A hybrid bond grinding wheel is engineered to bridge the performance gap between resin and metal bonds. Hybrid bond wheels deliver the high material removal rates of metal bond wheels. They also achieve the superior surface finishes characteristic of resin bond wheels. Choosing the right bond type, whether a metal bond or a resin bond, is critical for optimizing grinding operations. This choice impacts everything from cycle times to final part quality and overall cost. Understanding each bond’s distinct advantages is key to success.

Key Takeaways

- Metal bond wheels are very strong. They remove material fast. They are best for hard materials and last a long time.

- Resin bond wheels make surfaces very smooth. They are good for finishing work. They are also good for materials that get hot easily.

- Hybrid bond wheels combine the best of both. They remove material quickly and make surfaces smooth. They are good for jobs needing both speed and a nice finish.

- Choosing the right wheel depends on your job. Think about how fast you need to work. Also, think about how smooth the surface needs to be.

- Always consider the total cost. This includes the wheel’s price, how long it lasts, and how much time it saves.

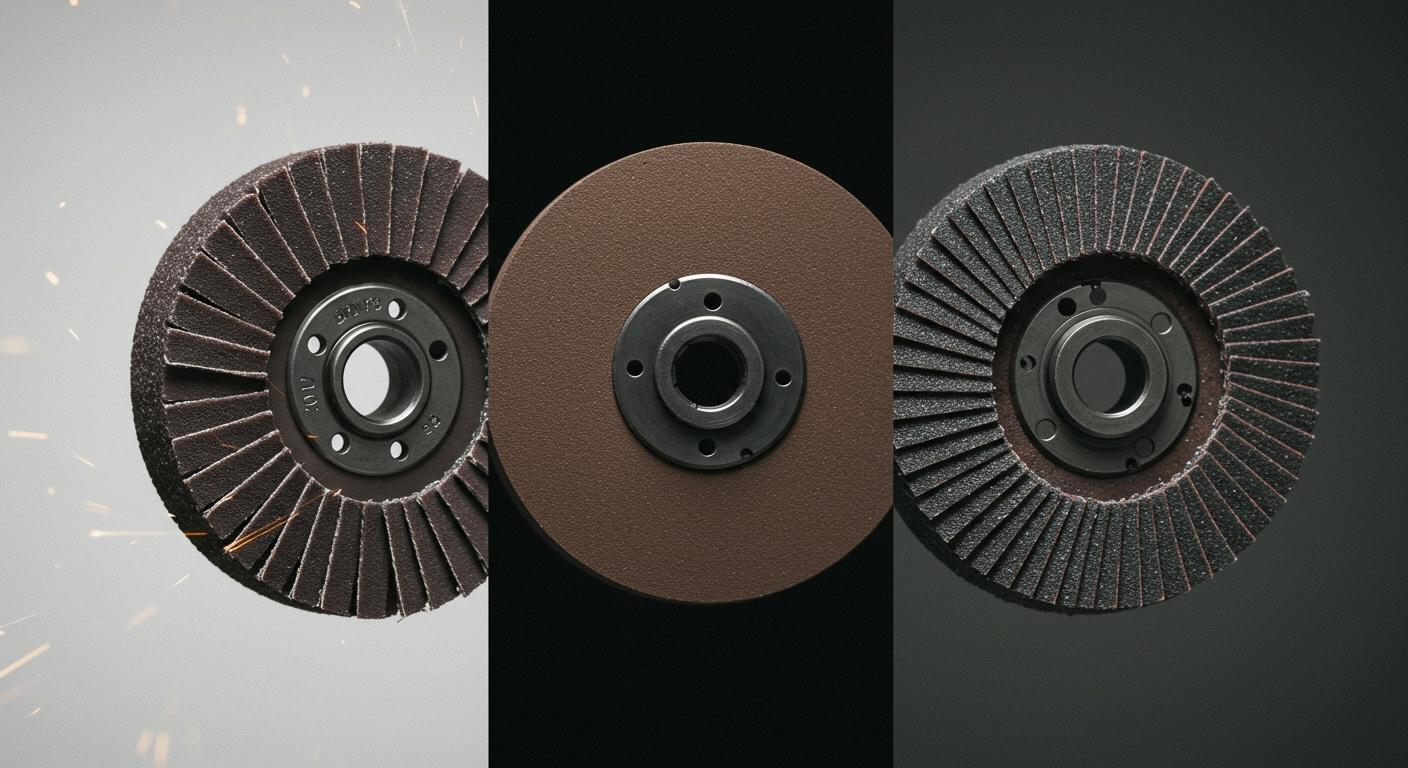

Defining the Bond Types

Understanding the fundamental differences between bond types helps operators select the perfect tool for their job. Each bond offers a unique set of characteristics tailored for specific grinding challenges.

The Durable Metal Bond

The metal bond is the workhorse of the grinding world, known for its exceptional durability and long life. At Aimgrind, our expertise lies in creating metal bond wheels designed for high-performance applications that demand extreme precision. These wheels use superhard abrasives like diamond or CBN. This construction makes them ideal for processing tough materials like ceramics, hard alloys, and composites.

Industries like aerospace and tool manufacturing rely heavily on the strength of a metal bond. For example, cBN bond wheels are essential for working with nickel-based superalloys in modern aircraft engines. Common applications include:

- Grinding engine components and turbine blades

- Finishing gears and bearings

- Shaping other critical parts that require high precision

The Finishing Power of Resin Bond

Resin bond wheels are the artists of the grinding world. They excel at creating smooth, high-quality surface finishes. The resin bond holds the abrasive grains with a softer grip compared to a metal bond. This characteristic allows worn grains to break away, exposing fresh, sharp cutting edges. This self-sharpening action results in a cooler, gentler grind. Operators choose resin bond wheels for finishing tasks and for grinding heat-sensitive materials where preventing thermal damage is a top priority.

