High-tech sectors are the leading industries benefiting from electroplated grinding tools. Key fields like aerospace and automotive require extreme precision for shaping exceptionally hard or complex materials. This demand for precision drives the global electroplated grinding wheel market, which was valued at US$2.5 billion in 2023. Manufacturers in these industries depend on the aggressive cutting action of the single-layer electroplated bond. This unique electroplated design makes achieving difficult shapes and tight tolerances possible.

Key Takeaways

- Electroplated grinding wheels help industries that need to shape very hard or complex materials with great accuracy.

- Aerospace and automotive industries use these wheels to make parts like engine components and brake systems very precise.

- Medical manufacturing uses these wheels to create sharp surgical tools and perfectly shaped implants from tough materials.

- The electronics industry uses these wheels to cut delicate materials like silicon wafers and hard ceramics without breaking them.

- These special wheels use diamond or CBN to cut materials, making them strong and long-lasting for tough jobs.

Key Industries and the Need for Precision Grinding

Modern industries face significant manufacturing hurdles. They work with advanced materials that are difficult to shape using standard tools. This challenge drives the need for specialized solutions capable of high-precision grinding.

Why These Sectors Depend on Specialized Wheels

High-tech sectors require specialized wheels because of the unique materials they use. These materials present several grinding challenges:

- Complex Geometries: Aerospace and medical parts often have intricate shapes that standard wheels cannot produce.

- Extreme Material Properties: Superalloys, composites, and ceramics are extremely tough, hard, or brittle.

- Material Damage Prevention: Incorrect grinding can cause chipping, cracking, or delamination, compromising the part’s integrity.

Achieving the necessary precision without causing thermal damage or residual stress is critical. An electroplated grinding wheel maintains its exact shape because the superabrasive is bonded to a pre-formed core. This single, aggressive electroplated layer ensures consistent performance for complex profiles.

The Role of Superabrasives like Diamond and CBN

Electroplated wheels use superabrasive materials to cut these tough materials. The two primary superabrasives are Diamond and Cubic Boron Nitride (CBN). The choice of superabrasive depends entirely on the workpiece material.

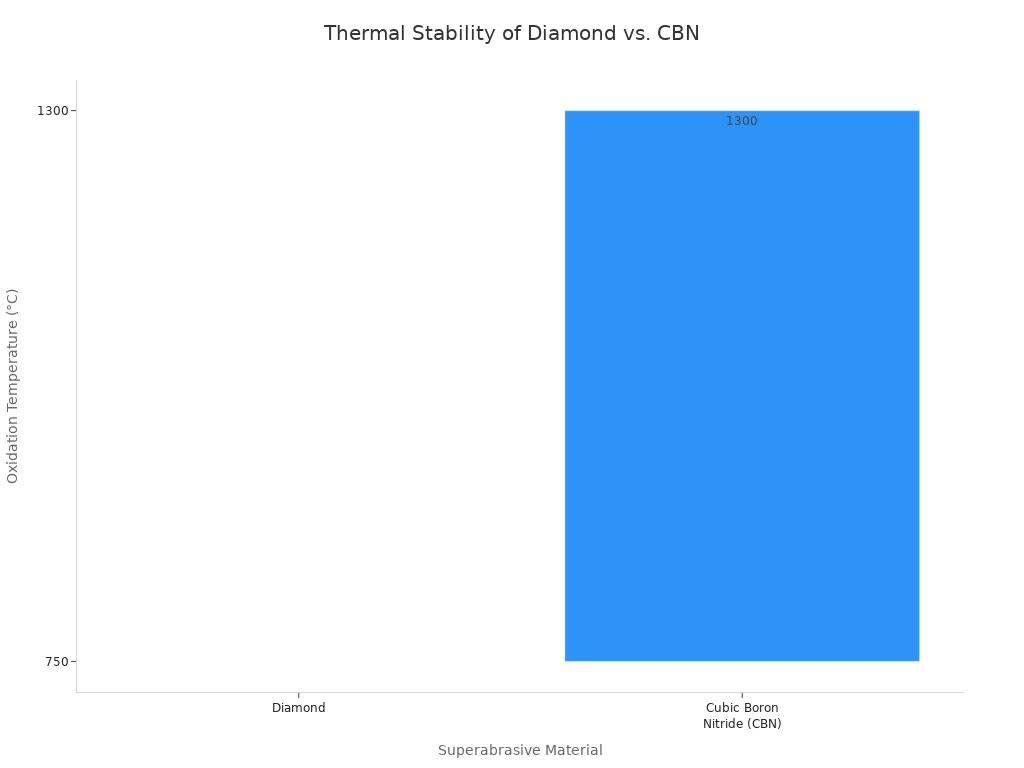

Diamond is the hardest known material, perfect for non-ferrous materials. However, it reacts chemically with iron at high temperatures. CBN, the second-hardest material, offers superior thermal stability. This makes it the ideal choice for grinding ferrous metals like hardened steel and superalloys, which are common in metalworking. The metalworking and foundry sectors rely on CBN’s stability for demanding applications. The foundry industry, in particular, benefits from CBN’s durability when grinding tough cast iron parts.

