Ultra-precision grinding technology provides significant benefits to the most demanding industries. These industries rely on precision grinding for critical applications where failure is not an option. The core benefits of precision grinding directly enhance component performance and reliability.

Key sectors and their components include:

- Aerospace: Turbine blades

- Medical: Orthopedic implants

- Automotive: Fuel injectors

- Optics: High-precision lenses

This level of precision is only possible with highly specialized grinding tools. The precision surface grinding benefits from this meticulous grinding process are vital. This precision grinding ensures every grinding task meets the highest quality standards.

Key Takeaways

- Ultra-precision grinding helps many important industries. These include aerospace, medical, automotive, and optics.

- This technology makes parts very accurate. It helps make turbine blades, medical implants, and car parts better.

- Precision grinding makes surfaces very smooth. This helps parts work better and last longer.

- Special tools like diamond grinding wheels are important. They help grind very hard materials with great accuracy.

Aerospace: Precision Grinding for Extreme Reliability

The aerospace industry demands the highest levels of precision and reliability. Components must withstand extreme temperatures, pressures, and stresses. Ultra-precision grinding delivers the necessary quality for these critical parts. The benefits of this process are essential for flight safety and operational efficiency.

Turbine Blades for Engine Efficiency

Jet engine efficiency depends heavily on the aerodynamic performance of turbine blades. Precision grinding is the key manufacturing process to achieve this. The grinding process creates an exceptionally smooth surface on blades made from advanced nickel-based superalloys. This finish reduces air resistance and optimizes airflow. A smoother surface can improve fuel efficiency by approximately 5%.

The precision of the grinding process is critical. Turbine blades require a surface roughness (Ra) of 0.5 µm or less. This level of finish enhances fatigue life by over 15% under constant stress. Achieving these tight tolerances involves advanced grinding techniques.

Key Grinding Innovations:

- Superabrasives: Cubic Boron Nitride (cBN) wheels are used for their stability when grinding hard superalloys.

- Creep-feed grinding: This method allows for high material removal rates in fewer passes, boosting production efficiency.

This meticulous grinding ensures every blade meets exact specifications, maximizing engine performance. The impact on accuracy from this grinding is immense.

Landing Gear Components for Safety

Landing gear components are vital for aircraft safety. They must endure immense forces during takeoff and landing. The structural integrity of these parts is non-negotiable. Precision grinding provides significant benefits by creating flawless surfaces free from microscopic defects. A failure analysis of a landing gear wheel showed that surface damage led to corrosion, which then caused fatigue cracking.

Proper grinding removes surface imperfections that could become starting points for cracks or corrosion. This precision process ensures components meet strict tolerances for a perfect fit and function. The final grinding step delivers the required surface integrity. This level of precision is fundamental to preventing catastrophic failures and ensuring passenger safety on every flight.

Medical Industry: Grinding for Biocompatibility and Accuracy

In medical applications, precision is not just a goal; it is a requirement for patient safety and device effectiveness. Ultra-precision grinding delivers the necessary accuracy and integrity for medical components. The benefits of this process are critical for both implantable devices and surgical instruments. This advanced grinding ensures that every component meets strict regulatory standards for quality.

Orthopedic Implants and Surgical Tools

Orthopedic implants like hip and knee joints demand an exceptionally smooth surface. Precision grinding creates this finish, which minimizes friction and wear inside the body. This process directly improves implant longevity and patient safety. The grinding must achieve a specific surface roughness, often between 0.1–0.4 μm, to prevent bacterial growth and ensure biocompatibility. This level of precision helps the implant integrate with the body.

Surgical tools also rely heavily on precision grinding. Instruments for neurosurgery or ophthalmic procedures require burr-free, razor-sharp edges. The grinding process provides this sharpness with incredible accuracy.

Examples of tools requiring this precision:

- Ophthalmic Cutting Knives

- Neurosurgical Drills and Burs

- Spinal Burrs for Minimally Invasive Surgery

This meticulous grinding enhances surgical accuracy and reduces patient trauma during delicate operations.

Ensuring Component Integrity and Quality

The integrity of medical devices is non-negotiable. Manufacturers use strict quality control methods to verify the results of the grinding process. These checks ensure every component meets the highest standards of quality and precision.

| Quality Control Method | Purpose |

|---|---|

| Visual Inspection | Checks for surface defects and proper finish quality. |

| Dimensional Verification | Uses micrometers to confirm parts meet exact size tolerances. |

| Functional Testing | Includes cut tests for scissors to verify sharpness. |

This rigorous testing confirms component integrity. The benefits of precision grinding are validated through these steps, ensuring every device is safe for medical applications. The final grinding step is fundamental to achieving the required integrity and performance.