The Versatile Hybrid Bond Grinding Wheel

A hybrid bond grinding wheel combines the best attributes of resin and metal bonds into a single, powerful tool. These advanced wheels incorporate a mix of resin and metal bonding agents. This blend creates a unique structure that provides the toughness of metal bond wheels and the fine-finishing capability of resin bond wheels.

Performance Boost: Studies show hybrid bond wheels can increase tool life by up to 28% and improve profile accuracy by up to 44%. This makes them a highly efficient choice for balanced operations.

The hybrid bond grinding wheel offers a versatile solution for applications needing both aggressive material removal and excellent surface precision. This makes hybrid bond wheels a game-changer for boosting productivity without compromising on quality.

Performance Metrics: A Head-to-Head Look

Choosing the right grinding wheel depends on its performance in key areas. Operators must evaluate each bond type based on speed, finish, longevity, and heat management to find the perfect match for their application.

Material Removal Rate (MRR)

Material Removal Rate measures how quickly a wheel can remove material from a workpiece. A higher MRR often leads to shorter cycle times and increased productivity.

- Metal Bond: Metal bond wheels are the champions of aggressive material removal. Their strong, durable bond holds abrasive grains securely, allowing for deep cuts and fast stock removal on very hard materials.

- Hybrid Bond: Hybrid bond wheels offer a significant boost in efficiency. Studies show they can reduce cycle times by 15-25% compared to older technologies when grinding HSS cutting tools. This performance bridges the gap between metal and resin bonds.

- Resin Bond: Resin bond wheels have a more moderate MRR. Their primary function is finishing, not rapid material removal.

Cycle Time Impact

The following table shows how a hybrid bond can increase throughput when grinding tungsten carbide. A lower cycle time means more parts are produced in the same amount of time.

| Feature | Conventional Resin Bond | Hybrid Bond | Impact |

|---|---|---|---|

| Cycle Time Per Part | Z minutes | 0.8Z – 0.9Z minutes | Increased throughput, lower labor cost per part |

Achievable Surface Finish

Surface finish refers to the final texture of the workpiece. A smoother finish, measured by a lower Ra value, is critical for parts requiring tight tolerances and a flawless appearance.