Quick Tip: The right superabrasive choice prevents tool wear and ensures a high-quality finish.

| Superabrasive | Best Suited Materials |

|---|---|

| Diamond | Carbide, Glass, Ceramics, Granite (Non-Ferrous) |

| CBN | Hardened Steel, Cast Iron, Superalloys (Ferrous) |

This strategic selection of a superabrasive is key to successful precision grinding operations.

Aerospace: Grinding for Critical Components

The aerospace industry operates under the strictest standards for safety and performance. Components must withstand extreme temperatures, pressures, and stresses. This requires advanced materials that are notoriously difficult to machine. Electroplated grinding wheels provide the necessary precision and power for these critical applications.

Turbine and Engine Component Shaping

Jet engine turbines contain parts made from nickel-based superalloys. These materials, like Inconel and Hastelloy, retain their strength at very high temperatures. However, their toughness makes shaping them a major challenge. The grinding process must be aggressive yet precise.

Pro Tip: Superalloys are chosen for their specific strengths. For example, INCONEL® 718 is valued for its reliability in disks, while HASTELLOY® X excels in combustor liners due to its oxidation resistance.

| Alloy | Where it fits best | Why engineers pick it |

|---|---|---|

| INCONEL® 718 | Disks, attachments, lower-temp blade hardware | Predictable heat treat, solid strength, widely available |

| HASTELLOY® X | Combustor liners, transitions, seals | Excellent oxidation resistance at very high temps |

| INCONEL® 625 | Seals, bellows, hot hardware around blades | Tough, corrosion/oxidation resistant, fabricable |

Electroplated CBN wheels are perfect for this task. The single, exposed abrasive layer creates a free-cutting action. This design delivers high material removal rates with less heat buildup. Manufacturers can achieve a high removal rate during grinding operations, shaping complex turbine blades and vanes efficiently without damaging the valuable superalloy.

Machining Advanced Composite Materials

Modern aerospace structures increasingly use Carbon Fiber Reinforced Polymers (CFRP). These materials are lightweight and strong but present unique machining problems.

- Rapid Tool Wear: The abrasive carbon fibers quickly dull standard tools.

- Material Damage: Composites can easily fray or delaminate, which weakens the part.

- Heat Sensitivity: Heat from grinding can damage the polymer matrix.

Electroplated diamond wheels solve these issues. Diamond is the hardest material, so it easily cuts through abrasive fibers with minimal wear. The electroplated bond holds the diamond particles securely, ensuring a clean cut that prevents delamination. This makes them the superior choice for the final grinding and finishing of aerospace composite parts, ensuring structural integrity and a perfect fit.

Automotive: High-Volume and Tolerance Control

The automotive industry balances mass production with the need for extreme precision. Key components must meet strict tolerances to ensure vehicle performance, safety, and longevity. This makes specialized grinding processes essential for modern vehicle manufacturing.