Automotive: Enhancing Performance and Efficiency

The automotive industry is a massive consumer of precision-engineered parts. The market for precision automotive components was valued at over $226 billion in 2024, reflecting the immense demand for high-quality parts. Ultra-precision grinding is essential for manufacturing efficiency and for producing components that boost vehicle performance and fuel efficiency. This grinding process delivers the tight tolerances needed for modern engines and drivetrains, maximizing operational efficiency across the board. The benefits of this precision are clear in the final production output.

Fuel Injectors and Engine Valves

Fuel injectors and engine valves are central to engine efficiency. The precision grinding of these parts directly impacts fuel combustion. A proper grinding process ensures a perfect seal between the valve and its seat. This seal is critical for engine health and performance. The grinding process offers several benefits.

Key outcomes of valve grinding include:

- Restoring the valve seat’s shape for uniform contact.

- Improving combustion, power output, and fuel efficiency.

- Extending the life of engine components by preventing wear.

This level of precision in the grinding process is fundamental to achieving optimal engine function and longevity. The manufacturing efficiency of this production process is key.

Drivetrain Gears and Bearings

Drivetrain components like gears and bearings transfer power from the engine to the wheels. Their precision dictates the smoothness and reliability of a vehicle. The grinding of bearings to specific tolerances is especially important. Bearing precision is often measured by an ABEC rating, where a higher number indicates tighter tolerances.

This precision grinding allows bearings to handle higher rotational speeds without failing. While it doesn’t increase load capacity, it enables the bearing to carry the same load at greater speeds. This capability is vital for high-performance vehicles and electric powertrains. The grinding process ensures high-efficiency production of these critical parts. This focus on precision in the production stage improves overall manufacturing efficiency.

Optics and Electronics: Achieving Flawless Surfaces

The optics and electronics industries depend on surfaces that are virtually perfect. Ultra-precision grinding is a fundamental technology for creating these flawless components. This process provides the extreme precision needed for light manipulation and semiconductor fabrication. The accuracy of the grinding process directly impacts the performance of high-tech devices.

Lenses, Mirrors, and Prisms

Optical components like lenses, mirrors, and prisms are essential for instruments such as telescopes and spectrometers. The Chandra X-ray Observatory, for example, uses high-precision mirrors to capture images of distant cosmic events. The effectiveness of these components relies entirely on their surface quality and dimensional accuracy. Precision grinding is the key to shaping glass and other brittle materials to exact specifications. This grinding ensures light is reflected or refracted without distortion.

The required precision is measured in fractions of a wavelength of light. Achieving these incredibly tight tolerances is a primary goal of the grinding process.

| Grade | Flatness Specification |

|---|---|

| Typical Grade | 1λ |

| Precision Grade | λ/4 |

| High Precision Grade | λ/20 |

This level of accuracy is non-negotiable for advanced systems. A precise surface from the grinding stage is critical for final polishing and achieving optimal optical performance.

Silicon Wafer Planarization

Silicon wafers are the foundation of all modern electronics. The market for advanced compound semiconductors is projected to reach $55.8 billion by 2027, driven by demand in EVs and 5G technology. This growth increases the need for perfectly flat wafers. The grinding process plays a vital role in wafer manufacturing.

Grinding is used for wafer thinning, a process that removes material with high efficiency. While Chemical Mechanical Planarization (CMP) provides the final ultra-smooth surface, precision grinding performs the initial shaping and achieves the target thickness.

This initial grinding step is crucial for controlling the wafer’s Total Thickness Variation (TTV). For a 300mm wafer, the TTV must be less than or equal to 10 micrometers. This strict precision ensures that subsequent manufacturing steps can produce reliable and powerful microchips. The grinding must be exact to prepare the wafer surface for its final, flawless state.

The Core of Ultra-Precision Grinding Technology: Aimgrind’s Tools

The remarkable achievements in aerospace, medical, and other sectors are not possible without the right tools. The success of ultra-precision grinding technology depends on advanced abrasives. Aimgrind provides the critical tools that empower these demanding industries. Our solutions are fundamental to achieving the highest standards in manufacturing and production.