Resin bond wheels are the top choice for achieving a high surface finish. The softer bond allows worn abrasives to fall away, exposing sharp new edges that create a smooth, clean surface. Research shows that increasing the wheel speed with a resin bond can produce an even better finish with fewer surface defects.

Hybrid wheels also deliver excellent finishes, though resin wheels maintain a slight edge for the finest work. The difference is often measured in micro-inches (μin.).

| Wheel Type | Surface Finish (Ra) |

|---|---|

| Resin-bond wheels | 8 to 10 μin. |

| Hybrid metal-bond wheels | 16 to 20 μin. |

Metal bond wheels typically produce the roughest surface finish. Their design prioritizes material removal over creating a smooth surface.

Tool Life and Form Holding

Wheel life is the total usable lifespan of a grinding wheel. Form holding is the wheel’s ability to maintain its shape and profile during grinding. Both are essential for maintaining precision and controlling costs.

The metal bond is engineered for maximum durability and superior form-holding. This robust construction ensures the wheel maintains its shape longer than any other system, which extends wheel life and guarantees consistent part precision.

The hybrid bond grinding wheel also provides an excellent wheel life and good form holding. It is often considered the industry standard for manufacturing cutting tools because it delivers faster material removal and higher thermal stability. This balance of features makes it a cost-effective choice for high-precision operations. The resin bond, due to its self-sharpening nature, has a shorter wheel life in comparison.

Heat Generation and Control

Grinding generates significant heat, which can damage the workpiece or alter its properties. Controlling this heat is vital for quality and precision.

- Resin Bond: The resin bond runs the coolest. Its ability to shed dull abrasive grains reduces friction, making it perfect for grinding heat-sensitive materials.

- Metal Bond: Metal bond wheels generate the most heat. The strong bond creates high friction, which requires an effective coolant system to prevent thermal damage to the part.

- Hybrid Bond: The hybrid bond offers a balanced thermal profile. It runs cooler than a metal bond but hotter than a resin bond, providing a versatile option for jobs that need both speed and careful heat management.

Ideal Applications for Each Bond

Selecting the right wheel bond is crucial for achieving optimal results. Each bond type excels in specific scenarios, from aggressive cutting to delicate finishing. Understanding these applications helps operators maximize efficiency and part quality.

When to Choose a Metal Bond Wheel

Operators should choose metal bond wheels for demanding, high-stock removal applications. The durable metal bond provides the long life needed for grinding extremely hard and brittle materials. These wheels are the top choice for high-performance grinding applications involving tough materials.

Ideal Materials for Metal Bond:

- Industrial ceramics (alumina, zirconia)

- Optical glass and quartz

- Semiconductor materials

- Hard alloys

These wheels, including cbn bond wheels, are essential in aerospace and automotive manufacturing. They handle high-volume production runs and precision grinding tasks where consistency is key.

When to Choose a Resin Bond Wheel

Resin bond wheels are the go-to solution for tasks requiring a mirror finish. Their self-sharpening nature provides a cool, gentle cut, making them perfect for heat-sensitive materials and achieving superior surfaces. Industries use them for finishing parts in automotive, aerospace, and medical applications. They are also preferred for tool and cutter grinding, including fluting and regrinding tungsten carbide tools, where maintaining sharp edges with high precision is critical.

When to Choose a Hybrid Wheel

A hybrid bond grinding wheel is the ideal choice for balanced operations that need both speed and a fine finish. Hybrid bond wheels boost productivity and improve part quality, making them valuable in high accuracy grinding applications. For example, the medical industry uses these wheels to manufacture devices where precision is non-negotiable. By combining the strengths of other bonds, a hybrid wheel offers a versatile solution that enhances efficiency without sacrificing quality.