Engine and Drivetrain Component Finishing

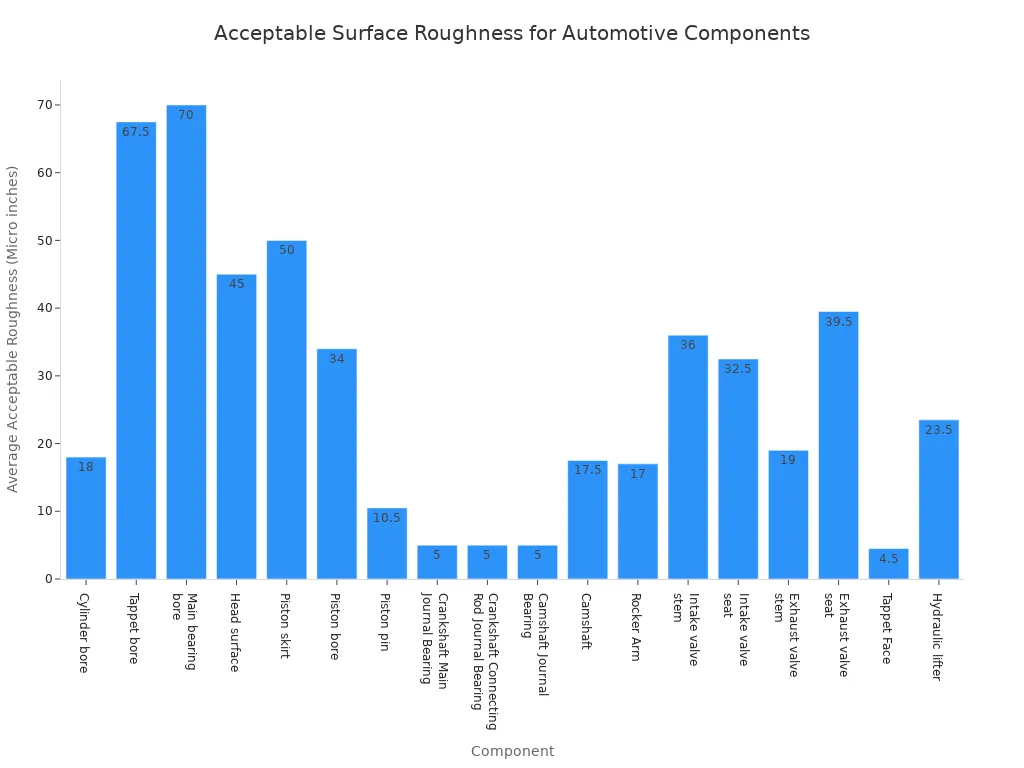

Engine and drivetrain parts work together under intense pressure and friction. Components like crankshafts, camshafts, and transmission gears require precision grinding to achieve the necessary durability and performance. A smooth surface finish is critical for reducing wear and improving efficiency. For example, parts like crankshaft journals and tappet faces need an exceptionally fine finish to operate smoothly.

Electroplated CBN wheels are ideal for this type of high-volume metalworking. They provide the aggressive grinding action needed to shape hardened steel alloys while maintaining the precise profiles required for automotive components.

Grinding Brake System Parts

Safety is the top priority in the automotive industry, and brake systems are a perfect example. Brake discs require a perfectly flat and smooth surface to ensure uniform wear and reliable braking performance. Many of these parts begin as rough castings from a foundry.

Did You Know? An uneven brake disc surface can cause vibrations and reduce braking effectiveness. Precision grinding eliminates these imperfections.

The final grinding step is crucial for achieving the required surface quality. An electroplated grinding wheel is excellent for this task because it holds its form perfectly. This form-holding ability allows it to create a consistently flat surface across thousands of parts. The single, sharp abrasive layer of an electroplated wheel ensures a clean, efficient cut, making it a go-to solution for critical automotive applications.

Medical Manufacturing: Accuracy for Biocompatible Materials

The medical industry demands the highest level of precision for tools and implants. Patient safety and successful outcomes depend on perfectly manufactured high-precision components. This makes specialized grinding techniques essential for working with advanced biocompatible materials.

Surgical Instrument Sharpening

Surgical instruments like scalpels and forceps require exceptionally sharp and durable edges. Manufacturers often use materials like 316L stainless steel and titanium alloys for these tools. Titanium is popular because it is lightweight, non-magnetic, and highly resistant to corrosion.

Achieving the necessary sharpness involves a careful grinding process. An electroplated grinding wheel is ideal for this task. The unique electroplated bond secures a single, highly exposed layer of superabrasive particles. This design creates a free-cutting action that sharpens edges with minimal heat, preventing damage to the instrument. The electroplated wheel holds its shape, ensuring consistent results for every tool.

Did You Know? The “L” in 316L stainless steel stands for “low carbon.” This low carbon content improves the steel’s resistance to corrosion, which is vital for medical tools that undergo frequent sterilization.

Medical Implants and Electroplated Diamond Grinding Wheels

Medical implants, such as artificial hip and knee joints, must fit a patient’s anatomy perfectly. An improper fit can lead to pain and implant failure. These devices are made from tough, biocompatible materials that are difficult to shape. Common materials include:

- Titanium Alloys (Ti-6Al-4V): Valued for their strength, low density, and excellent biocompatibility.

- Cobalt-Chromium (Co-Cr): Known for extreme hardness and wear resistance, making it suitable for joint surfaces.

- Zirconia: A bio-ceramic material with high strength and chemical stability.

Shaping these materials requires a powerful and precise grinding solution. Electroplated diamond grinding wheels provide the aggressive cutting force needed to machine these hard materials. The electroplated process allows for the creation of complex curved surfaces with extreme accuracy. This precision grinding ensures that implants have the exact shape needed for proper function, longevity, and patient comfort.

Electronics: Machining Brittle and Hard Materials

The semiconductor and electronics industry works with some of the most fragile and hard materials in manufacturing. Silicon, ceramics, and specialized glass require extreme precision during shaping. A small mistake can lead to costly defects. This makes specialized grinding tools essential for producing high-quality electronic components.

Processing Silicon and Semiconductor Wafers

Silicon wafers are the foundation of microchips. The process of cutting and thinning these wafers is full of challenges. Manufacturers must prevent issues that ruin the final product.