Aimgrind Diamond Grinding Wheels for Hard Materials

Hard and brittle materials like superalloys, ceramics, and composites require specialized grinding solutions. Aimgrind’s diamond grinding wheels are engineered for these exact applications. The choice of bond material is critical for performance on specific precision grinding machines. This choice directly impacts the quality of production.

For example, vitrified and resin bonds offer different advantages for grinding:

Feature Vitrified Bond Resin Bond Rigidity High Flexible Heat Resistance Excellent Lower Shape Retention Superior Good Best For Hard materials, precision General purpose, smooth finish

This level of material science ensures that every grinding operation on precision grinding machines is optimized. The right wheel selection improves the efficiency of production. Our advanced grinding technology is built into every tool. This focus on quality makes our wheels ideal for precision grinding machines in high-stakes production environments.

Custom Solutions for Demanding Applications

The diverse components discussed—from turbine blades to optical lenses—have unique requirements. A standard tool cannot meet every need. Aimgrind specializes in creating custom grinding solutions. We match our grinding wheels to your specific equipment and processes. This ensures our tools work perfectly with your precision grinding machines for any production run.

Our team analyzes your grinding challenge to design the ideal abrasive tool. This tailored approach maximizes the performance of precision grinding machines. It enhances the quality of your production. For many industries, this customization is key to successful production. We ensure our tools integrate seamlessly with your precision grinding machines. This commitment makes complex grinding tasks manageable and boosts production output. Our expertise supports your production goals on all types of precision grinding machines. We help you achieve superior results in your applications with tools designed for your precision grinding machines.

Explore how our customized diamond grinding wheels can elevate your ultra-precision grinding technology and production capabilities.

Critical industries depend on ultra-precision grinding technology for components where failure is not an option. This level of precision grinding demands advanced abrasive tools.

The required accuracy and quality are simply unattainable otherwise.

Specialized tools, like Aimgrind’s custom wheels, enable this ultra-precision grinding technology. This precision grinding empowers innovation, ensuring the highest accuracy and quality for mission-critical applications.