How to Select the Right Wheel

Choosing the right grinding wheel is a practical decision for engineers and machinists. A systematic approach ensures optimal performance, quality, and cost-effectiveness. This guide breaks down the key factors to consider.

Analyze Your Material

The first step is to analyze the workpiece material. Its properties, like hardness and heat sensitivity, dictate the best abrasive. For materials with high hardness, a softer grinding wheel is often better because it helps manage heat.

Abrasive Selection Guide

The table below shows which abrasives are suitable for different material types.

| Abrasive Type | Hardness | Suitable Materials (Examples) |

|---|---|---|

| Diamond | Very High | Sintered carbides, glass, ceramics, silicon |

| CBN | Very High | High-speed steel, tool steel, stainless steel |

| Silicon Carbide | High | Cast irons, non-ferrous metals, plastics |

Balance Speed vs. Precision

Operators must find the right balance between production speed and surface finish. A faster feed rate can increase output but may compromise surface quality. Achieving high precision often requires slower, more controlled grinding. An optimal solution keeps production time low while achieving a smooth finish. This balance is critical for demanding precision grinding tasks.

Calculate Total Cost of Ownership

The cheapest wheel is not always the most cost-effective. Operators should calculate the Total Cost of Ownership (TCO) to understand the true expense. TCO includes more than just the purchase price. Key factors include:

- Actual wheel life (parts per tool)

- Labor costs for tool changes

- Machine downtime

- Scrap and rework rates

A wheel with a longer wheel life and higher precision can significantly lower the overall cost per part.

Consider Coolant and Machine Parameters

Coolant and machine settings directly impact performance. Harder bonds, like metal, often work well with water-based coolants. Softer bonds may perform better with oil-based coolants or even dry grinding. Matching the wheel to machine parameters is essential for achieving consistent precision. A comprehensive service process, including problem diagnosis and parameter matching, ensures the wheel is perfectly aligned with the equipment and process for the best results.

Operators choose metal bond wheels for aggressive cutting and a long wheel life. They select resin bond wheels for delicate finishing. Hybrid bond wheels offer a balanced solution. The best wheel depends on application needs for speed, finish, and precision. The industry continues to innovate with advanced bonding systems.

- Manufacturers invest in metal bond technology for better performance.

- A resin bond and other systems are tailored for specific tasks.

Contact an expert like Aimgrind for a customized solution to achieve the highest precision and extend wheel life. Grind with Passion, Achieve with Aim.

FAQ

### What is the main difference between the three bond types?

Metal bonds offer the longest life and highest durability. Resin bonds provide the best surface finish. Hybrid bonds deliver a balanced performance, combining the speed of metal bonds with the finishing quality of resin bonds for versatile applications.

### Which wheel is best for fast material removal?

Metal bond wheels excel at fast material removal. Their strong bond securely holds the abrasive grains, allowing for aggressive grinding on very hard materials. This makes them the top choice for high-stock removal jobs where speed is a priority.

### How do I get the best possible surface finish?

Resin bond wheels produce the best surface finish. The bond allows dull abrasives to break away, exposing fresh cutting edges. This self-sharpening action results in a cooler grind and a smoother, mirror-like surface on the workpiece.

### When is a hybrid wheel the right choice?

Operators choose a hybrid wheel for balanced operations. It is the ideal solution when a job requires both fast material removal and a fine surface finish. This versatility boosts productivity without sacrificing the final part quality.

See Also

Selecting Optimal Bench Grinding Wheel Materials for Specific Applications

Picking the Perfect Metal Grinding Wheel for Your Fabrication Project

Identifying the Ideal Grinding Wheel for Your Carbide Tool Sharpening

Understanding Various Grinding Wheel Types and Their Real-World Uses

Choosing the Appropriate Grinding Wheel for Stainless Steel Fabrication

Contact Us

For More Grinding Solution or Customized Abrasive Tools