, constantly exposing fresh, sharp abrasive grains. Dull grains do not cut; they plow through the material, which dramatically increases grinding forces and heat. A wheel that is too hard will not break down correctly, leading to increased surface roughness on the finished parts.

For hard or brittle thin-walled materials like ceramics or advanced alloys, a high-performance wheel is essential. As a specialist in customized grinding solutions, Aimgrind understands these challenges. Aimgrind’s diamond grinding wheels are an excellent choice for these demanding applications. Their exceptional sharpness and durability reduce grinding forces, minimize heat generation, and ultimately help prevent deformation.

The bond material is equally important. Vitrified bonds, for example, offer significant advantages for precision machining. Their rigid structure and high porosity allow for efficient coolant delivery and debris removal. This reduces heat buildup and lowers grinding forces, enhancing both accuracy and efficiency.

Use Effective Dressing Techniques

Dressing is the process of reconditioning the grinding wheel’s cutting face. It is not just for cleaning; it is a crucial step to restore the wheel’s geometry and sharpness. An improperly dressed wheel can have uneven wear on its face. This inconsistency directly translates to geometric errors and poor surface quality on the workpiece.

A wheel that is clogged or has lost its profile cannot maintain the tight tolerances required for thin-walled parts. Regular and precise dressing ensures the wheel cuts cleanly and consistently. This practice removes loaded material and dull abrasive grains, restoring the wheel’s optimal cutting ability. Proper conditioning is a fundamental requirement for any high-precision machining operation involving delicate components.

Advanced Process and Thermal Control

Controlling the grinding environment is just as important as controlling the machine. Advanced process and thermal controls provide real-time adjustments and safeguards. These systems are essential for preventing the thermal deformation that can ruin delicate, thin-walled components. They ensure process stability and part integrity.

Utilize High-Pressure Coolant

Heat is a primary enemy when machining thin-walled parts. Excessive heat causes thermal deformation, which compromises dimensional accuracy. High-pressure coolant is a powerful tool to manage this risk.

Coolant does more than just cool. Its primary role is to act as a defense mechanism, forcefully flushing chips away from the grinding zone. This action prevents chips from clogging the wheel or getting trapped between the wheel and the workpiece, which would increase friction and heat.

Effective coolant application is critical for maintaining the structural integrity of the component.

- Pressure Levels: Coolant pressures can reach up to 1,500 psi (103.4 bar) for robust metal-bond wheels. However, more friable wheels may require lower pressures to avoid premature breakdown.

- Heat Removal: A consistent flow of high-pressure coolant directly at the cutting interface removes heat efficiently. This rapid cooling is vital to prevent thermal deformation and maintain the part’s specified geometry.

- Improved Machining: By keeping the cutting zone clean and cool, high-pressure coolant enables a more stable machining process, leading to better surface finishes and higher accuracy.

Implement In-Process Monitoring

Modern CNC machining relies on data to achieve ultimate precision. In-process monitoring uses sensors to track the grinding cycle in real time. This technology allows the system to detect and correct issues before they lead to scrapped parts.

Acoustic emission (AE) sensors are particularly effective. These devices listen to the sounds generated during machining.

An innovative technique even uses the coolant flow to transmit grinding sounds to an AE sensor. This allows the system to detect the slightest contact between the wheel and workpiece. It can automate functions like gap elimination and verify that the wheel is properly dressed, extending wheel life and improving the quality of the finished parts.

This level of monitoring helps prevent problems that cause thermal deformation. Companies using advanced machine monitoring have virtually eliminated scrap from tool wear. They achieve this by using real-time data for predictive maintenance and process optimization. This approach provides operators with automated alerts and clear instructions to address issues immediately. By integrating non-contact sensors like lasers to measure workpiece dimensions during the CNC cycle, manufacturers can ensure final accuracy and integrity.

Achieving precision with thin-walled parts requires a systematic approach. It starts with controlled clamping and low-force clamping. Proper clamping is vital for these thin-walled parts. Careful clamping, smart clamping, and diligent clamping prevent deformation. Combining this focus on workholding with optimized parameters, correct wheel selection, and process monitoring is the only way to guarantee precision.

FAQ

What is the primary cause of deformation in thin-wall grinding?

Excessive grinding force and heat buildup are the main causes of deformation. These factors create stress within the material. The component distorts to relieve this stress, leading to dimensional inaccuracies and potential part failure.

Why is a standard 3-jaw chuck bad for thin parts?

A standard 3-jaw chuck applies concentrated pressure at three points. This uneven force easily distorts or damages delicate components. Diaphragm or collet chucks are better because they distribute clamping force evenly around the part’s circumference.

What are the biggest challenges machining thin-walled parts?

The biggest challenges machining thin-walled parts involve managing part rigidity and controlling heat. The components are prone to vibration and thermal expansion. This makes achieving tight tolerances and a good surface finish difficult without causing deformation.

How does a “free-cutting” wheel help prevent deformation?

A free-cutting wheel uses sharp abrasives that require less pressure to remove material. This action reduces grinding forces and heat generation. Lower force and heat are essential for successful machining thin-walled parts without causing distortion.

Contact Us

For More Grinding Solution or Customized Abrasive Tools