FAQ

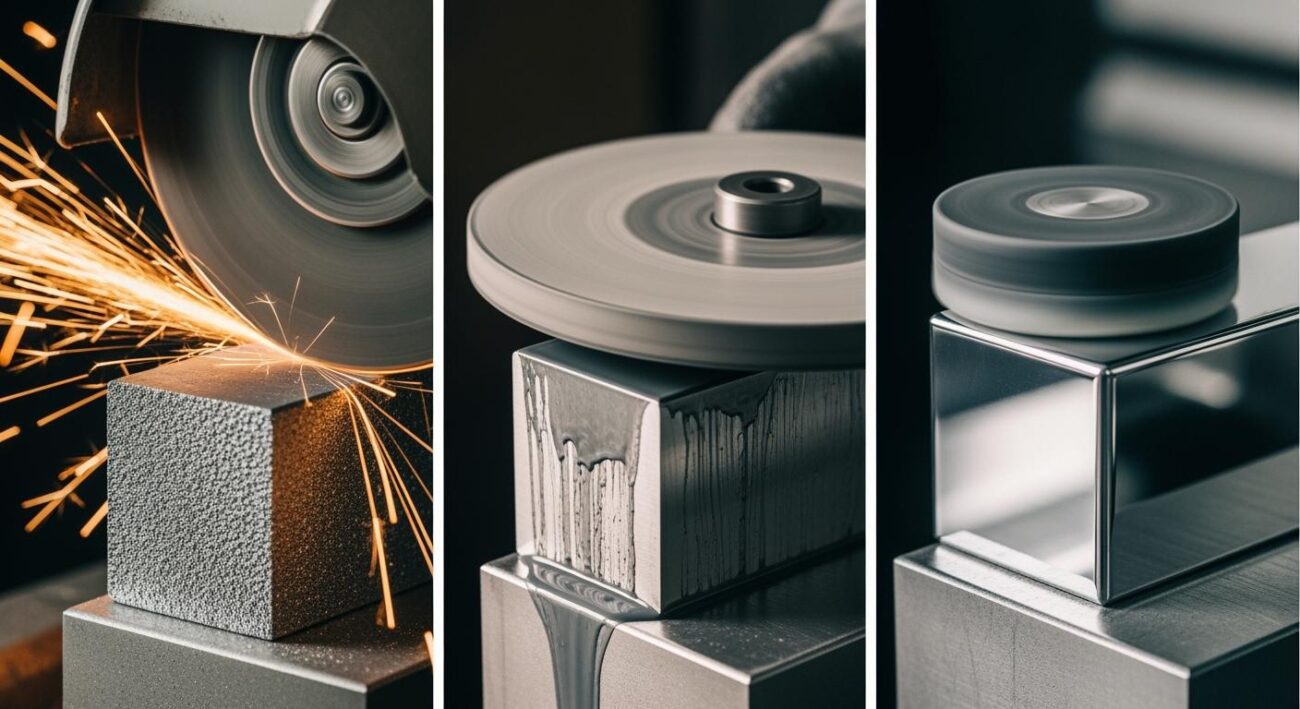

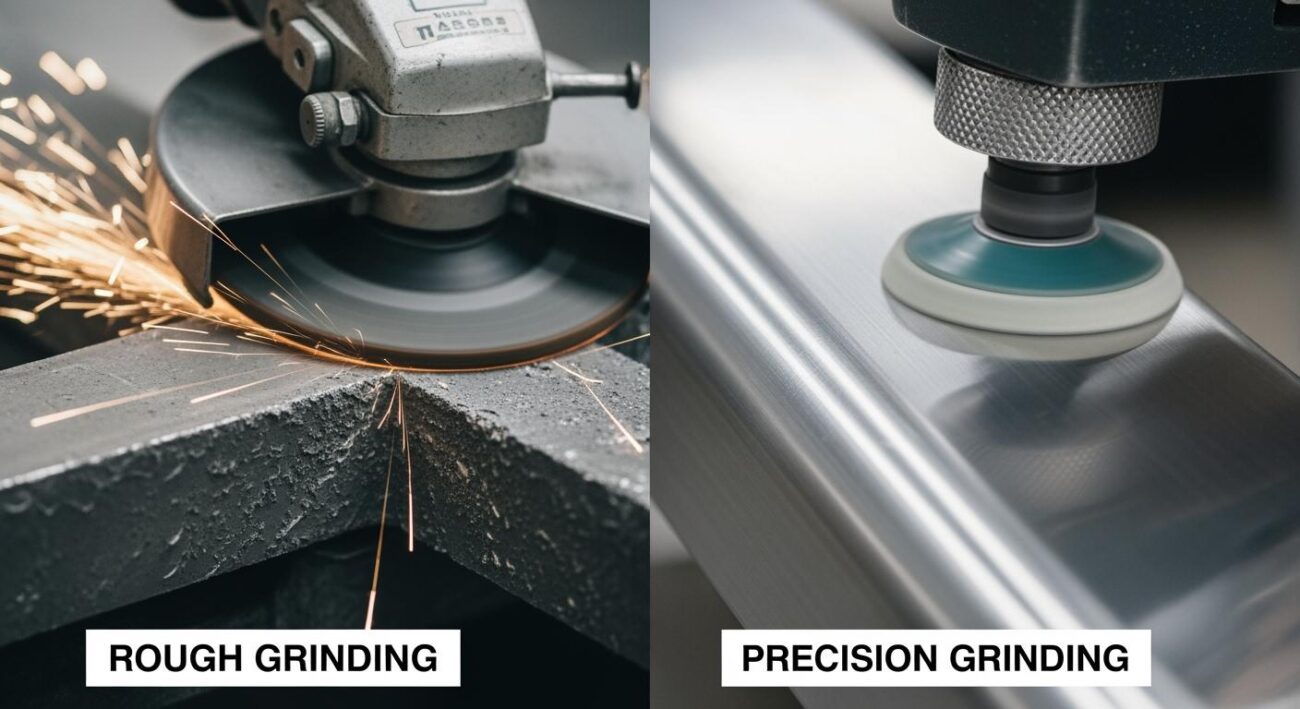

What is the main difference between standard and ultra-precision grinding?

Ultra-precision grinding achieves much tighter tolerances and superior surface finishes. It removes material at a microscopic level. This process is essential for high-performance parts where standard grinding is not accurate enough. The right tools are critical for these advanced precision grinding machines.

Why are diamond wheels essential for hard materials?

Diamond is the hardest known material. Diamond grinding wheels can effectively cut hard and brittle materials like ceramics, superalloys, and composites. Conventional abrasives would wear out quickly or fail to cut these materials efficiently on precision grinding machines.

How do I select the right grinding wheel for my application?

The best wheel depends on several factors:

- The material being ground

- The required surface finish

- Your specific equipment

Aimgrind offers custom solutions. We match the wheel’s bond and grit to your unique process and precision grinding machines for optimal results.

Contact Us

For More Grinding Solution or Customized Abrasive Tools