- Wafer Breakage: Incorrect grinding pressure can easily crack a delicate semiconductor wafer.

- Surface Damage: Scratches and pits on the wafer surface reduce device reliability.

- Flatness Control: Even minor warping can cause uneven cuts and lead to component failure.

Electroplated diamond wheels provide the necessary control for this delicate work. The metal core of an electroplated wheel acts as a heat sink, pulling heat away from the wafer. This prevents thermal damage. The sharp, single layer of diamond abrasive requires less grinding force, which significantly reduces the risk of chipping or cracking the semiconductor material. This results in clean cuts and a superior surface finish.

Shaping Ceramic and Glass Components

Modern electronics use many advanced ceramic and glass parts, such as ceramic resistor cores and high-performance substrates. These materials offer excellent electrical insulation and heat resistance. However, their extreme hardness makes them difficult to shape. Materials like alumina ceramic and sapphire glass can only be formed effectively through diamond grinding.

Fact: For large production runs, manufacturers fire near-net shapes of ceramic. They then use diamond grinding to meet the final dimensional requirements.

An electroplated wheel is perfect for this task. The electroplated bond holds diamond particles securely, allowing for the aggressive yet precise shaping of these hard materials. This process enables the creation of complex parts with tight tolerances. The result is high-quality components that are essential for the performance and reliability of today’s electronic devices.

Aimgrind’s High-Performance Diamond Grinding Wheels

Meeting the demands of modern industry requires more than standard tools. Aimgrind provides high-performance grinding wheels designed for the most challenging high-performance grinding applications. The brand delivers high-quality grinding solutions that enhance productivity and efficiency in precision grinding.

Custom Solutions for Hard Alloys

Aimgrind specializes in creating custom high-performance grinding tools for difficult materials. The brand adjusts the grinding wheel’s grade by modifying the abrasive and bond to match specific needs. This customization is vital for high-volume production or unique grinding processes. It offers tailored solutions for materials that are tough to machine. These materials include:

- Nickel-based superalloys

- Cobalt-based superalloys

- Ferrous alloys

- Tungsten carbide

This focused approach ensures that every electroplated grinding wheel is perfectly matched to the customer’s equipment and process. The result is superior cutting performance and optimal results for every high-performance grinding task.

The Aimgrind Electroplated Grinding Wheel Advantage

The Aimgrind electroplated diamond grinding wheels offer a distinct advantage in precision work. The unique electroplated bond provides ultra-high grit retention. This feature ensures the abrasive particles stay securely attached for a longer tool life and consistent cutting.

The single abrasive layer is a key feature of these high-performance grinding wheels. This design allows for a very aggressive cutting action, which improves material removal rates and makes the grinding process more efficient.

This sharp, efficient cutting edge minimizes material waste. The electroplated process creates a free-cutting action that is ideal for shaping hard alloys and ceramics. Aimgrind’s high-performance diamond grinding wheels deliver the high-performance and durability needed for today’s most demanding industries.

The aerospace and automotive industries drive the market for precision grinding, together representing over 40% of revenue. The demand for extreme precision makes the aggressive cut of an electroplated grinding wheel essential for modern manufacturing.

Its unique form-holding ability ensures consistent quality and meets the rising demand for high-quality products.

As industries push for higher standards, Aimgrind delivers customized grinding solutions to meet these critical precision challenges.

FAQ

What makes an electroplated grinding wheel special?

An electroplated bond holds a single, exposed layer of superabrasive grit. This design creates a very sharp and aggressive cutting action. It allows for high precision and efficient material removal, especially when creating complex shapes.

Which materials are best for electroplated wheels?

These wheels excel at grinding very hard or brittle materials. Diamond wheels work best on non-ferrous materials like ceramics, glass, and composites. CBN wheels are ideal for ferrous metals, including hardened steels and superalloys.

Why do aerospace and medical industries use these wheels?

These industries work with tough materials like superalloys and ceramics. Electroplated wheels provide the precision needed to shape critical parts. They create complex forms with tight tolerances, ensuring safety and performance for implants and engine components.

Are electroplated wheels durable?

Yes, they are very durable. The electroplating process creates a strong metallic bond that securely holds the abrasive particles. This ultra-high grit retention leads to a longer tool life and consistent performance during demanding grinding tasks.

See Also

Exploring Grinding Wheel Varieties and Their Essential Real-World Uses

Selecting the Optimal Metal Grinding Wheel for Your Specific Project

Picking the Perfect Bench Grinding Wheel Material for Your Requirements

Discovering the Ideal Grinding Wheel Dresser for Your Workshop

Guiding Your Selection of the Perfect Grinding Wheel for Stainless Steel

Contact Us

For More Grinding Solution or Customized Abrasive Tools